Introduction

The treatment of bone defects arising from traumatic

events, congenital abnormalities and infection involves

autografting and allografting of bone tissues (1,2), or

replacement surgery (3–5). The satisfactory clinical outcomes of

autografting and allografting (6)

are tempered, however, by problems of insufficient supply,

significant morbidity and risk of disease transmission, promoting

the development of alternative technologies, such as bone tissue

engineering (7,8). The primary purpose of bone tissue

engineering is to generate synthetic bone grafting substitutes

through the combination of scaffolding material, viable cells and

growth factors. In particular, biocompatible scaffolds are

garnering increased attention due to their provision not only of

structural support for cells, but also of an environment promoting

cell adhesion, differentiation and proliferation (9,10).

Chitosan (CS) is a newly developed biomedical

material with biocompatibility, low toxicity and biodegradability

(11,12), and its polysaccharide side chains

contain numerous amino and hydroxyl groups that serve as convenient

links for surface modifications. In addition, hydroxyapatite (HA),

a common biomaterial with chemical components similar to bone

mineral, has been widely used in orthopedics to facilitate bone

ingrowth and osseointegration (13,14).

The recent appreciation that the requirements of bone tissue

engineering scaffolds cannot be fulfilled by any single material,

has given rise to the concept of composite bone scaffolds. In this

context, CS/HA composites generated by wet chemical methods, such

as sol-gel, co-precipitation, in situ compositing and

electrochemical deposition (15–17),

have been shown to accelerate osseointegration (18).

Since cell differentiation and proliferation can

only occur following adhesion of cells to a biocompatible surface

(19), facilitation of this

process by improving cell-scaffold interactions is a desirable

property of a bone scaffold (20,21).

To this end, cell-scaffold adhesion has been shown to be promoted

by modification of the scaffold using small signaling molecules,

such as arginine-glycine-aspartic (RGD) or cell growth factors

(22), although another study

suggested that RGD peptide may actually inhibit bone formation

(23). The present study

investigated the material-cell interaction characteristics and

osseointegrative properties of an RGD-modified CS/HA (RGD-CS/HA)

composite scaffold to evaluate its potential application in bone

tissue engineering.

Materials and methods

Isolation and cultivation of bone marrow

stromal cells (BMSCs)

The present study was approved by the ethics

committee of The First Hospital of Harbin City (Harbin, China).

Fisher rats (n=100; weight range, 100–150 g) were provided by

Centre of Experimental Animal of Harbin Medical University (Harbin,

China). The animals were maintained in standard lab conditions at

25±2°C in a 12 h light/dark cycle. The animals were provided with

food and water ad libitum. Care of the rats was in

compliance with the 'Guide for the Care and Use of Laboratory

Animals' published by the National Institute of Health (24). BMSCs were isolated from rat femurs

according to the method reported by Tamada and Ikada (25), and cultivated in the control media

consisting of complete Dulbecco's modified Eagle's medium (DMEM,

Gibco-BRL, Carlsbad, CA, USA) supplemented with 10% fetal bovine

serum (FBS, Gibco-BRL) and 1% penicillin/streptomycin antibiotics

(Mediatech, Inc., Mooresville, NC, USA) in a 5% CO2

atmosphere at 37°C. The culture medium was replaced every 2–3 days

and cells were passaged at 90% confluence.

Preparation of the RGD-CS/HA

scaffold

The CS/HA composite was prepared by in situ

compositing combined with lyophilization. Briefly, 1.25 g

Ca(NO3)2•4H2O and 0.43 g

KH2PO4 were added to 100 ml acetic acid, and

the solution was stirred until fully dissolved. Then, 5.0 g CS

(Haihui Bioengineering Co., Ltd., Qingdao, China) was added to the

solution, and the mixture was stirred for 4 h at room temperature

to obtain a homogeneous 5 wt% CS solution. Subsequently, the CS

solution was cast onto the internal surface of a custom-made mold,

and the mold was soaked in 5 wt% NaOH to form a CS/HA hydrogel. The

hydrogel was washed with deionized water until the pH value of the

water was ~7, then air-dried in an oven at 60°C until a diameter of

10 mm was reached. The semi-dried CS/HA composite was lyophilized,

and cut into CS/HA disks with a diameter of 10 mm and a height of

1.5 mm. The CS/HA disks were sterilized in an autoclave at 120°C

for 30 min.

The RGD-CS/HA scaffold was prepared by physical

adsorption of the RGD peptide onto the CS/HA disks. Briefly, the

sterilized CS/HA samples were immersed in RGD solution (100 mg/l

C12H22N6O6;

Sigma-Aldrich, St. Louis, MO, USA) at 37°C for 24 h. The RGD-CS/HA

scaffold was obtained after washing in phosphate-buffered saline

(PBS) three times to remove free reagents, followed by air drying.

Spatial distribution of the RGD peptide on the CS/HA samples was

determined by labeling the RGD solution with fluorescein

isothiocyanate (FITC) followed by visualization using a Nikon E800

fluorescence microscope (Nikon Instruments Inc., Melville, NY,

USA).

RGD-CS/HA scaffold-BMSC interactions

Cell adhesion rate

A total of six RGD-CS/HA scaffolds were placed into

the well of a 24-well culture plate. In total, 1×104

cells diluted into 2 ml of control media supplemented with

10−9 mol/l Na-β-glycerophosphate (Trust and

Pharmaceutical Co., Ltd., Shanghai, China) and 10−8

mol/l dexamethasone were then added to each well. The scaffold-cell

construct was maintained in cell culture for 4 h at 37°C in a 5%

CO2 atmosphere, after which the RGD-CS/HA scaffolds were

washed three times with PBS to remove unattached cells. Adherent

cells were removed from the RGD-CS/HA scaffolds using trypsin-EDTA,

and counted using a Cell Counting kit-8 (Dojindo Molecular

Technologies, Inc., Rockville, MA, USA). The absorbance values were

measured at 450 nm using a Multiskan Mk3 (Thermo Fisher Scientific,

Waltham, MA, USA) for the initial cell solution (Ai) and

the unattached cell solution (Afree), and the cell

adhesion rate was estimated using the following equation: Cell

adhesion rate=(1-Afree/Ai) × 100. The average

cell adhesion rate of the six RGD-CS/HA scaffolds was

calculated.

Cell viability

BMSC viability on the RGD-CS/HA scaffold was

evaluated after 3 days of culture in DMEM supplemented with 10% FBS

using the Live/Dead Viability kit for mammalian cells (Life

Technologies, Saint Aubin, France). In this assay, calcein-AM

penetrates into the cytosol of viable cells and stains the cells

green, while ethidium homodimer-1 stains dead cell nuclei red.

Following 30 min of incubation at room temperature and rinsing with

PBS, BMSCs were observed using a FluoVie FV300 confocal laser

microscope (Olympus, Tokyo, Japan) and a Nikon E800 fluorescence

microscope.

Cell morphology

BMSC morphology on the RGD-CS/HA scaffold was

evaluated after 4, 24 and 48 h of culture in DMEM supplemented with

10% FBS. The RGD-CS/HA scaffolds were rinsed thoroughly with PBS to

remove the unattached cells, and then fixed using a 2.5%

glutaraldehyde solution (Sigma-Aldrich). Fixed cells were

dehydrated progressively in a graded ethanol series, after which

RGD-CS/HA scaffolds were sputter-coated with a gold-palladium layer

and examined using a scanning electron microscope (SEM, S-3400 N;

Hitachi, Toyko, Japan).

Alkaline phosphatase (ALP)

activity

Following 14 days of culture under osteogenic

conditions (DMEM supplemented with 10% FBS, 50 µg/ml vitamin

C(Trust and Pharmaceutical Co., Ltd.,), 10−9 mol/l

Na-β-glycerophosphate and 10−8 mol/l dexamethasone; Hao

Yuan Biological Pharmaceutical Co., Ltd., Shanghai, China), the

RGD-CS/HA scaffold was transferred to a 1.5-ml centrifuge tube. The

cell membrane was ruptured by ultrasonic cleaning to release the

proteins and DNA into the supernatant. Supernatant ALP activity was

measured using a rat alkaline phosphatase ELISA kit (R&D

Systems, Minneapolis, MN, USA) according to the manufacturer's

instructions. DNA was quantified using a PicoGreen kit (Genmed

Scientifics Inc., Wilmington, DE, USA) following standard protocol.

The absorbance was read at an excitation/emission of 480–530 nm on

a microplate reader. Three measurements were taken and the results

are reported as the mean ± standard deviation.

In vivo heterotopic ossification

The biocompatibility of the RGD-CS/HA scaffold was

evaluated through in vivo heterotopic ossification. Male

Fisher rats (n=60) were randomly divided into two groups. Following

anesthesia with 10% chloral hydrate (Trust and Pharmaceutical Co.,

Ltd.), a 2-cm incision was made in the back, and the subcutaneous

tissue and fascia were separated. Subsequently, RGD-CS/HA

(RGD-CS/HA group), or CS/HA (CS/HA control group) scaffolds were

implanted. The incision was then sutured using Yiqiao absorbable

sutures (Johnson & Johnson, New Brunswick, NJ, USA) and the rat

was injected with gentamicin (5 mg/kg; Shanxi Kang Pharmaceutical

Co., Ltd., Lihua Yuan, China). After implantation for 1 day, 1

week, 2 weeks, 4 weeks or 6 weeks, respectively (six rats at each

time point), scaffolds were collected and examined by X-ray

radiography (YSX0101; Yueshen Medical Equipment Co., Ltd.,

Guangzhou, China). The radiographs were imported using Image Pro

Plus software (Media Cybernetics, Inc., Rockville, MD, USA), and

the optical density value was calculated. Scaffolds were then fixed

using a 10% glutaraldehyde solution, decalcified, stained with

hematoxylin and eosin (H&E), mounted in resin and sectioned

into 5-µm samples prior to examination using an optical

microscope (S8; Olympus Corporation, Toyko, Japan).

In vivo bone defect repair

The osseointegrative properties of the RGD-CS/HA

scaffold were investigated using an in vivo bone defect

repair experiment. Briefly, 36 female New Zealand rabbits (weight

range, 2.0–2.5 kg) provided by the Centre of Experimental Animal of

Harbin Medical University were randomly divided into three groups.

Rabbits were intravenously anesthetized with 2% pentobarbital

(Wegene Co., Ltd., Shanghai, China), after which a 3-cm incision

was made in the radius of the front leg. After separation of

subcutaneous tissue and muscle, a bone defect with a length of 1.5

cm was established, with the osteotomy line ~3 cm away from the

distal end of the radius. For the RGD-CS/HA group, the RGD-CS/HA

scaffold was implanted into the bone defect area, and for the CS/HA

group, the CS/HA scaffold was used. The incision was then washed

with gentamicin and sutured. For the control group, no scaffold was

implanted and the incision was sutured directly. The rabbits were

injected with 10 mg/kg penicillin (Shanxi Kang Pharmaceutical Co.,

Ltd.) for 3 days, then examined by X-ray radiography after

implantation for 2, 4 and 8 weeks (four rabbits at each time

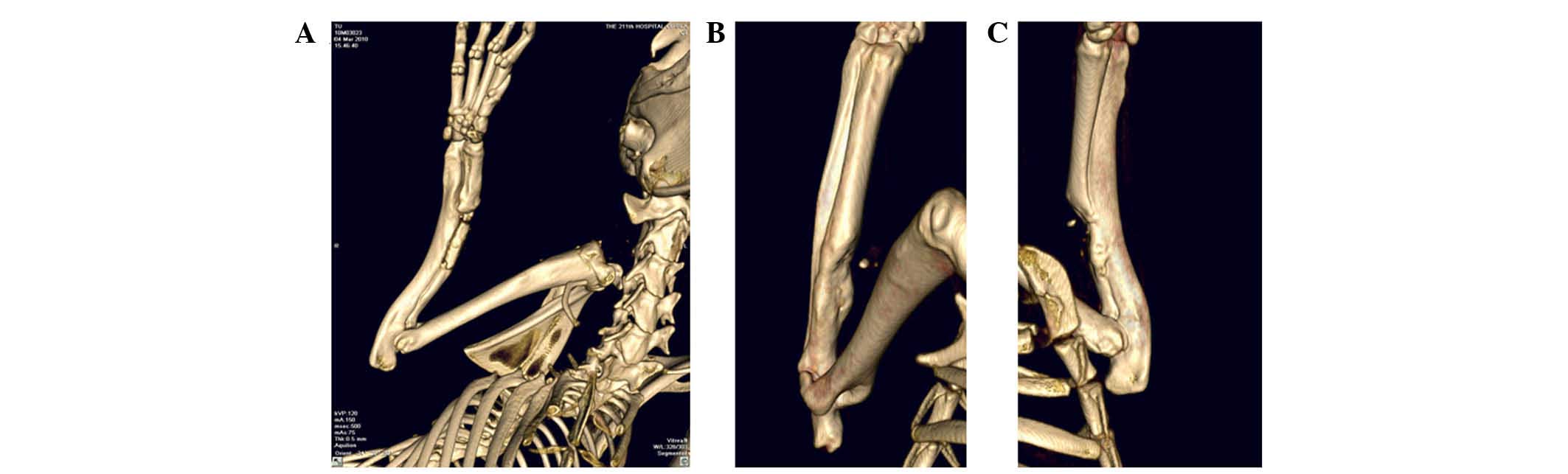

point). Additionally, for each group, three-dimensional (3D)

reconstruction of the bone defect area was performed 8 weeks after

implantation of the scaffolds using a electronic computer X-ray

tomography technique (Aquilion ONE, Toshiba, Tokyo, Japan;

thickness: 0.5 mm). Furthermore, the radius of the rabbit in the

RGD-CS/HA and CS/HA scaffold groups was obtained 8 weeks after

implantation, and the attached ligaments and muscles were carefully

dissected. The ends of the radius were mounted with denture powder

(Pigeon Dental Mfg. Co., Ltd., Shanghai, China), then placed in an

SMD-10 universal material tester (Mechanical Science Co., Ltd.,

Changchun, China) for three-point bending test with a loading speed

of 0.5 mm/min. The maximum applied load that the radius could bear,

and the bending rigidity, were recorded during the experiment, and

compared with values obtained for a normal radius. The average

value for four rabbits The average value of four rabbits from each

group were calculated, and the results were reported as the mean ±

standard deviation. The statistical significance was determined by

analysis of variance. P<0.05 was considered to indicate a

statistically significant difference. The animals were sacrificed

by injecting 4% pentobarbital sodium (4 ml/kg; Xitang Biological

Technology Co., Ltd., Shanghai, China).

Statistical Analysis

The results of the biomechanical assessments are

reported as the mean ± standard deviation and were analyzed using

Statistical Product and Service Solutions software (SPSS version

19.0; SPSS, Inc., Chicago, IL, USA). The statistical difference

among different groups was evaluated using one-way analysis of

variance. P<0.05 was considered to indicate a statistically

significant difference.

Results

Scaffold implantation

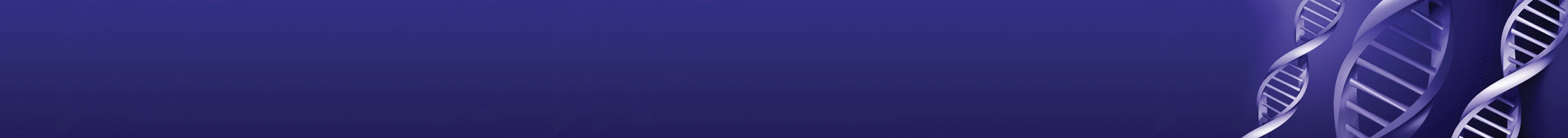

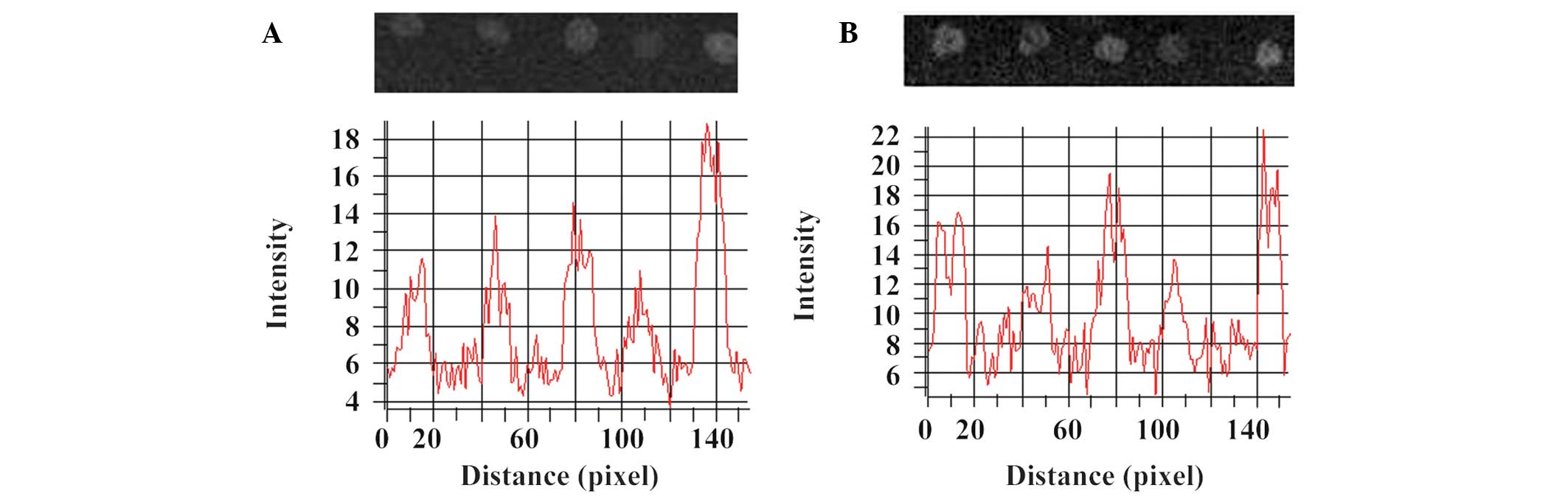

Fig. 1 shows

micrographs of the FITC-labeled RGD-CS/HA scaffold with and without

fluorescence. Under the non-fluorescent mode, the channel

morphology of the CS/HA composite was clearly visible, whilst under

the fluorescent mode, the CS/HA composite exhibited a homogeneous

bright green color, indicating uniform distribution of the RGD

peptide.

RGD-CS/HA scaffold-BMSC interactions

Cell adhesion rate

The adhesion rate of BMSCs to the RGD-CS/HA scaffold

in the initial incubation period (4 h) was 80.7% when the scaffold

was prepared using 100 mg/l CS solution, compared with 71.6% for

scaffold prepared using 50 mg/l CS solution. These results indicate

that RGD modification enhances the cell affinity of the CS/HA

composite.

Cell viability

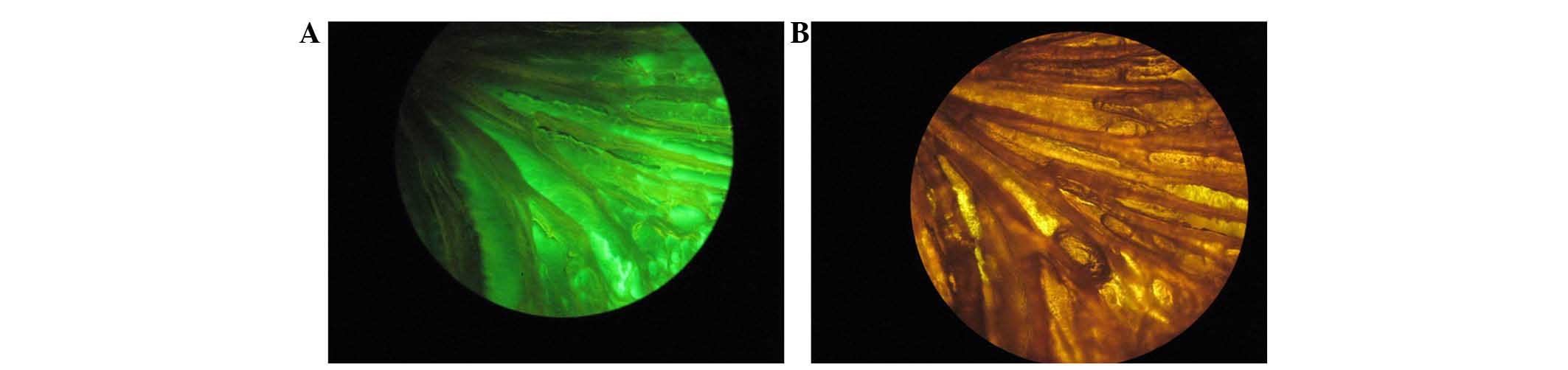

Confocal (Fig. 2A)

and fluorescence (Fig. 2B)

microscopy images of BMSCs in the Live/Dead cell assay show that

BMSCs were almost entirely viable, fusiform in shape, and evenly

distributed on the RGD-CS/HA scaffold, including the channel-shaped

pores. These results indicated the high cytocompatibility between

the RGD-CS/HA scaffold and BMSCs.

Cell morphology

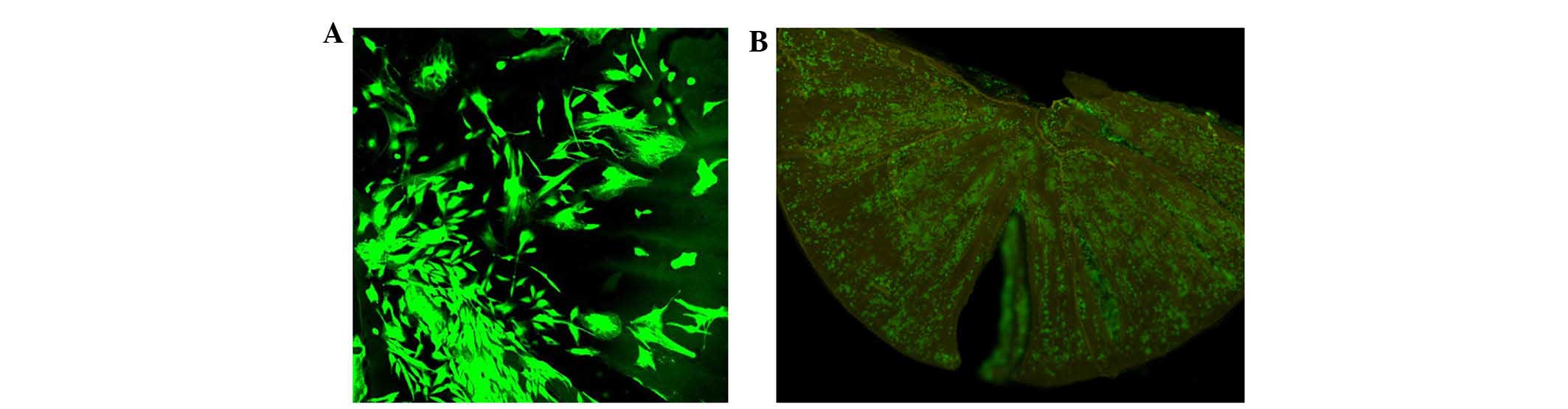

SEM images of BMSCs seeded on the RGD-CS/HA scaffold

indicate that after 4 h the BMSCs exhibited a round or elliptical

shape with almost no spread on the scaffold (Fig. 3A), whereas after 24 h of culture,

they had a flattened polygonal shape and exhibited pseudopodia

(Fig. 3B). After 48 h of culture

(Fig. 3C), BMSCs were well

distributed on the scaffold, had formed extracellular matrix, and

had made numerous cell-cell interactions.

Alkaline phosphatase (ALP)

activity

ALP is an essential enzyme for ossification and is a

well-defined marker for cell differentiation to an osteogenic

lineage. After 14 days of culture under osteogenic conditions, the

ALP content of the BMSCs on the RGD-CS/HA scaffold was elevated

(0.006±0.0008 U/l/ng), indicating that the BMSCs on the RGD-CS/HA

scaffold differentiated toward an osteogenic phenotype.

In vivo heterotopic ossification

X-ray radiographs and optical density values of the

implanted scaffolds in the RGD-CS/HA (Fig. 4A) and CS/HA (Fig. 4B) rat groups after 1 day, and 1, 2,

4 and 6 weeks indicate that, in the two groups, the lowest and

highest optical density values were observed 4 and 6 weeks after

implantation, respectively.

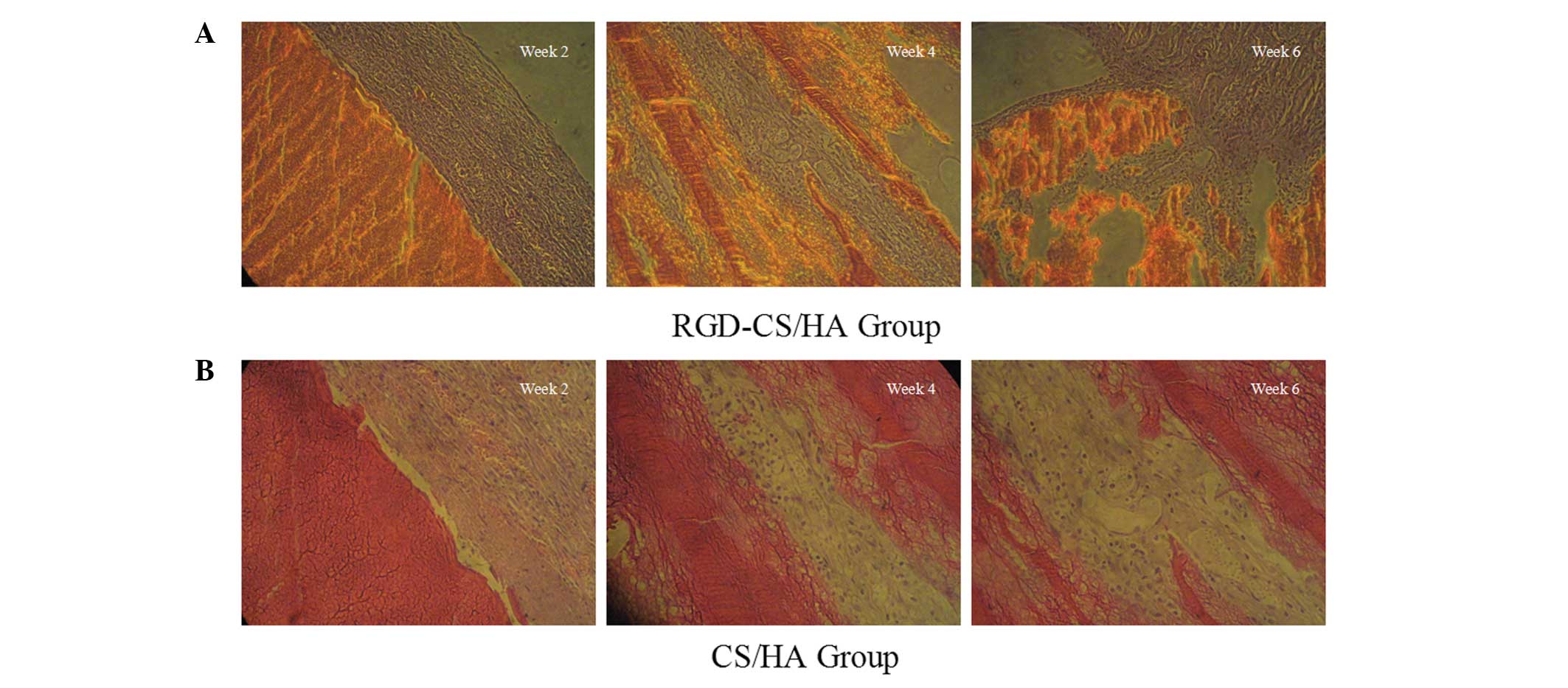

Optical micrographs

Optical micrographs of the implanted scaffolds in

the RGD-CS/HA rat group at 2, 4 and 6 weeks (Fig. 5A), indicate the presence of a small

number of chondrocytes and abundant blood vessels in the newly

formed tissues 2 weeks after implantation. Osteoclasts and

osteoblasts were evident after 4 weeks, whereas 6 weeks after

implantation, mature trabecular bone and medullary cavity were

observed, with blood vessels in between. By contrast, CS/HA

scaffolds were characterized by fibroblast hyperplasia giving rise

to predominantly fibrillar connective tissues 4 weeks after

implantation on the CS/HA scaffold, with only a small amount of

trabecular bone and number of collagen fibers visible after 6

weeks. These results indicated the superior biocompatibility of the

RGD-CS/HA compared with the CS/HA scaffold.

In vivo bone defect repair

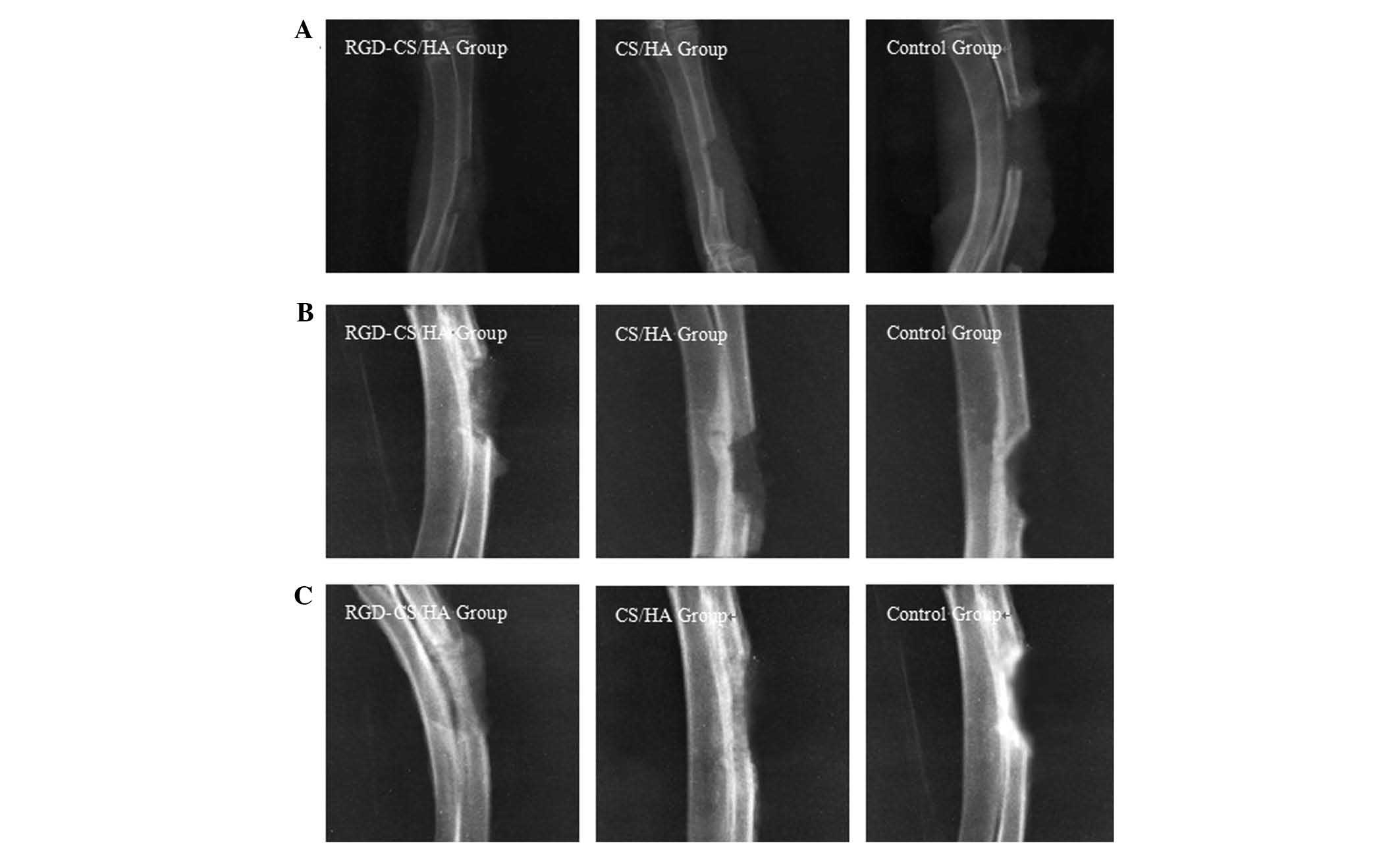

X-ray radiographs comparing rabbit radial bone

defects in the RGD-CS/HA, CS/HA and control groups indicate a low

density shadow in the RGD-CS/HA group only 2 weeks after

implantation (Fig. 6A), whereas 4

weeks after implantation (Fig.

6B), high and low density shadows were observed for the

RGD-CS/HA and CS/HA groups, respectively. Eight weeks after

implantation (Fig. 6C), de

novo bone tissue in the RGD-CS/HA group had a density

comparable to that of normal bone, whereas the relatively small

diameter of the de novo bone tissue in the CS/HA group

indicated that the scaffold had collapsed in vivo. In the

control group, a periosteal reaction was observed after 2 and 4

weeks, whereas after 8 weeks an increase in the density of the ends

of the radius was observed. 3D images obtained by X-ray tomography

(Fig. 7) confirmed that formation

of bone tissue after 8 weeks implantation was optimal on the

RGD-CS/HA scaffold. Consistent with these data, the maximum applied

load and bending rigidity of the radius in the RGD-CS/HA group were

comparable with those of the normal group (P>0.05) and

significantly higher than those of the CS/HA group (P<0.05;

Table I).

| Table IMaximum applied load and bending

rigidity of the radius in the different groups. |

Table I

Maximum applied load and bending

rigidity of the radius in the different groups.

| Group | Maximum applied

load (N) | Bending rigidity

(N/mm) |

|---|

| Normal radius |

166.22±18.83a | 62.90±4.88a |

| RGD-CS/HA |

152.57±14.63a | 57.80±5.33a |

| CS/HA | 79.25±18.35 | 36.36±6.35 |

Discussion

Bone tissue engineering has emerged as an important

method in the repair of bone defects, as well as replacement

surgery (26–28) and, in this context, there is

increasing interest in the development of composite scaffolds with

osseointegrative properties. Highly porous scaffolds with open

structures are considered to be the optimal candidates for bone

substitutes due to their facilitation of bone oxygenation and

angiogenesis (29). We have

previously shown that a CS/HA composite prepared by in situ

compositing in combination with lyophilization contained

channel-shaped and spherical pores with average sizes of 400 and

7.8 µm, respectively, and high porosity (30). The channel-shaped pores provide a

framework for bone ingrowth into the pores, and the spherical pores

are suitable for capillary ingrowth and extracellular matrix

interactions. In the present study, it was demonstrated that an RGD

peptide-modified CS/HA composite with increased cellular affinity

was superior to the CS/HA composite with respect to cell adhesion

rate, cell viability, cell morphology and ALP activity.

Furthermore, the scaffold had favorable osseointegrative

properties, as measured by in vivo heterotopic ossification

and bone defect repair, and possessed biomechanical properties

comparable to those of a normal radius. The present results

indicate that the RGD-CS/HA scaffold has promising potential for

bone tissue engineering applications.

The initial cell adhesion rate on a bone tissue

engineering scaffold is crucial for subsequent cell proliferation

and differentiation, and exerts a significant influence on the

subsequent morphogenesis of artificial tissues. The adhesion rate

of BMSCs in the current study is markedly higher than that of rat

osteosarcoma cells on RGD-modified CS scaffolds after 1 week of

culture (31). Although the

difference in the identity of the seed cells may contribute to this

discrepancy, it is hypothesized that it is also attributable to the

increased access of the BMSCs to the interior of the RGD-CS/HA

scaffold afforded by the presence of the channel-shaped pores. Such

a notion is supported by our visualization of BMSCs in the

channel-shaped pores of the scaffold, as well as by numerous

cell-cell interactions and the elevated ALP activity of BMSCs on

the RGD-CS/HA scaffold, which compares favorably to that of a

previous study (32).

The cell affinity of a scaffold is a key

consideration in bone tissue engineering. Scaffolds with a 3D

porous structure, such as that described, support nutrient supply

and promote cell adhesion and proliferation (33,34).

The cell adhesion, spreading and cytoskeletal properties of bone

scaffolds can be augmented by RGD modification of the scaffold

(35), a phenomenon attributed to

the formation of focal adhesion between RGD peptide and cell

membrane integrins (36). In the

present study, the RGD peptide was uniformly immobilized on the

CS/HA composite through physical adsorption, a method considered

superior to chemical grafting methods employed in other studies

(37,38).

The results of the in vivo heterotopic

ossification experiments showed that the post-implantation X-ray

optical densities of the RGD-CS/HA and CS/HA scaffolds were lowest

after 4 weeks and highest after 6 weeks. This may be attributed to

the fact that, relative to the rates of osseointegrative indices,

rates of CS degradation and HA adsorption were higher at 4 weeks,

and lower at 6 weeks post-implantation. In addition, the superior

performance of the RGD-CS/HA scaffold relative to the CS/HA

scaffold in the in vivo bone defect repair experiment is

attributable to presence of channel-shaped and spherical pores,

which stimulate the differentiation of BMSCs into osteoblasts and

chondrocytes, and support formation of new bone tissues (39). Furthermore, the elevated Ca and P

levels that have been reported to accompany HA adsorption may

enhance the osseointegrative properties of the differentiated

osteoblasts (21).

In conclusion, the present study demonstrated that

an RGD-CS/HA scaffold prepared by in situ compositing

combined with lyophilization had high biocompatibility,

cytocompatibility, histocompatibility and osseointegrative

properties, and represents a promising bone substitute for use in

bone tissue engineering applications.

Acknowledgments

The present study was financially supported by

Harbin Introduction of Talent Special Fund 2013, Harbin Special

Funds for Scientific and Technological Innovation Talent Research

(grant no. 2014RFQGJ038). The authors would like to thank Medjaden

Bioscience Limited for assisting in the preparation of this

manuscript.

References

|

1

|

Langer R and Vacanti JP: Tissue

engineering. Science. 260:920–926. 1993. View Article : Google Scholar : PubMed/NCBI

|

|

2

|

Temple HT and Malinin TI: Microparticulate

cortical allograft: An alternative to autograft in the treatment of

osseous defects. Open Orthop J. 2:91–96. 2008. View Article : Google Scholar : PubMed/NCBI

|

|

3

|

Zhang HY, Zhang SH, Luo JB, Liu YH, Qian

SH, Liang FH and Huang YL: Investigation of protein adsorption

mechanism and biotribological properties at simulated stem-cement

interface. J Tribology Transactions of ASME. 135:0323012013.

View Article : Google Scholar

|

|

4

|

Zanasi S: Innovations in total knee

replacement: New trends in operative treatment and changes in

peri-operative management. Eur Orthop Traumatol. 2:21–31. 2011.

View Article : Google Scholar : PubMed/NCBI

|

|

5

|

Zhang HY, Luo JB, Zhou M, Zhang Y and

Huang YL: Biotribological properties at the stem-cement interface

lubricated with different media. J Mech Behav Biomed Mater.

20:209–216. 2013. View Article : Google Scholar : PubMed/NCBI

|

|

6

|

Miller MA, Ivkovic A, Porter R, Harris MB,

Estok DM II, Smith RM, Evans CH and Vrahas MS: Autologous bone

grafting on steroids: Preliminary clinical results. A novel

treatment for nonunions and segmental bone defects. Int Orthop.

35:599–605. 2011. View Article : Google Scholar :

|

|

7

|

Carne GM, Ishaug SL and Mikos AG: Bone

tissue engineering. Nat Med. 1:1322–1324. 1995. View Article : Google Scholar

|

|

8

|

Baroli B: From natural bone grafts to

tissue engineering therapeutics: Brainstorming on pharmaceutical

formulative requirements and challenges. J Pharm Sci. 98:1317–1375.

2009. View Article : Google Scholar

|

|

9

|

Kamath MS, Ahmed SS, Dhanasekaran M and

Santosh SW: Polycaprolactone scaffold engineered for sustained

release of resveratrol: Therapeutic enhancement in bone tissue

engineering. Int J Nanomedicine. 9:183–195. 2014.PubMed/NCBI

|

|

10

|

Shahini A, Yazdimamaghani M, Walker KJ,

Eastman MA, Hatami-Marbini H, Smith BJ, Ricci JL, Madihally SV,

Vashaee D and Tayebi L: 3D conductive nanocomposite scaffold for

bone tissue engineering. Int J Nanomedicine. 9:167–181.

2014.PubMed/NCBI

|

|

11

|

Saravanan S, Sameera DK, Moorthi A and

Selvamurugan N: Chitosan scaffolds containing chicken feather

keratin nanoparticles for bone tissue engineering. Int J Biol

Macromol. 62:481–486. 2013. View Article : Google Scholar : PubMed/NCBI

|

|

12

|

Dessì M, Borzacchiello A, Mohamed TH,

Abdel-Fattah WI and Ambrosio L: Novel biomimetic thermosensitive

β-tricalcium phosphate/chitosan-based hydrogels for bone tissue

engineering. J Biomed Mater Res A. 101:2984–2993. 2013. View Article : Google Scholar

|

|

13

|

Shuai C, Gao C, Feng P, Peng S and Wen X:

Grain growth associates mechanical properties in

nano-hydroxyapatite bone scaffolds. J Nanosci Nanotechnol.

13:5340–5345. 2013. View Article : Google Scholar : PubMed/NCBI

|

|

14

|

Xia Y, Zhou P, Cheng X, Xie Y, Liang C, Li

C and Xu S: Selective laser sintering fabrication of

nano-hydroxy-apatite/poly-ε-caprolactone scaffolds for bone tissue

engineering applications. Int J Nanomedicine. 8:4197–4213.

2013.

|

|

15

|

Yamaguchi I, Tokuchi K, Fukuzaki H, Koyama

Y, Takakuda K, Monma H and Tanaka J: Preparation and microstructure

analysis of chitosan/hydroxyapatite nanocomposites. J Biomed Mater

Res. 55:20–27. 2001. View Article : Google Scholar : PubMed/NCBI

|

|

16

|

Zhang Y, Venugopal JR, El-Turki A,

Ramakrishna S, Su B and Lim CT: Electrospun biomimetic

nanocomposite nano-fibers of hydroxyapatite/chitosan for bone

tissue engineering. Biomaterials. 29:4314–4322. 2008. View Article : Google Scholar : PubMed/NCBI

|

|

17

|

Duan K and Wang RZ: Surface modifications

of bone implants through wet chemistry. J Mater Chem. 16:2309–2321.

2006. View

Article : Google Scholar

|

|

18

|

Wang F, Zhang YC, Zhou H, Guo YC and Su

XX: Evaluation of in vitro and in vivo osteogenic differentiation

of nano-hydroxy-apatite/chitosan/poly (lactide-co-glycolide)

scaffolds with human umbilical cord mesenchymal stem cells. J

Biomed Mater Res A. 102:760–768. 2014. View Article : Google Scholar

|

|

19

|

Zhang HY, Han JM, Sun YL, Huang YL and

Zhou M: MC3T3-E1 cell response to stainless steel 316L with

different surface treatments. Mater Sci Eng C Mater Biol Appl.

56:22–29. 2015. View Article : Google Scholar : PubMed/NCBI

|

|

20

|

El-Ghannam AR, Ducheyne P, Risbud M, Adams

CS, Shapiro IM, Castner D, Golledge S and Composto RJ: Model

surfaces engineered with nanoscale roughness and RGD tripeptides

promote osteoblast activity. J Biomed Mater Res A. 68:615–627.

2004. View Article : Google Scholar : PubMed/NCBI

|

|

21

|

Secchi AG, Grigoriou V, Shapiro IM,

Cavalcanti-Adam EA, Composto RJ, Ducheyne P and Adams CS: RGDS

peptides immobilized on titanium alloy stimulate bone cell

attachment, differentiation and confer resistance to apoptosis. J

Biomed Mater Res A. 83:577–584. 2007. View Article : Google Scholar : PubMed/NCBI

|

|

22

|

Yang F, Williams CG, Wang DA, Lee H,

Manson PN and Elisseeff J: The effect of incorporating RGD adhesive

peptide in polyethylene glycol diacrylate hydrogel on osteogenesis

of bone marrow stromal cells. Biomaterials. 26:5991–5998. 2005.

View Article : Google Scholar : PubMed/NCBI

|

|

23

|

Sawyer AA, Hennessy KM and Bellis SL:

Regulation of mesenchymal stem cell attachment and spreading on

hydroxyapatite by RGD peptides and adsorbed serum proteins.

Biomaterials. 26:1467–1475. 2005. View Article : Google Scholar

|

|

24

|

Clark JD, Gebhart GF, Gonder JC, Keeling

ME and Kohn DF: The 1996 Guide for the Care and Use of Laboratory

Animals. ILAR J. 38:41–48. 1997. View Article : Google Scholar

|

|

25

|

Tamada Y and Ikada Y: Fibroblast growth on

polymer surfaces and biosynthesis of collagen. J Biomed Mater Res.

28:783–789. 1994. View Article : Google Scholar : PubMed/NCBI

|

|

26

|

Zhang H, Blunt L, Jiang X, Brown L and

Barrans S: The significance of the micropores at the stem-cement

interface in total hip replacement. J Biomater Sci Polym Ed.

22:845–856. 2011. View Article : Google Scholar

|

|

27

|

Amini AR, Laurencin CT and Nukavarapu SP:

Bone tissue engineering: Recent advances and challenges. Crit Rev

Biomed Eng. 40:363–408. 2012. View Article : Google Scholar

|

|

28

|

Zhang HY, Blunt LA, Jiang XQ, Brown LT and

Barrans SM: The influence of bone cement type on production of

fretting wear on the femoral stem surface: A preliminary study.

Clin Biomech (Bristol Avon). 27:666–672. 2012. View Article : Google Scholar

|

|

29

|

Roohani SI, Tavangarian F and Emadi R:

Nanostructured bioactive glass coating on porous hydroxyapatite

scaffold for strength enhancement. Mater Lett. 62:3428–3430. 2008.

View Article : Google Scholar

|

|

30

|

Qu Z, Yan J, Li B, Zhuang J and Huang Y:

Improving bone marrow stromal cell attachment on

chitosan/hydroxyapatite scaffolds by an immobilized RGD peptide.

Biomed Mater. 5:0650012010. View Article : Google Scholar : PubMed/NCBI

|

|

31

|

Ho MH, Wang DM, Hsieh HJ, Liu HC, Hsien

TY, Lai JY and Hou LT: Preparation and characterization of

RGD-immobilized chitosan scaffolds. Biomaterials. 26:3197–3206.

2005. View Article : Google Scholar

|

|

32

|

Hofmann S, Hagenmuller H, Koch AM, Müller

R, Vunjak-Novakovic G, Kaplan DL, Merkle HP and Meinel L: Control

of in vitro tissue-engineered bone-like structures using human

mesenchymal stem cells and porous silk scaffolds. Biomaterials.

28:1152–1162. 2007. View Article : Google Scholar

|

|

33

|

Hutmacher DW: Scaffolds in tissue

engineering bone and cartilage. Biomaterials. 21:2529–2543. 2000.

View Article : Google Scholar : PubMed/NCBI

|

|

34

|

Mistry AS, Pham QP, Schouten C, Yeh T,

Christenson EM, Mikos AG and Jansen JA: In vivo bone

biocompatibility and degradation of porous fumarate-based

polymer/alumoxane nanocomposites for bone tissue engineering. J

Biomed Mater Res A. 92:451–462. 2010.

|

|

35

|

El-Ghannam AR, Ducheyne P, Risbud M, Adams

CS, Shapiro IM, Castner D, Golledge S and Composto RJ: Model

surfaces engineered with nanoscale roughness and RGD tripeptides

promote osteoblast activity. J Biomed Mater Res A. 68:615–627.

2004. View Article : Google Scholar : PubMed/NCBI

|

|

36

|

LeBaron RG and Athanasiou KA:

Extracellular matrix cell adhesion peptides: Functional

applications in orthopedic materials. Tissue Eng. 6:85–103. 2000.

View Article : Google Scholar : PubMed/NCBI

|

|

37

|

Kantlehner M, Finsinger D, Meyer J,

Schaffner P, Jonczyk A, Diefenbach B, Nies B and Kessler H:

Selective RGD-mediated adhesion of osteoblasts at surfaces of

implants. Angew Chem Int Ed. 38:560–562. 1999. View Article : Google Scholar

|

|

38

|

Haubner R, Bruchertseifer F, Bock M,

Kessler H, Schwaiger M and Wester HJ: Synthesis and biological

evaluation of a (99m) Tc-labelled cyclic RGD peptide for imaging

the alphavbeta3 expression. Nuklearmedizin. 43:26–32.

2004.PubMed/NCBI

|

|

39

|

Oliveira JM, Rodrigues MT, Silva SS,

Malafaya PB, Gomes ME, Viegas CA, Dias IR, Azevedo JT, Mano JF and

Reis RL: Novel hydroxyapatite/chitosan bilayered scaffold for

osteochondral tissue-engineering applications: Scaffold design and

its performance when seeded with goat bone marrow stromal cells.

Biomaterials. 27:6123–6137. 2006. View Article : Google Scholar : PubMed/NCBI

|