Introduction

In previous years, implanted prosthodontic dentures

have been applied as an effective way to repair either defective or

absent dentition. The surface characteristics and morphology of

implanted dentures affect the cell survival, adhesion,

proliferation and differentiation of dental tissues on denture

surfaces (1). Biologically inert

titanium (Ti) is widely used in dental implants due to the direct

contact between the implant material and the bone (1,2).

However, as a bioinert material, Ti cannot be biologically

integrated with bone tissue (3).

One approach to improve integration has been to roughen endosseous

areas of dental implants in order to increase the total surface

area available for osseous apposition. Surface roughness has been

demonstrated to alter osteoblast attachment, proliferation,

differentiation and extracellular matrix (ECM) production (4).

Another limitation of Ti implants is the short delay

between implantation and when they are able to impart bactericidal

capabilities, which may lead to the formation of dental plaques

surrounding implanted dentures (5). Several strategies have been developed

to overcome this surface-associated limitation of Ti implants

(6–10), including surface modification by

plasma immersion ion implantation and deposition (PIIID) (11–13).

PIIID generates surface layers that can integrate with specific

substrates and this technique has been used to incorporate zinc

(Zn) into the surfaces of Ti implants (14). Zn is a necessary element for

cellular activities and is specifically important in the

development and maintenance of bone structures (15).

In the current study, a PIIID technique was used to

implant Zn ions onto the smooth surfaces of pure Ti disks. The

physical structure and chemical composition of the modified

Zn-PIIID-Ti surfaces were evaluated by scanning electron microscopy

(SEM) and X-ray photoelectron spectroscopy (XPS), respectively and

then the biocompatibility of the Zn-PIIID-Ti surfaces with regard

to osteoblast function in vitro was examined.

Materials and methods

Preparation and surface characterization

of Ti disks

Pure Ti (grade 4) disks, 10 mm in diameter and 1 mm

thick were polished on one side to a mirror-like finish and then

sequentially subjected to ultrasonication in acetone, absolute

alcohol and deionized water. The clean disks were then air-dried

and stored in a desiccator. PIIID to implant and deposit Zn ions

was performed at the State Key Laboratory of Advanced Welding

Production Technology of the Harbin Institute of Technology

(Harbin, China) using the following parameters: Pulse voltage (V)

of 20 kv; pulse width (τ/) of 300 μs; Zn-ion pulsed cathodic

arc width of 300 μs and working pressure (P) of

1×10−1 Pa. The source of the Zn ions was a pulsed

cathodic arc. Ti disks were prepared with four different

implantation times (T) of 20 min (Zn-Ti-20 min group), 40 min

(Zn-Ti-40 min group), 60 min (Zn-Ti-60 min group) and 80 min

(Zn-Ti-80 min group). Commercially pure Ti (cp-Ti) disks without Zn

implantation were used in the control group.

The physical structure of modified Ti disks was

observed by SEM (Hitachi S-520; Hitachi, Ltd., Tokyo, Japan) and

their chemical composition was characterized by XPS using 300 W Al

Kα radiation and an ESCALab 220i-XL electron spectrometer (VG

Scientific, Ltd., East Grinstead, UK). Binding energies were

referenced to the C1s line at 284.8 eV from trace carbon and the

base pressure was 3×10−9 mbar.

Cell culture

MG-63 human osteosarcoma cells (purchased from the

Cancer Institute and Hospital, Chinese Academy of Medical Sciences,

Beijing, China) were grown in minimum essential medium with 10%

fetal calf serum (HyClone Laboratories, Inc., Logan, UT, USA), 100

IU/ml penicillin, 100 IU/ml streptomycin (North China

Pharmaceutical Group Corporation, Shijiazhuang, China) and 2 mM

L-glutamine in a humidified atmosphere of 5% CO2 at

37˚C. Cells were seeded onto surfaces of Zn-modified Ti disks in

the Zn-Ti-20, −40, −60 and −80 min groups as well as control disks

in 24-well plates at a seeding concentration of 2×104

cells/ml.

SEM observation of cell attachment

The morphology of attached cells was observed by SEM

(Hitachi S-520; Hitachi, Ltd.). Following culture for 48 h, the

Zn-modified and control Ti disks with attached cells were washed

with phosphate-buffered saline (PBS) and the cells were fixed

overnight in 2.5% glutaraldehyde. Following fixation, the samples

were sequentially dehydrated (10 min each) in increasing

concentrations of ethanol (20, 50, 70, 90 and 100%). Following

dehydration, they were immersed in isoamyl acetate (a critical

point drying fluid) for 1.5 min and finally sputter-coated with a

thin layer of gold/palladium for viewing by SEM.

Quantification of cell attachment and

proliferation

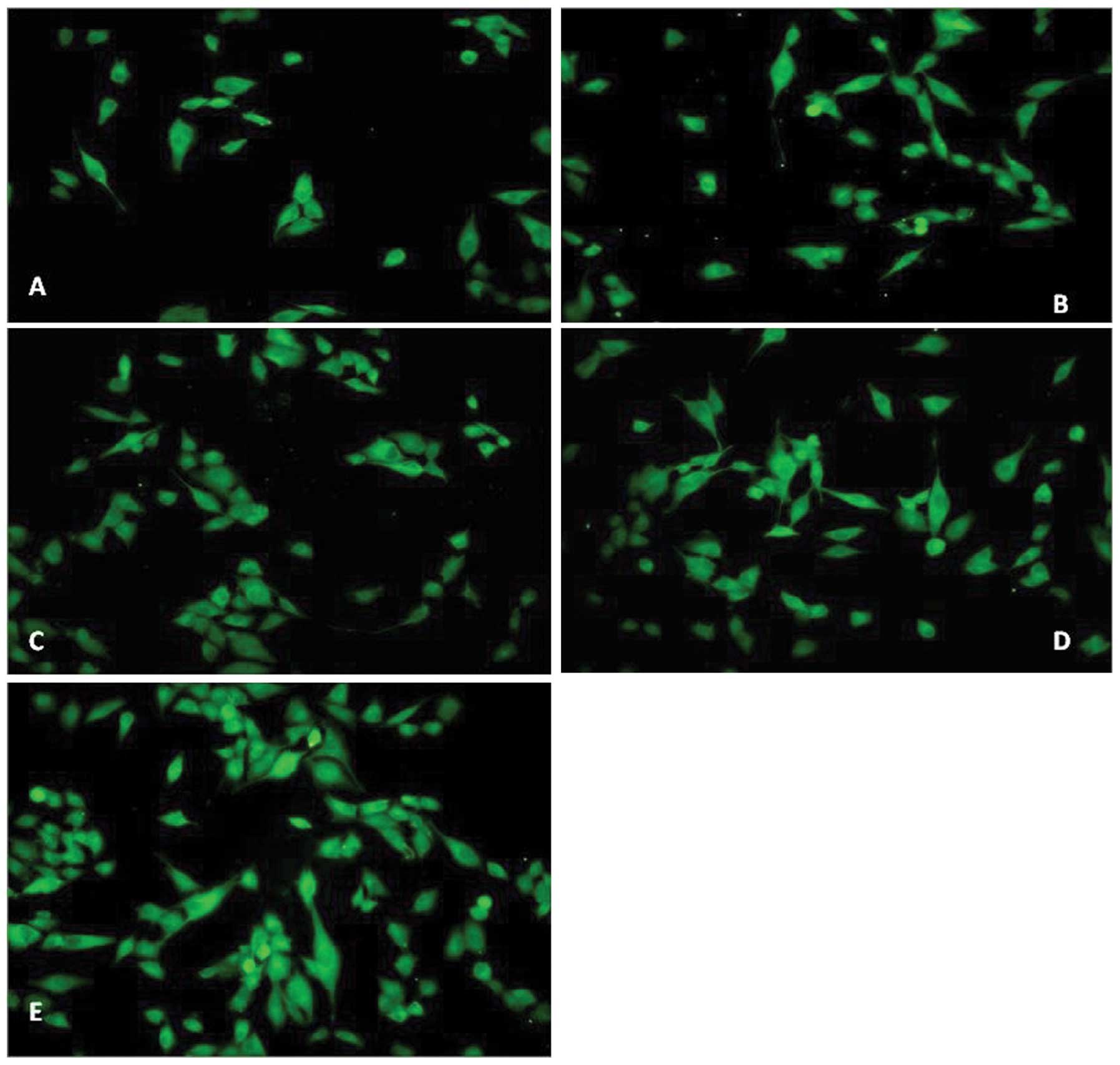

Cell attachment to the Zn-modified and control Ti

disks was quantified using acridine orange (AO) staining. Following

a specific incubation time (6, 24 or 48 h), samples were fixed in

95% ethanol and stained with 4×104 mg/ml AO for 1 min.

Following rinsing with PBS, the samples were examined under a

fluorescence microscope (FV1000; Olympus, Tokyo, Japan) and the

attached cells were counted in randomly selected 2 mm2

areas.

Flow cytometry for cell cycle

analysis

After 48 h, MG-63 cells were collected and prepared

for flow cytometry (FACSCalibur, Becton Dickinson Immunocytometry

Systems, San Jose, CA, USA). A total of 10,000 cells were counted

per sample and the fractions of cells in the G1, S and G2 phases of

the cell cycle were determined. This experiment was performed in

triplicate.

Statistical analysis

Data are expressed as the mean ± standard deviation.

Statistical analyses were performed using SPSS 12.0 software (SSPS,

Inc., Chicago, IL, USA). One-way analysis of variance was conducted

to assess differences among all quantitative indices. P<0.05 was

considered to indicate a statistically significant difference.

Results

Structure and chemical composition of

pure and Zn-modified Ti surfaces

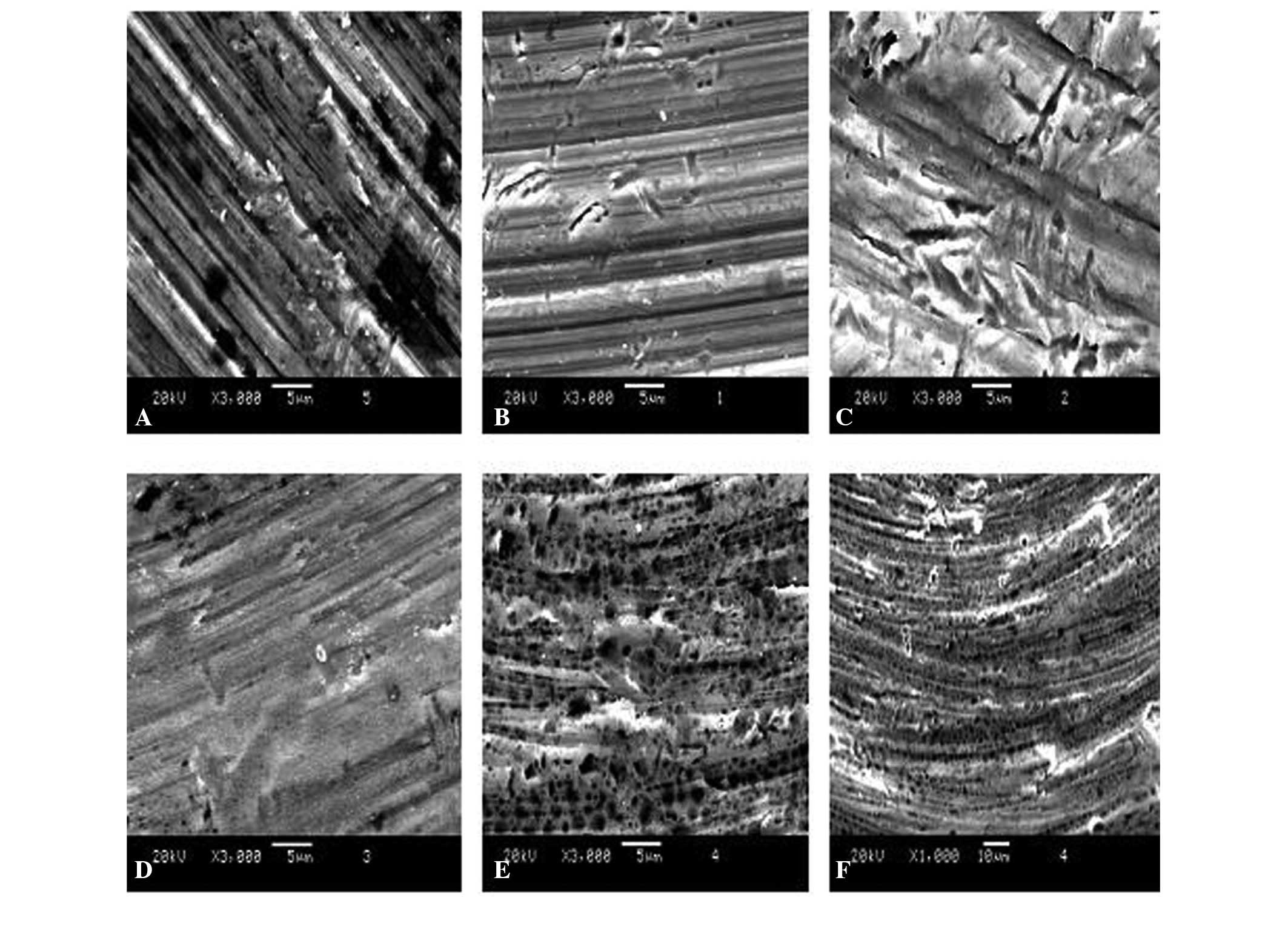

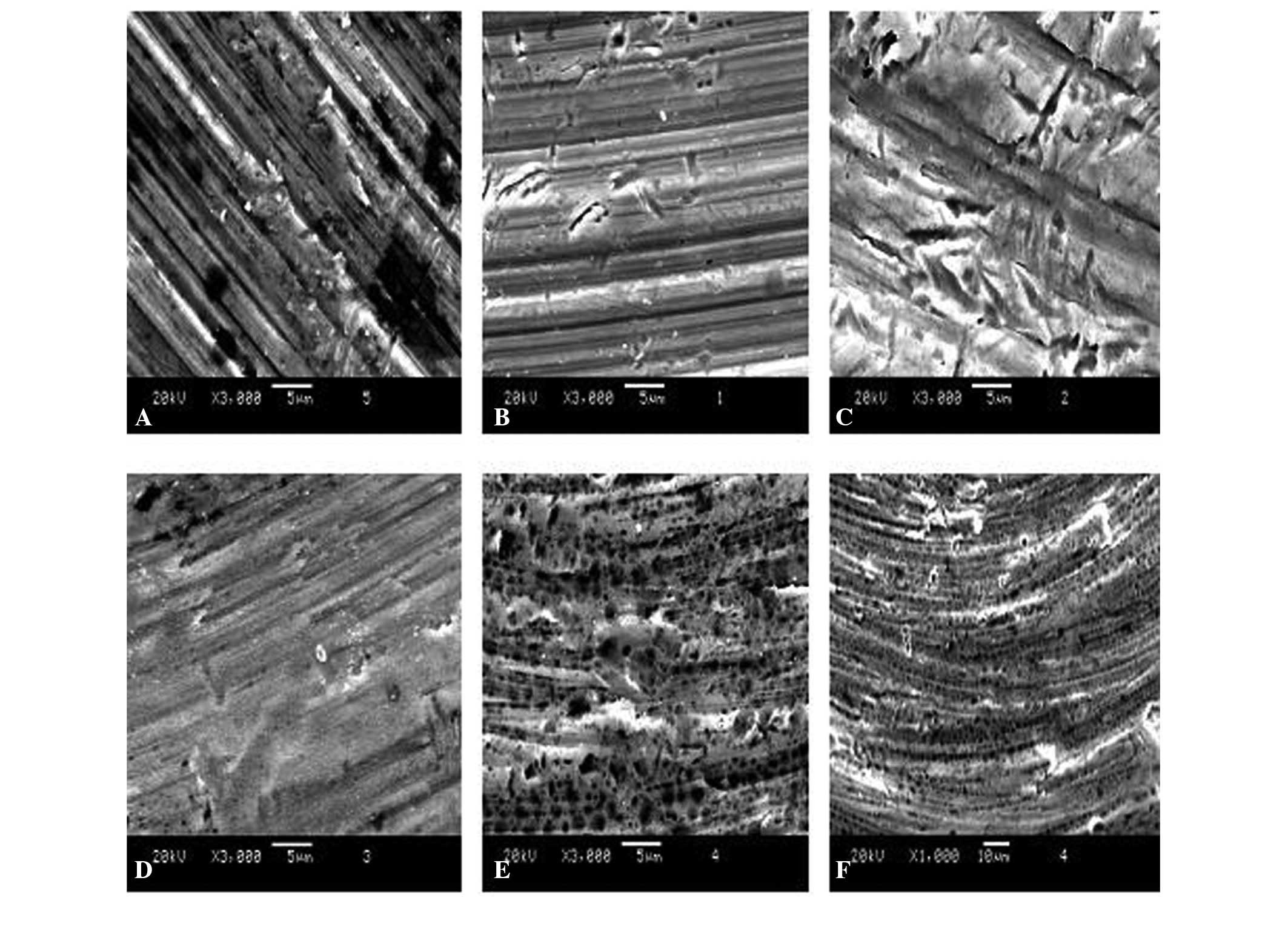

SEM images of the unmodified cp-Ti surfaces revealed

tiny fissures and fuzzy grain edges with smooth shapes (Fig. 1). By contrast, multiple

homogeneously and randomly distributed granular masses were

apparent on the Zn-PIIID-Ti surfaces with increasing Zn exposure

time. The Zn appeared to have penetrated into the base material and

deposited onto the surface. For longer implantation and deposition

times, the interstices among the distributed granular masses

increased. The size and shape of the masses were also increasingly

more homogeneous and the edges of the grains became much sharper,

but no significant differences were observed in the number of minor

fissures among the samples prepared with different exposure times

(P>0.05). SEM images revealed that the Ti surfaces exhibited a

rough ‘honeycomb’ structure in which the diameter was 60–100 nm

with PIIID processing. The ‘honeycomb’ structure deepened with

increasing processing time and surfaces in the Zn-Ti-80 min group

demonstrated a 200 nm deep structure with grade 9 smoothness and

0.4 μm roughness (Fig.

1F).

| Figure 1Scanning electron microscope images of

unmodified and Zn-modified Ti surfaces. (A) Commercially pure-Ti,

(B) Zn-Ti-20 min, (C) Zn-Ti-40 min, (D) Zn-Ti-60 min, (E) Zn-Ti-80

min and (F) Zn-Ti-80 min surfaces. (A-E) Magnification ×3,000,

scale bar=5 μm; (F) magnification ×1,000, scale bar=10

μm. TI, titanium; Zn, zinc. |

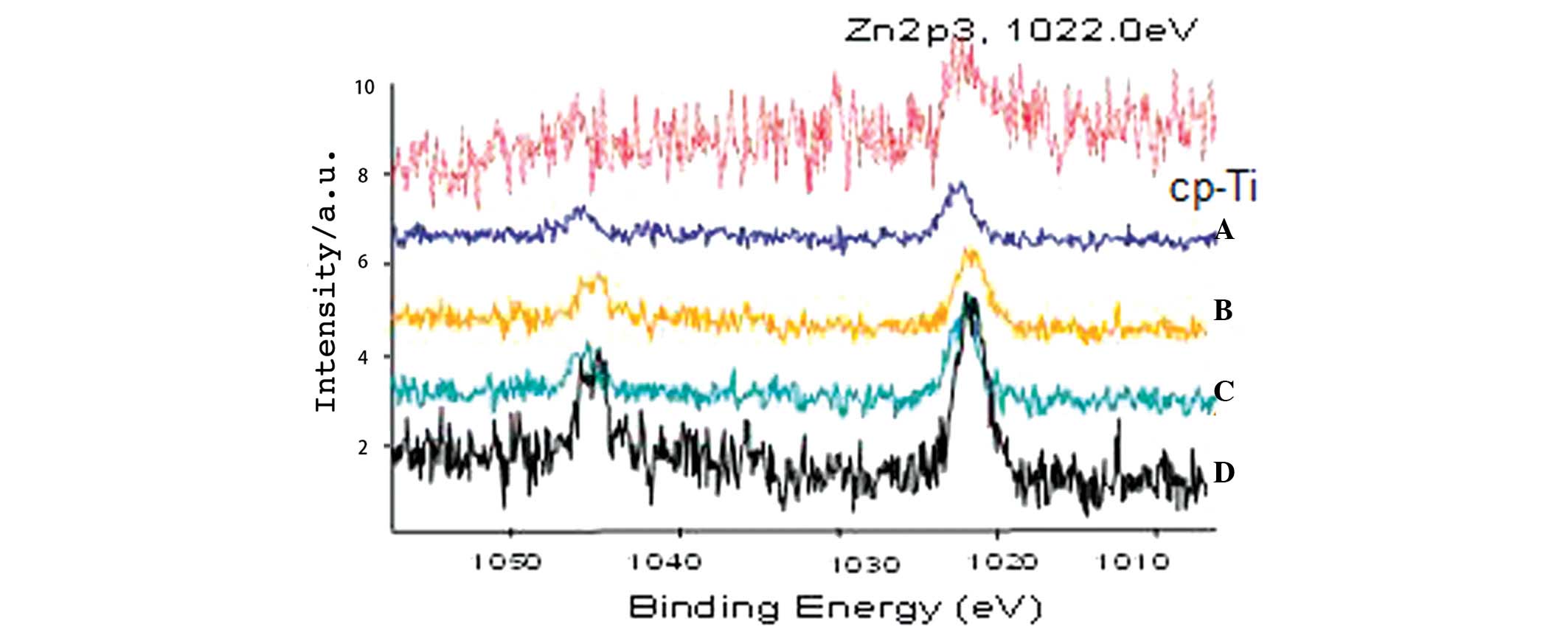

The XPS results revealed alterations in the surface

layer chemical composition upon Zn-PIIID (Fig. 2). The O1s peak relative intensity

significantly decreased following PIIID. An additional peak

corresponding to Zn-containing materials was also observed,

although its intensity was extremely weak. XPS analysis also was

used to obtain relative atomic concentrations of carbon, Ti and Zn

on the surface of each group (Table

I). In the Zn-Ti-20, −40, −60 and −80 min groups, the

percentages of Zn were 1.04±0.08, 1.32±0.06, 1.35±0.04 and

2.14±0.06, respectively.

| Table IX-ray photoelectron spectroscopy

elemental percentages for Zinc-plasma immersion ion implantation

and deposition on titanium surfaces. |

Table I

X-ray photoelectron spectroscopy

elemental percentages for Zinc-plasma immersion ion implantation

and deposition on titanium surfaces.

| Element | cp-Ti | Zn-Ti-20 min | Zn-Ti-40 min | Zn-Ti-60 min | Zn-Ti-80 min |

|---|

| Ti | 62.76±3.24 | 65.44±3.98 | 64.61±3.55 | 61.61±3.61 | 57.51±3.47 |

| O | 37.24±1.26 | 33.52±1.33 | 34.08±1.19 | 37.04±1.38 | 40.35±1.41 |

| Zn | 0.00 | 1.04±0.08a | 1.32±0.06a,b | 1.35±0.04a,b | 2.14±0.06a,b,c |

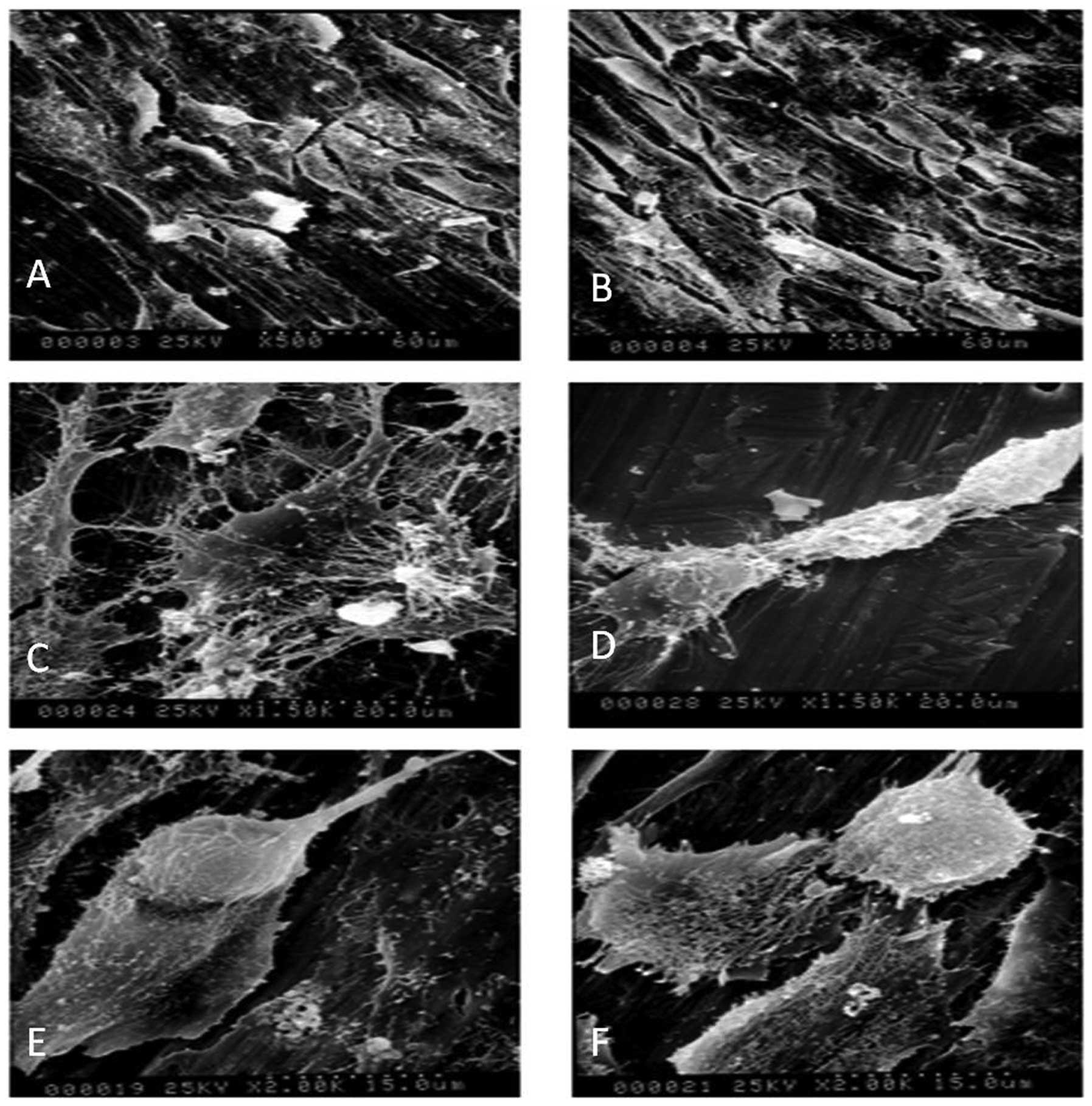

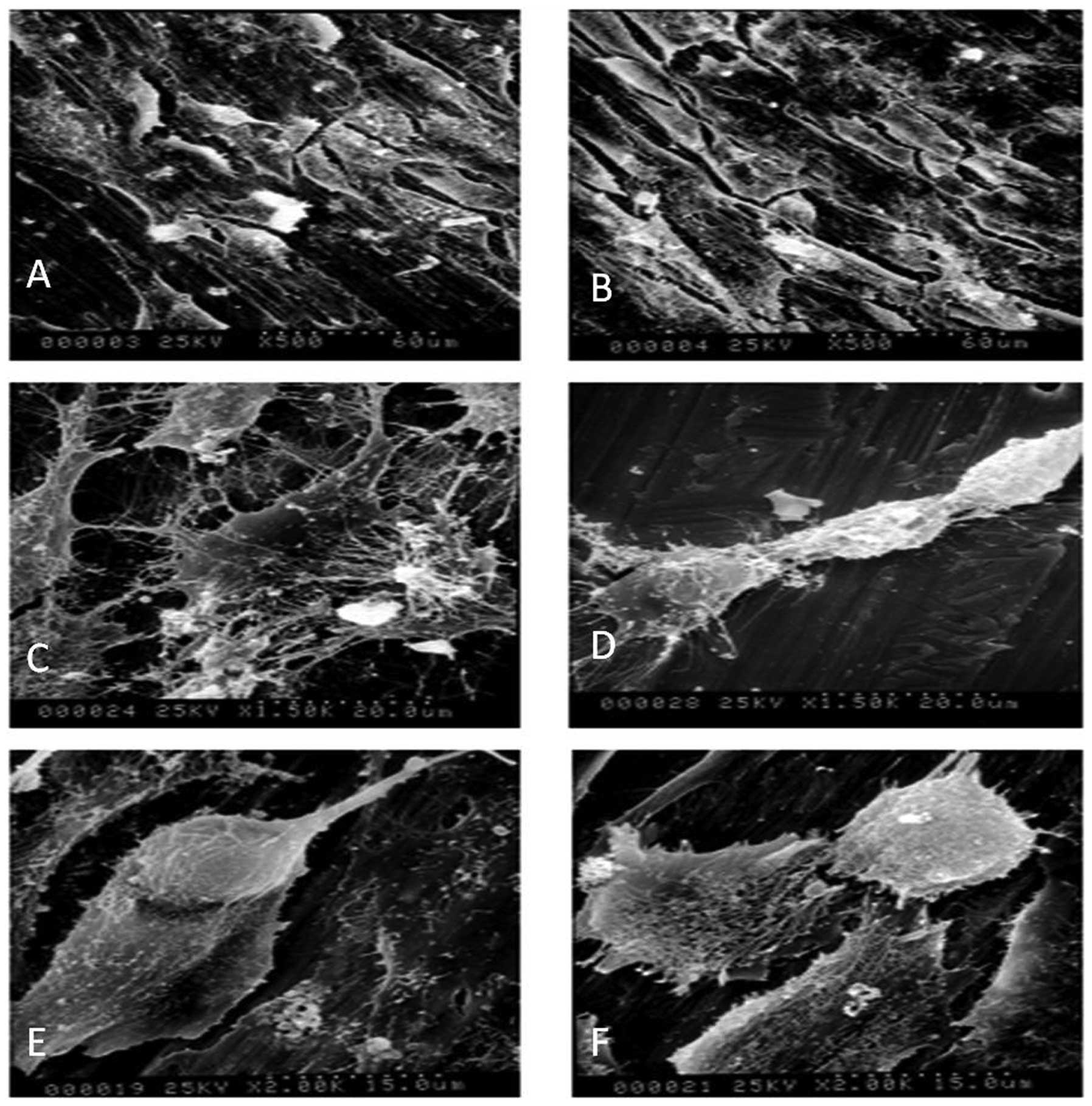

MG-63 morphological alterations on pure

and Zn-modified Ti surfaces

As shown in Fig.

3A, MG-63 cells typically have irregular polygon shapes, where

the ratio of the macro axis to the minor axis is usually greater

than those of other cells growing in the culture flask. SEM

analysis revealed that the in vitro morphology of MG-63

cells was altered on Zn-PIIID-Ti surfaces (Fig. 3B). Compared with the predominately

round cells observed on the cp-Ti disks (Fig. 3C), cells grown on the Zn-PIIID-Ti

disks exhibited a relatively improved spreading and fattening, with

an increased cell to substrate contact ratio (Fig. 3D). Increased Zn implantation

resulted in a greater density of attached cells. The cells secreted

considerable quantities of ECM protein that covered the granular

surface (Fig. 3E) and appeared to

be actively proliferating and differentiating (Fig. 3F). Cells on the Zn-PIIID-Ti

surfaces also had extensive networks of cytoplasmic processes that

extended to the underlying substrate and connected to neighboring

cells, whereas cells on the cp-Ti surfaces had far fewer and

shorter fibrillar extensions.

| Figure 3Scanning electron microscope images

demonstrating the morphology of MG-63 cells on unmodified and

Zn-modified Ti surfaces. (A and C) MG-63 cells on cp-Ti; (B and

D-F) MG-63 cells on Zn-Ti-20 min surfaces. (C) MG-63 cells were

primarily rounded on unmodified Ti surfaces, whereas on the (D)

Zn-modified Ti surfaces, cells assumed fusiform shapes with

well-spread pseudopodia and extensive networks of cytoplasmic

processes. (D) Secreted extracellular matrix was visible covering

the substrate granules and (E) cells undergoing division were

observed. (A and B) Magnification, ×500. (C and D) Magnification,

×1,500. (E and F) Magnification, ×2,000. Cp, commercially pure; TI,

titanium; Zn, zinc. |

Cell proliferation on pure and

Zn-modified Ti surfaces\

The initial attachment of cells is crucial to

subsequent cell spreading, proliferation and differentiation on

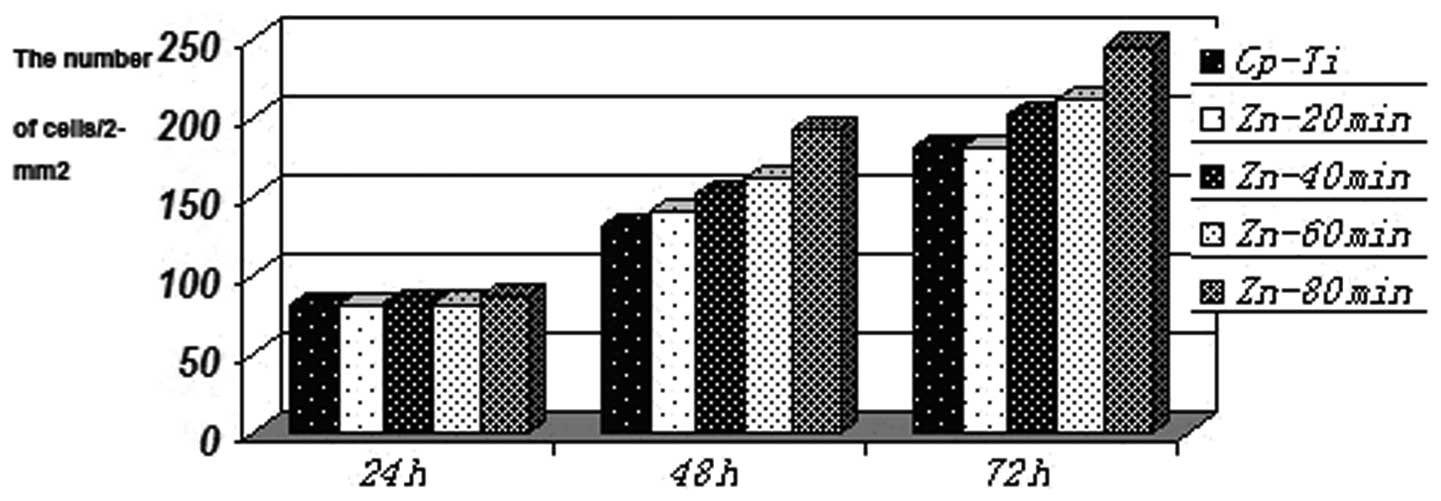

substrates. As shown in Fig. 4 by

fluorescence microscopy, the number of attached and proliferating

MG-63 cells increased with culture time for all samples. At 6 h

after cell seeding, there were no significant differences

identified in cell proliferation among the five samples

(P>0.05). However, after 24 h, a higher density of cells was

present on the Zn-PIIID-Ti surfaces compared with that on the cp-Ti

surface (P<0.05). This trend became more pronounced for higher

levels of Zn ion implantation and deposition, whereas no

significant difference in the quantified numbers of cells was noted

between the Zn-Ti-60 min and Zn-Ti-80 min groups (P>0.05;

Fig. 5).

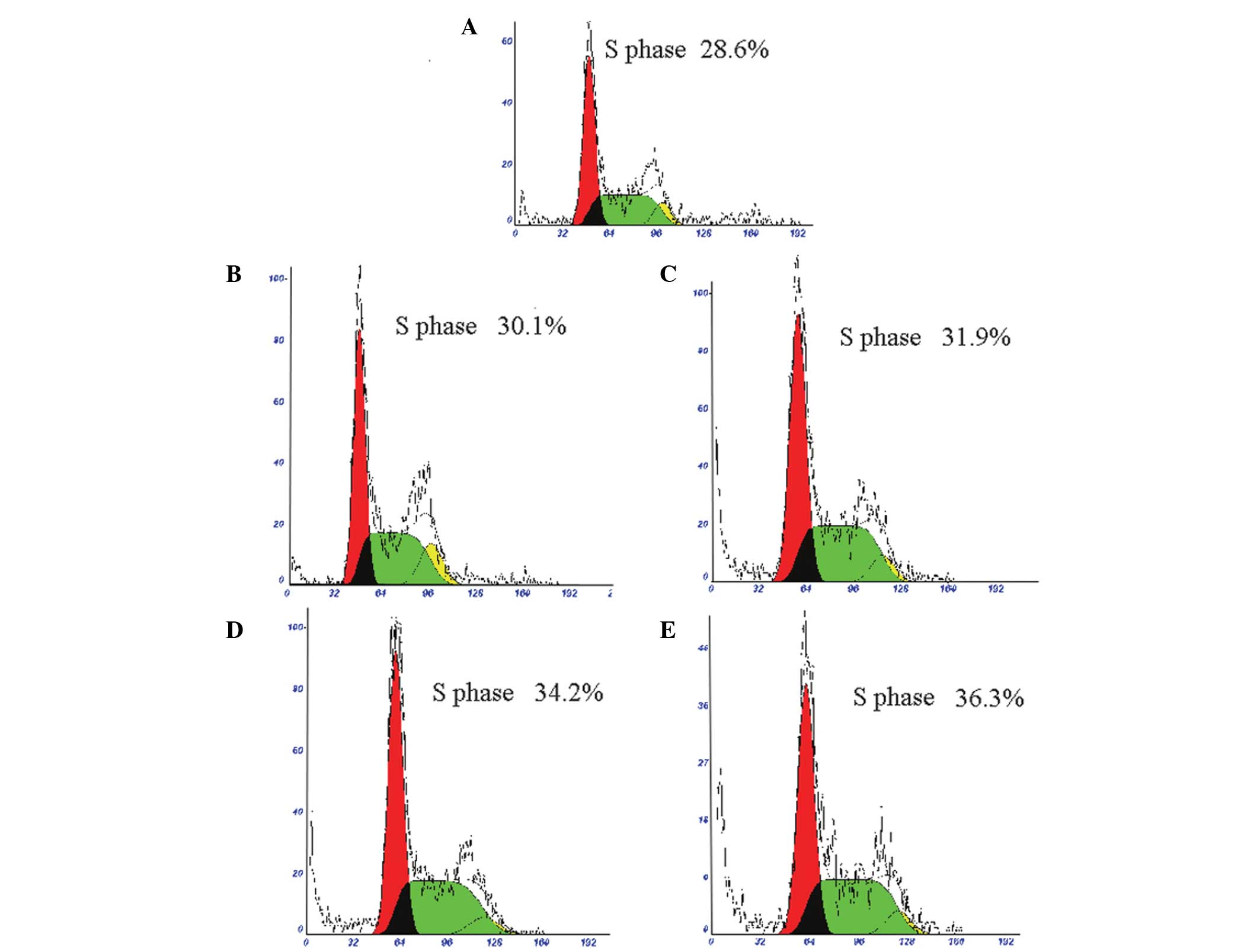

MG-63 cell cycle distribution on pure and

Zn-modified Ti surfaces

After 48 h in culture, flow cytometric analysis

revealed that the percentage of cells in S phase was 28.62% in the

cp-Ti group (Fig. 6A), 30.1% in

the Zn-Ti-20 min group (Fig. 6B),

31.9% in the Zn-Ti-40 min group (Fig.

6C), 34.2% in the Zn-Ti-60 min group (Fig. 6D) and 36.3% in the Zn-Ti-80 min

group (Fig. 6E). These percentages

for each of the five groups were significantly different from each

other (P<0.01) within this gradual increase in the S phase from

the Zn-Ti-20 min group to the Zn-Ti-80 min group. These results

demonstrated that the modified Zn-PIIID-Ti surfaces may inhibit

MG-63 cell apoptosis as well as promote proliferation.

Discussion

Previous studies have reported that increased

surface roughness of Ti implants improves t he rate of

osseointegration and biomechanical fixation (16–18).

Surface roughness in the nanometer range is important in the

absorption of proteins and adhesion of osteoblastic cells and thus

affects the rate of osseointegration (19). However, surface roughness at this

scale is difficult to achieve using chemical treatments. In

addition, the optimal surface nanotopography for selective

adsorption of proteins that enable adhesion of osteoblastic cells

and rapid bone apposition remains to be elucidated. Therefore,

other roughening methods with more predictable outcomes are

required.

PIIID overcomes the limitations of regular ion beam

implantation and is suitable for processing samples with complex

shapes (20). Following PIIID

processing, the anti-corrosion, anti-abrasion and anti-fatigue

properties of materials are significantly improved and therefore,

it has gained attention worldwide and is now used in several

biomedical applications (11–13).

In the present study, PIIID was used to implant and deposit Zn ions

within and onto the smooth surface of cp-Ti.

According to XPS analysis, with increasing Zn ion

implantation and deposition time, carbon, Ti and Zn signals

increased on the Zn-PIIID-Ti surfaces, whereas oxygen signals

decreased. The significant Zn content on the surface reached its

maximum with the 80 min deposition time. Following implantation and

deposition, the surfaces contained ZnO and TiO2. SEM

imaging revealed that following Zn-PIIID, dispersed lumps had

formed on the originally smooth Ti surface and this may explain why

certain Zn ions were implanted within the substrate matrix in the

form of interstitial atoms, while other Zn ions deposited directly

onto the Ti surface. Notably, the physical structure of the

Zn-Ti-80 min sample surface was the most homogeneous among assessed

surfaces, indicating that the size of granular masses became more

uniform with increasing PIIID processing time. SEM, in turn

revealed that Ti surfaces exhibited a rough ‘honeycomb’ structure

with a diameter range of 60–100 nm upon PIIID processing. The

‘honeycomb’ structure continually deepened with increasing PIIID

processing time and reached a depth of 200 nm with grade 9

smoothness and 0.4 μm roughness in the Zn-Ti-80 min group.

Thus, the present study demonstrated that the PIIID technique for

Ti surface modification offers an easy and effective way to

increase the roughness of the surfaces of Ti implants and the

degree of roughness achieved is more significant, with a deeper

nanostructure, than that generated using other methods (6,21,22).

MG-63 cells were seeded onto pure and Zn-modified Ti

surfaces in order to assess the effects of Zn implantation and

deposition on the biocompatibility of the Ti surfaces. SEM images

revealed pseudopodia extending from osteoblasts residing on the

Zn-modified Ti surfaces, indicating active cellular metabolism.

Cells extended multiple long and slender pseudopodia that inserted

between the granules of the Zn-modified Ti surfaces and formed

anchoring structures for strong adhesion. The present study also

revealed that the density of attached cells on the Zn-modified

surfaces was significantly greater than that observed on the

unmodified Ti surfaces and the secretion of ECM proteins followed

this trend as well, with ECM proteins covering the granules of

Zn-modified Ti surfaces. The current findings are in agreement with

the electron microscopy images presented in previous studies

(14,23,24)

of murine bone marrow cells grown on hydroxyapatite-coated cp-Ti

surfaces following 2 h incubation.

Based on the collective results of the present

study, it is concluded that Ti substrates modified using Zn PIIID

exhibit improved biocompatibility with the MG-63 cell line compared

with cp-Ti and thus may be applicable in a wide variety of dental

implants. Experiments to determine the in vivo performance

of these Zn-modified Ti substrates are underway. Based on the

present results demonstrating the biocompatibility of these

substrates as well as previous findings that Zn-modified Ti

surfaces discourage bacterial adhesion (14), it is expected that Zn-modification

of Ti may enhance the success rate of dental implants.

Acknowledgments

This study was supported by the Beijing Natural

Science Foundation (grant no. 7112124) and the Natural Science

Foundation of Hebei Province (grant no. H2013209040).

References

|

1

|

Rudy RJ, Levi PA, Bonacci FJ, Weisgold AS

and Engler-Hamm D: Intraosseous anchorage of dental prostheses: an

early 20th century contribution. Compend Contin Educ Dent.

29:220–222. 2008.PubMed/NCBI

|

|

2

|

Elias CN, Oshida Y, Lima JH and Muller CA:

Relationship between surface properties (roughness, wettability and

morphology) of titanium and dental implant removal torque. J Mech

Behav Biomed Mater. 1:234–242. 2008. View Article : Google Scholar

|

|

3

|

Condie R, Bose S and Bandyopadhyay A: Bone

cell-materials interaction on Si microchannels with bioinert

coatings. Acta Biomater. 3:523–530. 2007. View Article : Google Scholar : PubMed/NCBI

|

|

4

|

Hara T, Matsuoka K, Matsuzaka K, Yoshinari

M and Inoue T: Effect of surface roughness of titanium dental

implant placed under periosteum on gene expression of bone

morphogenic markers in rat. Bull Tokyo Dent Coll. 53:45–50. 2012.

View Article : Google Scholar : PubMed/NCBI

|

|

5

|

Oga M, Arizono T and Sugioka Y: Bacterial

adherence to bioinert and bioactive materials studied in vitro.

Acta Orthop Scand. 64:273–276. 1993. View Article : Google Scholar : PubMed/NCBI

|

|

6

|

Li F and Zhu L: Effect of

surfactant-induced cell surface modifications on electron transport

system and catechol 1,2-dioxygenase activities and phenanthrene

biodegradation by Citrobacter sp. SA01. Bioresour Technol.

123:42–48. 2012. View Article : Google Scholar : PubMed/NCBI

|

|

7

|

Nieciecka D, Nawara K, Kijewska K, et al:

Solid-core and hollow magnetic nanostructures: Synthesis, surface

modifications and biological applications. Bioelectrochemistry.

93:2–14. 2013. View Article : Google Scholar

|

|

8

|

Yamaguchi H, Ino S, Hamano N, Okada S and

Teranaka T: Examination of bond strength and mechanical properties

of Y-TZP zirconia ceramics with different surface modifications.

Dent Mater J. 31:472–480. 2012. View Article : Google Scholar : PubMed/NCBI

|

|

9

|

Iwai Y, Matsuda Y, Nakatsuka M, Mikami Y

and Kumabe S: A preliminary study of the dental implant therapy -

initial osteogenesis of human mesenchymal stem (HMS0014) cells on

titanium discs with different surface modifications. Okajimas Folia

Anat Jpn. 88:133–140. 2012. View Article : Google Scholar : PubMed/NCBI

|

|

10

|

Qin Z, Huang Y, Liao Q, Zhang Z and Zhang

Y: Effect of surface modifications on ZnO nanorod arrays electrode

for dye-sensitized solar cells. J Nanosci Nanotechnol. 12:463–468.

2012. View Article : Google Scholar : PubMed/NCBI

|

|

11

|

Wang L, Huang L, Xie Z, Wang X and Tang B:

Fourth-generation plasma immersion ion implantation and deposition

facility for hybrid surface modification layer fabrication. Rev Sci

Instrum. 79:0233062008. View Article : Google Scholar : PubMed/NCBI

|

|

12

|

Kwok SC, Yang P, Wang J, Liu X and Chu PK:

Hemocompatibility of nitrogen-doped, hydrogen-free diamond-like

carbon prepared by nitrogen plasma immersion ion

implantation-deposition. J Biomed Mater Res A. 70:107–114. 2004.

View Article : Google Scholar : PubMed/NCBI

|

|

13

|

Yang P, Huang N, Leng YX, et al:

Activation of platelets adhered on amorphous hydrogenated carbon

(a-C:H) films synthesized by plasma immersion ion

implantation-deposition (PIII-D). Biomaterials. 24:2821–2829. 2003.

View Article : Google Scholar : PubMed/NCBI

|

|

14

|

Xua JA, Ding G, Li JL, et al: Zinc-ion

implanted and deposited titanium surfaces reduce adhesion of

Streptococccus mutans. Appl Surf Sci. 256:7540–7544. 2010.

View Article : Google Scholar

|

|

15

|

Anna K, Nina P, Yuri K, et al: Coating

zinc oxide submicron crystals on poly(methyl methacrylate) chips

and spheres via ultrasound irradiation. Ultrason Sonochem.

15:839–845. 2008. View Article : Google Scholar : PubMed/NCBI

|

|

16

|

Le Guéhennec L, Soueidan A, Layrolle P and

Amouriq Y: Surface treatments of titanium dental implants for rapid

osseointegration. Dent Mater. 23:844–854. 2007. View Article : Google Scholar

|

|

17

|

Chung SH, Kim HK, Shon WJ and Park YS:

Peri-implant bone formations around (Ti,Zr)O(2)-coated zirconia

implants with different surface roughness. J Clin Peridontol.

40:404–411. 2013. View Article : Google Scholar

|

|

18

|

Sul YT: Electrochemical growth behavior,

surface properties, and enhanced in vivo bone response of

TiO2 nanotubes on microstructured surfaces of blasted,

screw-shaped titanium implants. Int J Nanomedicine. 5:87–100. 2010.

View Article : Google Scholar : PubMed/NCBI

|

|

19

|

Triplett RG, Frohberg U, Sykaras N and

Woody RD: Implant materials, design and surface topographies: their

influence on osseointegration of dental implants. J Long Term Eff

Med Implants. 13:485–501. 2003. View Article : Google Scholar

|

|

20

|

Sosa NE, Chen C, Liu J, et al: Nanoscale

structure, composition and charge transport analysis of transparent

conducting oxide nanowires written by focused ion beam

implantation. J Am Chem Soc. 132:7347–7354. 2010. View Article : Google Scholar : PubMed/NCBI

|

|

21

|

Minagar S, Berndt CC, Wang J, Ivanova E

and Wen C: A review of the application of anodization for the

fabrication of nanotubes on metal implant surfaces. Acta Biomater.

8:2875–2888. 2012. View Article : Google Scholar : PubMed/NCBI

|

|

22

|

Saksø M, Jakobsen SS, Saksø H, et al: Acid

etching and plasma sterilization fail to improve osseointegration

of grit blasted titanium implants. Open Orthop J. 6:376–382. 2012.

View Article : Google Scholar : PubMed/NCBI

|

|

23

|

Hempel U, Hefti T, Dieter P and Schlottig

F: Response of human bone marrow stromal cells, MG-63 and SaOS-2 to

titanium-based dental implant surfaces with different topography

and surface energy. Clin Oral Implants Res. 24:174–182. 2013.

View Article : Google Scholar

|

|

24

|

Cosar M, Ozer AF, Iplikcioglu AC, et al:

The results of beta-tricalcium phosphate coated hydroxyapatite

(beta‑TCP/HA) grafts for interbody fusion after anterior cervical

discectomy. J Spinal Disord Tech. 21:436–441. 2008. View Article : Google Scholar : PubMed/NCBI

|