Introduction

Recombinant Ganoderma lucidum

immunomodulatory protein (rLZ-8), expressed using a Pichia yeast

eukaryotic expression system (1–3), was

the first member of the fungal immunomodulatory protein (FIP)

family discovered in mushrooms. It has been shown that rLZ-8 enjoys

a promising prospect as a new class I drug, since it induces

apoptosis in K562 and HL60 cells and acts as an immunomodulating

protein in a variety diseases, including in the non-obese diabetes

mouse model and in immunomodulation of food-induced allergic

reactions (4–14). However, rLZ-8 has a MW of only 13

kDa and its dynamic properties, such as the half-life, are not

satisfactory, which enormously limits its clinical application

(15–19).

In this study, we explored a strategy to overcome

the natural shortcomings of rLZ-8 using conventional PEGylation

technology to prolong its half-life and to enhance its stability

(20–27). We optimized the modification and

purification process, successfully prepared the single-point

modification product and carried out an initial characterization of

the association between the modification sites and the activity of

the modified product. This study has provided insights into the

structure-activity relationship of rLZ-8 and has also laid a

foundation for the development of long-acting formulations of

rLZ-8.

Materials and methods

Instruments and reagents

The following instruments/instrument systems were

used in this study: HPLC System (Shimadzu, Japan); AKTA Explorer

100 protein purification workstation (GE Healthcare, Franklin

Lakes, NJ, USA); ultrafiltration cup (GE Healthcare); gel imager

(Tanon, Shanghai, China); SDS-PAGE electrophoresis system (GE

Healthcare); electrospray ionization source high-resolution tandem

mass spectrometer (ESI-Q/TOF, Applied Biosciences, Carlsbad, CA,

USA) and laser desorption time-of-flight mass spectrometry

(MALDI-TOF/TOF, Applied Biosciences); Hiload 16/70 Superdex™ 75 gel

column (GE Healthcare). Methoxy-PEG-succinimidyl propionate

mPEG-SPA (5 kDa) was purchased from YareBio (Shanghai, China), and

the recombinant Ganoderma lucidum immunomodulatory protein

(rLZ-8) was obtained from our laboratory.

Modification optimization

Method

Optimization of the output of the single-point

modification reaction was carried out by altering one single effect

factor and keeping other factors the same in multi-level repeated

trials. The effect of each factor on the conformation of reaction

products was analyzed using SDS-PAGE and high-performance liquid

chromatography (HPLC).

Effect of pH and ionic strength

The modification of rLZ-8 with mPEG-SPA (1:12,

mol:mol) was carried out in a series of buffer systems at varying

pH, namely pH 4.0, 5.0, 6.0, 7.0 or 8.0, and then in pH 8.0

phosphate buffer with varying ionic strengths, at 0.025, 0.05, 0.1

or 0.2 M, at room temperature for 2 h, away from light. The results

were analyzed by SDS-PAGE followed by gel imaging after staining

with barium iodide and Coomassie Brilliant Blue.

Effect of reaction time and

temperature

In order to address the effect of time and

temperature on the modification reaction, rLZ-8 and mPEG-SPA (1:12,

mol:mol) were incubated together in a phosphate buffer system (0.1

M, pH 8.0) at 4, 16, 25 and 37°C, and sampled every 0.5 h for

analysis by HPLC, up to 2.5 h.

Effect of molar ratio of rLZ-8 and

mPEG-SPA

rLZ-8 and mPEG-SPA in a phosphate buffer system (0.1

M, pH 8.0) at molar ratios of 1:1, 1:3, 1:6, 1:12 and 1:24, were

mixed at room temperature for 2 h, away from light. HPLC and

SDS-PAGE with barium iodide or Coomassie Brilliant Blue staining

were used to monitor the reaction products.

Purification and identification of the

desired target product

The target product was purified using a Hiload 16/70

Superdex 75 gel chromatographic column with 0.05 M phosphate buffer

containing 0.15 M NaCl (pH 7.0) and a flow rate of 1 ml/min. After

equilibrating the column with the phosphate buffer for 2 column

volumes (120 ml), iso-concentration elution was applied for another

1.5 column volumes, with peak collection at every 2 ml and

detection wavelengths of 280, 254 and 215 nm. Every peak was

detected using SDS-PAGE and HPLC and the retention times of the

confirmed peaks were recorded.

Measurement of the biological activity

of the target product

A lymphocyte transformation test (BrdU reagent box)

was performed according to the manufacturer's instructions in order

to determine the biological activity of rLZ-8 and mPEG-SPA-rLZ-8.

The lymphocyte transformation test is based on the fact that

lymphocytes stimulated by certain antigens transform and

proliferate when re-exposed to the same antigens. The biological

activity of antigens is measured by monitoring the proliferation of

stimulated cells, and by measuring the incorporation of BrdU into

replicating DNA. A chromophore coupled to an anti-BrdU antibody

enables spectrophotometric detection of proliferating cells.

Analysis of the initial

characteristics of the target product Detection of protein

content

We used the Lowry method to measure the protein

concentration of the reaction product according to the guidelines

of the Chinese Pharmacopoeia 2010 Appendix VIB.

Validation of molecular weight and

modification site

Firstly, the sample (in the form of dry powder) was

placed into 50 mM NH4HCO to prepare a 1 mg/ml sample

solution. A 20-μl aliquot of the sample solution was then diluted

to obtain a 10-mM solution by adding 100 mM dithiothreitol (DTT)

and heating at 56°C for 1 h. After cooling the mixture to room

temperature, 250 mM indole-3-acetic acid (IAA) was added to obtain

a 25-mM sample solution and this mixture was protected from light

for 1 h. After completion of this step, 0.5 μg Trypsin was added

and the sample was digested at 37°C for 12 h. Finally, the reaction

was ended by adding 1 μl of 10% trifluoroacetic acid (TFA). The

digestion products and matrix were mixed at a proportion of 1:3 and

dried atmospherically. The peptide mass was detected by PMF

analysis in order to identify the PEGylated site on rLZ-8 in the

following modes: the mass spectra for the 500–4000 m/z range were

determined in the reflection positive ion mode and the 1000–10000

m/z range was determined in the linear positive ion mode.

Results

Modification optimization

Effect of pH and ionic strength

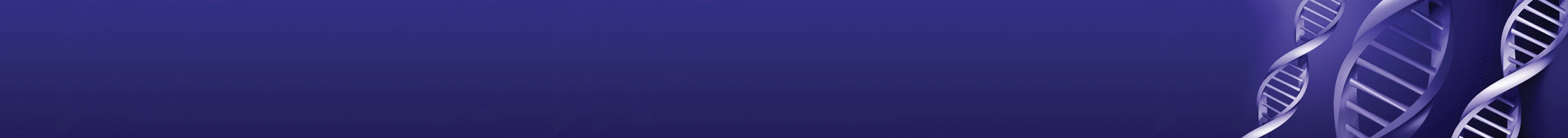

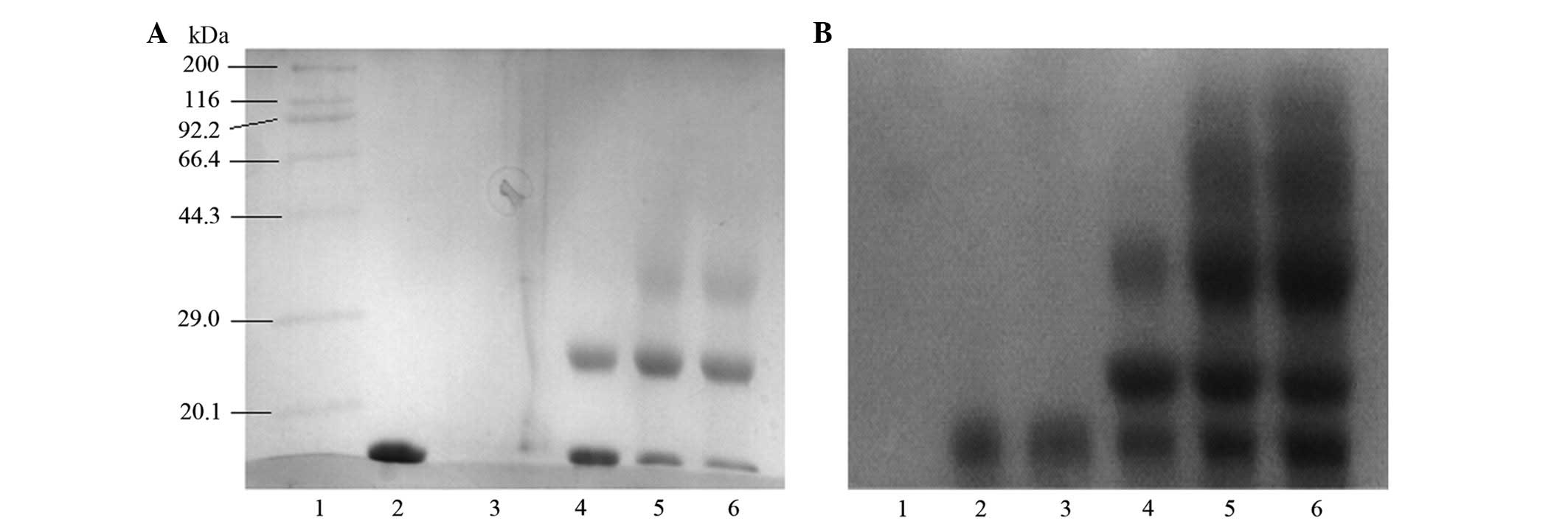

The results of SDS-PAGE analysis of the PEGylation

reaction mixture following barium iodide staining are shown in

Fig. 1. As the figure indicates,

no modification reaction (indicated by the appearance of higher-MW

bands) occurred until pH 5.0, and a weak reaction occurred between

pH 5.0 and 7.0. When the pH was >8, the reaction was more

efficient and numerous modification products were detected. By

contrast, variation of ionic strength hardly affected the

modification reaction. Therefore, we chose pH 8.0 as the reaction

pH in further studies.

Effect of reaction time and

temperature

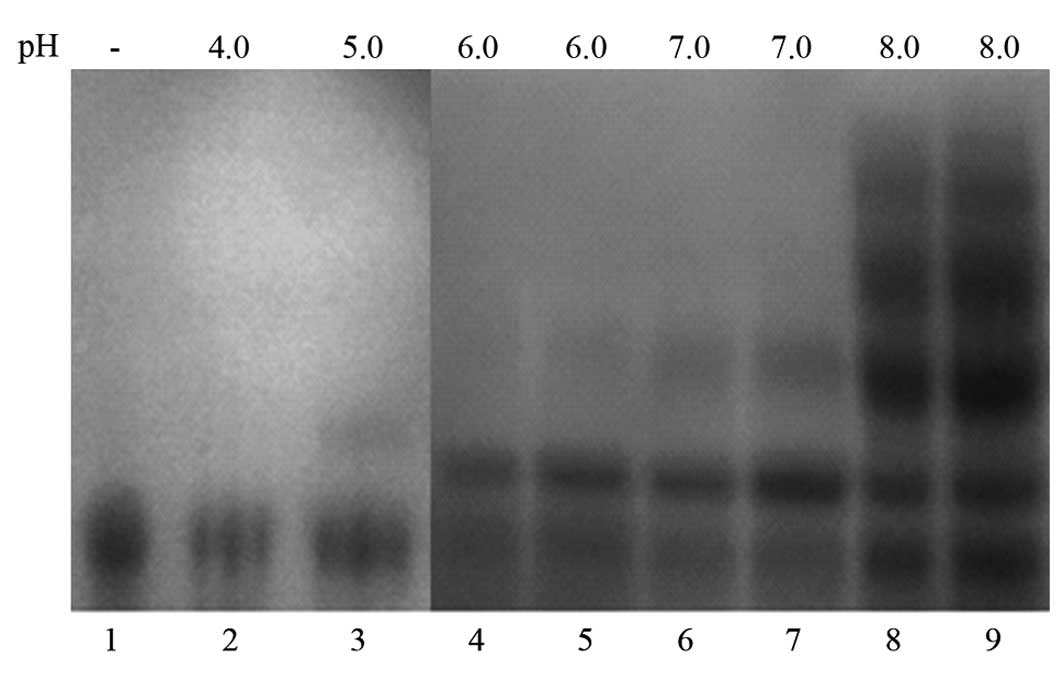

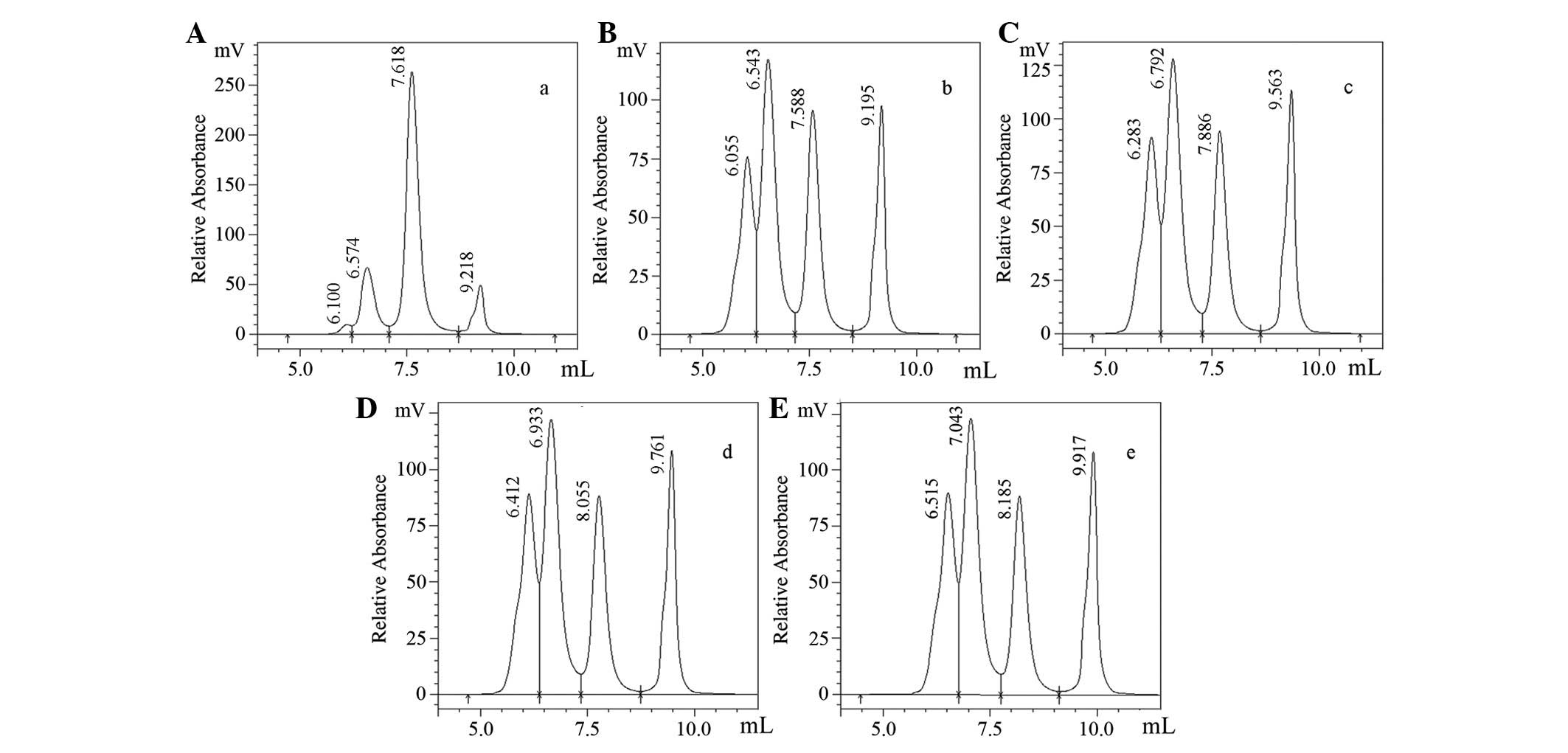

The reaction products were single and relatively

unstable at 0.5 h, which indicates the reaction was still in

progress (Fig. 2A). Between 1 and

2.5 h, the reaction results appeared to be similar (as shown in

Fig. 2B-E) and the reaction

products did not change significantly (Fig. 3), indicating that the reaction had

reached equilibrium after 1 h. Additionally, the experiment was

undertaken at room temperature, since temperature did not have a

significant effect on the reaction products (data not shown). As a

result, we chose room temperature and 2 h as the reaction

conditions.

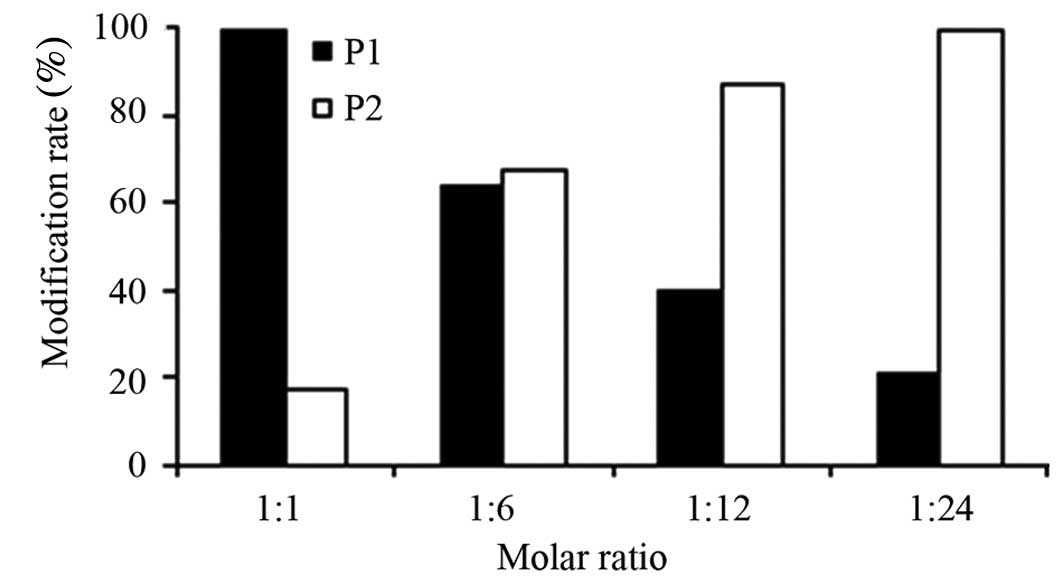

Effect of molar ratio of rLZ-8 and

mPEG-SPA

Fig. 4 illustrates

how the molar ratios of rLZ-8 to mPEG-SPA influenced the

modification reaction. The modification products became

increasingly varied (as indicated by the less discrete appearance

of the higher-MW bands) when the molar ratio of rLZ-8 to mPEG-SPA

was decreased. Only one type of modification product occurred at

the molar ratio of 1:1, so each modification product occupies 100%

of the product, with the exception of the remaining unmodified

rLZ-8. When the molar ratio was 1:24, there were four modification

products and each one contributed to 18.57% of the total mixture

(Figs. 4 and 5). For ease of purification, a molar

ratio of 1:1 was chosen for single-point modification.

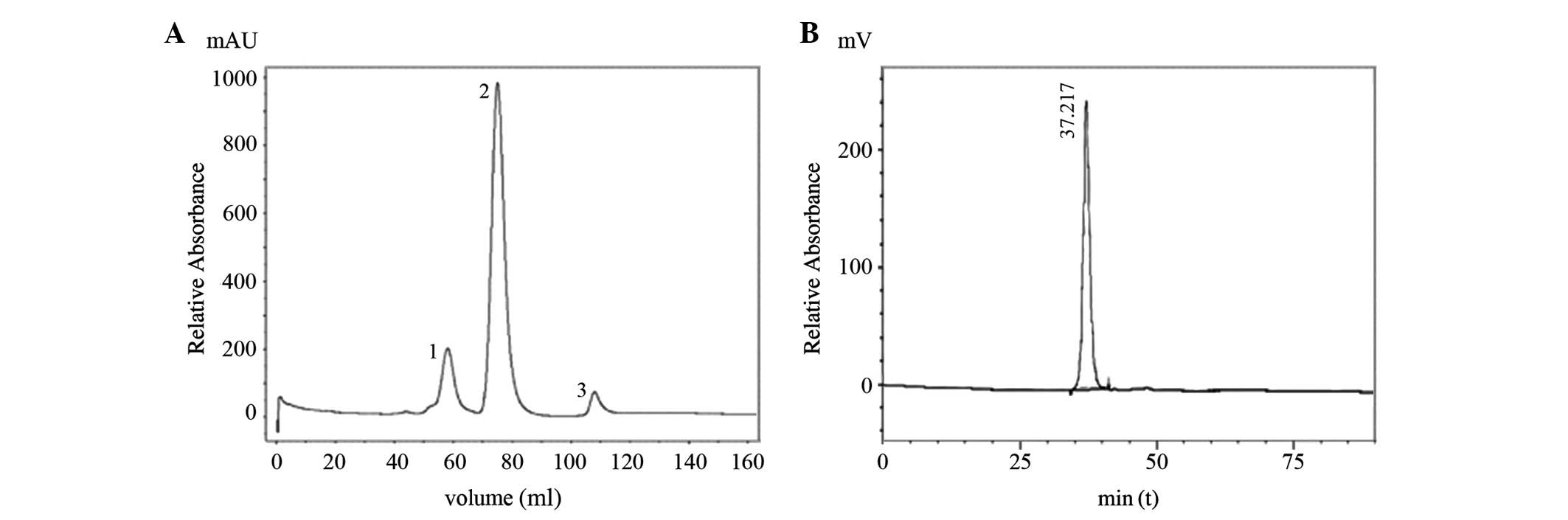

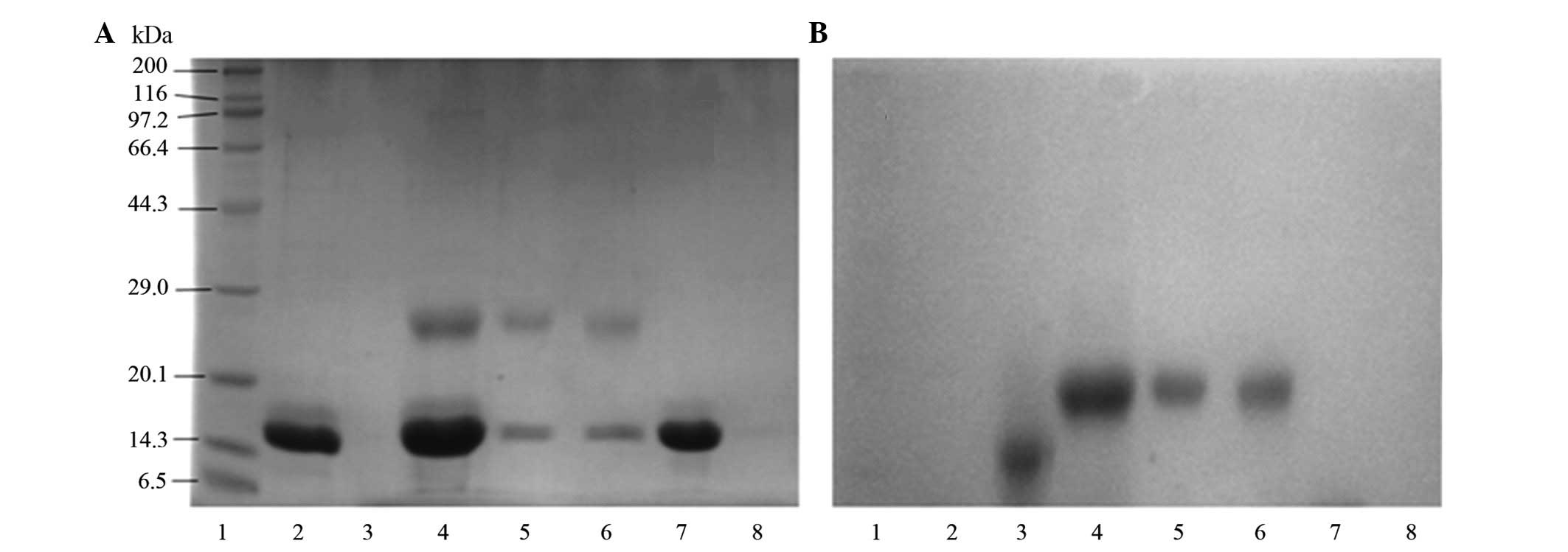

Purification and identification of the

target product

As shown in Fig. 6A

and Fig. 7, only one type of

modification product occurred at a molar ratio of 1:1. According to

the molecular sieve principle, the purity of the purification

product may reach 99% after being purified using a Superdex 75 gel

chromatographic column, a result that we also observed when using

this chromatographic purification method (Fig. 6B).

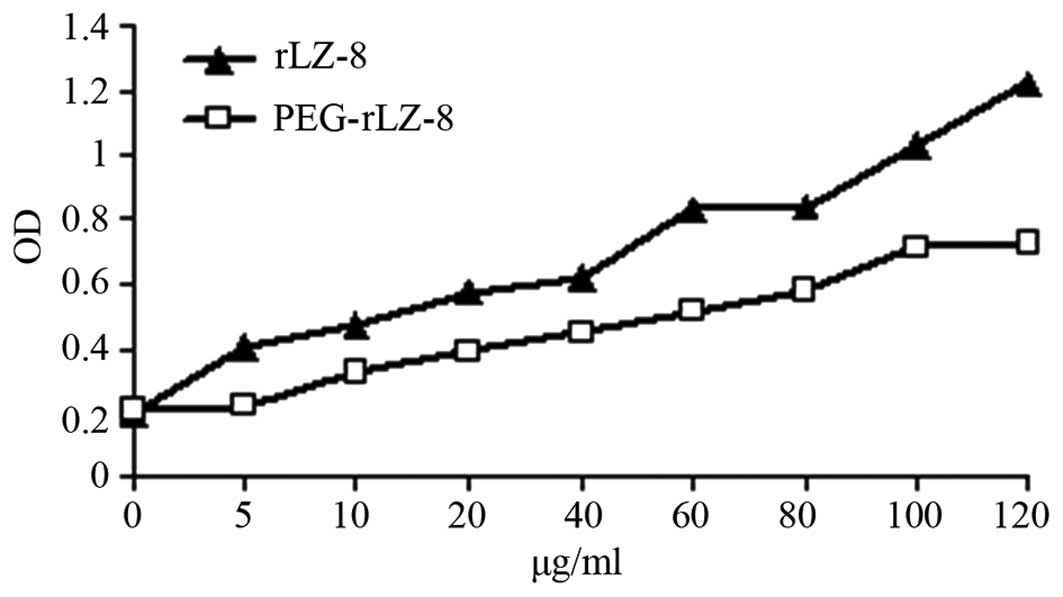

Biological activity of the purified

target product

The biological activities of rLZ-8 and PEG-rLZ-8 (as

assessed using a BrdU incorporation assay) are shown in Fig. 8. When modified by PEG, the activity

of the modification products of rLZ-8 decreased as expected.

Preliminary analysis of the

characteristics of target products

Detection of protein content

The Lowry method was used to determine the

concentration of protein in the modification product due to its

outstanding linear correlation, both before and after modification.

The amount of rLZ-8 decreased from 5 to 0.96 mg following the

modification and purification process.

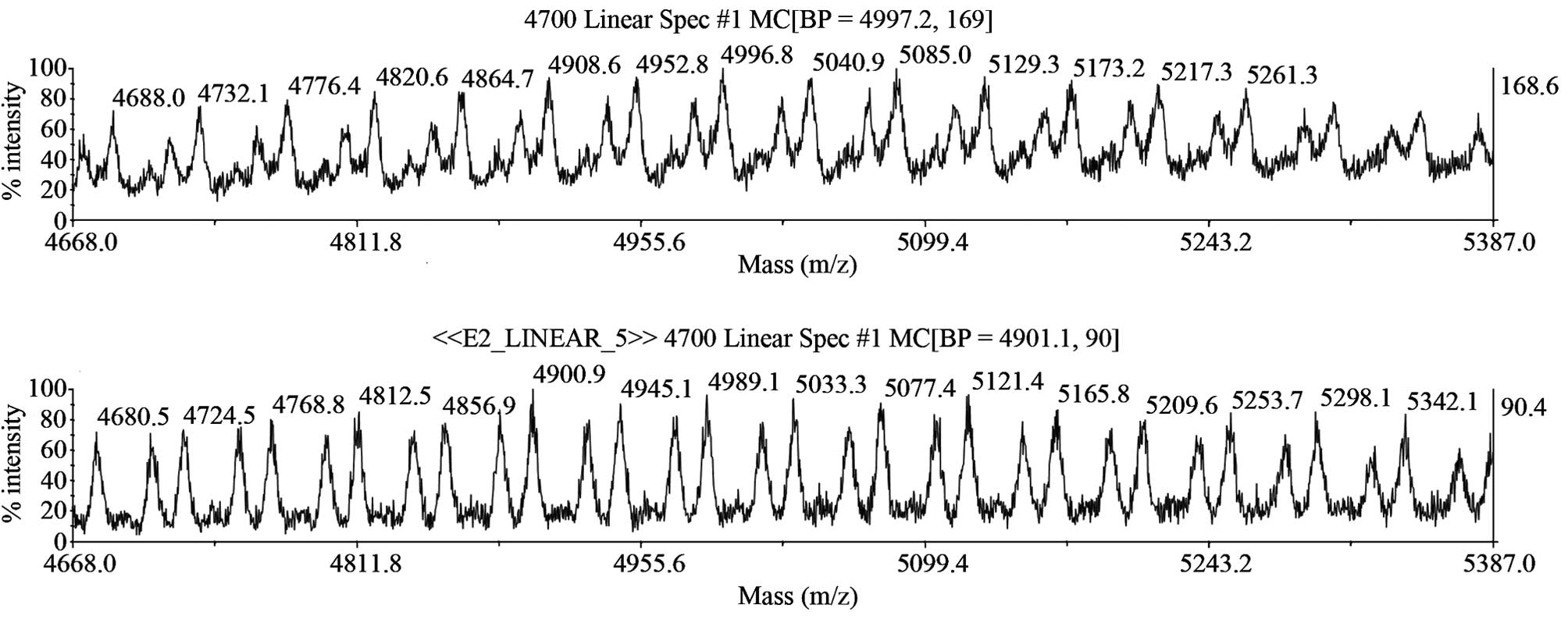

Validation of molecular weight and

modification site

Several points were considered in order to correctly

identify the modification site. Firstly, the PEG-peptide may not

match the expected peptide mass fingerprint (PMF) and those that

match usually represent unPEGylated peptides in the modification

sample. Secondly, the PEGylated site is always located at the

N-terminus or on a Lys side chain. Thirdly, PEGylated Lys is

usually intractable to enzymatic cleavage, in which case, when Lys

is modified at least one uncleaved site is always included, and the

margin between the PEG-peptide and PEG should be close to the

theoretical MW of the peptide, while the MS/MS peak shape of the

PEG-peptide should be consistent with that of PEG.

From the data, we conclude that Lys is not the

PEGylated site, as all Lys in the PEG-protein matched the PMF and

the molecular weight of the PEG-peptides were close to that of PEG.

Therefore, we concluded that the PEGylated site did not fall within

the 75–111 amino acid fragment of rLZ-8 (this fragment is 4205.9858

Da). In the determination of the PMF of the PEG-protein, N-terminal

peptides with and without the M fragment (SDTALIFR) were observed,

so the PEGylated site is estimated to be at the N-terminus, as the

falling off of M in the process is not expected to affect the

correspondence in MW between the peptides and the PMF (Fig. 9). Furthermore, the margin of the MW

between PEG-peptides and PEG are relatively close to M, which

provides further evidence that the PEGylated site is located at the

N-terminus.

Discussion

In this study, we established a strategy for

modifying rLZ-8 using mPEG-SPA and evaluated the effect of various

reaction parameters on the modification reaction. The pH of the

reaction buffer was the determining factor in the modification

reaction, and the modification reaction could not be carried out

under acidic conditions. The desired reaction products were

recovered in pH 8.0 phosphate buffer solution; however, the molar

ratio of rLZ-8 to mPEG-SPA was also an important factor affecting

the reaction products. A molar ratio of 1:1 yielded a single-site

modification product, and the composition of the reaction products

became more and more complex as the amount of mPEG-SPA was

increased. When the molar ratio was >1:12, there were four

species of products, of ~66, 44, 30 and 17.9 kDa. The reaction

temperature had almost no effect on the modification reaction, and

the reaction reached equilibrium after 1 h. From these data, we

concluded that the best conditions to obtain a single-site modified

product are: 0.05 M, pH 8.0 phosphate buffer solution, a 1:1 molar

ratio of rLZ to mPEG-SPA, and stirring at room temperature for 2 h,

protected from light.

PEG modification sites are generally at the

N-terminus or on Lys side chains. The structural analysis of rLZ-8

(17) revealed that the active

form of rLZ-8 is a non-covalently bonded dimer and that each

monomer contains 6 Lys. Therefore, in theory, one rLZ-8 molecule

may combine with 1–7 mPEG-SPA molecules, but the mPEG can only

modify the N-terminus of the protein. Since mPEG-SPA has long-chain

branches and is sticky, the greater the amount of mPEG-SPA that

combines with the protein, the greater the reduction in activity,

and the more complex the product composition is likely to be. In

this study, we focused on optimizing reaction conditions to obtain

a single-site modified product.

The MW of the single-site modified product is ~17.9

kDa, so we selected the Superdex 75 separation column to purify the

modification reaction mixture. Purification results revealed that

the modified products can be separated completely from the

unreacted rLZ-8 and that the small molecule byproducts can be

removed. Moreover, the single-site modified products were of high

purity and the excess rLZ-8 could be recycled and reused in the

experiment. Separation and purification of a variety of modified

products in excess of mPEG-SPA is more difficult, and further

studies are required to optimize recovery of other modification

products.

An in vitro assay for assessing the

biological activity of the single-site modified product indicated

that mPEG-SPA altered the efficacy of the protein in a lymphocyte

transformation assay. Additional in vivo experiments should

be carried out to determine the pharmacokinetic properties, such as

the half-life and effective dose, of the modified rLZ-8. Such

detailed analysis is likely to facilitate the clinical application

of modified products such as PEGylated rLZ-8.

Acknowledgements

This study was supported by the Science and

Technology Development Program of Jilin Province (Grant No.

20090941).

References

|

1

|

Liang C, Zhang S, Liu Z and Sun F:

Ganoderma lucidum immunomodulatory protein(Lz-8) expressed

in Pichia pastoris and the identification of

immunocompetence. Sheng Wu Gong Cheng Xue Bao. 25:441–447.

2009.

|

|

2

|

Lin JW, Hao LX, Xu GX, Sun F, Gao F, Zhang

R and Liu LX: Molecular cloning and recombinant expression of a

gene encoding a fungal immunomodulatory protein from Ganoderma

lucidum in Pichia pastoris. World J Microbiol

Biotechnol. 25:383–390. 2009. View Article : Google Scholar

|

|

3

|

Murasugi A, Tanaka S, Komiyama N, Iwata N,

Kino K, Tsunoo H and Sakuma S: Molecular cloning of a cDNA and a

gene encoding an immunomodulatory protein, Ling Zhi-8, from a

fungus, Ganoderma lucidum. J Biol Chem. 266:2486–2493.

1991.PubMed/NCBI

|

|

4

|

Wang XL, Liang CY, Li HR, Li BZ and Sun F:

Recombinant Ganoderma lucidum immunoregulatory protein

(rLZ-8) induces nuclear-stress apoptosis in K562 cells. Zhongguo

Mian Yi Xue Za Zhi. 26:616–618. 2010.(In Chinese).

|

|

5

|

Guo Q, Sun H, Liang CY, Zhang SQ, Liu ZY

and Sun F: Inhibiting and apoptosis-inducing effects of recombinant

Ganoderma lucidum immunoregulatory protein on HL60 cells.

Zhongguo Mian Yi Xue Za Zhi. 26:520–522. 2010.(In Chinese).

|

|

6

|

Liang CY, Zhang SQ and Sun F: The dynamic

observation: cellular localization of fluorescein isothiocyanate

labeled recombinant Ganoderma lucidum immunoregulatory

protein (rLZ-8) in NB4 APL cell. Chemical Journal of Chinese

Universities: CJCU. 30:479–483. 2009.

|

|

7

|

Kino K, Mizumoto K, Sone T, Yamaji T,

Watanabe J, Yamashita A, Yamaoka K, Shimizu K, Ko K and Tsunoo H:

An immunomodulating protein, Ling Zhi-8 (LZ-8) prevents insulitis

in non-obese diabetic mice. Diabetologia. 33:713–718. 1990.

View Article : Google Scholar : PubMed/NCBI

|

|

8

|

Haak-Frendscho M, Kino K, Sone T and

Jardieu P: Ling Zhi-8: a novel T cell mitogen induces cytokine

production and upregulation of ICAM-1 expression. Cell Immunol.

150:101–113. 1993. View Article : Google Scholar : PubMed/NCBI

|

|

9

|

Hsieh KY, Hsu CI, Lin JY, Tsai CC and Lin

RH: Oral administration of an edible-mushroom-derived protein

inhibits the development of food-allergic reactions in mice. Clin

Exp Allergy. 33:1595–1602. 2003. View Article : Google Scholar : PubMed/NCBI

|

|

10

|

Liu YH, Kao MC, Lai YL and Tsai JJ:

Efficacy of local nasal immunotherapy for 10. Dp2-induced airway

inflammation in mice: using Dp2 peptide and fungal immunomodulatory

peptide. J Allergy Clin Immunol. 112:301–310. 2003. View Article : Google Scholar : PubMed/NCBI

|

|

11

|

Ho JC, Sze SC, Shen WZ and Liu WK:

Mitogenic antivity of edible mushroom lectins. Biochim Biophys

Acta. 1671:9–17. 2004. View Article : Google Scholar : PubMed/NCBI

|

|

12

|

Wasser SP and Weis AL: Therapeutic effects

of substances occurring in higher Basidiomycetes mushrooms: a

modern perspective. Crit Rev Immunol. 19:65–96. 1999.PubMed/NCBI

|

|

13

|

Llovet JM and Bruix J: Systematic review

of randomized trials for unresectable hepatocellular carcinoma:

chemoembolization improves survival. Hepatology. 37:429–442. 2003.

View Article : Google Scholar

|

|

14

|

Liang CY, Li H, Zhou H, Zhang SQ, Liu ZY,

Zhou Q and Sun F: Recombinant Lz-8 from Ganoderma lucidum

induces endoplasmic reticulum stress-mediated autophagic cell death

in SGC-7901 human gastric cancer cells. Oncol Rep. 27:1079–1089.

2012.

|

|

15

|

van der Hem LG, van der Vliet JA, Bocken

CF, Kino K, Hoitsma AJ and Tax WJ: Ling Zhi-8: studies of a new

immunomodulating agent. Transplantation. 60:438–443.

1995.PubMed/NCBI

|

|

16

|

Zhu JQ, Liang CY, Feng K, Gai XD, Sun X

and Sun F: Purification and properties of recombinant Ganoderma

lucidum immunoregulatory protein. Chem Res Chin Univ. 29:1–4.

2008.

|

|

17

|

Huang L, Sun F, Liang CY, He YX, Bao R,

Liu L and Zhou CZ: Crystal structure of LZ-8 from the medicinal

fungus Ganoderma lucidium. Proteins. 75:524–527. 2009.

View Article : Google Scholar : PubMed/NCBI

|

|

18

|

Lin WH, Hung CH, Hsu CI and Lin JY:

Dimerisation of the N-terminal amphipathic α-helix domain of the

fungal immunomodulatory protein from Ganoderma tsugae

(Fip-gts) defined by a yeast two-hybrid system and site-directed

mutagenesis. J Biol Chem. 272:20044–20048. 1997.PubMed/NCBI

|

|

19

|

Tanaka S, Ko K, Kino K, Tsuchiya K,

Yamashita A, Murasugi A, Sakuma S and Tsunoo H: Complete amino acid

sequence of an immunomodulatory protein, ling zhi-8 (LZ-8). An

immunomodulator from a fungus, Ganoderma lucidium, having

similarity to immunoglobulin variable regions. J Biol Chem.

264:16372–16377. 1989.PubMed/NCBI

|

|

20

|

Roberts MJ, Bentley MD and Harris JM:

Chemistry for peptide and protein PEGylation. Adv Drug Deliv Rev.

54:459–476. 2002. View Article : Google Scholar : PubMed/NCBI

|

|

21

|

Fee CJ and Van Alstine JM: PEG-proteins:

Reaction engineering and separation issues. Chem Eng Sci.

61:924–939. 2005.

|

|

22

|

Kinstler O, Molineux G, Treuheit M, Ladd D

and Gegg C: Mono-N-terminal poly(ethylene glycol)-protein

conjugates. Adv Drug Deliv Rev. 54:477–485. 2002. View Article : Google Scholar : PubMed/NCBI

|

|

23

|

Greenwald RB: PEG drugs: an overview. J

Control Release. 74:159–171. 2001. View Article : Google Scholar : PubMed/NCBI

|

|

24

|

Seyfried BK, Siekmann J, Belgacem O,

Wenzel RJ, Turecek PL and Allmaier G: MALDI linear TOF mass

spectrometry of PEGylated (glyco)proteins. J Mass Spectrom.

45:612–617. 2010.PubMed/NCBI

|

|

25

|

Ronda L, Pioselli B, Bruno S, Faggiano S

and Mozzarelli A: Electrophoretic analysis of PEGylated

hemoglobin-based blood substitutes. Anal Biochem. 408:118–123.

2011. View Article : Google Scholar : PubMed/NCBI

|

|

26

|

Zhai Y, Zhao Y, Lei J, Su Z and Ma G:

Enhanced circulation half-life of site-specific PEGylated rhG-CSF:

optimization of PEG molecular weight. J Biotechnol. 142:259–266.

2009. View Article : Google Scholar : PubMed/NCBI

|

|

27

|

Moosmann A, Christel J, Boettinger H and

Mueller E: Analytical and preparative separation of PEGylated

lysozyme for the characterization of chromatography media. J

Chromatogr A. 1217:209–215. 2010. View Article : Google Scholar : PubMed/NCBI

|