Introduction

Protein A separated from the Staphylococcus

aureus cell wall (PA) can specifically combine with

immunoglobulin (Ig)G, IgM and IgA in most mammals (1). Protein A can combine with the Fc

fragment of immunoglobulin. The ligation of protein A with certain

genes was shown not to influence binding sites between antibody and

antigen (2). PA does not contain

disulfide bonds due to absence of cysteine and cystine; its

physical properties are therefore very steady (3). Under acidic conditions, even combined

with heating, the activity of PA does not change. PA exogenous

expression was implemented in E. coli (4). Separated or recombinant PA

specifically combines with Fc fragments of human IgG1, IgG2 and

IgG4 in vitro. Since its discovery, PA has been received

attention by various researchers and has a widespread application

in immunology and molecular biology experiments (4).

Similar to protein A, protein G (PG) is an protein

of the Streptococcus cell wall; however, it is more useful

in IgG separation and purification (5). As protein A, protein G can bind to

the Fc region of immunoglobulin and numerous subtypes of IgG,

including IgG1, IgG2, IgG3 and IgG4 (6). Although the 4th spatial structure of

protein A is similar to that of protein G, they differ in their

amino acid composition, and therefore, protein G but not protein A

can be used for separating monoclonal antibodies (7). Compared with protein A, protein G has

a stronger IgG-binding capacity, but it does not bind to IgM, IgD

or IgA. The affinity of protein G to Ig is more advanced than that

of PA and of greater commercial value (3). During antibody separation and

purification, albumin is the main contamination source; therefore,

the albumin binding site on protein G was removed in preparation of

the present study. For convenient purification, a 6xHis label was

added to the C terminal of protein G in our prelimary experiments,

as described previously (8). E.

coli high-density fermentation is widely applied in recombinant

protein production and efficiency can be enhanced by improving

parameters of these methods (9,10).

At present, there is only a limited number of studies on PG

fermentation production as well as separation and purification. In

the present study, PG was produced by high-density fermentation of

recombinant gene engineered bacteria, and highly efficient

separation and purification techniques were implemented, providing

a theoretical and practical basis for further studies and PG

production.

Materials and methods

Strain

The E. coli strain BL21 with recombinant

vector pET32b-PG was established in our preliminary works (data not

shown) at the Gene Engineering Laboratory of Bioengineering College

of Beijing Electronic Technology Training College (Beijing, China)

(8). The E. coli strains

BL21 and pET32b were purchased from Takara Biotechnology., Co.,

Ltd. (Dalian, China).

Ragents

Yeast extracts and tryptone were purchased from

Oxoid Ltd. (Basingstoke, UK), and isopropyl

β-D-1-thiogalactopyranoside (IPTG) and kanamycin were purchased

from Takara Bio Inc. (Otsu, Japan). Buffers and solutions used were

1 mol/l pH 7.5

NaH2PO4-Na2HPO4 buffer,

5 mol/l pH 7.5 iminazole, 0.5 mol/l NaOH, 0.1 mol/l

NiSO4, 4 mol/l pH 7.5 NaCl and 20% ethanol solution.

Unless otherwise stated, all other chemical reagents were purchased

from Sinopharm Group Co., Ltd. (Beijing, China).

Instruments

The GE Image Scanner III (GE Healthcare, Little

Chalfont, UK), a NBS5LBioflo3000 fermenter (New Brunswick

Scientific Co., Edison, NJ, USA), an ultrasonicator (Ningbo Scientz

Biotechnology Co., Ltd., Ningbo, China), a high-speed centrifuge

(5810 R; Eppendorf, Hamburg, Germany), a Unico 7200

spectrophotometer (Unico Instrument Co., Shanghai, China), vertical

slab electrophoresis apparatus (Bio-Rad Laboratories, Inc.,

Hercules, CA, USA), AKTA purifier UPC10 (GE Healthcare) and a

chromatography column (diameter, 5 cm; length, 20 cm; Shanghai

BioRc Co., Ltd., Shanghai, China) were used.

Media

Primary seed medium [Luria-Bertani

(LB) medium]

The medium contained yeast extracts (5 g/l),

tryptone (10 g/l) and NaCl (10 g/l) at pH 7.3 in a total of 1 l

distilled water. The solution was sterilized at 121°C for 20 min,

and ampicillin (50 μg/m) and kanamycin (50 mg/l) were then

added.

Secondary seed medium (2xYT

medium)

The medium contained yeast extracts (10 g/l),

tryptone (16 g/l) and NaCl (5 g/l) at pH 7.3 in a total of 1 l

distilled water. The solution was sterilized at 121°C for 20 min,

and kanamycin (50 mg/l) and Amp (50 μg/ml) were added.

Fermentation medium

The medium contained yeast extracts (64 g), tryptone

(102 g), glucose (6.4 g), disodium hydrogen phosphate (48 g),

potassium dihydrogen phosphate (9.6 g), ammonium chloride (3.2 g),

CaCl2 (0.035 g), NaCl (1.6 g), MgSO4 (3.2 g)

and vitamin B1 (0.1 g), pH 7.2, with distilled water added to give

1 l of total volume. The medium was sterilized under high pressure

at 115°C for 30 min, and Amp (50 μg/ml) and kanamycin (50

mg/l) were added.

Feed supplement medium

The medium contained yeast extracts (200 g),

tryptone (20 g), glucose (10 g), MgSO4 (5 g),

(NH4)2SO4 (5 g) and vitamin B1

(0.1 g), and distilled water was added to give 0.8–1l of total

volume. The medium was sterilized under high pressure at 115°C for

30 min, and then Amp (50 μg/ml) and kanamycin (50 mg/l) were

added.

Strain activation, cultivation and

fermentation

Working seed medium preserved at −20°C was

defrosted. 10 μl seed medium was diluted with a gradient

from 10−5 to 10−6 to 10−7 and

coated on an LB plate containing Amp and kanamycin for cultivating

under 37°C for 16–18 h until single colonies were formed. For the

primary seed F1 fermentation strain, a single colony was

selected from the plate, inoculated in 50 ml LB medium containing

Amp and kanamycin in a 250-ml flask, cultivated at 37°C with

agitation at 200 rpm for 8–10 h until the optical density at 600 nm

(OD600) of the bacterial suspension reached 0.025–0.035.

For the second seed F2, the fermentation strain

F1 was inoculated in 200 ml 2xYT medium containing Amp

and kanamycin in a 1,000-ml flask at 0.5% inoculum size, cultivated

at 37°C with agitation at 200 rpm for 7–8 h until the

OD600 of the bacterial suspension reached 0.03–0.05.

500 ml grown F2 seed liquid was

inoculated in a fermenter containing Amp and kanamycin and

cultivated at 37°C until the OD600 reached 0.40–0.50.

Subsequently, 0.1–0.2 mmol/l IPTG was added for induction for

3.5–4.0 h. Compressed air was used as the air source with an air

flow of 1 vvm and 30–45% dissolved oxygen. Pure oxygen was added

2.5 h after initiation of fermentation, with the pH controlled at

7.0–7.2. Sampling was conducted once per hour to measure the

OD600 until it reached a maximum value. The feed

supplement speed was controlled using a feed supplement influx at

10–40% during the cultivating period, increased by 10% as the

fermentation time progressed; it was controlled using a feed

supplement influx at 20–40% during the induction period, with the

maximum feed supplement speed in the first hour of the induction

period. Feed supplementation was stopped half an hour prior to

opening the fermenter at the end of the process.

Measurement of the concentration of

recombinant engineered bacteria

A Unico 7200 spectrophotometer was adopted to

measure the OD600, with distilled water as the control.

The sample from fermentation broth was washed using distilled water

three times, and diluted to 0.2–0.8 at OD600.

Ultrasonic fragmentation of

recombinant E. coli BL21

The centrifuged bacterial bodies were weighed and

added into 10 mmol/l phosphate buffer (pH 7.0,

Na2HPO4-NaH2PO4) at a

ratio of 1:10. Following mixing, the suspension was cooled with ice

water and subjected to ultrasonication at 200 watt for 100–150

times (10 sec on, 10 sec off). Following ultrasonication, the

solution was transferred into centrifuge tubes, centrifuged at

15,000 ×g for >20 min with the supernatant carefully removed,

and the supernatant was filtered through double layered filter

paper and a 0.8-μm membrane in sequence to remove any

particles. To the filtered sample, NaCl (0.5 mol/l) and iminazole

(5 mmol/l) were added, and the resulting solution was loaded onto

columns for purification.

Nickel column purification

Five milliliter desalting solution (containing 1.46

mg total protein) was purified on 30 ml

diethylaminoethanol-sepharose fast flow (DEAE-FF). Balance solution

1 (10 mmol/l sodium phosphate and 0.5 mol/l NaCl; pH 7.5) was used

for balancing five column volumes at a flow speed of 1 cm/min; the

sample was slowly pumped into the nickel nitrilotriacetic acid

(Ni-NTA)-agarose column (Puribest, Shanghai, China) at a flow speed

of 0.5 cm/min; following loading of the sample, the column was

flushed with five column volumes of balance solution 1 and balance

solution 2 (10 mmol/l sodium phosphate and 0.05 mol/l NaCl; pH 7.5)

in sequence, followed by five column volumes of washing solution 1

(10 mmol/l sodium phosphate, 0.05 mol/l NaCl and 0.02 mol/l

iminazole; pH 7.5). The column was then flushed with 2–3 column

volumes of spent eluent 1 (10 mmol/l sodium phosphate, 0.05 mol/l

NaCl and 0.1 mol/l iminazole; pH 7.5) for collecting the target

protein, and then washed with regeneration solution 1 (10 mmol/l

sodium phosphate, 0.05 mol/l NaCl and 0.4 mol/l iminazole; pH 7.5)

for regeneration of the nickel column.

Gel filtration (Sephadex G-25) for

desalination

The column was washed with five column volumes of

balance solution 3 (10 mM sodium phosphate; pH 7.5) at a flow speed

of 1 cm/min. The sample was then loaded onto the column, and at a

flow speed of 0.5 cm/min, the column was flushed with five volumes

of balance solution 3 for collecting the protein sample.

Negative ion exchange column

purification DEAE-FF

Five milliliter lysate was purified on 20 ml Ni-NTA

Agarose, using a UV280 nm detector to detect the products. Five

column volumes of balance solution 3 (10 mM sodium phosphate

solution; pH 7.5) were used for balancing at a flow speed of 1

cm/min. The sample was slowly loaded onto the column (Puribest),

and at a flow speed of 0.5 cm/min, the column was flushed with five

column volumes of balance solution 3 and washing solution 2 (10

mmol/l sodium phosphate and 0.05 mol/l NaCl; pH 7.5) in sequence.

Subsequently, the column was washed with 2–3 column volumes of

spent regenerant 2 (10 mmol/l sodium phosphate and 0.1 mol/l NaCl;

pH 7.5), spent regenerant 3 (10 mmol/l sodium phosphate and 0.15

mol/l NaCl; pH 7.5) and spent regenerant 4 (10 mmol/l sodium

phosphate and 0.2 mol/l NaCl; pH 7.5) for eluting the target

protein. The column was then treated with regeneration solution 2

(10 mmol/l sodium phosphate and 0.5 mol/l NaCl; pH 7.5) for

regenerating the ion exchange solid phase.

Protein detection

The recombinant PG (rPG) protein in the samples was

identified as follows: 12% SDS-PAGE (Bio-Rad Laboratories, Inc.),

gel staining with 0.25% Commassie Blue staining solution (methanol:

acetic acid: dH2O=5:1:5), destaining with a solution

(methanol: acetic acid: dH2O=2:3:35). Following

destaining, the gel was visualized by GE Image scanner III (GE

Healthcare). The protein concentration was measured by the methods

according to Bradford or Lowry (11) with bovine serum albumin as the

standard (8).

Purity determination and

identification of rPG

The purified dried rPG was dissolved in 50 mM sodium

phosphate buffer (pH 7.2) containing 50 mM NaCl and underwent high

performance liquid chromatography (HPLC; Agilent 1200, Santa Clara,

CA, USA; TSK-GEL G2000SWXL, 5 μm, 7.8 mmx300 mm; Tosoh Co.,

Tokyo, Japan), alongside molecular weight standards bovine serum

albumin (66.4 kDa), ovalbumin (44.3 kDa), pepsin (35.0 kDa),

lysozyme (14.3 kDa), insulin (58.8 kDa) and hydroxocobalamine (1.4

kDa). All the standards were purchased from Tiangen (Tiangen

Biotech Co., Ltd, Beijing, China). The mobile phase, at a flow rate

of 0.5 ml/min, was 50 mM sodium phosphate buffer (pH 7.2)

containing 50 mM NaCl. The experiment was monitored using a UV

detector (280 nm).

The purified rPG and the commercialized PG were

separated by 12% SDS-PAGE gel, and were transferred to

polyvinylidene difluoride (PVDF) membranes using semi-dry

electro-blotting apparatus (Bio-Rad Laboratories, Inc.). The

transfer was carried out for 2 h at 18 V. Subsequently, the

membranes were blocked with TBST (20 mmol/l Tris-HCl, pH 8.0; 150

mmol/l NaCl; 0.05% Tween) containing 5% non-fat milk for 1 h, and

then incubated with a 1:10,000 dilution of goat horseradish

peroxidase-conjugated anti-Protein G antibody (cat. no. SA101;

Tiangen Biotech Co., Ltd) at room temperature for 1 h. The membrane

was then washed six times with TBST (10 min per wash), and positive

bands in the membrane were detected by Enhanced Chemiluminescent

reagent (Beyotime Institute of Biotechnology, Beijing, China).

Statistical analysis

SPSS 13.0 statistical software (SPSS Inc., Chicago,

IL, USA) was used to analyze the data. Measurement data were

compared using one-sample t-test. P<0.05 was considered to

indicate a statistically significant difference.

Results

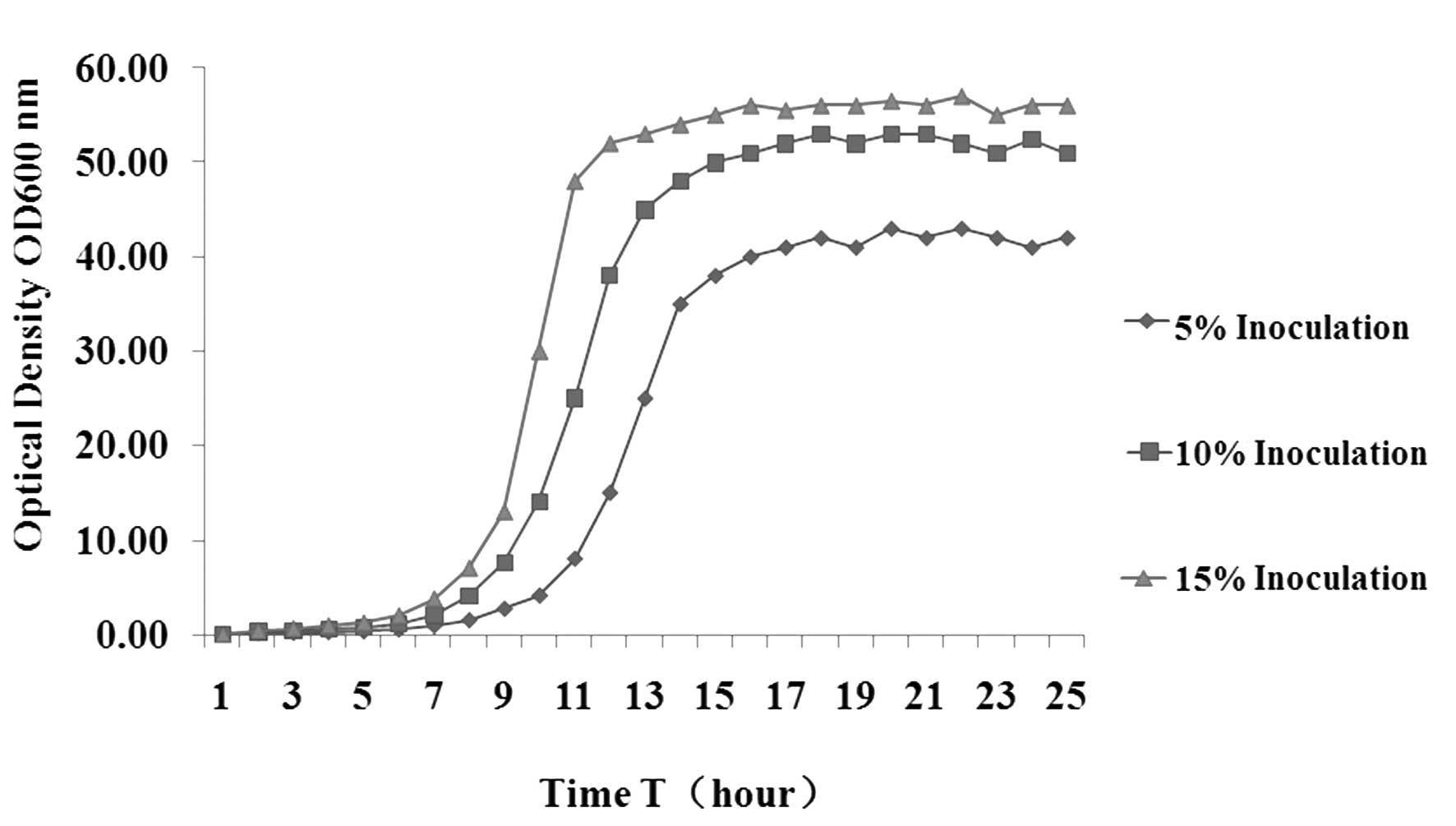

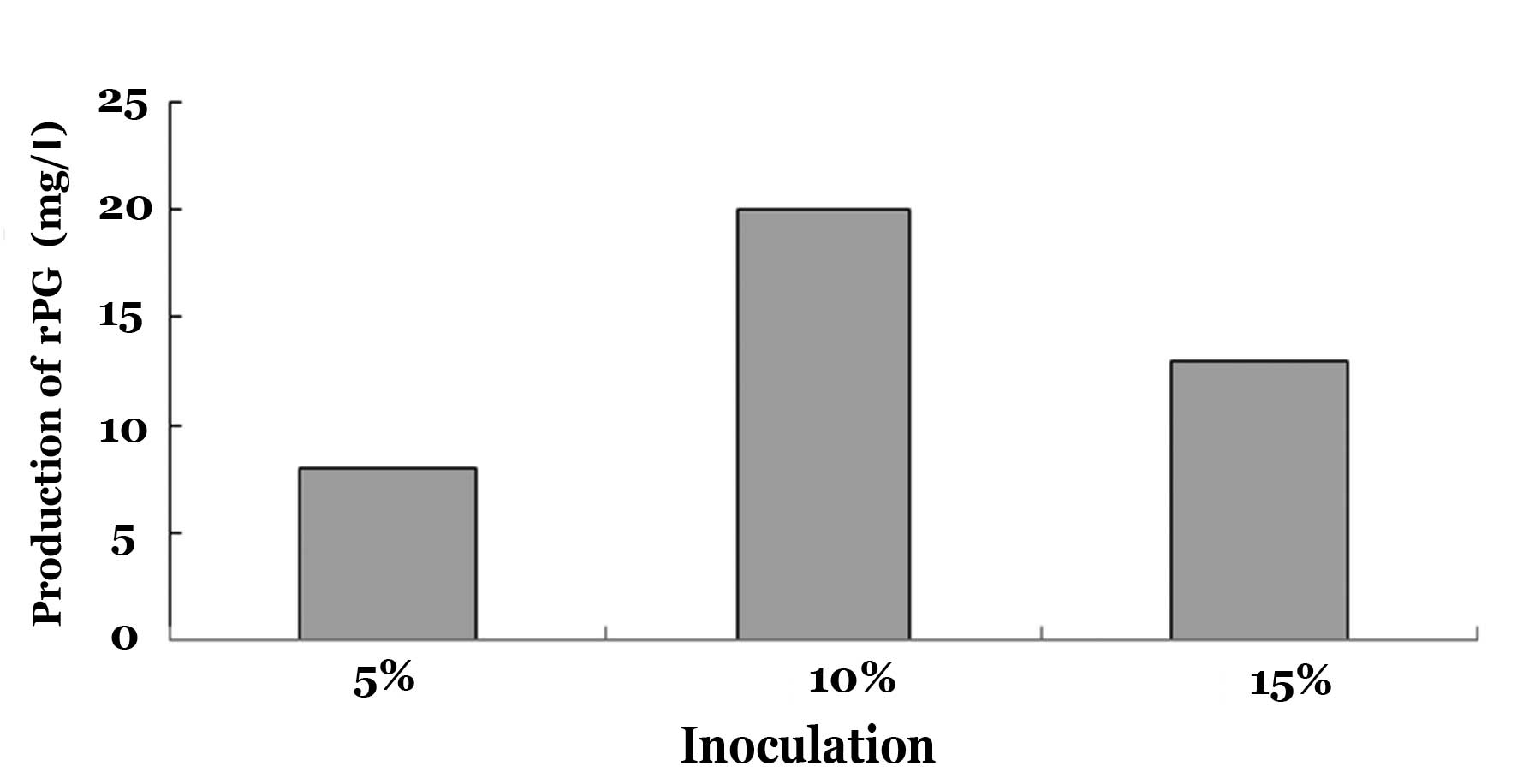

Influence of the seed inoculum size on

the productivity and time of fermentation

The productivity and time of PG fermentation were

influenced by the inoculum size in the fermenter. In the

fermentation experiments, inoculum sizes of 5, 10 and 15% were

adopted (Fig. 1) in order to

observe their influence on the mass of bacterial bodies. The

results indicated that at a relatively low inoculum size of 5%, the

lag phase was significantly longer, which may be due to strain

aging, extended growth time and a lower number of bacteria in the

stationary phase, resulting in lower protein expression. However,

at 10% inoculum size, the lag phase was significantly shortened,

and the rapid proliferation of recombinant bacteria during

fermentation made them enter the Logarithmic growth phase earlier

with more nutrition for target product synthesis, leading to a

recombinant PG productivity of 20 mg/l (Fig. 2). When the inoculum size was 15%,

the large amount of bacteria exhausted the availability of

nutrition bacterial growth, resulting in a very short lag phase.

The density of bacteria in the stationary phase was >10% of the

inoculum size, but exogenous PG productivity decreased (Fig. 2); the potential cause of this is

that nutrition was absorbed by the large amount of bacteria, while

there was less nutrition for PG production; in addition, the

metabolic waste of the bacteria may have had a negative effect on

subsequent PG synthesis.

Dissolved oxygen levels affect the

productivity and time of fermentation

The dissolved oxygen concentration is another

important factor influencing bacterial growth during high-density

fermentation. The bacterial density and recombinant protein

productivity are influenced by the concentration of dissolved

oxygen. E. coli require a large amount of oxygen for

metabolism during rapid proliferation, and therefore, a timely

supply of saturated oxygen is very important. The bacterial density

was very high at the late period of high-density fermentation,

which therefore required extremely large amounts of dissolved

oxygen to maintain target protein synthesis. The compressed air

used in the present study was not sufficient to meet the oxygen

demand of the bacteria, as indicated by a DO2 value of 0

or even a negative value, high bacterial density and a bacterial

wet weight of 150 g/l, while PG expression levels remained low.

During the initial fermentation period, the required quantities of

oxygen were not high; therefore, the present study used pressured

air with levels of dissolved oxygen controlled at 30–45% during the

initial period. Following 2.5 h of fermentation, oxygen was added,

and at the late period of fermentation, high-pressure pure oxygen

was supplied to enhance the oxygen supply.

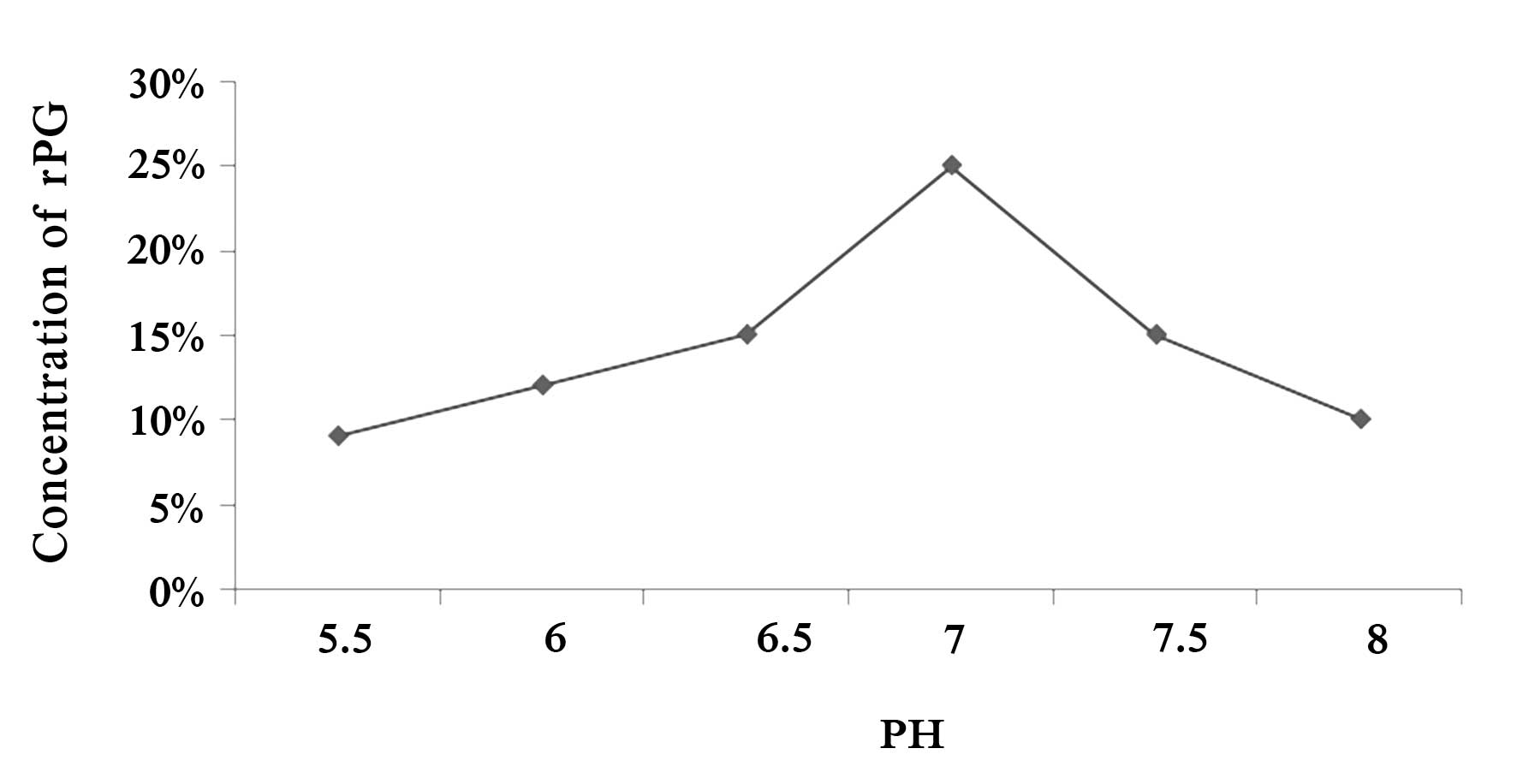

Influence of the pH on fermentation

efficiency

pH variance in the fermentation environment

influences the internal environment and variance in the cell

metabolism of bacteria; furthermore, it directly influences the

biomass of genetically engineered bacteria and the amount of gene

expression of the product. The influence of the initial pH value of

the medium on the production of PG was investigated in the present

study. A higher or lower initial pH value of the medium resulted in

reduced PG expression, while maximum production of recombinant PG

was achieved when the pH of the medium was 7.0 at the beginning of

the fermentation (Fig. 3).

IPTG influences the amount of PG

expression

Following the logarithmic phase, the bacteria were

cultivated with the inducer IPTG at 0, 0.1, 0.2, 0.3, 0.4 and 0.5

mmol/l for 4 h, and the content of recombinant PG in the soluble

protein of the bacteria was analyzed. The amount of rPG expression

increased as the IPTG concentration was enhanced, but above a

concentration of 0.2 mmol/l IPTG did not lead to any further

obvious improvement of PG expression; in fact, it decreased to a

certain extent (results not shown). Therefore, the IPTG

concentration used for induction was fixed at 0.2 mmol/l. The

induction time of IPTG influenced the levels of PG expression, as

shown in Fig. 4. The amount of rPG

protein expression gradually increased as the induction time was

increased from 1 h and reached a peak when induction was performed

for 4 h, leading to an rPG yield of 20% of total proteins. However,

further extension of the induction time decreased the yield of

recombinant PG, which may be due to degradation or denaturation of

PG over longer time periods.

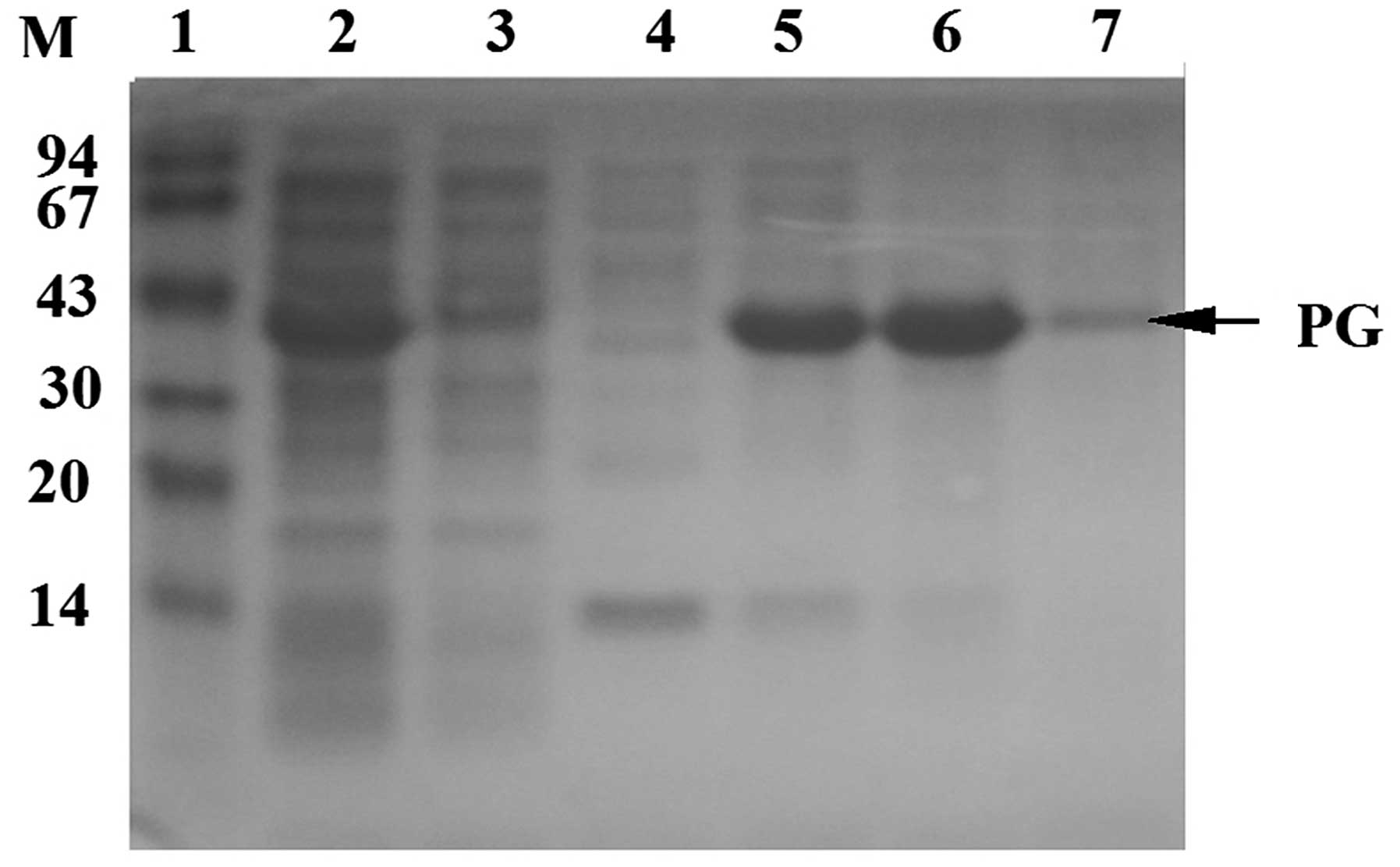

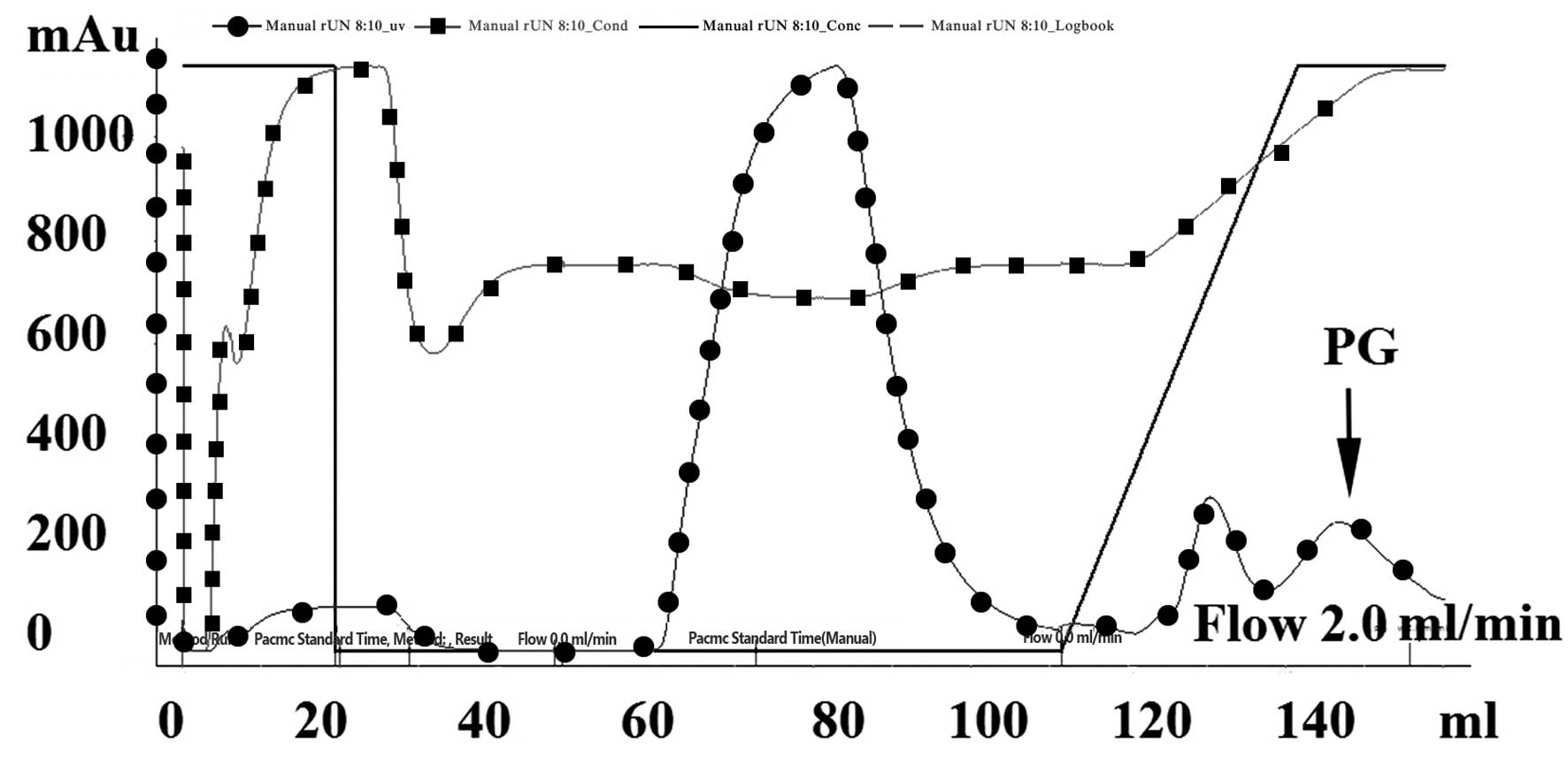

PG separation and purification

Metal chelate affinity chromatography, also known as

fixed metal ion affinity chromatography, utilizes the coordination

interaction between various metal ions, including Cu2+,

Zn2+, Ni2+, Co2+ and

Fe3+, and histidines on the protein surface as a

principle for separation and purification. Agarose gel containing

these fixed metal ions is able to selectively purify proteins

containing multiple histidines. In a previous study (12), PG with a C terminus containing six

histidines was separated from cell lysate using a Ni-NTA affinity

column, desalinated by gel filtration (Sephadex G-25) and purified

by anion exchange column (DEAE-FF). In the present study, PG was

obtained at a maximum yield following one step of nickel column

affinity chromatography (Fig. 5).

Following gel filtration and anion exchange column chromatography,

an PG purity of >95% was achieved (Fig. 4).

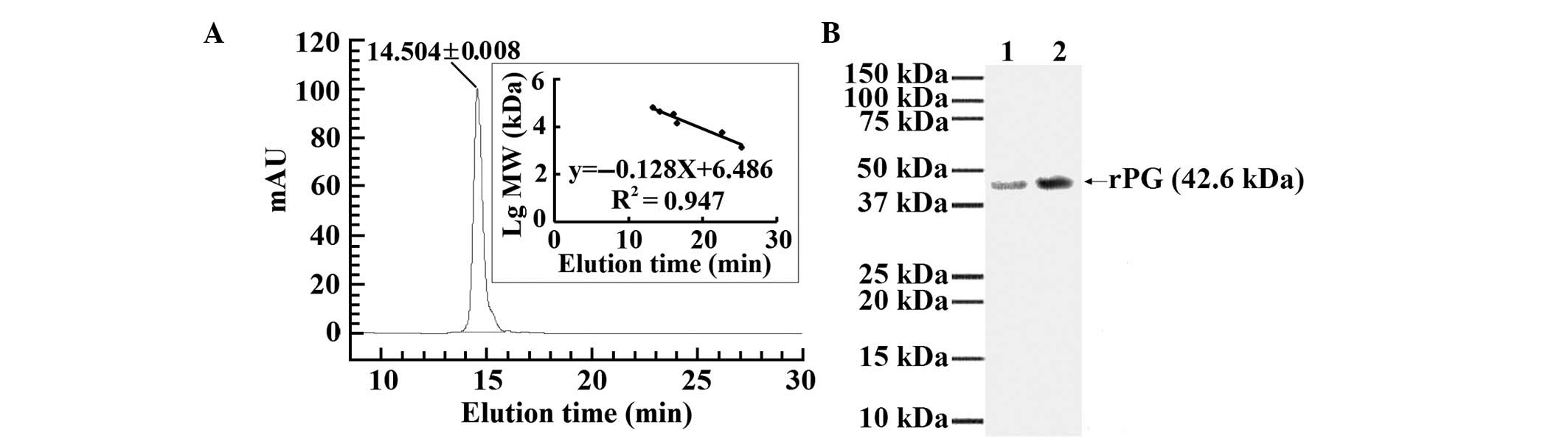

Purity and identification of rPG

The purified rPG showed a single peak at UV

adsorption 280 nm following HPLC (Fig.

6A). To detect the IgG-binding ability of the purified rPG and

compare the ability with that of the commercialized PG, each

protein was separately immobilized onto PVDF at a protein

concentration of 15 μg for the purified rPG and the

commercialized PG. The purified rPG and the commercialized PG were

shown to bind well to goat IgG (Fig.

6B).

Statistical analysis of purification

methods

The highest rPG expression level was >20% of the

total protein being expressed. The rPG was isolated and purified

with affinity Ni-NTA chromatography and Anion exchange DEAE-FF

chromatography. A final yield of 15±1.8 ml of 0.45 mg/ml rPG was

obtained, giving a cumulative yield of 86.3±6.8% for rPG (Table 1).

| Table ISummary of the purification of rPG

expressed in E. coli BL21. |

Table I

Summary of the purification of rPG

expressed in E. coli BL21.

| Purification

step | Volume (ml) | Total protein

(mg) | rPG (mg) | Purity (%) | Cumulative

yield(%) |

|---|

| Ultra sonication | 10±1 | 29.2±0.3 | 7.8±0.5 | 26.7±2 | 100 |

| Ni-NTA

chromatography | 20±1.5 | 7.5±0.2 | 7.2±0.1 | 96.1±3.9 | 92.8±7.3 |

| Desalting column | 25±2.3 | 7.3±0.1 | 7.0±0.1 | 95.9±2.7 | 90.2±7.1 |

| DEAE-FF | 15±1.8 | 6.9±0.1 | 6.7±0.1 | 97.1±2.8 | 86.3±6.8 |

Discussion

PG is a cell wall protein separated from

Streptococcus and is able to bind to the Fc fragment of IgG

of most mammals, but it binds to human IgM, IgD and IgA. In

preliminary experiments, a recombinant E. coli strain

expressing PG was generated, with albumin and cell surface binding

sites removed in order to reduce cross reaction and non-specific

binding. Therefore, recombinant PG had higher affinity for Igs than

natural protein G and protein A; it can be applied widely in

immunochemistry by replacing secondary antibodies whilst having

high affinity and stability. PG high density fermentation

technology using the recombinant E. coli BL21 strain as well

as improved conditions of recombinant PG separation and

purification were assessed in the present study in order to

establish a basis for the development of a large-scale production

of PG.

In high-affinity fermentation, the biggest

difficulty is the large amount of acetic acid generated during the

fermentation process, which has an inhibiting effect on bacterial

growth and protein expression (13). Acetic acid synthesis is influenced

by the strain type, cultivating conditions and carbon source supply

method. To eliminate acetic acid during high-density fermentation,

genes associated with acetic acid synthesis are removed by gene

engineering method and acetic acid is removed by dialysis (13). Simply increasing the biomass does

not always increase the productivity but likely results in acetic

acid accumulation (14). During

fermentation in the present study, acetic acid synthesis was

reduced by balancing the feed supplements, which is the most common

method (15–17). In the present study, nutrition such

as a carbon source was added at the exponential growth phase in

order to ensure that nutrition and oxygen supply are maximal,

according to the methodology used in most high-density fermentation

processes (18). In the present

study, the concentration of acetic acid was reduced using

recombinant E. coli BL21 and a carbon source was added to

balance the feed supplements.

High production of target proteins depends on high

concentration of bacteria, which in turn largely depends on a

saturated oxygen supply during high-density fermentation. The

oxygen demand of the microorganisms largely exceeded the oxygen

concentration supplied in the fermentation device. In the present

study, the oxygen concentration was artificially enhanced by using

pure oxygen (13) and enhancing

the oxygen gas pressure (17,19).

Apart from being influenced by acetic acid and

oxygen, the production of PG target protein is influenced by

nutrition. In the present study, high concentrations of bacteria

and protein product were obtained by controlling the influx speed

and concentration of feed supplement (20).

Ni-NTA affinity column chromatography allowed for

simple recombinant protein separation, as it contained a 6xHis

affinity label, providing it with adsorption sites. In perliminary

experiments, a 6 His codon was added to the C-terminal region of

the PG gene to facilitate the extraction of large amounts of target

protein from bacterial lysate. PG was obtained at high purity

through desalination by gel filtration and ion exchange

chromatography.

A subsequent study will focus on further exploration

of recombinant PG activity.

Acknowledgments

The present study was funded by the Beijing

Municipal Education Commission of Science and Technology General

Program (no. SQKM201210858002).

References

|

1

|

Bjork I, Petersson BA and Sjoquist J: Some

physiochemical properties of protein A from Staphylococcus aureus.

Eur J Biochem. 29:579–584. 1972. View Article : Google Scholar : PubMed/NCBI

|

|

2

|

Chen YW, Wang H, Hupert M and Soper SA:

Identification of methicillin-resistant Staphylococcus aureus using

an integrated and molecular microfluidic system. Analyst.

138:1075–1083. 2013. View Article : Google Scholar : PubMed/NCBI

|

|

3

|

Sheerin DJ, Menon C, Zur Oven-Krockhaus S,

Enderle B, Zhu L, Johnen P, Schleifenbaum F, Stierhof YD, Huq E and

Hiltbrunner A: Light-activated phytochrome A and B interact with

members of the SPA family to promote photomorphogenesis in

Arabidopsis by reorganizing the COP1/SPA complex. Plant Cell.

27:189–201. 2015. View Article : Google Scholar : PubMed/NCBI

|

|

4

|

Graille M, Stura EA, Corper AL, Sutton BL,

Taussig MJ, Charbonnier JB and Silverman GJ: Crystal structure of a

Staphylococcus aureus protein A domain complexed with the Fab

fragment of a human IgM antibody: structural basis for recognition

of B-cell receptors and super antigen activity. Proc Natl Acad Sci

USA. 97:5399–5404. 2000. View Article : Google Scholar

|

|

5

|

Ditse Z, Adrian PV, Kuwanda L and Madhi

SA: Association of Streptococcus pneumoniae common protein antigen

(CPA) antibodies and pneumococcal nasopharyngeal colonization in

HIV-infected and HIV-uninfected African children. Vaccine.

31:4421–4427. 2013. View Article : Google Scholar : PubMed/NCBI

|

|

6

|

Kmiecik S and Kolinski A: Folding pathway

of the B1 domain of protein G explored by a multiscale modeling.

Biophys J. 94:726–736. 2008. View Article : Google Scholar

|

|

7

|

Eliasson M, Andersson R, Olsson A, Wigzell

H and Uhlén M: Differential IgG-binding characteristics of

staphylococcal protein A, streptococcal protein G, and a chimeric

protein AG. J Immunol. 142:575–581. 1989.PubMed/NCBI

|

|

8

|

Green MR and Sambrook J: Expressing cloned

genes for protein production, purification, and analysis. Molecular

cloning. 4th edition. Cold Spring Harbor Laboratory Press; Long

Island, NY: pp. 1481–1611. 2012

|

|

9

|

Lee Y and Blanch H: Recombinant protein

expression in high cell density fed-batch cultures of Escherichia

coli. Biotech. 10:1550–1556. 1992. View Article : Google Scholar

|

|

10

|

Riesenberg D and Guthke R:

High-cell-density cultivation of microorganisms. Appl Microbiol

Biotechnol. 51:422–430. 1999. View Article : Google Scholar : PubMed/NCBI

|

|

11

|

Lowry OH, Rosenburg NJ, Farr AL and

Randall RJ: Protein measurement with the Folin phenol reagent. J

Biol Chem. 193:265–275. 1951.PubMed/NCBI

|

|

12

|

Hutt M, Färber-Schwarz A, Unverdorben F,

Richter F and Hontermann RE: Plasma half-life extension of small

recombinant antibodies by fusion to immunoglobulin-binding domains.

J Biol Chem. 287:4462–4469. 2012. View Article : Google Scholar :

|

|

13

|

Jenzsch M, Lange M, Bär J, Rahfeld JU and

Lubbert A: Bioreactor retrofitting to avoid aeration with oxygen in

Pichia pastoris cultivation processes for recombinant protein

production. Chem Eng Res Design. 82:1144–1152. 2004. View Article : Google Scholar

|

|

14

|

DeLisa MP, Chae HJ, Weigand WA, Valdes JJ,

Rao G and Bentley WE: Generic model control of induced protein

expression in high cell density cultivation of Escherichia coli

using on-line GFP-fusion monitoring. Bioproc Biosyst Eng. 24:83–91.

2001. View Article : Google Scholar

|

|

15

|

Lara AR, Caspeta L, Gosset G, Bolívar F

and Ramírez OT: Utility of an Escherichia coli strain engineered in

the substrate uptake system for improved culture performance at

high glucose and cell concentrations: An alternative to fed-batch

cultures. Biotechnol Bioeng. 99:893–901. 2008. View Article : Google Scholar

|

|

16

|

Matsui T, Sato H, Yamamuro H, Misawa S,

Shinzato N, Matsuda H, Takahashi J and Sato S: High cell density

cultivation of recombinant Escherichia coli for hirudin variant 1

production. J Biotechnol. 134:88–92. 2008. View Article : Google Scholar : PubMed/NCBI

|

|

17

|

Knoll A, Bartsch S, Husemann B, Engel P,

Betina S, Stockmann C, Seletzky J and Buchs S: High cell density

cultivation of recombinant yeasts and bacteria under

non-pressurized and pressurized conditions in stirred tank

bioreactors. J Biotechnol. 132:167–179. 2007. View Article : Google Scholar : PubMed/NCBI

|

|

18

|

Sandén AM, Prytz I, Tubulekas I, Förberg

C, Le H, Hektor Andrea, Neubauer Peter, Pragai Z, Harwood C, Ward

A, Picon A, de Mattos JT, Postma P, Farewell A, Nyström T, Reeh S,

Pedersen S and Larsson G: Limiting factors in Escherichia coli

fed-batch production of recombinant proteins. Biotechnol Bioeng.

81:158–166. 2003. View Article : Google Scholar

|

|

19

|

Belo I, Pinheiro R and Mota M: Fed-batch

cultivation of Saccharomyces cerevisiae in a hyperbaric bioreactor.

Biotechnol Prog. 19:665–671. 2003. View Article : Google Scholar : PubMed/NCBI

|

|

20

|

Eiteman MA and Altman E: Overcoming

acetate in Escherichia coli recombinant protein fermentations.

Trends Biotechnol. 24:530–536. 2006. View Article : Google Scholar : PubMed/NCBI

|