Introduction

Since Zuk et al (1) extracted pluripotent stem cells from

fat in 2001, adipose-derived stem cells (ADSCs) have become a focus

of research into tissue engineering, due to their multiple

advantages, including extensive sources, convenient extraction

methods and the ability to be rapidly amplified. A number of

studies have confirmed that ADSCs can differentiate into multiple

cell types in vitro, including bone, cartilage, fat, muscle,

neural and endothelial cells (2–6),

indicating characteristics similar to bone marrow stromal stem

cells and a prospective application in tissue engineering.

Furthermore, cartilage is recognized as the most suitable tissue

for construction by tissue engineering, thus ADSCs have great

potential as seed cells for cartilage tissue engineering. Cartilage

tissue engineering requires large quantities of seed cells in the

short-term, which can maintain a chondrocyte phenotype in the

process of in vitro culture.

It is difficult to meet these requirements with

traditional static culture, whilst three-dimensional dynamic

culture is able to accelerate cell proliferation and be conducive

to chondrogenic differentiation and phenotype maintenance (7). Therefore, the present study applied

bioreactor technology combined with microcarriers to rapidly

amplify and induce chondrogenic differentiation in ADSCs. The aim

was to investigate the proliferation and differentiation of ADSCs

on microcarriers, and explore the feasibility of clinical

application in the future.

Materials and methods

Materials

Type I collagenase, dexamethasone,

2-phospho-L-ascorbic acid (vitamin C), ITS liquid media supplement

and Cytodex 3 microcarrier beads (Sigma-Aldrich, Poole, UK);

trypsin, Dulbecco’s modified Eagle’s medium (DMEM)-high glucose

(Gibco Life Technologies, Carlsbad, CA, USA); fetal bovine serum

(FBS; Beijing Yuan Heng Sheng Ma Biotechnology Institute, Beijing,

China); recombinant murine FGF-basic and TGF-β1 (PeproTech EC Ltd.,

London, UK); type II collagen mouse anti-human monoclonal antibody

(Beijing Zhongshan Co., Beijing, China); a rotating bioreactor

(Synthecon, Inc., Houston, TX, USA); and an inverted microscope

(Olympus IX70; Olympus Corporation, Tokyo, Japan).

Isolation and culture of ADSCs

The present study and the collection of human fat

tissue was under the ethical approval of the Chinese PLA General

Hospital Ethics Committee (Beijing, China). The infrapatellar fat

pad removed during knee arthroplasty was maintained in strictly

aseptic conditions, and stem cells were separated within 30 min of

harvest. The superficial fascia and small blood vessels on the

surface of the fat tissue were carefully removed with microsurgical

scissors, D-Hank’s solution was used to wash the samples three

times to remove red cells. The fat was cut into pieces, added to 5X

0.075% type I collagenase, stirred for 30 min at 37°C and

centrifuged at 671 × g for 5 min to release the fat and the

supernatant. It was then washed again with D-Hank’s solution,

filtered through a 100-mesh filter (BD Biosciences, Suzhou, China)

and centrifuged at 168 × g for 5 min. Then the precipitation was

washed twice in D-Hank’s solution, which was prepared in the Key

Laboratory of PLA (Chinese PLA General Hospital, Beijing, China)

and contained KCl (0.4 g/l), KH2PO (0.06 g/l), NaCl (8.0

g/l), NaHCO3 (0.35 g/l),

Na2HPO4.7H2O (0.06 g/l) and phenol

red (0.02 g/l). The cells were then resuspended in 10% FBS

containing high-glucose DMEM medium, with a change of medium after

48 h. When the cells were at 80% confluency, 0.25% trypsin was used

for digestion passage culture. At the second passage, the medium

was changed to cartilage-inducing liquid (5 ng/ml FGF-2; 10 ng/ml

TGF-β1; 50 μg/ml vitamin C; 10−7 M dexamethasone; and 1X

ITS) for cartilage differentiation.

Pretreatment with Cytodex 3

The dry weight of 50 mg microcarriers was placed

into 10-ml clean glass bottles, with 10 ml phosphate-buffered

saline (PBS; Sigma-Aldrich) without calcium and magnesium ions, and

incubated at room temperature for at least 3 h to expand the

microcarriers. The supernatant was discarded with a polyethylene

aluminum compound pipe straw, the microcarriers were cleaned twice

with PBS without calcium and magnesium ions, which was then

discarded prior to the addition of 10 ml fresh PBS without calcium

and magnesium ions. The samples then underwent high pressure

sterilization for 20 min, the supernatant liquid was removed and

the microcarriers were cleaned with culture liquid. They were then

stored in a refrigerator at 4°C.

Cell culture methods

The Cytodex 3 microcarriers (50 mg) and ADSCs (final

concentration, 1×105/ml) were added to a 10-ml rotary

cell culture system (RCCS; Synthecon, Inc., Houston, TX, USA)

culture container, then the cartilage inducing medium was added to

fill the container. The container with cell-microcarriers complex

was connected to the rotating base. The device was put in a 5%

CO2 incubator and was cultured at 37°C. In order to

fully mix cells, the container was rotated at a force of 5 rpm for

5 min and paused for 5 min alternately, which was repeated for

several cycles, it was then continuously rotated and gradually

adjusted to 10–12 rpm. Once the culture medium exhibited a yellow

color and a PH value <7.0, the medium was changed. Static

culture was conducted by seeding 1×105/ml ADSCs into

five wells of a 6-well plate, 2 ml in each well. During the

culture, the medium was changed every 2–3 days to maintain a

sufficient quantity of cells.

Cell morphological observation and

counting

Human ADSCs were cultured for 1, 3, 5 and 7 days,

and under the inverted microscope, the morphology of the ADSCs and

the proliferation on the surface of the microcarriers were

assessed. The chondrocytes on the surface of the microcarrier were

digested, separated and counted with a blood cell counting plate

(Yancheng Glass Instrument Company, Yancheng, China), then a cell

growth curve was constructed. Cell microcarrier samples were taken

on day 3 to be observed by scanning electron microscopy (Hitachi

S-4500; Hitachi, Tokyo, Japan), and the cell morphology and matrix

secretion was observed. The static monolayer culture of ADSCs in

the control group was observed to assess the ADSC morphology and

proliferation at days 1, 3, 5 and 7. They were then collected and

the survival rate was calculated using a trypan blue dye exclusion

test. Finally, a cell growth curve was constructed based on whole

cell counts.

Cytochemical and immunocytochemical

analysis

The ADSCs growing on the microcarriers and those in

monolayer culture were harvested, digested and smeared. They were

then subjected to safranin-O and toluidine blue staining to observe

the levels of glycosaminoglycan (GAG) synthesis and secretion from

the extracellular matrix. The type II collagen monoclonal antibody

was incubated with the cells with DAB (Beijing Hepten and Protein

Biomedical Institute, Beijing, China) as the substrate, and the

immunoperoxidase method was used for development. Brown staining

indicated positive staining, and thus the occurrence of type II

collagen secretion and synthesis.

Results

ADSC adherent growth on the surface of

the Cytodex 3 microcarriers

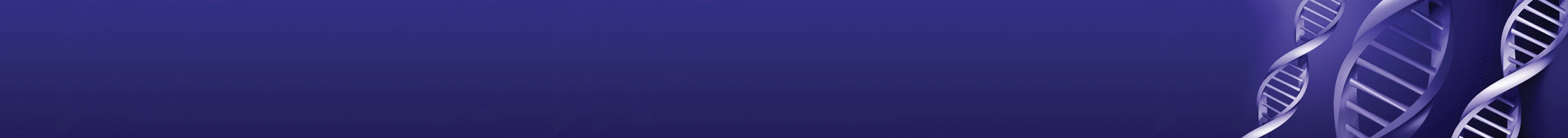

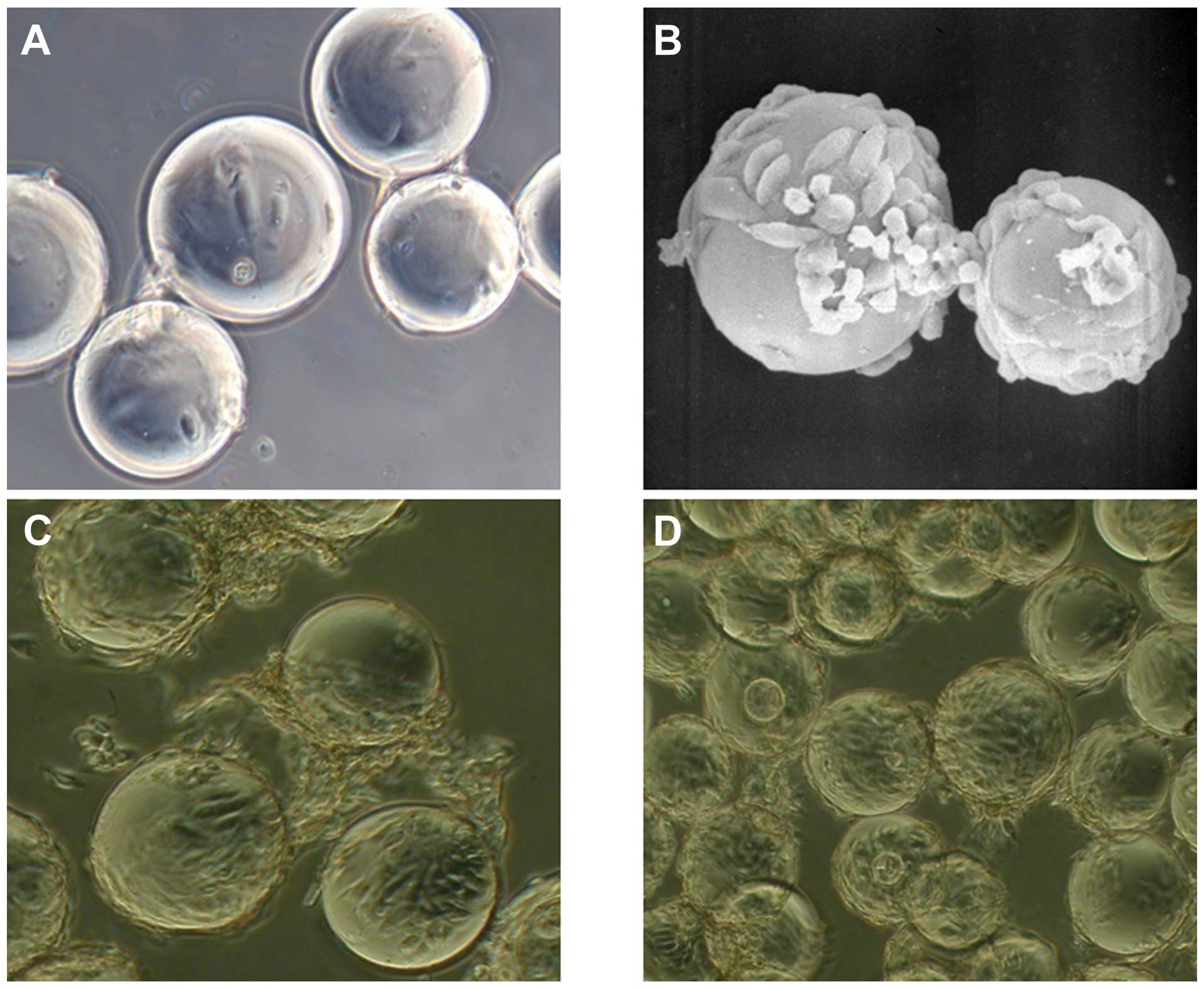

Three hours following inoculation, a number of cells

had adhered to the surface of microcarriers. After 24 h, the

majority of the cells had adhered to microcarriers, and only a

small number of dead cells were present in the medium. Cells

gradually changed from a spherical and hemispherical to a short

fusiform shape, and occasionally there were pseudopodium with

irregular shapes (Fig. 1A).

| Figure 1Morphological observation of cell

microcarriers with SEM and light microscopy. (A) ADSCs cultured on

microcarriers for 24 h and viewed with a light microscope

(magnification, ×400). Cells gradually attach to surface of the

microcarrier, becoming short and fusiform. (B) ADSCs cultured on

microcarriers for 3 days observed by SEM (magnification, ×800). The

cell number increased significantly after 3 days, and became long

and fusiform in shape. (C) ADSCs cultured on microcarriers for 5

days, observed with a light microscope (magnification, ×400). Cell

culture on microcarriers. The majority of the microcarrier surface

was covered with overlapping-growth cells and microcarriers

presented cluster-style growth. (D) ADSCs cultured on microcarriers

for 7 days, observed with a light microscope (magnification, ×400).

Microcarriers were completely covered with overlapping cells and

widespread cell connections between the microcarriers were

identified. SEM, scanning electron microscopy; ADSC,

adipose-derived stem cell. |

On day 3, the number of cells on the surface of the

microcarriers increased significantly, and the adherent cells were

apparent on a different focal plane. Cell matrix secretion around

the cells, and occasionally connecting cells between the

microcarriers, were observed. Cells were spindle-shaped and flat.

There were few dead cells in the medium, and cells adhered well to

microcarriers (Fig. 1B). On the

5th day, the majority of the microcarrier surface was covered with

cells and cells had grown in layers, with abundant extracellular

matrix secretion, indistinguishable single cell morphology, and

large cell connection bodies between microcarriers, whilst

microcarriers displayed cluster growth (Fig. 1C). On the 7th day, microcarrier

surfaces were completely covered by cells overlapping as a mass,

leading to a rough, uneven surface on the microcarriers. There were

widespread cell connections between the microcarriers, and there

were almost no dead cells in the medium (Fig. 1D).

Growth of ADSCs in static culture

Two hours after cells were treated with the

induction medium, cells began to adhere to the wall, and after 24

h, all cells were adherent. The cells were spindle-shaped or

polygonal, and were slightly larger than non-induced ADSCs. Once

fully adherent, cells began to rapidly proliferate, after 3 days

they reached a level of 50% fusion, and after 5 days they reached

80% fusion. Along with the increase in cell density, the

proliferation slowed down, and after 7 days, almost complete fusion

was reached.

Growth curves of ADSCs under two

different culture modes

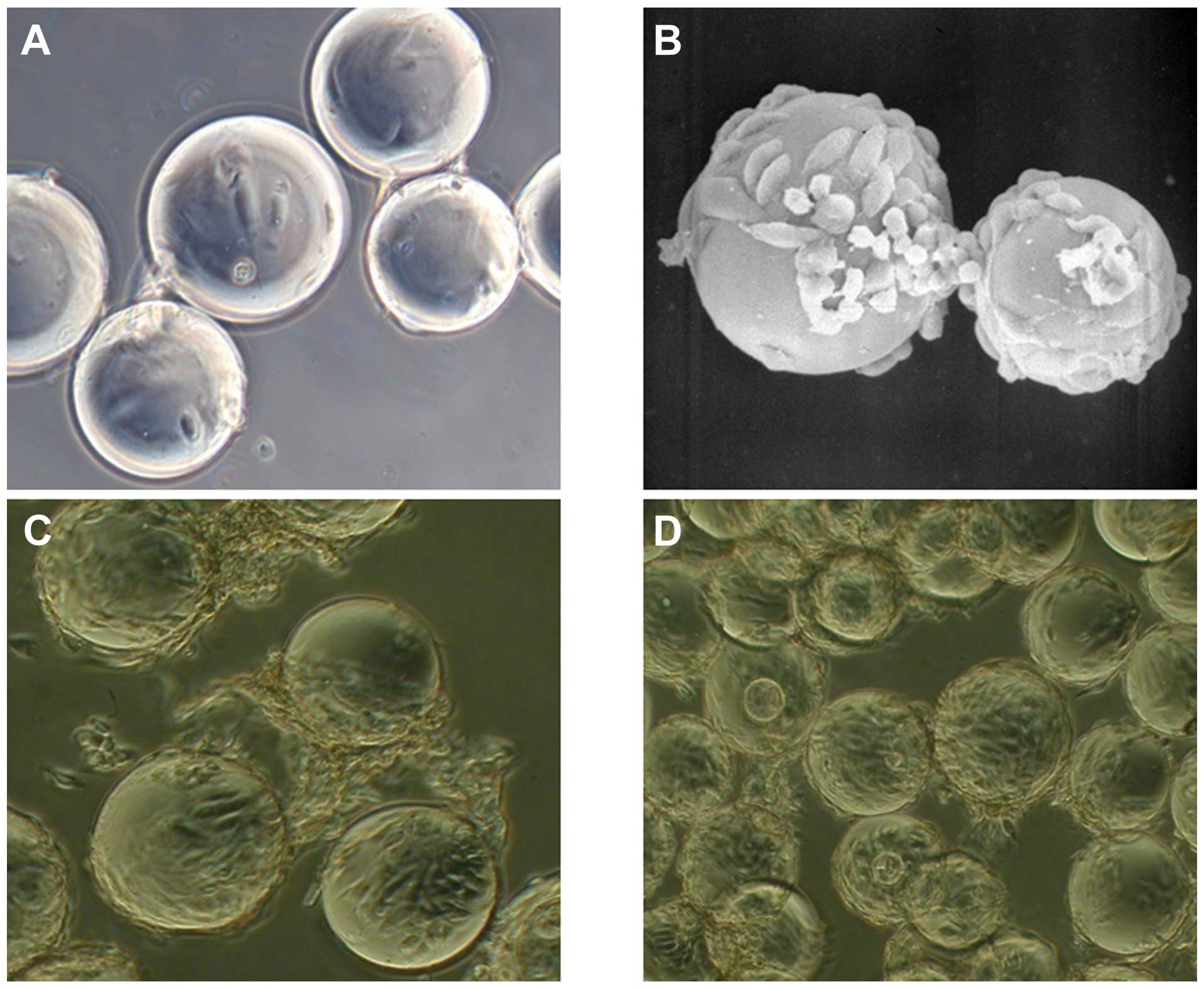

On days 1, 3, 5 and 7, ADSCs were harvested from the

RCCS container and common culture bottle and were counted, and the

growth curves were as presented in Fig. 2. The Trypan blue dye exclusion test

indicated that the survival rate of ADSCs harvested from the

microcarriers was >90%. According to the blood cell count, it

was clear that the growth of ADSCs accelerated from day 3 after

RCCS inoculation, and the cell density reached its highest value at

day 7, ~19 times the initial inoculation. On day 7, the total

number of harvested cells cultured in a static monolayer was ~6

times the original.

Analysis of cytochemistry and

immunocytochemical examination

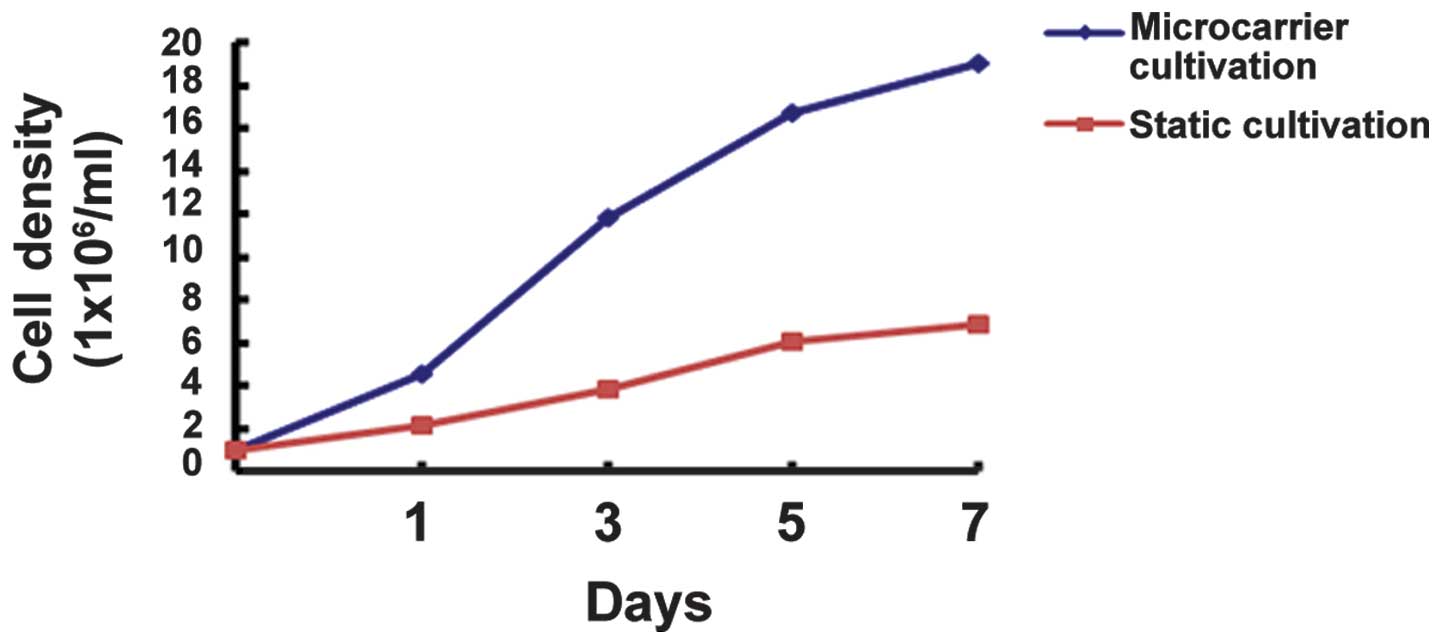

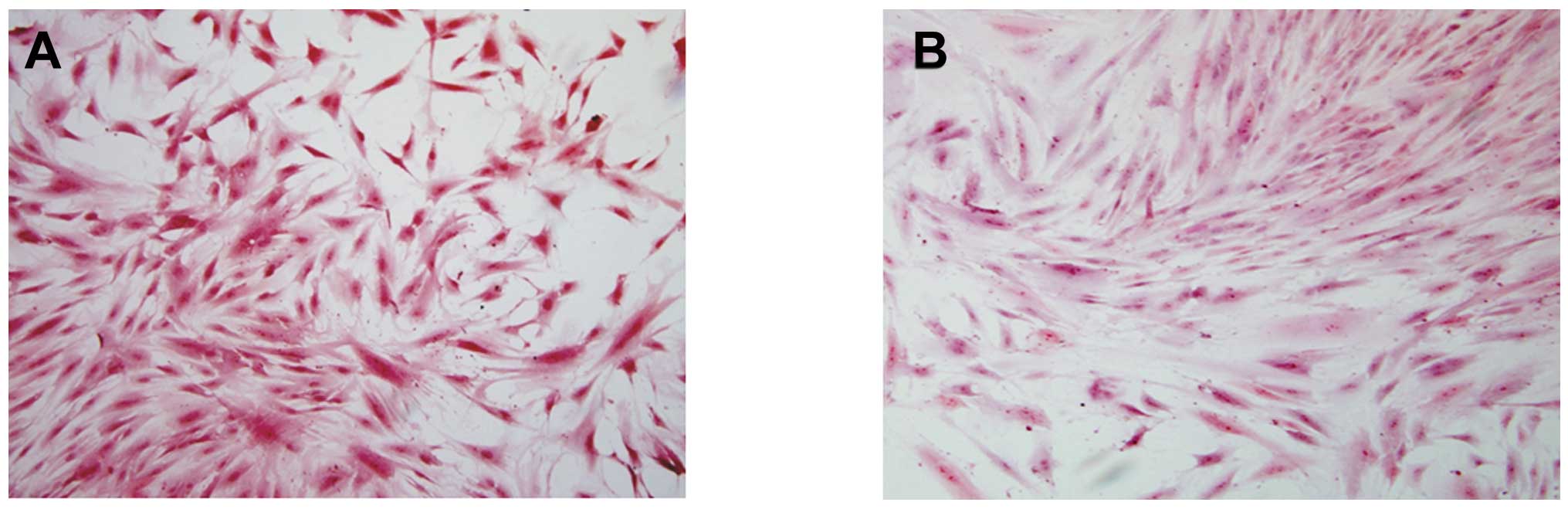

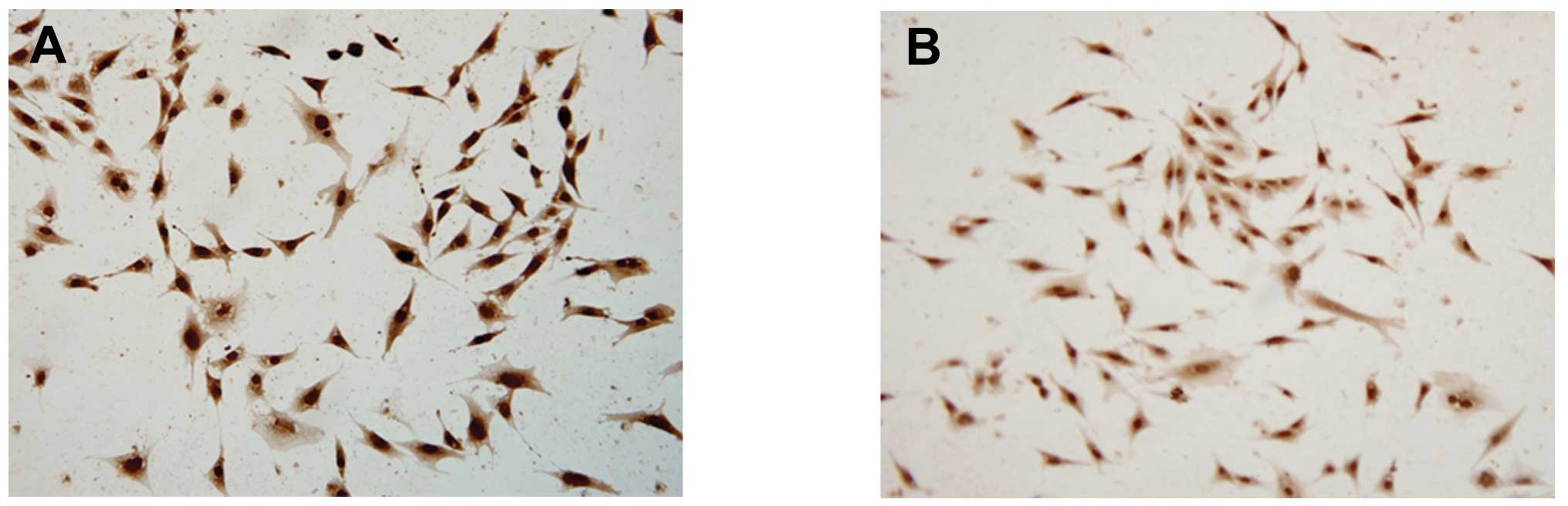

It was demonstrated by ADSC smear staining in the

two groups, that toluidine blue (Fig.

3) and safranin-O (Fig. 4)

staining in the microcarrier culture was strongly positive, and was

stronger than that in the static culture group. The positive

staining indicated that the extracellular matrix contained a high

level of GAGs; and type II collagen staining was also strongly

positive (Fig. 5), indicating that

the ADSCs cultured on the microcarriers through dynamic induction

culture were able to express matrix components characteristic of

cartilage.

Discussion

ADSCs are relatively easy to obtain and have a wider

range of sources compared with bone marrow stromal stem cells. De

Ugarte et al (8) identified

no significant difference between bone marrow-derived stem cells

and ADSCs in the time taken to obtain them, the cell growth

kinetics, cell aging, gene transfection and cell adhesion

properties. Thus, ADSCs have exceptional advantages and prospects

as seed cells for cartilage tissue engineering.

The clinical application of cartilage tissue

engineering often requires a great quantity of seed cells, and

studies have demonstrated that when the cell number is

<1×107/ml, it is not able to form cartilage or can

only generate small amounts (9).

The traditional method of amplification culture is slow and does

not reliably maintain the stem cell phenotype subsequent to

induction; and studies have demonstrated that appropriate

mechanical stimulation and three-dimensional culture conditions are

conducive to the differentiation of ADSCs into chondrocytes, and

promote the synthesis of extracellular matrix (10,11);

the dynamic three-dimensional culture combines the mechanical

environment with the three-dimensional culture surface, to further

improve the biochemical and biomechanical function of cartilage

tissue engineering.

Microcarriers are widely used for the large-scale

culture of attachment-dependent cells (12,13),

as they possess an increased surface area for cell adhesion, and

thus, numerous seed cells can be harvested in a short time period

(14). The microcarrier dynamic

culture is the combination of using microcarriers with a

bioreactor, and has been widely used in the field of tissue

engineering. In the dynamic process of cultivation, external fluid

mechanical stimulation is able to significantly increase cell

proliferation and promote synthesis of DNA. Using the bioreactor

and microcarrier technique, the cell concentration can reach

1×108/ml (15,16), which is difficult to achieve under

conventional culture conditions. The microcarrier has a larger

specific surface area (110 g Cytodex 3 provides ~4600

cm2 surface area) (17)

than a common culture flask, and it can cultivate up to hundreds of

times more cells and meet the required quantities of seed cells to

construct a large volume of tissue. The rotating bioreactor (RCCS)

was also used, as the whole culture container is driven by the

motor to rotate along a horizontal axis, so the culture medium and

cell particles rotate together with the rotary container, the

microcarrier particles can form a liquid suspension track on the

horizontal axis, and the gravity, buoyancy and shear force can

achieve a balance, which constitutes a microgravity environment

conducive to cell aggregation. This balances the amplification of

growth in each direction of the microcarriers’ surface. In this

dynamic environment, cells and nutrients are prone to homogeneous

distribution, which can significantly improve the exchange of

nutrients and metabolites throughout the microenvironment,

maintaining the homogeneity and stability of the culture

environment and effectively promoting cell proliferation.

Another problem facing tissue construction is how to

maintain the induced phenotype, and not to allow cells to undergo

dedifferentiation. The correct hydrostatic pressure and shear

stress aids in maintaining the phenotype and function of cartilage

cells (18–21). The use of a biological reactor and

microcarrier with dynamic three-dimensional culture provides an

effective environment for cell proliferation, and also the periodic

mechanical stimulation required in the process of cell

differentiation. This serves an important function in the

mechanical environment, which can effectively promote

differentiation of the stem cells into chondrocytes (22–25).

In a dynamic environment, the enhanced cell activity coupled with

the inductive factors, leads to increased production and secretion

of proteins to form the specific extracellular matrix and promote

the differentiation and maturation of cells.

In conclusion, this type of dynamic culture

microenvironment provides cell aggregation, fast three-dimensional

growth and effective differentiation conditions, and provides the

most effective method for tissue engineering. The results of the

current study confirmed this. In the present study, the ADSCs

quickly attached, extended and rapidly proliferated on the

microcarriers. On day 7, cells covered the surfaces of the

microcarriers completely, and grew, projecting out from the

microcarriers. The microcarriers connected with each other and

formed masses. The number of cells in the microcarrier culture

increased by almost 20-fold in one week, while that of the static

culture increased only by 6-fold, and histochemical and

immunohistochemical analysis indicated that microcarrier culture

cells possessed improved phenotypes and extracellular matrix

production. The current study used ADSCs as seed cells to construct

cartilage tissue, providing an experimental basis, and the

foundation for future investigation of cartilage tissue

engineering.

Acknowledgements

The present study was supported by the 863 National

Program (grant no. 2002AA205021) and the Beijing Municipal Science

and Technology Commission (grant no. H060920050630).

References

|

1

|

Zuk PA, Zhu M, Mizuno H, et al:

Multilineage cells from human adipose tissue: implications for

cell-based therapies. Tissue Eng. 7:211–228. 2001. View Article : Google Scholar : PubMed/NCBI

|

|

2

|

Zuk PA, Zhu M, Ashjian P, et al: Human

adipose tissue is a source of multipotent stem cells. Mol Biol

Cell. 13:4279–4295. 2002. View Article : Google Scholar : PubMed/NCBI

|

|

3

|

Planat-Benard V, Silvestre JS, Cousin B,

et al: Plasticity of human adipose lineage cells toward endothelial

cells: physiological and therapeutic perspectives. Circulation.

109:656–663. 2004. View Article : Google Scholar : PubMed/NCBI

|

|

4

|

Ogawa R, Mizuno H, Watanabe A, et al:

Osteogenic and chondrogenic differentiation by adipose-derived stem

cells harvested from GFP transgenic mice. Biochem Biophys Res

Commun. 313:871–877. 2004. View Article : Google Scholar : PubMed/NCBI

|

|

5

|

Ogawa R, Mizuno H, Watanabe A, et al:

Adipogenic differentiation by adipose derived stem cells harvested

from GFP transgenic mice including relationship of sex differences.

Biochem Biophys Res Commun. 319:511–517. 2004. View Article : Google Scholar : PubMed/NCBI

|

|

6

|

Fujimura J, Ogawa R, Mizuno H, et al:

Neural differentiation of adipose-derived stem cells isolated from

GFP transgenic mice. Biochem Biophys Res Commun. 333:116–121. 2005.

View Article : Google Scholar : PubMed/NCBI

|

|

7

|

Marlovits S, Tichy B, Truppe M, et al:

Collagen expression in tissue engineered cartilage of aged human

articular chondrocytes in a rotating bioreactor. Int J Artif

Organs. 26:319–330. 2003.PubMed/NCBI

|

|

8

|

De Ugarte DA, Morizono K, Elbarbary A, et

al: Comparison of multi-lineage cells from human adipose tissue and

bone marrow. Cells Tissues Organs. 174:101–109. 2003. View Article : Google Scholar : PubMed/NCBI

|

|

9

|

Koch RJ and Gorti GK: Tissue engineering

with chondrocytes. Facial Plast Surg. 18:59–68. 2002. View Article : Google Scholar : PubMed/NCBI

|

|

10

|

Winter A, Breit S, Parsch D, et al:

Cartilage-like gene expression in differentiated human stem cell

spheroids: a comparison of bone marrow-derived and adipose

tissue-derived stromal cells. Arthritis Rheum. 48:418–429. 2003.

View Article : Google Scholar : PubMed/NCBI

|

|

11

|

Ogawa R, Mizuno S, Murphy GF and Orgill

DP: The effect of hydrostatic pressure on three-dimensional

chondroinduction of human adipose-derived stem cells. Tissue Eng

Part A. 15:2937–2945. 2009. View Article : Google Scholar : PubMed/NCBI

|

|

12

|

Costa AR, Withers J, Rodrigues ME, et al:

The impact of microcarrier culture optimization on the

glycosylation profile of a monoclonal antibody. Springerplus.

2:252013. View Article : Google Scholar : PubMed/NCBI

|

|

13

|

Chu L and Robinson DK: Industrial choices

for protein production by large scale cell culture. Cur Opin

Biotechnol. 12:180–187. 2001. View Article : Google Scholar

|

|

14

|

Rudolph G, Lindner P, Gierse A, et al:

Online monitoring of microcarrier based fibroblast cultivations

with in situ microscopy. Biotechnol Bioeng. 99:136–145. 2008.

View Article : Google Scholar

|

|

15

|

Saris DB, Sanyal A, An KN, et al:

Periosteum reponds to dynamic fluid pressure by proliferating in

vitro. J Orthop Res. 17:668–677. 1999. View Article : Google Scholar : PubMed/NCBI

|

|

16

|

Griffiths B: Scale-up of suspension and

anchorage-dependent animal cells. Mol Biotechnol. 17:225–238. 2001.

View Article : Google Scholar : PubMed/NCBI

|

|

17

|

Dan JL, Xu JZ, Zhou Q, et al: Culturing

human mesenchymal stem cells in vitro in large scale on

microcarriers. Orthop J Chin. 12:1158–1160. 2004.(In Chinese).

|

|

18

|

Parkkinen JJ, Ikonen J, Lammi MJ, et al:

Effects of cyclic hydrostatic pressure on proteoglycan synthesis in

cultured chondrocytes and articular cartilage explants. Arch

Biochem Biophys. 300:458–465. 1993. View Article : Google Scholar : PubMed/NCBI

|

|

19

|

Lammi MJ, Inkinen R, Parkkinen JJ, et al:

Expression of reduced amounts of structurally altered aggrecan in

articular cartilage chondrocytes exposed to high hydrostatic

pressure. Biochem J. 304:723–730. 1994.PubMed/NCBI

|

|

20

|

Simon WH, Mak A and Spirt A: The effect of

shear fatigue on bovine articular cartilage. J Orthop Res. 8:86–93.

1990. View Article : Google Scholar : PubMed/NCBI

|

|

21

|

Tomatsu T, Imai N, Takeuchi N, Takahashi K

and Kimura N: Experimentally produced fractures of articular

cartilage and bone. The effects of shear forces on the pig knee. J

Bone Joint Surg Br. 74:457–462. 1992.PubMed/NCBI

|

|

22

|

van der Kraan PM, Buma P, van Kuppevelt T

and van den Berg WB: Interaction of chondrocytes, extracellular

matrix and growth factors: relevance for articular cartilage tissue

engineering. Osteoarthritis Cartilage. 10:631–637. 2002. View Article : Google Scholar : PubMed/NCBI

|

|

23

|

Dickinson SC, Sims TJ, Pittarello L, et

al: Quantitative outcome measures of cartilage repair in patients

treated by tissue engineering. Tissue Eng. 11:277–287. 2005.

View Article : Google Scholar : PubMed/NCBI

|

|

24

|

Li Z, Kupcsik L, Yao SJ, Alini M and

Stoddart MJ: Mechanical load modulates chondrogenesis of human

mesenchymal stem cells through the TGF-beta pathway. J Cell Mol

Med. 14:1338–1346. 2010. View Article : Google Scholar

|

|

25

|

Li Z, Yao SJ, Alini M and Stoddart MJ:

Chondrogenesis of human bone marrow mesenchymal stem cells in

fibrin-polyurethane composites is modulated by frequency and

amplitude of dynamic compression and shear stress. Tissue Eng Part

A. 16:575–584. 2010. View Article : Google Scholar

|