Introduction

Magnesium (Mg) and its alloys are susceptible to

dissolution in aqueous solutions due to their extremely low

corrosion potential, particularly in alloys containing chloride ion

electrolytes (1). For this

reason, Mg alloys have attracted considerable attention as

potential implant materials (2–8).

The interest in Mg alloys has been primarily motivated by their

biocompatibility, biodegradability and desirable mechanical

properties. For instance, the tensile strength and elastic modulus

of Mg alloys are closer to those of bone, as compared with the

commonly used steel and titanium alloys (2–8). A

previous in vivo study suggested that Mg alloy implantation

in animal models promoted new bone formation and biocompatibility

(2). Therefore, Mg and Mg alloys

may be used as biodegradable materials for orthopedic implants.

The Mg alloys that have been investigated as implant

materials are mostly commercial alloys designed for the

transportation industry (8). Most

of these commercial Mg alloys contain aluminium (Al) and rare earth

metals. However, Al is neurotoxic (9), whereas severe hepatotoxicity has

been detected following the administration of rare earth metals

(10). Therefore, the exploration

of novel non-toxic or low-toxicity Mg alloy systems has become a

research highlight.

In this study, a medical Mg alloy, designated as

Mg-Nd-Zn-Zr (JDBM), was further evaluated for its cytocompatibility

in vitro. This alloy contains a Mg matrix and approximately

3% rare earth metals (11).

Preliminary results revealed that JDBM possessed favorable in

vitro biocompatibility to rabbit chondrocytes (12). In this study, rabbit chondrocytes

were further used as an in vitro model to evaluate the

effects of JDBM, brushite

(CaHPO4·2H2O)-coated JDBM

(C-JDBM), AZ31, WE43, pure Mg and Ti alloys (TC4). The effects of

the Mg and Mg alloys on the adhesion, viability, proliferation and

apoptosis of chondrocytes were investigated. The glycosaminoglycan

(GAG) and collagen II (Col II) content, as well as the mRNA

expression of Col II and aggrecan were also investigated.

Materials and methods

Sample and extract preparation

JDBM was previously developed for biomaterial

applications by our group (11).

C-JDBM, the commercial Mg alloys, WE43 and AZ31, pure Mg (Shanxi

Yanbixin Magnesium Co., Ltd., Shanxi, China), and the Ti alloy, TC4

(Daiyuan, Shanghai, China), were analyzed for comparison. The

detailed preparation of these materials has been described in our

previous study (11).

Disk samples, 10 mm in diameter and 2.0 mm in

height, were obtained by electrode discharge machining from the

extruded JDBM, WE43, AZ31 and TC4 rods, as well as from high-purity

Mg ingots (99.99%). All samples were ground using SiC paper of up

to 1,200 grit and polished with 1 µm diamond abrasive paste,

followed by a series of ultrasonic cleaning in acetone, ethanol and

distilled water. The details of the

CaHPO4·2H2O treatment of the JDBM

disc, including the fabrication of the coating and the evaluation

of its properties are described in another study of ours (13). Prior to the in vitro

cytocompatibility experiments, the samples were sterilized with

ethylene oxide for 24 h.

Sample extracts were prepared according to ISO

10993. The disk samples were immersed in 1.7584 ml Dulbecco’s

modified Eagle’s medium with F12 (DMEM/F12) supplemented with 10%

fetal bovine serum (FBS) (both from Gibco-BRL, Carlsbad, CA, USA),

with a surface area-to-extraction medium volume ratio of 1.25

cm2/ml. The samples were then incubated in a humidified

atmosphere with 95% humidity and 5% CO2 at 37°C for 72

h. The supernatant was collected, and the obtained extracts were

refrigerated at 4°C and used within 3 days.

Chondrocyte harvest and culture

Chondrocytes were isolated from aseptically

harvested articular cartilage from the knee joints of adult New

Zealand rabbits weighing 2.0–2.5 kg. The cartilage samples were

rinsed in sterile phosphate-buffered saline (PBS) (pH 7.4;

Gibco-BRL) containing penicillin and streptomycin (100 U/ml and 100

µg/ml, respectively) (HuaBei, Shijiazhuang, China). The

samples were then cut into 1–2 mm3 fragments, placed in

a spinner flask containing 0.25% trypsin-EDTA (Gibco-BRL) at 37°C

for 30 min, and rinsed thrice in sterile PBS. The slices as

prepared samples were subsequently digested with 0.2% Col II

(Sigma, St. Louis, MO, USA) in sterile PBS at 37°C for a further

12–16 h. The chondrocytes were then harvested, counted and seeded

onto 25 cm2 culture flasks at a cell density of

2×104/cm2 in DMEM/F12 with 10% FBS

(Gibco-BRL). The cells were then cultured in an incubator (Thermo

8000; Thermo Fisher Scientific, Inc., Shanghai, China) at 37°C with

95% humidity and 5% CO2 for 7–10 days. The cell culture

medium was replenished every 3 days. The cells were passaged when

they reached 80–90% confluence. Cells at passage 2 were used for

further experiments.

Cell adhesion assay

Cell suspensions of 1.5 ml each were seeded into

24-well plates containing the JDBM, C-JDBM, AZ31, WE43, pure Mg and

TC4 disc samples, at a cell density of 1×105 cells/ml.

The culture medium was replenished daily. The cultures were

incubated in a humidified atmosphere (95%) with 5% CO2

at 37°C. The samples were collected after 1 and 3 days of

incubation and washed thrice with PBS (pH 7.4; Gibco-BRL) to remove

the non-adherent cells. The cells were then fixed in 2.5%

glutaraldehyde (Boster, Wuhan, China) solution at room temperature

for 2 h followed by rinsing thrice with PBS. Following gradient

ethanol dehydration (50, 60, 70, 80, 90 and 100%; for 10 min

gradient ethanol dehydration), the samples were dried in a

hexamethyldisilazane solution (Wuhan Boster Biological Technology,

Ltd.). The samples were subsequently sputter-coated with gold. The

surfaces of the cell-adhered experimental samples were observed by

scanning electron microscopy (SEM; FEI Quanta 250; FEI Co.,

Hillsboro, OR, USA). Three parallel samples were used for each

experimental condition.

Another set of 6 parallel samples were treated

according to the method described above. However, these samples

were fixed in 4% paraformaldehyde solution (Wuhan Boster Biological

Technology, Ltd.) at room temperature for 30 min and rinsed thrice

with PBS (pH 7.4; Gibco-BRL), followed by staining with a

4′,6-diamidino-2-phenylindole (DAPI) solution (5 µg/ml)

(Beyotime Institute of Biotechnology, Jiangsu, China) for 10 min.

The samples were again rinsed thrice with PBS, for 5 min for each

wash. The surfaces of the cell-adhered experimental samples were

observed and recorded using an inverted phase contrast microscope

(Olympus IX70; Olympus Corp., Tokyo, Japan).

Indirect cell cytotoxicity and

proliferation assay

The cells cultured in DMEM/F12 alone were used as

the negative controls, whereas those cultured in DMEM/F12 medium

with 10% DMSO (Beyotime Institute of Biotechnology) were used as

the positive controls. The cells were incubated in 96-well cell

culture plates at 5×103 cells per 100 µl medium

in each well for 24 h to allow attachment. The culture medium was

then replaced with 100 µl of the extraction medium with the

respective treatments. The 96-well cell culture plates were then

observed under an optical microscope (CSW-30B; Shenzhen Coosway

Optical Technology Co., Ltd, Shenzhen, China) on days 1, 3 and 5

following incubation. The culture medium was replenished every 2

days. Six parallel wells were established for each tested sample. A

total of 20 µl

3-(4,5-dimethylthiazol-2-yl)-2,5-diphenyltetrazolium bromide (MTT)

(Sigma) solution (5 mg/ml in PBS) was added to each well. The

samples were then placed in a cell incubator for 4 h. Subsequently,

100 µl of the formazan solubilization solution [10% SDS in

0.01 MHCl (Sigma)] were added to each well and the plates were

again incubated overnight in a cell incubator with a humidified

atmosphere (95%) and 5% CO2 at 37°C. The

spectrophotometric absorbance of the samples at 570 nm was measured

using a microplate reader (Bio-Rad 680; Bio-Rad, Hercules, CA,

USA).

Another set of 6 parallel 96-well cell culture

plates were used to observe and record the cell morphology. The

test condition was the same the as one described above, and the

medium was replaced with 100 µl extraction medium. Following

incubation for 1, 3 and 5 days, the 96-well cell culture plates

were collected and rinsed thrice with PBS (pH 7.4; Gibco-BRL), and

then stained with Alcian blue and DAPI solution (5 µg/ml)

(both from Beyotime Institute of Biotechnology). The cell

morphologies of the samples in the 96-well cell culture plates were

observed and recorded using an inverted phase contrast microscope

(Olympus IX70; Olympus Corp.). Three parallel wells were

established for each stain.

Cell apoptosis assay

The chondrocytes were analyzed as follows: 7

treatment groups were set, namely, a negative control (DMEM/F12

medium), a JDBM, C-JDBM, AZ31, WE43 pure Mg and TC4 group. Cell

suspensions (10 ml) were seeded into 75 cm2 culture

flasks at a cell density of 1×105 cells/ml and incubated

for 24 h to allow attachment. The medium was then replaced with 10

ml extraction medium or DMEM/F12 medium. The culture media were

replaced after 2 days with 10 ml. Three parallel culture flasks

were established for each treatment condition. Following incubation

of the cells in a cell incubator for 5 days, the culture flasks

were observed under an optical microscope. Chondrocyte apoptosis

was assessed using the Alexa Fluor® 488 Annexin V/Dead

Cell Apoptosis kit (Invitrogen Life Technologies, Carlsbad, CA,

USA) with Alexa Fluor® 488 Annexin V and propidium

iodide (PI) (Beyotime Institute of Biotechnology) for flow

cytometry (Navios; Beckman Coulter, Inc., Brea, CA, USA). The assay

was performed according to the manufacturer’s instructions.

GAG quantification assay

The quantification of the GAG content was conducted

by a modification of the dimethylmethylene blue method (Beyotime

Institute of Biotechnology) (14). The chondrocytes were treated as

follows: the cells were seeded in 6-well cell culture plates at a

density of 1×105 cells/well and incubated for 24 h to

allow attachment. The medium was changed with 3 ml of extraction

medium every 2 days. Following incubation of the cells under the

cell culture conditions for 5 days, the 6-well cell culture plates

were observed under an optical microscope. Three parallel wells

were established for each treatment condition. After rinsing in PBS

(pH 7.4; Gibco-BRL), a cytolysate (RIPA; Wuhan Boster Biological

Technology, Ltd.) was added to each well at 0.4 ml/well and

vortexed for 10 sec. An aliquot (40 µl) of the digest was

assayed for the total GAG content by the addition of 200 µl

of 1,9-dimethylmethylene blue dye solution (Beyotime Institute of

Biotechnology). The absorbance was determined at 595 nm using a

microplate reader (Bio-Rad 680; Bio-Rad). The amount of GAG was

extrapolated from a standard curve based on shark chondroitin

sulfate.

Col II content assay and enzyme-linked

immunosorbent assay (ELISA)

The chondrocytes were treated as described above.

The cells were seeded in 12-well plates at a density of

5×104 cells/well. The cells were then incubated for 24 h

to allow attachment. The medium was then changed with 2 ml of

extraction medium every 2 days. Following incubation of the cells

in a humidified atmosphere (95%) with 5% CO2 at 37°C for

5 days, the 12-well cell culture plates were observed under an

optical microscope. Three parallel wells were established for each

treatment condition. After the cell culture plates were placed on

ice and rinsed in PBS (pH 7.4; Gibco-BRL), a cytolysate (RIPA;

Wuhan Boster Biological Technology, Ltd.) was added to each well at

0.2 ml/well, vortexed for 10 sec, and centrifuged for 10 min at

10,000 x g according to the manufacturer’s instructions. An ELISA

kit (R&D Systems, Minneapolis, MN, USA) was used for the

quantitative determination of rabbit Col II levels in the cell

cultures from each well. ELISA was conducted according to the

manufacturer’s instructions. The spectrophotometric absorbance of

the samples at 450 nm was measured using a microplate reader

(Bio-Rad 680; Bio-Rad). The standard curve was calculated according

to the concentration and absorbance of the standard, asw ell as

based on the curve to extrapolate the corresponding concentration

of the sample.

RNA extraction and quantitative-reverse

transcription PCR (RT-qPCR)

The chondrocytes were seeded into 25 cm2

culture flasks at a density of 4×105 cells per flask and

incubated for 24 h to allow attachment. The medium was then changed

with 5 ml of the respective extracts every 2 days. DMEM/F12 medium

was used as a negative control. Following incubation of the cells

in a humidified atmosphere (95%) with 5% CO2 at 37°C for

5 days, the culture flasks were observed under an optical

microscope. Three parallel wells were established for each

treatment condition. Total RNA from the chondrocytes in the

different groups was isolated using TRIzol reagent (Invitrogen Life

Technologies). First-strand cDNA was synthesized using the

RevertAid First Strand cDNA Synthesis kit (Thermo Fisher

Scientific, Inc., Waltham, MA, USA), as previously described

(12). Quantitative PCR (qPCR)

was performed to amplify rabbit GAPDH, aggrecan and Col II using

the LightCycler DNA Master SYBR-Green I kit (Roche, Basel,

Switzerland) according to the manufacturer’s instructions. The

copies of target cDNA were normalized to GAPDH expression

(housekeeping gene). Each PCR reaction was repeated thrice for each

independent sample. The primers used were the same as those in a

previous study of ours (12).

Statistical analysis

Three replicates were conducted for each test

(cytotoxicity test, N=6) and are presented as the mean values ±

standard deviation (SD). ANOVA for repeated measurements was used

for the MTT assay data. Multivariate ANOVA and the

multiple-comparison post hoc test [least significant difference

(LSD)] were subsequently conducted for pairwise comparisons between

groups at each time point. One-way ANOVA, followed by the

multiple-comparison post hoc test [Student-Newman-Keul (SNK) test;

Tukey’s test], was performed using SPSS (version 16.0) software for

other group comparisons. Mauchly’s test of sphericity was used to

determine whether there were any associations among the repeatedly

measured data. If any (p≤0.05), multivariate ANOVA was then

performed, or the Greenhouse-Geisser corrected results were taken

into consideration. The effects of treatment were evaluated by

estimating between subject variance. The repeated measurement

effect or its interactive effect with the treatment group was

evaluated by estimating within subject variance. The method of

Bonferroni was used to perform pairwise comparisons of the

repeatedly measured data at different measurement times in each

treatment group. A value of p<0.05 was considered to indicate a

statistically significant difference.

Results

Cell adhesion and morphology

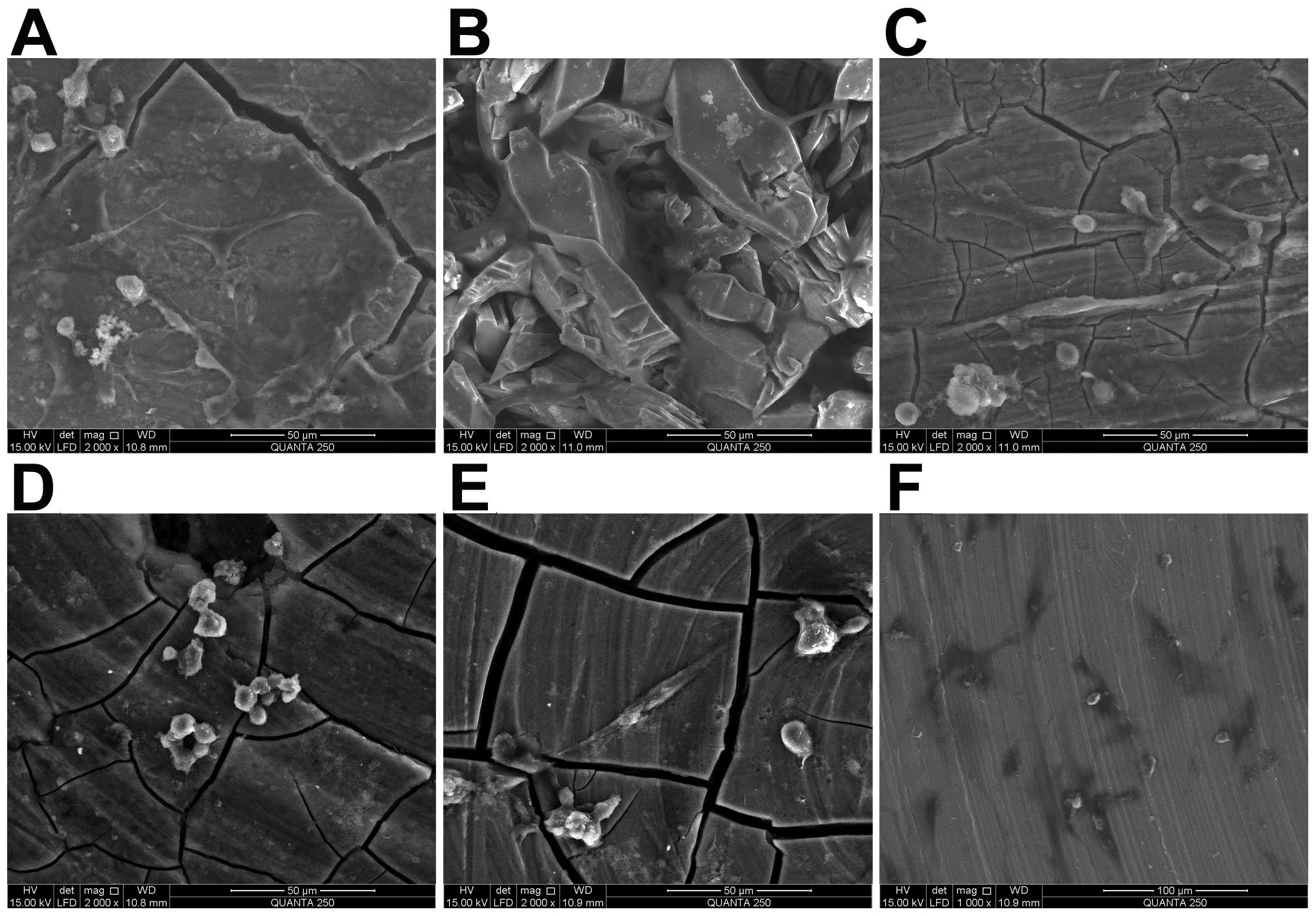

The morphologies of the chondrocytes cultured on the

discs of JDBM, C-JDBM, AZ31, WE43, pure Mg and TC4 for 1 or 3 days

are illustrated in Figs. 1 and

2.

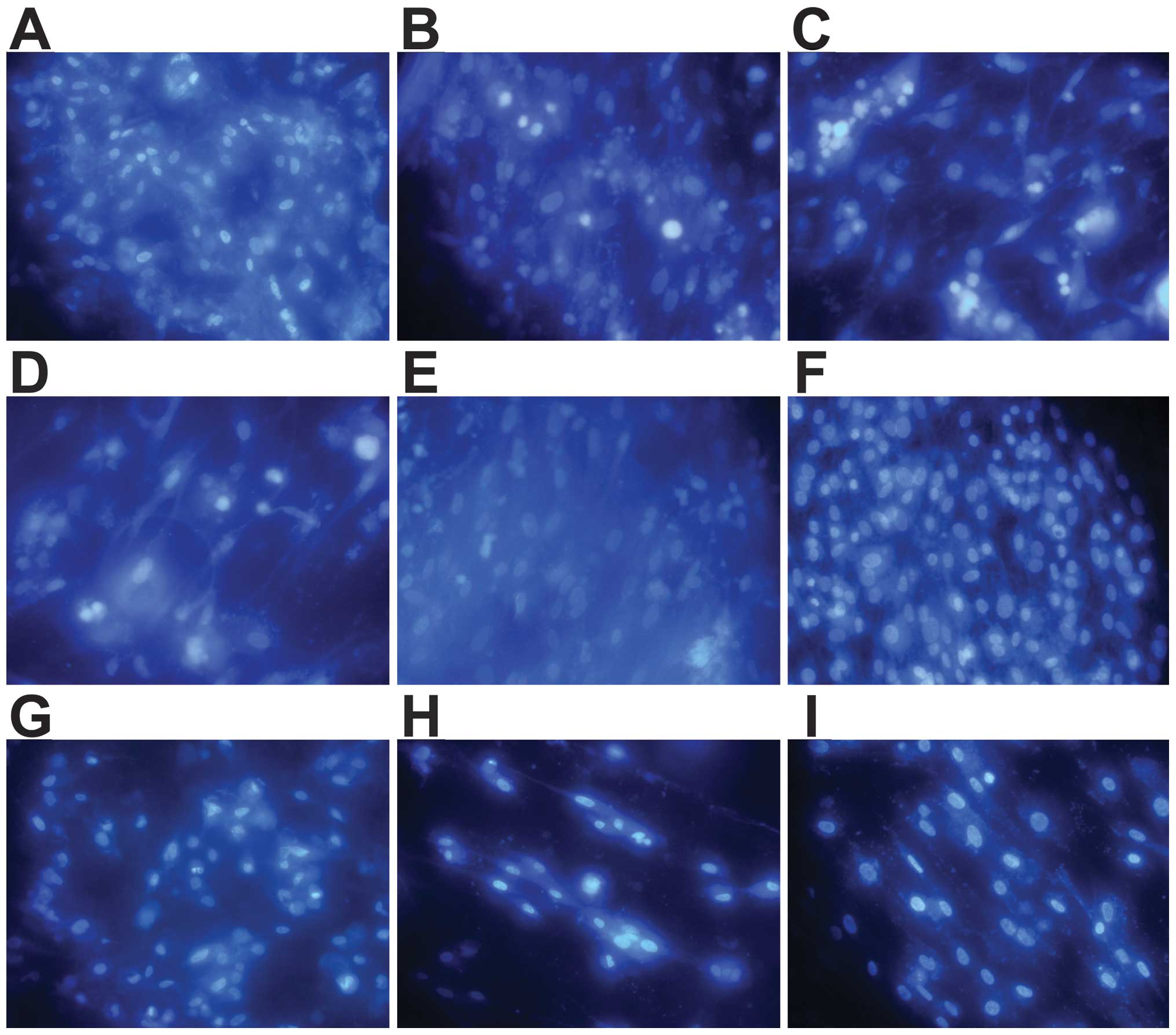

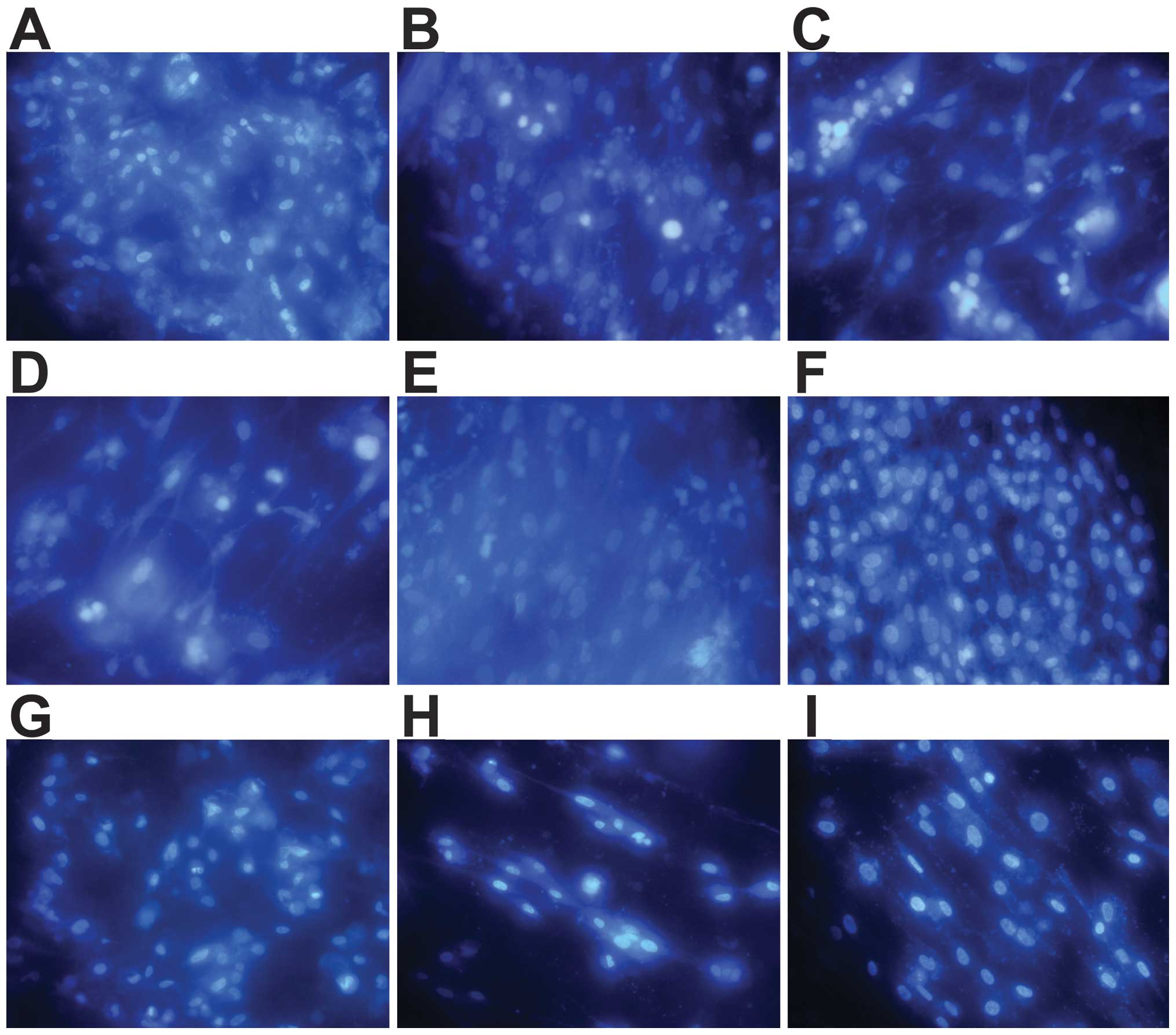

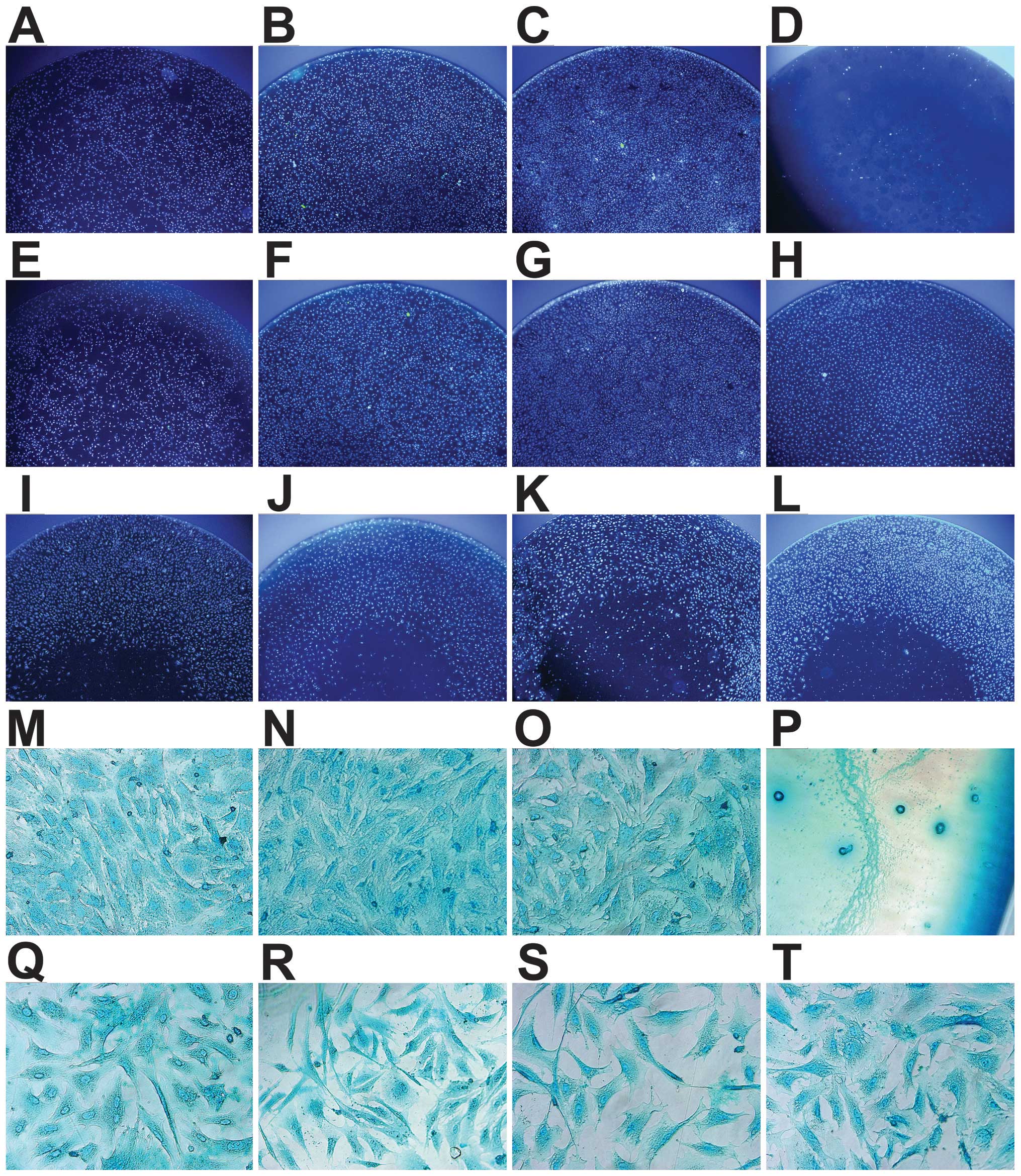

| Figure 24′,6-Diamidino-2-phenylindole (DAPI)

staining of chondrocytes (x400 magnification). Cells cultured for 3

days on (A) brushite

(CaHPO4·2H2O)-co ated JDBM

(C-JDBM), (B) Mg-Nd-Zn-Zr (JDBM), (C) AZ31, (D) WE43, (E) pure

magnesium (Mg), and (F) TC4. Cells cultured for 1 day on (G)

C-JDBM, (H) pure Mg, and (I) TC4. A few cells were already observed

on the samples after 1 day of culture (G–I). After 3 days of

culture, the number of cells on the discs increased (A–F). Among

the cultures, a significantly greater number of adhered cells was

observed on the surfaces of the C-JDBM and TC4 discs (A and F,

respectively), whereas the least number of cells was observed on

the WE43 disc (D). |

The chondrocytes cultured on the discs presented

with a highly elongated, irregular and round shape. A few cells

were already observed on the samples after 1 day of culture

(Fig. 2G–I). After 3 days of

culture, the number of cells on the discs increased (Fig. 2A–F). Among the cultures, a

significantly greater number of adhered cells was observed on the

surfaces of the C-JDBM and TC4 discs (Fig. 2A and F, respectively), whereas the

least number of cells was observed on the WE43 disc (Fig. 2D).

Indirect cytotoxicity and proliferation

assay

The absorbance of the chondrocytes cultured on the

different extracts, DMEM/F12 and 10% DMSO media for 1, 3, and 5

days is shown in Fig. 3. The

morphologies of the chondrocytes after 1, 3, and 5 days of

incubation are presented in Fig.

4. As shown in Fig. 3, the

absorbance of all groups of cells increased with time. As shown in

Table I, the time effect (day)

and the effects of day x group interaction were statistically

significant (p<0.05), indicating that the research target

changed with time. Furthermore, the role of the time factor varied

within each group. Tests on the between-subject effects indicated

that the grouping factor influenced the results, and each group of

targets generally differed (p<0.05). Likewise, the absorbance of

C-JDBM (Fig. 3) was greater than

that of the negative control and TC4, although the difference was

not significant (p>0.05). The absorbance of the remaining groups

showed significantly lower results (p<0.05). By contrast, no

significant differences were observed among the JDBM, AZ31, WE43

and pure Mg groups (p>0.05), thereby indicating that these

alloys have high cytocompatibility with chondrocytes.

| Figure 3Results of cytotoxicity assay of the

Mg-Nd-Zn-Zr (JDBM), brushite

(CaHPO4·2H2O)-coated JDBM

(C-JDBM), AZ31, WE43, pure magnesium (Mg), and TC4 extraction

media, as wel as the Dulbecco’s modified Eagle’s medium with F12

(DMEM/F12) culture media, with and without 10% DMSO [mean ±

standard deviation (SD)] on chondrocytes after 1, 3 and 5 days.

*P<0.05 (positive control vs. all treatments;

negative control, C-JDBM, and TC4 vs. the other Mg alloys and Mg).

#P>0.05 (negative control vs. C-JDBM vs. TC4; JDBM

vs. AZ31 vs. WE43 vs. Mg). Negative control, cells cultured in

DMEM/F12 alone; positive control, cells cultured in DMEM/F12 medium

with 10% DMSO. |

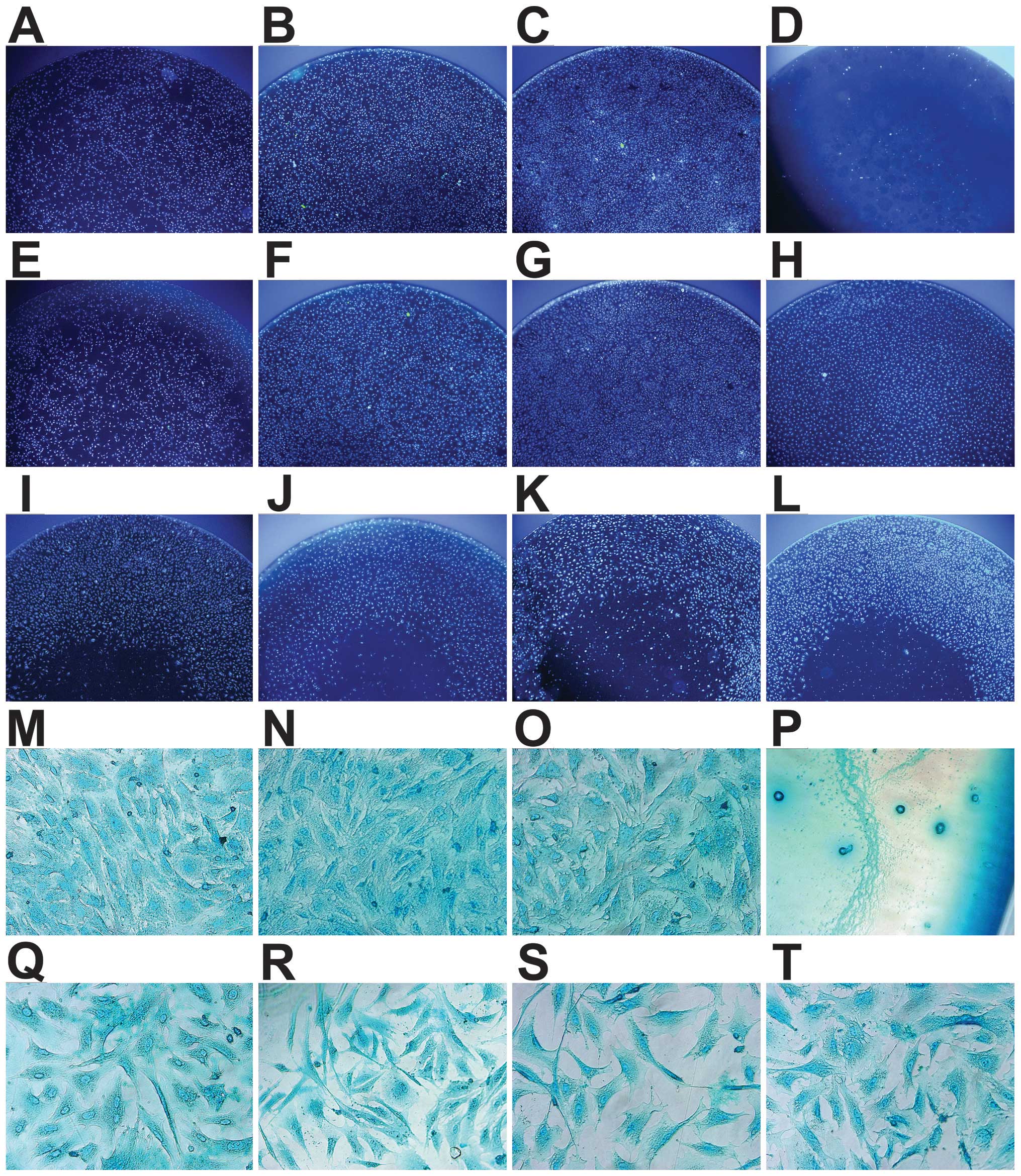

| Figure 4Morphology of the chondrocytes

follwoing 1, 3 and 5 days of incubation with: (A–C and M)

Dulbecco’s modified Eagle’s medium with F12 (DMEM/F12), (D and P)

10% DMSO medium, (E–G and N) brushite

(CaHPO4·2H2O)-coated JDBM

(C-JDBM), (H and O) Ti alloy (TC4), (I and Q) Mg-Nd-Zn-Zr (JDBM),

(J and R) AZ31, (K and S) WE43, and (L and T) pure magnesium (Mg).

(A–C and E–G) Cells were incubated for 1, 3 and 5 days,

respectively. (D and H–T) Cells were incubated for 3 days. (A–L)

Cells were stained with 4′,6-diamidino-2-phenylindole (DAPI) (x40

magnification). (M–T) Cells were stained with Alcian blue (x400

magnification). A greater number of cells was observed in the

negative control group (B), C-JDBM (F) and TC4 (H) groups after 3

days, as compared with the other groups (I–L), due to the loss of

cells in the center of the other culture plates, while no other

differences were observed between them. (A–C and E–G) The number of

cells was directly associated with the incubation time. The

chondrocytes in the positive control group were extremely scarce (D

and P), and unlike the elongated, polygonal, deltoid or irregular

shape of the other chondrocytes (M–O and Q–T), their morphology had

changed to a small and round shape (P), whereas the cells from all

the other treatment groups appeared normal. |

| Table IStatistical analysis of time, group

factor effect and day x group interaction effect. |

Table I

Statistical analysis of time, group

factor effect and day x group interaction effect.

| Mauchly’s test of

sphericitya |

|---|

|

|---|

| Within subjects

effect | Mauchly’s W | Approx.

Chi-square | Df | Sig. | εb

|

|---|

| | | | |

Greenhouse-Geisser | Huynh-Feldt | Lower-bound |

|---|

|

|---|

| Day | 0.917 | 3.380 | 2 | 0.185 | 0.923 | 1.000 | 0.500 |

|---|

| Tests of within

subjects effects |

|

| Source | Type III sum of

squares | | Df | Mean square | F-value | Sig. |

|

| Day | | | | | | |

| Sphericity

assumption | 1.597 | | 2 | 0.798 | 475.791 | 0.000 |

|

Greenhouse-Geisser | 1.597 | | 1.847 | 0.865 | 475.791 | 0.000 |

| Huynh-Feldt | 1.597 | | 2.000 | 0.798 | 475.791 | 0.000 |

| Lower-bound | 1.597 | | 1.000 | 1.597 | 475.791 | 0.000 |

| Day x group | | | | | | |

| Sphericity

assumption | 0.802 | | 14 | 0.057 | 34.132 | 0.000 |

|

Greenhouse-Geisser | 0.802 | | 12.927 | 0.062 | 34.132 | 0.000 |

| Huynh-Feldt | 0.802 | | 14.000 | 0.057 | 34.132 | 0.000 |

| Lower-bound | 0.802 | | 7.000 | 0.115 | 34.132 | 0.000 |

| Error (day) | | | | | | |

| Sphericity

assumption | 0.134 | | 80 | 0.002 | | |

|

Greenhouse-Geisser | 0.134 | | 73.868 | 0.002 | | |

| Huynh-Feldt | 0.134 | | 80.000 | 0.002 | | |

| Lower-bound | 0.134 | | 40.000 | 0.003 | | |

|

| Tests of between

subjects effects |

|

| Source | Type III sum of

squares | | Df | | Mean square | F-value | Sig. |

|

| Intercept | 15.060 | | 1 | | 15.060 | 3.608E3 | 0.000 |

| Group | 4.437 | | 7 | | 0.634 | 151.828 | 0.000 |

| Error | 0.167 | | 40 | | 0.004 | | |

The analysis of cell morphology (Fig. 4) presented similar results as

those of the MTT assay. A greater number of cells was observed in

the negative control group (Fig.

4B), C-JDBM (Fig. 4F) and TC4

(Fig. 4H) groups after 3 days, as

compared with the other groups (Fig.

4I–L), due to the loss of cells in the center of the other

culture plates, while no other differences were observed between

them. As shown in Fig. 4A–C and

E–G, the number of cells was directly associated with the

incubation time. The chondrocytes in the positive control group

were extremely scarce (Fig. 4D and

P), and unlike the elongated, polygonal, deltoid or irregular

shape of the other chondrocytes (Fig.

4M–O and Q–T), their morphology had changed to a small and

round shape (Fig. 4P), whereas

the cells from all the other treatment groups appeared normal.

Apoptosis assay

The results from cell apoptosis assay (Fig. 5) were similar to those obtained by

MTT assay and the analysis of cell morphology (Figs. 3 and 4). The cells cultured on C-JDBM and TC4

were comparable with those of the negative control group

(p>0.05), in terms of the apoptotic rate, whereas the apoptotic

rate of the cells in the other groups was higher (p<0.05). There

were no statistically significant differences observed among the

JDBM, AZ31, WE43 and pure Mg groups (p> 0. 05).

| Figure 5Apoptotic rate of chondrocytes

cultured in 25 cm2 plates after 5 days of incubation

with Mg-Nd-Zn-Zr (JDBM), brushite

(CaHPO4·2H2O)-coated JDBM

(C-JDBM), AZ31, WE43, pure magnesium (Mg), and TC4 extraction

media, as well as in Dulbecco’s modified Eagle’s medium with F12

(DMEM/F12). *P<0.05 (DMEM/F12, C-JDBM and TC4 vs.

JDBM, AZ31, WE43, and Mg). #P>0.05 (DMEM/F12 vs.

C-JDBM vs. TC4, JDBM vs. AZ31 vs. WE43 vs. Mg). Negative control,

cells cultured in DMEM/F12 alone; positive control, cells cultured

in DMEM/F12 medium with 10% DMSO. |

Total GAG quantification assay

The results obtained from the analysis of the GAG

content (Fig. 6) were comparable

to those obtained by MTT assay and the analysis of cell morphology

(Figs. 3 and 4) and apoptosis assay (Fig. 5). The GAG content in the cells

cultured on C-JDBM and TC4 was comparable to that of the negative

control, while the GAG content did not differ between the cells in

the other groups. There was no statistically significant difference

observed in the GAG content between the JDBM, AZ31, WE43 and pure

Mg groups (p>0.05).

| Figure 6Total glycosaminoglycan (GAG) content

of chondrocytes cultured in 25 cm2 plates after 5 days

of incubation with Mg-Nd-Zn-Zr (JDBM), brushite

(CaHPO4·2H2O)-coated JDBM

(C-JDBM), AZ31, WE43, pure magnesium (Mg), and TC4 extraction

mediums, as well as Dulbecco’s modified Eagle’s medium with F12

(DMEM/F12). *P<0.05 (DMEM/F12, C-JDBM and TC4 vs.

JDBM, AZ31, WE43, and Mg). #P>0.05 (DMEM/F12 vs.

C-JDBM vs. TC4, JDBM vs. AZ31 vs. WE43 vs. Mg). Negative control,

cells cultured in DMEM/F12 alone; positive control, cells cultured

in DMEM/F12 medium with 10% DMSO. |

Col II content and ELISA

The results from ELISA were not satisfactory as the

values obtained for the JDBM, AZ31, WE43 and Mg samples were

extremely low, much lower than those of the kit (0.1–30 ng/ml).

Moreover, the negative control, as well as the C-JDBM and TC4

groups, only had values of 0.112±0.0083, 0.122±0.0068 and

0.101±0.0089 ng/ml, respectively (data not shown, as these results

were lower than the lower limit of the measuring range of the

kit).

RT-qPCR

As shown in Fig.

7, the results of the analysis of the relative mRNA expression

levels of aggrecan and Col II in the chondrocytes following 5 days

of incubation under the different treatment conditions were

consistent with those obtained form the other assays (Figs. 3Figure 4Figure 5–6) and with the results of our previous

study (12). The results revealed

that the cytocompatibility of JDBM was comparable to that of AZ31,

WE43 and pure Mg. Furthermore, the

CaHPO4·2H2O coating significantly

improved its compatibility.

| Figure 7Aggrecan and collagen II (Col II)

gene expression relative to GAPDH after 5 days of incubation with

the Mg-Nd-Zn-Zr (JDBM), brushite

(CaHPO4·2H2O)-coated JDBM

(C-JDBM), AZ31, WE43, pure magnesium (Mg), and TC4 extraction

media, with Dulbecco’s modified Eagle’s medium with F12 (DMEM/F12)

as the control. *P<0.05 (DMEM/F12, C-JDBM and TC4 vs. JDBM,

AZ31, WE43, and Mg). #P>0.05 (DMEM/F12 vs. C-JDBM vs.

TC4, JDBM vs. AZ31 vs. WE43 vs. Mg). Negative control, cells

cultured in DMEM/F12 alone; positive control, cells cultured in

DMEM/F12 medium with 10% DMSO. |

Discussion

Despite numerous studies on Mg alloys for biomedical

applications, the majority of these studies focused on the

commercial Mg alloys that may be harmful to the human body

(8–10). The JDBM alloy was originally

developed as a Mg alloy for medical implants (11,12,15). The main aim of this study was to

evaluate the cytocompatibility of JDBM to chondrocytes, which may

be used for cartilage tissue engineering. The biocompatibility of

different cell lines with the same Mg alloy may be significantly

different (16). However,

chondrocytes, widely used as ‘seed’ cells in cartilage tissue

engineering, have been rarely used to study the biocompatibility of

Mg alloys. Our preliminary study presented positive results

(12); thus, further

investigation was performed. In the present study, JDBM and C-JDBM

served as the test groups, whereas the AZ31, WE43, pure Mg and TC4

alloy group were set up as the control group, aside from the

negative and positive controls. Comparisons among groups revealed

that JDBM and C-JDBM had better reference values as regards their

cytocompatibility, based on previous positive results obtained for

AZ31, WE43, and TC4 alloys, as well as pure Mg (1,2,17–19).

Cell direct adhesion experiments revealed efficient

chondrocyte growth, distribution and adhesion to all material

surfaces (Figs. 1 and 2). The adhesion behavior of the

chondrocytes is similar to that of MG-63 cells, L929 cells, human

bone marrow stromal cells (hBMSCs) and MC3T3-E1 cells on the

surface of Mg alloys (7,17,20,21). Furthermore, as shown in Fig. 2, the number of cells that had

adhered to the surface of the C-JDBM and TC4 discs (Figs. 2A and F) was greater than that of

the other groups (Fig. 2B–E),

thereby indicating the better biocompatibility of chondrocytes with

C-JDBM and TC4 than the others. Although the cells cultured on the

WE43 alloy appeared to be fewer (Fig.

2D), the biocompatibility of WE43 is not necessarily worse than

that of other non-coating materials. According to the study by

Witte et al (22), the

direct cell assay reduces cell viability more rapidly than the

indirect cytotoxicity tests. Cells are known to be very sensitive

to environmental fluctuations, including ion release, changes in pH

and hydrogen evolution. The disintegrated particles and corrosion

product Mg(OH)2 for Mg-based biomaterials, as well as

the influencing factors increased when the cells were directly

exposed to the material. To be specific, the significant increase

in the pH of cell culture media caused by Mg alloy degradation may

have an adverse effect on the cells (8,18,22-24). Besides, a corrosion product layer

is formed during the corrosion process of Mg and Mg alloys. During

immersion, the corrosion product gradually falls from the surface

due to the severe mismatch between the substrate and the corrosion

product layer (1). The formed

corrosion product and departure process make it difficult for the

cells to attach to the surface. Furthermore, the high hydrogen

evolution rate affects cell attachment and proliferation. Once a

Mg-based material is immersed in the cell culture medium, the

hydrogen gas evolves from the sample surface, which may deteriorate

cell adhesion and the ensuing proliferation process. With a high pH

value, Mg(OH)2 and zinc hydroxide [Zn(OH)2]

precipitate easily during the incubation period from the surface of

the sample, but also in the culture medium. However, the toxicity

of micro-sized Zn(OH)2 may be related to the particle

concentration. Nair et al (25) indicated that micro-ZnO is

extremely toxic to MG63 cells at a concentration above 100

µm (with an ~50% loss in cell viability). There were

different environment fluctuations for each sample. Due to the

aforementioned reasons, we changed the medium once a day to reduce

the influence of these fluctuations on the cells.

The SEM micrograph revealed few chondrocytes on the

TC4 disc. However, a few cells were fluorescently stained on the

parallel sample (Fig. 2F). The

lower adhesive force of chondrocytes, as compared with other cells

may account for this result. Chondrocyte digestion possibly occurs

more rapidly than other cells, including MC3T3-E1 cells in flask

cultures; it only needs approximately 30–60 sec. Thus, the

chondrocytes may have easily dropped off from the surface of the

TC4 samples due to their complex treatment process prior to SEM.

The shadows in Fig. 1F show the

chondrocytes spreading and falling off. Moreover, Mg alloys have

rougher surfaces following degradation than the Ti alloy, which

then favors chondrocyte adhesion onto Mg alloys.

Based on indirect cell cytotoxicity and

proliferation assay, the cytocompatibility of JDBM was comparable

with that of AZ31, WE43 and pure Mg; however, it may be

significantly improved by

CaHPO4·2H2O coating. Cell

viability increased with time, which was in accordance with the

results obtained by direct and indirect adhesion assays (Figs. 2 and 4), as well as those of previous studies

(7,16,17,20). The cell counts in parallel 96-well

plates were consistent with those obtained by MTT assay and the

anlaysis of cell morphology (Figs.

3 and 4). A greater number of

cells was observed in the negative control, C-JDBM and TC4 groups.

Some cells had disappeared from the center of the plates in the

JDBM, AZ31, WE43 and pure Mg groups. The following reasons may

account for these results: firstly, the obvious increase in the pH

in the media caused by Mg alloy corrosion had an adverse effect on

cell viability, as previously mentioned (7,8,17,19,23,24). Our preliminary results presented

high pH values for uncoated samples (12); however, further and more detailed

investigations are warranted to clarify this issue. Secondly,

chondrocytes can be expanded in vitro in monolayer culture,

although this multiplication may lead to dedifferentiation

beginning from 3 or 4 passages. This process makes the cells become

fibroblast-like as they lose their round phenotype and become

spindle-shaped, while switching their collagen production from

types II, IX and XI to types I, III and V (26–29). Given the limitations of a low

initial number of cells and their dedifferentiation, chondrocytes

are multiplied in monolayer culture to increase the number of cells

and are then transferred to a three-dimensional culture system to

regain their phenotype (26,27,29). Thus, in the present study, we used

cells that were passaged twice to eliminate such limitations.

Apparently, the viability of the chondrocytes is inferior to that

of other cells (26,27,29). Thirdly, the wells of 96-well

plates are small, and surface tension brings more cell suspensions

to the periphery, and more cells gathered together are more

susceptible to survival than sparse ones.

The results obtained by MTT and apoptosis assays, as

well as the from the analysis of GAG and Col II content alongside

the relative mRNA expression of aggrecan and Col II were likewise

similar. GAG, Col II, aggrecan and Col II mRNA expression are

unique to chondrocytes (14,26–29). The cells were visibly well

attached to the coating and proliferated normally. These results

can be explained by the corrosion protecting effect of the brushite

coating, as discussed above, thereby improving the

cytocompatibility. The purity of Mg alloys and surface modification

may reduce the degradation rate of Mg and its alloys (7,17,19,20,22,30). Mg purity has improved as

metallurgical techniques have improved. Surface modification

includes alkali-heat treatment, carbonate treatment, ion plating

deposition of Ti, surface plasma immersion ion implantation,

micro-arc oxidation, fluoride coating and phosphate coating.

Calcium phosphate (Ca-P) coatings are widely used on bone implant

materials due to their favorable biocompatibility and

osteoconductive properties (7,31).

The brushite (CaHPO4·2H2O) coating

has been reported to significantly improve the biocorrosion

resistance and osseous integration of Mg alloys (7). In this study,

CaHPO4·2H2O was coated onto JDBM

alloys through chemical deposition. Compared with other surface

treatment methods, the CaHPO4·2H2O

coating is simpler and easier to control. Furthermore,

CaHPO4·2H2O is applicable to

implants of complex shapes and low-temperature processes. This last

feature is of particular importance during the surface modification

of Mg implants due to the low melting point of Mg (17,30). The Ca-P coating can effectively

reduce the degradation rate of Mg and its alloys. Our findings

confirm the excellent biocompatibility and desirable protective

effects of the coated sample, which is in agreement with the

results previously reported (7,17,20,30,31).

The property difference of our proposed coated and

uncoated alloys may be attributed to the following reasons:

firstly, the alkalization effect caused by the rapid corrosion of

Mg alloys is undesirable for cell adhesion, growth and

proliferation; this alkalization effect rapidly increases the pH of

the SBF until pH >9.0 within approximately 2 h, which is beyond

the pH range suitable for cell survival, before it finally reaches

a relatively stable value of 10.5 (32). According to previously reported

results, the Ca-P coating can serve as an effective corrosion

inhabiting layer and reduce the increase in pH of simulated body

fluid (33). Although cells are

very sensitive to environmental fluctuations, particularly

fluctuations in pH (22–24), a Ca-P coating can improve the

corrosion resistance of JDBM alloys and provide an environment for

cells with a suitable pH (12,30). Thus, the Ca-P coating would

likewise benefit cell adhesion and growth. The in vitro cell

assays, including cell adhesion, MTT, apoptosis, GAG content assay

and RT-PCR, demonstrated that C-JDBM had an excellent cellular

response due to the CaHPO4·2H2O

coating.

Mg and Ca ions have been previouly demonstrated to

promote cell viability and proliferation, which are known to

promote cell differentiation (7,34).

Mg ions at an appropriate concentration can activate bone cells by

influencing the protein synthesis and ancillary processes (2,34).

Furthermore, Mg ion concentrations of up to 10.286 mM have been

reported to be safe to human bone marrow-derived stromal cells

(24). Another study demonstrated

that physiologically high extracellular Mg concentrations (10 mM)

enhance chondrocyte proliferation and redifferentiation in distinct

concentration ranges (16). Mg is

likewise known to be active in cell adhesion mechanisms (35). Furthermore, Mg hydroxide may

enhance osteoblast activity and decrease the osteoclast number

temporarily in peri-implant bone remodeling (36). Overall, the Mg ion and

Mg(OH)2 may enhance the viability, proliferation, and

adhesion ability of chondrocytes.

Finally, calcium (Ca) ions are essential in chemical

signaling for cells (37). Ca

ions on the material surfaces favor protein absorption, e.g.,

fibronectin and vitronectin, which are important cell

attachment-promoting proteins. Therefore, Ca ions improve cell

attachment and spreading onto the surface (38). The enhanced Mg ion concentration

elevates the calcium concentration (39), which is suitable for the

nucleation of the Ca-P containing compounds. This mechanism

verifies that Mg is capable of osteoconductivity (39,40). Bone growth on an implant surface

requires the presence of sufficient amounts of Ca and phosphate

ions (17). Therefore,

CaHPO4·2H2O enhances the cellular

response.

The combined results show that the presence of Ca

and Mg ions, together with a more stable pH, may increase cell

proliferation with C-JDBM, as compared with the uncoated JDBM,

AZ31, WE43 and Ti alloys or pure Mg (12).

In conclusion, in this study, the Mg alloy, JDBM,

was investigated as a medical biodegradable material in terms of

its cytocompatibility to chondrocytes in vitro. JDBM

demonstrated high biocompatibility to chondrocytes, which was

similar to the performance of AZ31, WE43 and pure Mg. The

CaHPO4·2H2O coating may

significantly improve its biocompatibility, which was attributed to

the presence of Mg and Ca ions, as well as its more stable pH.

Acknowledgments

The present study was sponsored by grants from the

Science and Technology Commission of Shanghai Municipality

(11DJ1400300), the National Natural Science Foundation of China

(nos. 81271961 and 51174136), and the National Key Technology

Research and Development Program of China (2012BAI18B01).

References

|

1

|

Song G, Atrens A, St John D, Wu X and

Nairn J: The anodic dissolution of magnesium in chloride and

sulphate solutions. Corros Sci. 39:1981–2004. 1997. View Article : Google Scholar

|

|

2

|

Witte F, Kaese V, Haferkamp H, Switzer E,

Meyer-Lindenberg A, Wirth CJ and Windhagen H: In vivo corrosion of

four magnesium alloys and the associated bone response.

Biomaterials. 26:3557–3563. 2005. View Article : Google Scholar

|

|

3

|

Witte F, Fischer J, Nellesen J, Crostack

HA, Kaese V, Pisch A, Beckmann F and Windhagen H: In vitro and in

vivo corrosion measurements of magnesium alloys. Biomaterials.

27:1013–1018. 2006. View Article : Google Scholar

|

|

4

|

Xu L, Yu G, Zhang E, Pan F and Yang K: In

vivo corrosion behavior of Mg-Mn-Zn alloy for bone implant

application. J Biomed Mater Res A. 83:703–711. 2007. View Article : Google Scholar : PubMed/NCBI

|

|

5

|

Kannan MB and Raman RKS: In vitro

degradation and mechanical integrity of calcium-containing

magnesium alloys in modified-simulated body fluid. Biomaterials.

29:2306–2314. 2008. View Article : Google Scholar : PubMed/NCBI

|

|

6

|

Staiger MP, Pietak AM, Huadmai J and Dias

G: Magnesium and its alloys as orthopedic biomaterials: A review.

Biomaterials. 27:1728–1734. 2006. View Article : Google Scholar

|

|

7

|

Xu L, Pan F, Yu G, Yang L, Zhang E and

Yang K: In vitro and in vivo evaluation of the surface bioactivity

of a calcium phosphate coated magnesium alloy. Biomaterials.

30:1512–1523. 2009. View Article : Google Scholar

|

|

8

|

Witte F, Hort N, Vogt C, Cohen S, Kainer

KU, Willumeit R and Feyerabend F: Degradable biomaterials based on

magnesium corrosion. Curr Opin Solid State Mater Sci. 12:63–72.

2008. View Article : Google Scholar

|

|

9

|

El-Rahman SS: Neuropathology of aluminum

toxicity in rats (glutamate and GABA impairment). Pharmacol Res.

47:189–194. 2003. View Article : Google Scholar : PubMed/NCBI

|

|

10

|

Hirano S and Suzuki KT: Exposure,

metabolism, and toxicity of rare earths and related compounds.

Environ Health Perspect. 104(Suppl 1): S85–S95. 1996. View Article : Google Scholar

|

|

11

|

Yuan G, Zhang X, Niu J, Tao H, Chen D, He

Y, Jiang Y and Ding W: Research progress of new type of degradable

biomedical magnesium alloys JDBM. Chin J Nonferrous Met.

21:2476–2488. 2011.

|

|

12

|

Liao Y, Ouyang Y, Niu J, Zhang J, Wang Y,

Zhu Z, Yuan G, He Y and Jiang Y: In vitro response of chondrocytes

to a biodegradable Mg-Nd-Zn-Zr alloy. Mater Lett. 83:206–208. 2012.

View Article : Google Scholar

|

|

13

|

Niu J, Yuan G, Liao Y, Mao L, Zhang J,

Wang Y, Huang F, Jiang Y, He Y and Ding W: Enhanced biocorrosion

resistance and biocompatibility of degradable Mg-Nd-Zn-Zr alloy by

brushite coating. Mater Sci Eng C Mater Biol Appl. 33:4833–4841.

2013. View Article : Google Scholar : PubMed/NCBI

|

|

14

|

Lin YJ, Yen CN, Hu YC, Wu YC, Liao CJ and

Chu IM: Chondrocytes culture in three-dimensional porous alginate

scaffolds enhanced cell proliferation, matrix synthesis and gene

expression. J Biomed Mater Res A. 88:23–33. 2009. View Article : Google Scholar

|

|

15

|

Zhang XB, Yuan GY, Mao L, Niu JL and Ding

WJ: Biocorrosion properties of as-extruded Mg-Nd-Zn-Zr alloy

compared with commercial AZ31 and WE43 alloys. Mater Lett.

66:209–211. 2012. View Article : Google Scholar

|

|

16

|

Feyerabend F, Fischer J, Holtz J, Witte F,

Willumeit R, Drücker H, Vogt C and Hort N: Evaluation of short-term

effects of rare earth and other elements used in magnesium alloys

on primary cells and cell lines. Acta Biomater. 6:1834–1842. 2010.

View Article : Google Scholar

|

|

17

|

Geng F, Tan LL, Jin XX, Yang JY and Yang

K: The preparation, cytocompatibility, and in vitro biodegradation

study of pure β-TCP on magnesium. J Mater Sci Mater Med.

20:1149–1157. 2009. View Article : Google Scholar : PubMed/NCBI

|

|

18

|

Popat KC, Leoni L, Grimes CA and Desai TA:

Influence of engineered titania nanotubular surfaces on bone cells.

Biomaterials. 28:3188–3197. 2007. View Article : Google Scholar : PubMed/NCBI

|

|

19

|

Keim S, Brunner JG, Fabry B and Virtanen

S: Control of magnesium corrosion and biocompatibility with

biomimetic coatings. J Biomed Mater Res B Appl Biomater. 96:84–90.

2011. View Article : Google Scholar

|

|

20

|

Li J, Song Y, Zhang S, Zhao C, Zhang F,

Zhang X, Cao L, Fan Q and Tang T: In vitro responses of human bone

marrow stromal cells to a fluoridated hydroxyapatite coated

biodegradable Mg-Zn alloy. Biomaterials. 31:5782–5788. 2010.

View Article : Google Scholar : PubMed/NCBI

|

|

21

|

Zhang SX, Li JA, Song Y, Zhao C, Zhang X,

Xie C, Zhang Y, Tao H, He Y, Jiang Y and Bian YJ: In vitro

degradation, hemolysis and MC3T3-E1 cell adhesion of biodegradable

Mg-Zn alloy. Mater Sci Eng C Mater Biol Appl. 29:1907–1912. 2009.

View Article : Google Scholar

|

|

22

|

Witte F, Feyerabend F, Maier P, Fischer J,

Störmer M, Blawert C, Dietzel W and Hort N: Biodegradable

magnesium-hydroxy-apatite metal matrix composites. Biomaterials.

28:2163–2174. 2007. View Article : Google Scholar : PubMed/NCBI

|

|

23

|

Serre CM, Papillard M, Chavassieux P,

Voegel JC and Boivin G: Influence of magnesium substitution on a

collagen-apatite biomaterial on the production of a calcifying

matrix by human osteoblasts. J Biomed Mater Res. 42:626–633. 1998.

View Article : Google Scholar : PubMed/NCBI

|

|

24

|

Yang C, Yuan G, Zhang J, Tang Z, Zhang X

and Dai K: Effects of magnesium alloys extracts on adult human bone

marrow-derived stromal cell viability and osteogenic

differentiation. Biomed Mater. 5:0450052010. View Article : Google Scholar : PubMed/NCBI

|

|

25

|

Nair S, Sasidharan A, Divya Rani VV, Menon

D, Nair S, Manzoor K and Raina S: Role of size scale of ZnO

nanoparticles and microparticles on toxicity toward bacteria and

osteoblast cancer cells. J Mater Sci Mater Med. 20(Suppl 1):

S235–S241. 2009. View Article : Google Scholar

|

|

26

|

Chaipinyo K, Oakes BW and van Damme MPI:

Effects of growth factors on cell proliferation and matrix

synthesis of low-density, primary bovine chondrocytes cultured in

collagen I gels. J Orthop Res. 20:1070–1078. 2002. View Article : Google Scholar : PubMed/NCBI

|

|

27

|

Brodkin KR, García AJ and Levenston ME:

Chondrocyte phenotypes on different extracellular matrix

monolayers. Biomaterials. 25:5929–5938. 2004. View Article : Google Scholar : PubMed/NCBI

|

|

28

|

Martin I, Suetterlin R, Baschong W,

Heberer M, Vunjak-Novakovic G and Freed LE: Enhanced cartilage

tissue engineering by sequential exposure of chondrocytes to FGF-2

during 2D expansion and BMP-2 during 3D cultivation. J Cell

Biochem. 83:121–128. 2001. View Article : Google Scholar : PubMed/NCBI

|

|

29

|

Gagne TA, Chappell-Afonso K, Johnson JL,

McPherson JM, Oldham CA, Tubo RA, Vaccaro C and Vasios GW: Enhanced

proliferation and differentiation of human articular chondrocytes

when seeded at low cell densities in alginate in vitro. J Orthop

Res. 18:882–890. 2000. View Article : Google Scholar

|

|

30

|

Du H, Wei Z, Wang H, Zhang E, Zuo L and Du

L: Surface microstructure and cell compatibility of calcium

silicate and calcium phosphate composite coatings on Mg-Zn-Mn-Ca

alloys for biomedical application. Colloids Surf B Biointerfaces.

83:96–102. 2011. View Article : Google Scholar

|

|

31

|

Hench LL: Bioceramics. J Am Ceram Soc.

81:1705–1728. 1998. View Article : Google Scholar

|

|

32

|

Song GL and Song SZ: A possible

biodegradable magnesium implant material. Adv Eng Mater. 9:298–302.

2007. View Article : Google Scholar

|

|

33

|

Xu L, Zhang E and Yang K: Phosphating

treatment and corrosion properties of Mg-Mn-Zn alloy for biomedical

application. J Mater Sci Mater Med. 20:859–867. 2009. View Article : Google Scholar

|

|

34

|

Rude RK, Gruber HE, Wei LY, Frausto A and

Mills BG: Magnesium deficiency: Effect on bone and mineral

metabolism in the mouse. Calcif Tissue Int. 72:32–41. 2003.

View Article : Google Scholar

|

|

35

|

Paul W and Sharma CP: Nanoceramic

matrices: Biomedical applications. Am J Biochem Biotechnol.

2:41–48. 2006. View Article : Google Scholar

|

|

36

|

Janning C, Willbold E, Vogt C, Nellesen J,

Meyer-Lindenberg A, Windhagen H, Thorey F and Witte F: Magnesium

hydroxide temporarily enhancing osteoblast activity and decreasing

the osteoclast number in peri-implant bone remodelling. Acta

Biomater. 6:1861–1868. 2010. View Article : Google Scholar

|

|

37

|

Ilich JZ and Kerstetter JE: Nutrition in

bone health revisited: A story beyond calcium. J Am Coll Nutr.

19:715–737. 2000. View Article : Google Scholar

|

|

38

|

Feng B, Weng J, Yang BC, Qu SX and Zhang

XD: Characterization of titanium surfaces with calcium and

phosphate and osteoblast adhesion. Biomaterials. 25:3421–3428.

2004. View Article : Google Scholar : PubMed/NCBI

|

|

39

|

TenHuisen KS and Brown PW: Effects of

magnesium on the formation of calcium-deficient hydroxyapatite from

CaHPO 4·2H2O and

Ca4(PO4)2O. J Biomed Mater Res.

36:306–314. 1997. View Article : Google Scholar : PubMed/NCBI

|

|

40

|

Witte F, Reifenrath J, Müller PP, Crostack

H-A, Nellesen J, Bach FW, Bormann D and Rudert M: Cartilage repair

on magnesium scaffolds used as a subchondral bone replacement.

Materialwiss Werkstofftech. 37:504–508. 2006. View Article : Google Scholar

|