Introduction

Numerous types of congenital heart defect and

peripheral vascular disease require repairing with vascular

conduits. Autologous vascular grafts often cannot be used for this

purpose due to limited sources, donor site morbidity or even damage

from a pre-existing disease (1).

However, synthetic materials, including expanded

polytetrafluoroethylene (ePTFE) and polyethylene terephthalate

fibre (Dacron) have been widely used in cases of large vessel

lesions (2). However, these

materials are usually non-degradable and lack the potential for

growth. Furthermore, these grafts often suffer from immunologic and

thrombotic complications, including rejection, stenosis,

thrombosis, calcium deposition and infection, as revealed by

long-term follow-up studies (3).

Tissue engineering, in which regenerating vascular

grafts are constructed using cells and degradable scaffolds, allows

for an alternative approach to resolve these problems (4). Promising results have been reported

using tissue-engineered blood vessels (TEBVs) (5), but the repairable vascular defects

are limited to small diameters (<6 mm) under low blood pressure

(6–8). In cases with larger vessels (>6 mm

in diameter), the biomechanical properties of these engineered

grafts cannot sufficiently withstand the powerful impact of blood

flow (9).

In addition, tissue engineering approaches are

limited by the availability of autologous cells. These cells have

often shown a limited replicative capacity, particularly when they

originated from older donors. Therefore, it is necessary to find an

autologous source of progenitor vascular cells with a high

proliferative capacity for the preparation of TEBVs. A possible

solution is the use of bone marrow-derived cells (BMCs), which have

demonstrated multiple cell differentiation abilities and a high

proliferation potential. In previous studies, BMCs have been found

to differentiate into smooth muscle (SM)-like cells or endothelial

cells in vitro (10–15).

Furthermore, when compared with embryonic stem cells, BMCs are not

confounded by ethical considerations and are readily available for

research. In addition, bone marrow aspiration is less invasive and

carries a reduced risk of morbidity at the donor site and may thus

be a promising alternative cell source for vascular tissue

engineering (16–18).

The aim of the present study was to engineer a large

vessel (6 mm in diameter) with canine BMCs and a polyglycolic acid

(PGA) scaffold in a pulsatile flow bioreactor for four weeks of

dynamic cultivation. PGA is a useful scaffold material, as its

rapid degradation prevents the accumulation of degraded fragments

in the body (4). The mechanical

properties of the vessel engineered in the present study were then

assessed in order to test the applicability of the developed method

to the engineering of various organ parts, including blood vessels

and large muscular tubular structures, such as the oesophagus,

intestine or ureter.

Materials and methods

Experimental animals

Twelve adult beagles (6 months old) were purchased

from Chenhang Experimental Animal Raising Farm (Shanghai, China).

The experimental protocol was approved by the Animal Care and

Experimental Committee of Shanghai Jiao Tong University School of

Medicine (Shanghai, China). All the protocols of animal handling

were approved by the Research Ethical Committee of the

hospital.

BMCs isolation and culture

Following sacrifice via intravenous administration

of 50 mg/kg 1% alpha-chloralose (LongDan Pharmaceutical and

Chemical Co., Shanghai, China), bone marrow (10 ml from each dog)

was aspirated from the humeri of the dogs and mixed with heparin

(100 unit heparin/ml bone marrow; Sigma-Aldrich, St. Louis, MO,

USA). Four healthy canine abdominal arteries were donated for use

in the study by the Cardiovascular Research Centre of the Shanghai

9th People's Hospital (Shanghai, China). The bone marrow and

heparin mixture was centrifuged on a Ficoll-Paque density gradient

(Amersham Bioscience, Arlington Heights, IL, USA) for 20 min at 352

× g. Bone marrow mononuclear cells (BMMNCs) were isolated from the

buffy coat layer between the Ficoll-Paque reagent and blood plasma

component and washed three times in phosphate-buffered saline (PBS;

Sigma-Aldrich) solution. The BMMNCs were cultured in low-glucose

Dulbecco's modified Eagle's medium (LG-DMEM; Gibco-BRL, Invitrogen

Life Technologies, Inc., Carlsbad, CA, USA) supplemented with 10%

fetal bovine serum (FBS; HyClone Laboratories, Logan, UT, USA), 100

U/ml penicillin (Sigma-Aldrich), and 100 mg/ml streptomycin

(Sigma-Aldrich) at 37°C with 95% humidity and 5% CO2.

The medium was replaced twice a week. The characterization of the

BMCs was determined by their CD marker profiles and their ability

to differentiate into osteogenic, adipogenic and chondrogenic

lineages as previously reported (data not shown) (19). BMCs at passage 2 were used for the

vessel construction. Prior to seeding, the identity of the BMCs was

confirmed by immunofluorescent staining with mouse monoclonal

anti-α-smooth muscle actin (α-SMA; cat. no. C6198; Sigma-Aldrich),

rabbit monoclonal anti-α-calponin (cat. no. ab46794; Abcam,

Cambridge, UK) and mouse monoclonal anti-smooth muscle myosin heavy

chain (SM-MHC; cat. no. M7786; Sigma-Aldrich), all at a dilution of

1:100.

Culture of BMC-PGA sheets in dishes

A total of 30 mg unwoven PGA fibres (Albany

International Research Company Inc., Albany, NY, USA) were

constructed into a 35×30×2 mm mesh. The scaffold was first soaked

in 75% ethanol (Sigma-Aldrich) for 2 h. Subsequently, it was washed

three times with PBS and incubated in DMEM for 10 min. The medium

was removed, and the scaffold was incubated at 37°C prior to being

used. The BMCs were collected and re-suspended in the culture

medium at a density of 6×107 cells/ml. Finally,

3×107 cells were evenly seeded onto the PGA mesh in

100-mm culture dishes (Falcon, Oxnard, CA, USA). To accomplish the

complete adhesion of the BMCs to the fibres, the cell scaffold

constructs were then incubated at 37°C with 95% humidity and 5%

CO2 for 4 h. Thereafter, sufficient DMEM with 10% FBS

was added to the dish to cover the construct. The cell-PGA sheet

was incubated for another five days prior to being placed into the

bioreactor.

Scanning electron microscopic (SEM)

observation

For the observation of the growth conditions of the

cells on the PGA, parts of the cell-PGA sheets were harvested for

an SEM examination after five days of culture. The samples were

first pre fixed with 2.5% glutaraldehyde (Sigma-Aldrich) for 2 h at

4°C and then washed three times with PBS. Thereafter, the samples

were post fixed with 1% osmic acid (Sigma-Aldrich) for 2 h at 4°C.

After washing with PBS three more times, the samples were

dehydrated through an ethanol gradient (Sigma-Aldrich), mounted,

sputter-coated with gold and then viewed under a scanning electron

microscope (Quanta 200; FEI, Hillsboro, OR, USA).

Vessel reactor preparation

The blood vessel reactor (Hongli, Shanghai, China)

was a closed-loop perfusion system that primarily consisted of a

culture chamber, silicone tubes, a media reservoir, a peristaltic

pump, a magnetic valve and a pressure meter. The culture chamber

including the four culture dishes was composed of transparent

polycarbonate with four lids for gas exchange (Fig. 1). The 6-mm outer diameter

medical-grade silicone tube was threaded through the side arms of

the chamber and secured. Sterile PBS was pumped from the media

reservoir through the silicone tubes and back into the reservoir.

The circulation was managed by a peristaltic pump and a magnetic

valve. The former provided continuous fluid flow at a rate of

0.01–1,000 ml/min. The latter was periodically closed under the

control of a custom-made computer. The periodic closing of the

valve produced a pulsed flow in the bioreactor that attempted to

mimic the circulation system in vivo (blood vessel

bioreactor: Designed and manufactured by Professor Hong Li;

Department of Life Information and Instrument Engineering, Hangzhou

Electronic Science and Technology University, Hangzhou, Zhejiang,

China). Therefore, it was possible to adjust the corresponding

radial distension rate of the silicone tube by modifying the flow

rate. The pressure meter showed the changes in the media pressure,

which was necessary for the modification of the circulation system.

Prior to use, the culture chamber was sterilised with ethylene

oxide.

Dynamic culture in the vessel

reactor

After being cultured in dishes for five days, the

cell PGA sheets were wrapped around the silicone tubes and further

fixed by biodegradable sutures (Ethicon, Inc., Somerville, NJ, USA;

Fig. 2B) in the culture chamber of

the vessel reactor. The sheets were covered with DMEM containing

10% FBS in the chamber. Thereafter, the culture chamber was

connected to the entire vessel reactor. Sterile PBS flowed through

the silicone tubes in a pulsatile manner at a frequency of 75

beats/min. The flow rate was gradually increased and adjusted

(70–80 ml/min) to reach a radial distension of ~5% of the original

diameter of the constructs. The culture chamber was placed in the

incubator at 37°C for four weeks, and the culture media was changed

twice a week. Cell-PGA constructs cultured under static conditions

without pulsatile radial stress were used as controls.

Histological analyses

After four weeks of culture, the engineered vessel

walls were harvested, fixed in 10% formalin (Sigma-Aldrich) and

embedded in paraffin (Sigma-Aldrich). The vessels were then

sequentially cut into 4-µm sections. The sections were then

subjected to haematoxylin and eosin (HE) or Masson's trichrome and

Gomori staining (all stains were from Sigma-Aldrich).

Biomechanical testing and hydroxyproline

assay

A tensile tester (4456; Instron, Norwood, MA, USA)

was used in the biomechanical tests. As previously reported

(20), the engineered vessel wall

was placed between the jaws of the tester with a constant

elongation (3 mm/min) applied along the longitudinal axis until

rupture occurred to determine the maximum tensile force. To

determine the suture-holding strength, 5–0 polypropylene sutures

(Ethicon, Inc.) were placed in four quadrants of the vessel wall at

a location of 1 mm from the vessel edge, followed by constant

elongation (3 mm/min) along the longitudinal axis of the vessel in

the same tester until the sutures pulled through the edge of the

vessel (21). For the

hydroxyproline assay, the vessel wall was dried and weighed. The

total hydroxyproline content of each vessel was determined by a

colorimetric assay, as described by Reddy and Ewemeka (22). In the current study, a

Sigma-MAK008, Hydroxyproline Assay Kit (Sigma-Aldrich) and Genesys

20 Spectrophotometer (Z376027; Sigma-Aldrich) were used. Native

canine abdominal arteries (6 mm in diameter) served as the normal

controls in all of the above tests.

Statistical analysis

Each experiment was repeated at least three times.

As the original data were normally distributed, the results were

expressed as the mean ± standard deviation. Significant differences

between values were determined using Student's t-test. A

P-value less than 0.05 was considered to indicate a statistically

significant difference. All of the statistical analyses were

performed using SPSS version 16 (SPSS, Inc., Chicago, IL, USA).

Results

Culture of BMCs

After 4–5 days of culture in the plates, the BMCs

were elongated and showed a spindle-like shape. Within another 2 3

days, the cells reached confluency and were subsequently passaged

onto a fresh plate. Immunofluorescent staining of the cells at

passage 2 showed that nearly half of the cells were positive for

anti-alpha-SMA, calponin and SM-MHC staining (Fig. 2).

Culture of BMC-PGA constructs in

dishes

Passage-2 BMCs were seeded onto the PGA mesh. After

24 h of culture, the cells began to spread and extended along the

length of the fibres. After another five days of culture in the

dishes, a cell-PGA sheet was formed (Fig. 3A). Micrographs showed that the

abundant BMCs had adhered to the PGA fibres, with secreted

extracellular matrix (ECM) filling the space between the fibres

(Fig. 3B), which was further

confirmed by SEM observation (Fig.

3C).

Dynamic culture in the vessel

reactor

After being placed into the bioreactor, the BMC-PGA

constructs were incubated for four weeks (Fig. 3D). In the dynamic group, the

constructs demonstrated a glossy and tubular structure with a round

lumen of 6 mm in diameter (Fig.

4A). The engineered vessel in the dynamic group already

exhibited excellent elasticity after four weeks of culture. The

vessel wall had the capacity to repeatedly rebound to its original

shape after deformation to a flat shape with tweezers. By contrast,

the vessel walls in the static culture group showed a collapsed

lumen and rough surface (Fig. 4B).

In addition, the control vessels grown for 4 weeks in static

culture failed to show any elasticity and easily collapsed upon the

application of pressure.

Histological observation

After four weeks of culture in the bioreactor,

several layers of smooth muscle-like cells and a few collagenous

fibres were revealed by histological examination (Fig. 5A and B). The PGA fibres did not

degrade completely, and a few elastic fibres were observed at this

time-point (Fig. 5C). By contrast,

disorganised and randomly distributed cells, randomly organized

collagenous fibres and small elastic fibres were observed in the

static group (Fig. 5D–F). The

above results were further confirmed by immunohistochemical

staining for α-SMA and calponin (data not shown), using a canine

abdominal artery as a positive control (Fig. 5G–I).

Biomechanical testing and hydroxyproline

assay

There were significant differences in the

biomechanical properties between the dynamic and static groups.

After being cultured for four weeks, the tensile strength (Fig. 6) and the suture-holding retention

strength (Fig. 7) of the dynamic

group were much higher (P<0.05) than those in the static group.

In addition, the biomechanical properties of the dynamic group

attained nearly 40% of those of the native canine abdominal

arteries.

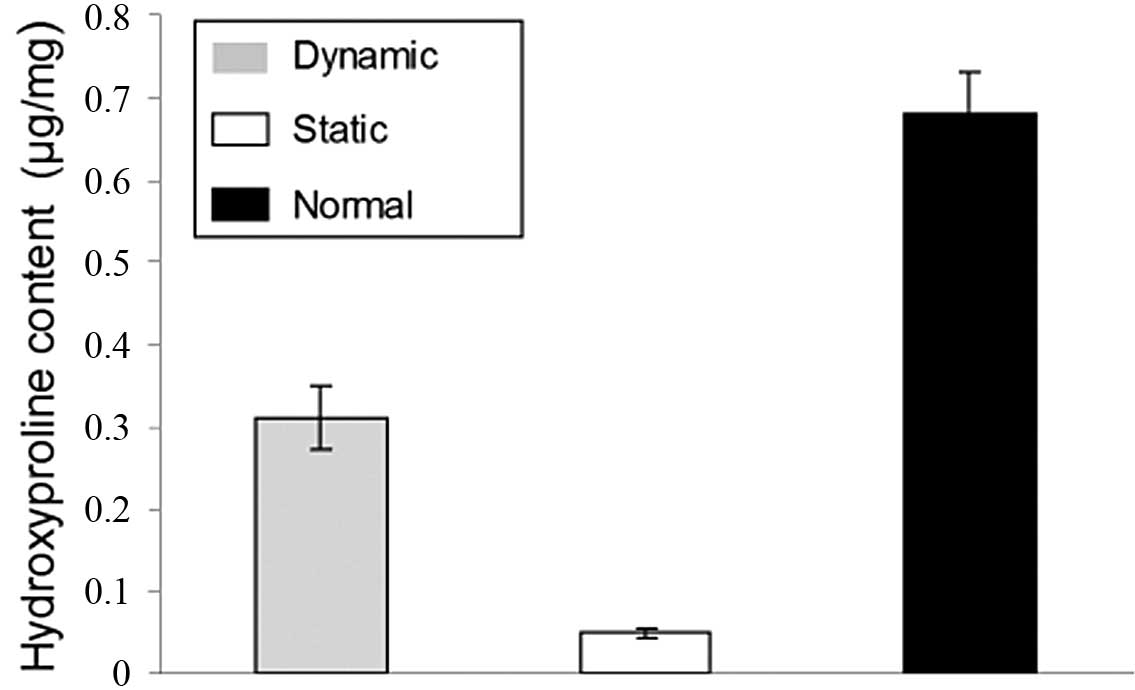

The hydroxyproline content of the dynamic group was

significant higher (P<0.05) than that in the static group at the

same time-points (Fig. 8). The

hydroxyproline concentration in the dynamic group reached ~40% of

that in the native canine abdominal arteries.

Discussion

Numerous studies have demonstrated the potential

ability of BMCs to differentiate into vascular cell types and serve

as 'seed cells' in vitro (14,23–28).

In such applications, BMCs may require an extended period during

which they are seeded and cultured in vitro prior to being

implanted in vivo. In the present study, the cultured BMCs,

without any requirement for additional cytokines or transgenic

technology, were used to construct an elastic large muscular vessel

wall under pulsatile stimulation in a bioreactor. After culture,

the newly formed tissues showed SM cell-like characteristics,

including morphological indicators, the expression of SM cell

specific cytoskeletal markers (α SMA and calponin) and fine

biomechanical properties. These results demonstrated that BMCs are

able to differentiate into SM or SM-like cells in vitro and

may be utilised as a potential cell source for the tissue

engineering of SMs, particularly that of large-diameter aortas.

The ideal vascular substitute should be

non-thrombogenic and resistant to infections as well as possess

good biocompatibility, biological characteristics, sufficient

mechanical properties and compliance that match those of the native

vessels, as well as be able to respond to physiological stimuli

with vasomotion and remodelling (29). As to the repair of large vessels

under high blood pressure, strong mechanical and haemodynamic

properties are of great importance for the success of the

substitute, which has been shown in the successful application of

synthetic materials, including Dacron and ePTFE, even in the

absence of endothelial cell sheeting (30,31).

Previous studies have indicated that good mechanical properties are

most important in the engineering of large blood vessels (1,4,29).

To create novel and functional TEBVs in

vitro, cells were seeded onto biodegradable polymer scaffolds

in the present study. An optimal polymer scaffold supports

biological tissue growth by providing the proper surface for cell

attachment, proliferation, differentiation and the secretion of

extracellular ECM proteins, as well as by directing new tissue

formation. PGA is one of the most widely used polymer scaffold

materials in the engineering of numerous types of tissue, including

blood vessels, as it undergoes rapid degradation to soluble, safe

by-products through the chemical hydrolysis of the chain ester

linkages and supports cellular adhesion and collagenous matrix

deposition (32,33). However, rapidly degrading PGA may

substantially damage the tissue mechanics. This effect was apparent

in the control group of the present study.

To overcome this limitation, several vessel

bioreactors have been developed and utilised for vascular tissue

engineering with the aim of mimicking a suitable physiological

environment for the arterial vessel wall (6,34–37).

The blood's mechanical force is an important physiological

component of the environment experienced by cells: It promotes the

circumferential orientation of the cells as well as the deposition

of the extracellular matrix and likely contributes to the survival

of the implanted substitute. Several studies reported on the

effects of the cyclic strain observed in smooth muscle cells, whose

responses demonstrated an increased production of growth factors,

enhanced synthesis or proliferation of the matrix and an increased

content of contractile protein (38–40).

Kim and Mooney found more elastin and contractile SMCs in the

constructs cultured under a cyclic strain than in the controls (no

strain) (41). Stegemann et

al (42) showed that four days

of exposure to periodic mechanical strain increased aortic SMC

proliferation in rats. Hamilton et al (43) demonstrated that cyclic strain can

be used to stimulate the expression of SMC specific genes in

primary BMCs. Similarly, the results of the present study

demonstrated that the engineered vessel walls exhibited improved

biomechanical properties following pulsatile stimulation with

cyclic mechanical training in the bioreactor compared with those of

vessels cultured under static conditions. Furthermore, the present

study confirmed that vessels grown in dynamic culture exhibited

good orientation of smooth muscle layers and even organization of

the collagenous fibres according to histological observation.

In elastic and muscular arteries, elastin is a

critical structural and regulatory matrix protein that has an

important and dominant role in conferring elasticity to the vessel

wall (44). Elastin also regulates

vascular smooth muscle cell activity and phenotype (40,45).

Several scaffolds have been studied to promote elastin

biosynthesis. Long and Tranquillo (46) demonstrated that more elastin was

secreted by SMCs on fibrin gels than on collagen gels. According to

a study by Ramamurthi and Vesely (47), a scaffold composed of hyaluron gels

cross-linked with divinyl sulfone had the ability to increase the

amount of elastin secreted by the SMCs. Thomas and Nair (48) showed promising results according to

which the SMCs exhibited increased elastin production on a

co-polymer of natural biodegradable gelatin with vinyl acetate

(GeVAc) after mechanical stimulation. These studies indicated that

a scaffold can have a significant impact on the synthesis of

elastin. Therefore, further studies focusing on modifying PGA

fibres with fibrin or cross-linking it with other promising

materials may be beneficial for engineering improved vessel walls

with a higher elastin content.

In the present study, Masson staining of artery

sections for the identification of SMCs revealed red staining of

native arteries, while the staining was faint in the construct

cells, indicating that the nutrient supply in the engineered vessel

was poor. As the vessel grew while being wrapped around a silicone

tube, the nutrients in the culture media are required to pass

through the thick vessel wall to reach the inner part. This implies

that the thickness of the engineered vessel wall was limited in the

culture system of the present study. Further improvements in the

culture system are required in future studies.

Several previous studies have demonstrated that the

mechanical stimulation of cells has significant effects on the cell

phenotype, ECM deposition and mechanical properties of the graft

(48–52). An optimal culture strategy should

facilitate the efficient regeneration of vascular tissue. The

stimulation of BMCs with a 10% strain for 7 days was reported to

obviously upregulate the expression of α-SMA and h1-calponin

(48). In addition, Oluwole et

al (53) demonstrated that the

cyclic deformation of a 350- and 2,500-µ strain applied at 1

Hz to 10-day-old bone marrow cultures resulted in elevated levels

of alkaline phosphatase and prostacyclins. In the present study, a

5% radial distension of the vessels was achieved using a rate of 75

beats/min, which is similar to the circulation conditions in native

adult vessels in vivo. The mechanical properties of the

vessel walls engineered under the dynamic culture were

significantly higher than those cultured under the static

conditions but did not attain the same parameters as the native

arteries. Therefore, it is necessary to plan an advanced control

strategy and optimise the regeneration process of the vascular

tissue inside the vessel bioreactor. Specifically, future studies

should address the pulse rate, deformation rate, pulsatile pressure

and culture duration.

In conclusion, an elastic large vessel wall (6 mm in

diameter) was constructed in the present study using a PGA seeded

with BMCs under pulsatile flow conditions in a vessel bioreactor.

The dynamically cultured constructs exhibited a superior tissue

constitution according to histological examination, as well as

enhanced mechanical properties compared with the constructs that

were grown in stationary culture. Further studies will focus on

seeding endothelial cells on the surface of the lumen to engineer

composite vascular conduits and to repair canine aortic

defects.

Acknowledgments

The present study was supported by the National

Natural Science Foundation of China (grant no. 81000842). The

authors would like to thank Professor Hong Li (Department of Life

Information and Instrument Engineering, Hangzhou Electronic Science

and Technology University, Hangzhou, China), and Demin Ying, Lijuan

Zong and Bing Zhong (laboratory technicians of the Department of

Plastic and Reconstructive Surgery, Shanghai 9th People's Hospital,

School of Medicine, Shanghai Jiaotong University, Shanghai, China)

for their technical support.

References

|

1

|

Naito Y, Shinoka T, Duncan D, Hibino N,

Solomon D, Cleary M, Rathore A, Fein C, Church S and Breuer C:

Vascular tissue engineering: Towards the next generation vascular

grafts. Adv Drug Deliv Rev. 63:312–323. 2011. View Article : Google Scholar : PubMed/NCBI

|

|

2

|

Khait L and Birla RK: Bypassing the

patient: Comparison of biocompatible models for the future of

vascular tissue engineering. Cell Transplant. 21:269–283. 2012.

View Article : Google Scholar

|

|

3

|

Wang F, Mohammed A, Li C, Ge P, Wang L and

King MW: Degradable/non-degradable polymer composites for in-situ

tissue engineering small diameter vascular prosthesis application.

Biomed Mater Eng. 24:2127–2133. 2014.PubMed/NCBI

|

|

4

|

Woods I and Flanagan TC: Electrospinning

of biomimetic scaffolds for tissue-engineered vascular grafts:

Threading the path. Expert Rev Cardiovasc Ther. 12:815–832. 2014.

View Article : Google Scholar : PubMed/NCBI

|

|

5

|

Weinberg CB and Bell E: A blood vessel

model constructed from collagen and cultured vascular cells.

Science. 231:397–400. 1986. View Article : Google Scholar : PubMed/NCBI

|

|

6

|

Wang Y, Hu J, Jiao J, Liu Z, Zhou Z, Zhao

C, Chang LJ, Chen YE, Ma PX and Yang B: Engineering vascular tissue

with functional smooth muscle cells derived from human iPS cells

and nanofibrous scaffolds. Biomaterials. 35:8960–8969. 2014.

View Article : Google Scholar : PubMed/NCBI

|

|

7

|

Niklason LE, Gao J, Abbott WM, Hirschi KK,

Houser S, Marini R and Langer R: Functional arteries grown in

vitro. Science. 284:489–493. 1999. View Article : Google Scholar : PubMed/NCBI

|

|

8

|

Watanabe M, Shin'oka T, Tohyama S, Hibino

N, Konuma T, Matsumura G, Kosaka Y, Ishida T, Imai Y, Yamakawa M,

et al: Tissue-engineered vascular autograft: Inferior vena cava

replacement in a dog model. Tissue Eng. 7:429–439. 2001. View Article : Google Scholar : PubMed/NCBI

|

|

9

|

Nerem RM and Seliktar D: Vascular tissue

engineering. Ann Rev Biomed Eng. 3:225–243. 2001. View Article : Google Scholar

|

|

10

|

Galmiche MC, Koteliansky VE, Brière J,

Hervé P and Charbord P: Stromal cells from human long-term marrow

cultures are mesenchymal cells that differentiate following a

vascular smooth muscle differentiation pathway. Blood. 82:66–76.

1993.PubMed/NCBI

|

|

11

|

Kashiwakura Y, Katoh Y, Tamayose K,

Konishi H, Takaya N, Yuhara S, Yamada M, Sugimoto K and Daida H:

Isolation of bone marrow stromal cell-derived smooth muscle cells

by a human SM22alpha promoter: In vitro differentiation of putative

smooth muscle progenitor cells of bone marrow. Circulation.

107:2078–2081. 2003. View Article : Google Scholar : PubMed/NCBI

|

|

12

|

Shimizu K, Sugiyama S, Aikawa M, Fukumoto

Y, Rabkin E, Libby P and Mitchell RN: Host bone-marrow cells are a

source of donor intimal smooth-muscle-like cells in murine aortic

transplant arteriopathy. Nat Med. 7:738–741. 2001. View Article : Google Scholar : PubMed/NCBI

|

|

13

|

Gong Z, Calkins G, Cheng EC, Krause D and

Niklason LE: Influence of culture medium on smooth muscle cell

differentiation from human bone marrow derived mesenchymal stem

cells. Tissue Eng Part A. 15:319–330. 2009. View Article : Google Scholar : PubMed/NCBI

|

|

14

|

Wang N, Ren GD, Zhou Z, Xu Y, Qin T, Yu RF

and Zhang TC: Cooperation of myocardin and smad2 in inducing

differentiation of mesenchymal stem cells into smooth muscle cells.

IUBMB Life. 64:331–339. 2012. View

Article : Google Scholar : PubMed/NCBI

|

|

15

|

Kusuma S, Facklam A and Gerecht S:

Characterizing human pluripotent stem cell-derived vascular cells

for tissue engineering applications. Stem Cells Dev. 24:451–458.

2015. View Article : Google Scholar

|

|

16

|

Prockop DJ: Marrow stromal cells as stem

cells for nonhematopoietic tissues. Science. 276:71–74. 1997.

View Article : Google Scholar : PubMed/NCBI

|

|

17

|

Pittenger MF, Mackay AM, Beck SC, Jaiswal

RK, Douglas R, Mosca JD, Moorman MA, Simonetti DW, Craig S and

Marshak DR: Multilineage potential of adult human mesenchymal stem

cells. Science. 284:143–147. 1999. View Article : Google Scholar : PubMed/NCBI

|

|

18

|

Krause DS, Theise ND, Collector MI,

Henegariu O, Hwang S, Gardner R, Neutzel S and Sharkis SJ:

Multi-organ, multi-lineage engraftment by a single bone

marrow-derived stem cell. Cell. 105:369–377. 2001. View Article : Google Scholar : PubMed/NCBI

|

|

19

|

Colter DC, Sekiya I and Prockop DJ:

Identification of a subpopulation of rapidly self-renewing and

multipotential adult stem cells in colonies of human marrow stromal

cells. Proc Natl Acad Sci USA. 98:7841–7845. 2001. View Article : Google Scholar : PubMed/NCBI

|

|

20

|

Fujiwara H, Oda K, Saiki Y, Sakamoto N,

Ohashi T, Sato M, Tabata Y and Tabayashi K: The wrapping method

using biodegradable felt strips has a preventive effect on the

thinning of the aortic wall: Experimental study in the canine

aorta. J Vasc Surg. 43:349–356. 2006. View Article : Google Scholar : PubMed/NCBI

|

|

21

|

Schaner PJ, Martin ND, Tulenko TN, Shapiro

IM, Tarola NA, Leichter RF, Carabasi RA and Dimuzio PJ:

Decellularized vein as a potential scaffold for vascular tissue

engineering. J Vasc Surg. 40:146–153. 2004. View Article : Google Scholar : PubMed/NCBI

|

|

22

|

Reddy GK and Ewemeka CS: A simplified

method for the analysis of hydroxyproline in biological tissues.

Clin Biochem. 29:225–229. 1996. View Article : Google Scholar : PubMed/NCBI

|

|

23

|

Cho SW, Kim IK, Lim SH, Kim DI, Kang SW,

Kim SH, Kim YH, Lee EY, Choi CY and Kim BS: Smooth muscle-like

tissues engineered with bone marrow stromal cells. Biomaterials.

25:2979–2986. 2004. View Article : Google Scholar : PubMed/NCBI

|

|

24

|

Gong Z and Niklason LE: Small-diameter

human vessel wall engineered from bone marrow-derived mesenchymal

stem cells (hMSCs). FASEB J. 22:1635–1648. 2008. View Article : Google Scholar : PubMed/NCBI

|

|

25

|

Zhang G, Drinnan CT, Geuss LR and Suggs

LJ: Vascular differentiation of bone marrow stem cells is directed

by a tunable three-dimensional matrix. Acta Biomater. 6:3395–3403.

2010. View Article : Google Scholar : PubMed/NCBI

|

|

26

|

Sekiguchi H, Ii M, Jujo K, Yokoyama A,

Hagiwara N and Asahara T: Improved culture-based isolation of

differentiating endothelial progenitor cells from mouse bone marrow

mononuclear cells. PloS One. 6:e286392011. View Article : Google Scholar

|

|

27

|

van den Akker NM, Kolk FF, Jeukens F,

Verbruggen S, Gagliardi M, Dullens S, Heschel I, Post MJ, Molin DG

and Waltenberger J: Vascular potency of Sus scrofa bone

marrow-derived mesenchymal stem cells: A progenitor source of

medial but not endothelial cells. Tissue Eng Part A. 18:828–839.

2012. View Article : Google Scholar

|

|

28

|

Roh JD, Brennan MP, Lopez-Soler RI, Fong

PM, Goyal A, Dardik A and Breuer CK: Construction of an autologous

tissue-engineered venous conduit from bone marrow-derived vascular

cells: Optimization of cell harvest and seeding techniques. J

Pediatr Surg. 42:198–202. 2007. View Article : Google Scholar : PubMed/NCBI

|

|

29

|

Xu H, Su J, Sun J and Ren T: Preparation

and characterization of new nano-composite scaffolds loaded with

vascular stents. Int J Mol Sci. 13:3366–3381. 2012. View Article : Google Scholar : PubMed/NCBI

|

|

30

|

Friedman SG, Lazzaro RS, Spier LN, Moccio

C and Tortolani AJ: A prospective randomized comparison of Dacron

and polytetrafluoroethylene aortic bifurcation grafts. Surgery.

117:7–10. 1995. View Article : Google Scholar : PubMed/NCBI

|

|

31

|

Peck M, Gebhart D, Dusserre N, McAllister

TN and L'Heureux N: The evolution of vascular tissue engineering

and current state of the art. Cells Tissues Organs. 195:144–158.

2012. View Article : Google Scholar :

|

|

32

|

Pankajakshan D and Agrawal DK: Scaffolds

in tissue engineering of blood vessels. Can J Physiol Pharmacol.

88:855–873. 2010. View

Article : Google Scholar : PubMed/NCBI

|

|

33

|

Gui L, Zhao L, Spencer RW, Burghouwt A,

Taylor MS, Shalaby SW and Niklason LE: Development of novel

biodegradable polymer scaffolds for vascular tissue engineering.

Tissue Eng Part A. 17:1191–1200. 2011. View Article : Google Scholar :

|

|

34

|

Engbers-Buijtenhuijs P, Buttafoco L, Poot

AA, Dijkstra PJ, de Vos RA, Sterk LM, Geelkerken RH, Vermes I and

Feijen J: Biological characterization of vascular grafts cultured

in a bioreactor. Biomaterials. 27:2390–2397. 2006. View Article : Google Scholar

|

|

35

|

Arrigoni C, Chittò A, Mantero S and

Remuzzi A: Rotating versus perfusion bioreactor for the culture of

engineered vascular constructs based on hyaluronic acid. Biotechnol

Bioeng. 100:988–997. 2008. View Article : Google Scholar : PubMed/NCBI

|

|

36

|

Song Y, Wennink JW, Kamphuis MM, Sterk LM,

Vermes I, Poot AA, Feijen J and Grijpma DW: Dynamic culturing of

smooth muscle cells in tubular poly (trimethylene carbonate)

scaffolds for vascular tissue engineering. Tissue Eng Part A.

17:381–387. 2011. View Article : Google Scholar

|

|

37

|

Couet F and Mantovani D: A new bioreactor

adapts to materials state and builds a growth model for vascular

tissue engineering. Artif Organs. 36:438–445. 2012. View Article : Google Scholar

|

|

38

|

Seliktar D, Nerem RM and Galis ZS: The

role of matrix metalloproteinase-2 in the remodeling of cell-seeded

vascular constructs subjected to cyclic strain. Ann Biomed Eng.

29:923–934. 2001. View Article : Google Scholar

|

|

39

|

Stegemann JP and Nerem RM: Phenotype

modulation in vascular tissue engineering using biochemical and

mechanical stimulation. Ann Biomed Eng. 31:391–402. 2003.

View Article : Google Scholar : PubMed/NCBI

|

|

40

|

Nikolovski J, Kim BS and Mooney DJ: Cyclic

strain inhibits switching of smooth muscle cells to an

osteoblast-like phenotype. FASEB J. 17:455–457. 2003.PubMed/NCBI

|

|

41

|

Kim BS and Mooney DJ: Scaffolds for

engineering smooth muscle under cyclic mechanical strain

conditions. J Biomech Eng. 122:210–215. 2000. View Article : Google Scholar : PubMed/NCBI

|

|

42

|

Stegemann JP, Hong H and Nerem RM:

Mechanical, biochemical and extracellular matrix effects on

vascular smooth muscle cell phenotype. J Appl Physiol (1985).

98:2321–2327. 2005. View Article : Google Scholar

|

|

43

|

Hamilton DW, Maul TM and Vorp DA:

Characterization of the response of bone marrow-derived progenitor

cells to cyclic strain: Implications for vascular

tissue-engineering applications. Tissue Eng. 10:361–369. 2004.

View Article : Google Scholar : PubMed/NCBI

|

|

44

|

Patel A, Fine B, Sandig M and Mequanint K:

Elastin biosynthesis: The missing link in tissue-engineered blood

vessels. Cardiovasc Res. 71:40–49. 2006. View Article : Google Scholar : PubMed/NCBI

|

|

45

|

Opitz F, Schenke-Layland K, Cohnert TU,

Starcher B, Halbhuber KJ, Martin DP and Stock UA: Tissue

engineering of aortic tissue: Dire consequence of suboptimal

elastic fiber synthesis in vivo. Cardiovasc Res. 63:719–730. 2004.

View Article : Google Scholar : PubMed/NCBI

|

|

46

|

Long JL and Tranquillo RT: Elastic fiber

production in cardiovascular tissue-equivalents. Matrix Biol.

22:339–350. 2003. View Article : Google Scholar : PubMed/NCBI

|

|

47

|

Ramamurthi A and Vesely I: Evaluation of

the matrix-synthesis potential of crosslinked hyaluronan gels for

tissue engineering of aortic heart valves. Biomaterials.

26:999–1010. 2005. View Article : Google Scholar

|

|

48

|

Thomas LV and Nair PD: The effect of

pulsatile loading and scaffold structure for the generation of a

medial equivalent tissue engineered vascular graft. Biores Open

Access. 2:227–239. 2013. View Article : Google Scholar : PubMed/NCBI

|

|

49

|

Kanda K, Matsuda T and Oka T: Mechanical

stress induced cellular orientation and phenotypic modulation of

3-D cultured smooth muscle cells. ASAIO J. 39:M686–M690. 1993.

View Article : Google Scholar : PubMed/NCBI

|

|

50

|

Chiquet M, Matthisson M, Koch M,

Tannheimer M and Chiquet-Ehrismann R: Regulation of extracellular

matrix synthesis by mechanical stress. Biochem Cell Biol.

74:737–744. 1996. View Article : Google Scholar : PubMed/NCBI

|

|

51

|

Kim BS and Mooney DJ: Scaffols for

engineering smooth muscle under cyclic mechanical strain

conditions. J Biomech Eng. 122:210–215. 2000. View Article : Google Scholar : PubMed/NCBI

|

|

52

|

Shi ZD and Tarbell JM: Fluid flow

mechanotransduction in vascular smooth muscle cells and

fibroblasts. Ann Biomed Eng. 39:1608–1619. 2011. View Article : Google Scholar : PubMed/NCBI

|

|

53

|

Oluwole BO, Du W, Mills I and Sumpio BE:

Gene regulation by mechanical forces. Endothelium. 5:85–93. 1997.

View Article : Google Scholar : PubMed/NCBI

|