Introduction

Synthetic angiotensin-I-converting enzyme (ACE)

inhibitory (ACEI) drugs, including captopril, lisinopril, enalapril

and ramipril, are effective to treat cardiovascular disease.

However, side effects accompany the application of these drugs,

including proteinuria, altered sense of taste, allergic skin

rashes, cough and drug fever (1).

Isolation of effective natural ACEI peptides from diets or crops is

an attractive prospect. A series of ACEI peptides derived from food

protein sources have been identified, including from fermented

milk, cheddar cheeses (2), hen egg

white (3), tuna (4), rice (5), soybean (6), peanut meal (7), skate (Okamejei kenojei) skin

gelatin (8), flaxseed (9) and pumpkin (10). These ACEI peptides were commonly

collected using proteolytic hydrolysis methods or during

fermentation processing. Although ACEI peptides from natural food

are considered to be safe, they exhibit low efficacy in comparison

with synthetic ACEI drugs. Sunflower protein is an important source

for ACEI peptides. The procedure for the purification of ACEI

peptides derived from sunflower protein, includes the gel

filtration chromatography, affinity chromatography and

reverse-phase chromatography (11,12).

However, it is important to improve the entrapment efficiency and

to reduce the release of ACEI peptides.

Liposomes have unique physicochemical properties

including the ability to incorporate lipophilic, amphiphilic and/or

hydrophilic compounds, and the ability to improve the stability and

reduce the toxicity of encapsulated drugs (13,14).

Different methodologies are reported to prepare multi-lamellar

vesicles, large unilamellar vesicles and small unilamellar vesicles

(15). Liposomes formed by

thin-film ultrasonic methods have also been widely reported in the

literatures (16–19). However, the production of these

phospholipids vesicles is poorly reproducible as that ACEI

peptides-liposomal experimental set-up is not described in

detail.

In this study, it was aimed to optimize the

encapsulation conditions for producing liposome ACEI peptides by

employing response surface methodology (RSM). In addition,

fractional factorial design (FFD) and the central composite design

were also used to identify the most important variables for

optimizing the encapsulation conditions during the experiments.

Materials and methods

Materials and chemical reagents

Defatted sunflower meal was supplied by China Oil

& Foodstuffs Corporation (Shihezi Branch, China). Alcalase

(ExPASy entry EC 3.4.21.62, Bacillus licheniformis; 2.4 L),

and flavourzyme (ExPASy entry EC 3.4.11.1; 1,000 mg) were purchased

from Novozymes (Bagsvard, Denmark). ACE (ExPASy entry EC 3.4.15.1,

rabbit lung; 0.25 U/ml) and N-[3-(2-furyl)

acryloyl]-L-phenyl-alanylglycylglycine (FAPGG) substrate were

purchased from Sigma-Aldrich (Merck KGaA, Darmstadt, Germany).

Bicinchoninic acid (BCA) protein kit and bovine serum albumin were

purchased from Beijing Kangwei Century Biotechnology Co., Ltd.

(Beijing, China). Cholesterol, L-α-dipalmitoyl phosphatidylcholine

(DPPC), phosphatidylcholine (PC), soybean phospholipids (SP),

sphingomyelin (SM),

1-myristoyl-2-palmitoyl-sn-glycero-3-phosphatidylcholine (MPPC),

and polyethylene glycol (PEG; molecular weight, 2,000) were

purchased from Rizhao Jia Qing Trading Co., Ltd. (Rizhao, China).

All other chemicals and reagents were of analytical grade.

Preparation of sunflower protein

isolates

Defatted sunflower meal flour (20 g) was extracted

by stirring for 1 h in 200 ml 60% ethanol aqueous solution.

Following vacuum filtration, the residue was washed twice with

distilled water and extracted by stirring for 1 h in 200 ml NaOH

(0.05 M) at room temperature. Following centrifugation at 7,155.2 ×

g for 20 min, an additional extraction was performed with half the

volume of alkaline solution. The pH of the supernatant was adjusted

to the isoelectric point (pH 4.3) of sunflower proteins, and the

precipitate formed was recovered by a centrifugation as described

above, washed with distilled water and freeze-dried until further

use.

Sunflower protein-derived ACEI peptides were

prepared according to Villanueva et al (20) and Dadzie et al (21) with modifications: Adjusted

hydrolysis pH for Alcalase from 8 to 8.5 and for Flavourzyme from 7

to 6.5. In the present study, the fraction of molecular mass <3

kDa was gained by ultrafiltration following hydrolysis and then

added to an open column (1.6×100 cm) packed with Sephadex G-25 gel

Beijing RuiDa HengHui Science and Technology Development Co.,

Ltd.,(Beijing, China), that had been pre-equilibrated with

distilled water.

The ACEI peptides were eluted by distilled water at

the speed of 60 ml/h and the elution peaks were monitored at 220

nm. Those fractions (IC50, 2.63±0.08 µg/ml) were vacuum

freeze-dried and stored at −20°C until use (22).

Preparation of liposome containing

ACEI peptides

Liposomal ACEI peptides were prepared by thin-film

ultrasonic method as described by Ferreira et al (23) and Cortesi et al (24) with certain modifications. The

obtained liposome preparation was incubated at room temperature

under continuous stirring (180 mot/min) for 16–18 h in order to

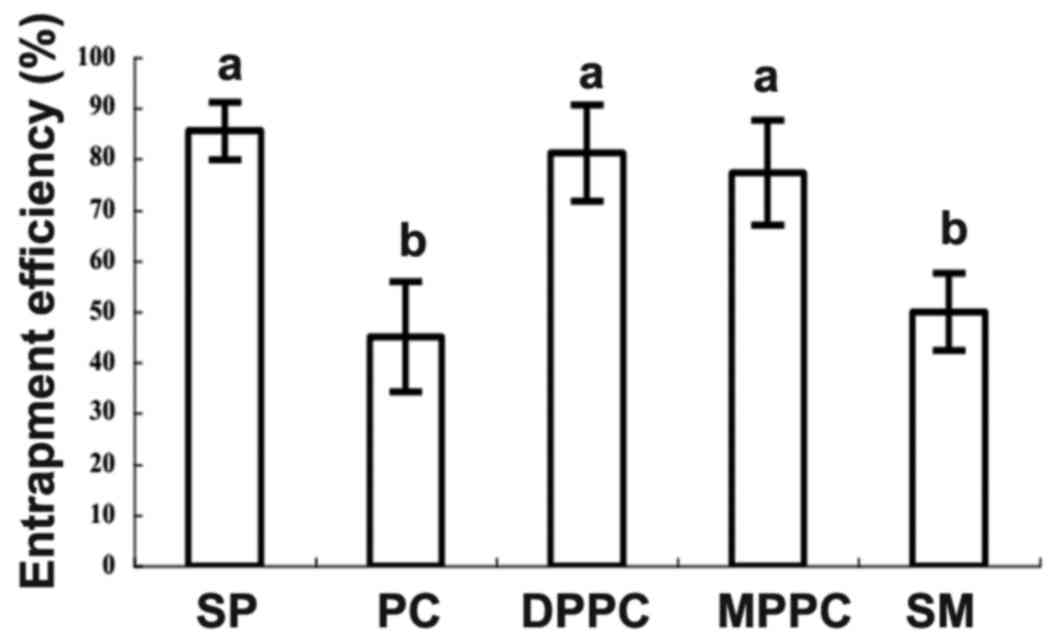

achieve higher entrapment efficiency (25). The preparation of liposome

containing ACEI peptides was confirmed by scanning electron

microscope (SEM) (JSM-6490LV; JEOL, Ltd., Tokyo, Japan).

Determination of entrapment

efficiency

Entrapment efficiency of liposomal ACEI peptides was

determined using Centrifree® (EMD Millipore, Billerica,

MA, USA) according to previously reported method (26) with certain modifications: The

supernatant was analyzed via a BCA Protein Quantitation kit

(aforementioned) at 562 nm to determine the amount of

unencapsulated ACEIPs. A standard curve was established with bovine

serum albumin.

Liposomal ACEI peptides release assay

in vitro

An ACEI peptides release experiment was performed

using the dialysis method according to Cortesi et al

(24) with slight modification:

The adjusted molecular weight of the dialysis tube was reduced from

10,000–12,000 to 8,000–10,000. Analysis of ACEIPs content from by

HPLC to BCA Protein Quantitation kit.

FFD

A reduced (26-2) factorial design at two

levels with resolution IV was selected. The variables were coded

according to the following equation:

xi=(Xi-X0)/ΔXi; where

xi was the coded value of an independent variable,

Xi was the real value of an independent variable,

X0 was the real value of an independent variable at the

central point, and ΔXi was the step change value.

Central composite design (CCD)

In order to describe the nature of the response

surface in the optimum region, a central composite design RSM was

performed to examine the effect of the three independent variables

X1 (phospholipids to cholesterol ratio), X5

(ultrasound time), and X6 (phospholipids to ACEI

peptides ratio) at five levels for each variable on the entrapment

efficiency.

Statistical analysis

Design expert 8.0.5 software (Stat-Ease, Inc.,

Minneapolis, MN, USA) was used for analysis of variance (ANOVA) of

the mean responses fitted to a second order polynomial to obtain

regression equations. Entrapment efficiencies were compared using

one-way ANOVA and Bonferroni multiple comparisons test. P<0.05

was considered to indicate a statistically significant difference.

The adequacy of the model to navigate the design space of the

responses was determined using the coefficient of determination

(R2) and a lack of fit test. Two-dimensional (2D)

contour plots and three-dimensional (3D) response surface plots for

the responses were generated for two independent variables while

fixing the remaining variable at coded 0 levels. The release

profile of liposome containing ACEI peptides and the fitted curve

for the percentage ACEI peptides released and release time were

constructed by Origin 8.0 (OriginLab Corporation, Northampton, MA,

USA).

Results and Discussion

Effects of phospholipids on

preparation of liposome containing ACEI peptides

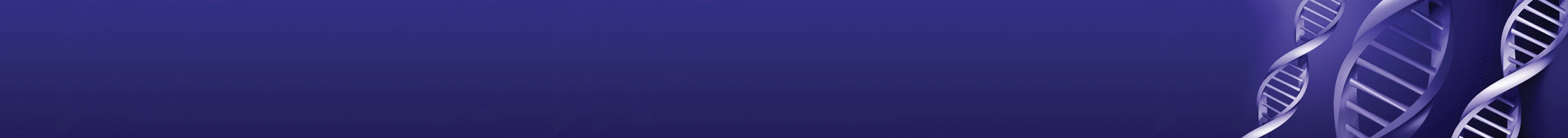

In order to identify the most appropriate

phospholipids for ACEI peptide entrapment, five phospholipids (SP,

PC, DPPC, MPPC and SM) were used to prepare the liposome containing

ACEI peptides (Fig. 1). The SP

formulation had the highest entrapment efficiency (85.57±5.68%),

followed by DPPC formulation (81.24±9.41%) and MPPC (77.31±10.32%),

and there was no significant difference among them. By contrast, PC

and SM formulation exhibited much lower entrapment efficiency (PC,

45.07±0.78%; SM, 50.03±7.55%), which were significantly lower than

those of the SP, MPPC and DPPC formulations. These results were

consistent with a previous report, in which there were markedly

different interactions among peptides and various types of charged

liposome (27). Therefore, the SP

formulation was chosen to further optimize the entrapment

conditions for producing liposomal ACEI peptides because of its

higher efficiency and lower cost. Liposomal ACEI peptides were

imaged using SEM (Fig. 2).

Screening of preparation conditions

for liposomal ACEI peptides using FFD

A 26-2 FFD was applied to evaluate the

impact of six factors. The entrapment efficiency of liposomal ACEI

peptides markedly varied in a range from 40.28–90.91%. The

factorial analysis of variances indicated that the ratio of

phospholipids to cholesterol (X1), ultrasound time

(X5) and the ratio of phospholipids to ACEI peptides

(X6) were significant factors (P<0.001), which

affected entrapment efficiency of liposomal ACEI peptides, while

PEG-2000 dosage, NaCl concentration in PBS and hydration

temperature were non-significant factors (Table I). In this case, there was

significant interaction between X1 and X6,

between X1 and X4 (P<0.01). Using multiple

regression analysis, the response variables and the test variables

were related by the second-order polynomial equation as follows:

Y1=76.32–4.56X1-9.84X5+7.71X6+3.27X1X4-2.66X1X5+3.52X1X6.

The values of R2 and adjusted R2 were 88.76

and 83.58%, respectively, indicating that the model fitted well

with the experimental data. The comparable values revealed that

non-significant factors were not included in the model. The P-value

of lack-of-fit in ANOVA was insignificant for the model at a

confidence level of 95% (P=0.0605), suggesting that the model

represented the data satisfactorily.

| Table I.Analysis of variances results of

fractional factorial designs for entrapment efficiency

(Y1) of liposomal angiotensin-I-converting enzyme

inhibitory peptides. |

Table I.

Analysis of variances results of

fractional factorial designs for entrapment efficiency

(Y1) of liposomal angiotensin-I-converting enzyme

inhibitory peptides.

| Source | Sum of squares | Degrees of

freedom | Mean square | F-value | P-value

(Prob>F) |

|---|

| Model | 3,314.86 | 6 | 552.48 | 43.82 | <0.0001 |

| X1 | 332.70 | 1 | 332.70 | 26.39 |

0.0002 |

| X5 | 1,550.39 | 1 | 1,550.39 | 122.97 | <0.0001 |

| X6 | 950.18 | 1 | 950.18 | 75.36 | <0.0001 |

|

X1X4 | 170.69 | 1 | 170.69 | 13.54 |

0.0032 |

|

X1X5 | 113.21 | 1 | 113.21 | 8.98 |

0.0111 |

|

X1X6 | 197.68 | 1 | 197.68 | 15.68 |

0.0019 |

| Curvature | 268.28 | 1 | 268.28 | 21.28 |

0.0006 |

| Residual | 151.29 | 12 | 12.61 |

|

|

| Lack of fit | 144.99 | 9 | 16.11 | 7.66 |

0.0605 |

| Pure error | 6.31 | 3 | 2.10 |

|

|

| Corrected

total | 3,734.43 | 19 |

|

|

|

CCD and response surface analysis for

liposomal ACEI peptides preparation

RSM is a popular and effective method to solve

multivariate problems and optimize several responses in many types

of experimentation (28,29). Based on the results of FFD

analysis, the factors (X1, X5 and

X6) were selected for a further optimization of the

entrapment efficiency of liposomal ACEI peptides using a Box-Wilson

CCD with six replicates at center point for each factor. PEG-2000

dosage (X2), NaCl concentration in PBS (X3),

hydration temperature (X4) were set as 4%, 50 mM/l and

45°C, respectively. The second-order polynomial equation is as

follows: Y2=78.34+1.89 X1-7.46

X5-9.89 X6-0.13 X1

X5-2.57 X1 X6+2.79 X5

X6-4.06

X12-13.29X52-0.61

X62; where Y2 is the predicted

entrapment efficiency in real value, and X1,

X5 and X6 are the coded values of independent

variable the ratio of phospholipids to cholesterol, ultrasound time

and the ratio of phospholipids to ACEI peptides, respectively.

Table II presents

results of the second-order response surface model in the form of

ANOVA. The Fisher's F-test with a very low probability value

[(Prob>F) <0.0001] indicated the model was highly

significant. The model fitted the data with an acceptable

determination coefficient (R2=0.9761) and no significant

lack-of-fit (P=0.1491), which indicated that the sample variation

of 97.61% could be attributed to the independent variables, and the

model did not explain only 2.39% of the total variations. The

adjusted determination coefficient (R2=0.9546) was also

satisfactory to confirm the significance of the model. Meanwhile,

the low value of coefficient of variation (CV=5.26%) implicated

accuracy and reliability of the experiments.

| Table II.Analysis of variances for the

entrapment efficiency (Y2) in coded level variables. |

Table II.

Analysis of variances for the

entrapment efficiency (Y2) in coded level variables.

| Source | Sum of squares | Degrees of

freedom | Mean square | F-value | P-value

(Prob>F) |

|---|

| Model | 4,927.74 | 9 | 547.53 | 45.35 | <0.0001 |

| X1 | 48.58 | 1 | 48.58 | 4.02 |

0.0727 |

| X5 | 759.19 | 1 | 759.19 | 62.88 | <0.0001 |

| X6 | 1,337.10 | 1 | 1,337.10 | 110.74 | <0.0001 |

|

X1X5 | 0.13 | 1 | 0.13 | 0.01 |

0.9192 |

|

X1X6 | 52.75 | 1 | 52.75 | 4.37 |

0.0631 |

|

X5X6 | 62.49 | 1 | 62.49 | 5.17 |

0.0462 |

|

X12 | 238.00 | 1 | 238.00 | 19.71 |

0.0013 |

|

X52 | 2,544.30 | 1 | 2,544.30 | 210.72 | <0.0001 |

|

X62 | 5.29 | 1 | 5.29 | 0.44 |

0.5231 |

| Residual | 120.74 | 10 | 12.07 |

|

|

| Lack of fit | 88.18 | 5 | 17.64 | 2.71 |

0.1491 |

| Pure error | 32.56 | 5 | 6.51 |

|

|

| Corrected

total | 5,048.48 | 19 |

|

|

|

The regression analysis showed that the ultrasound

time (X5) and the ratio of phospholipids to ACEI

peptides (X6) had a very significant linear effect on

entrapment efficiency. Meanwhile the ultrasound time

(X5) and the ratio of cholesterol to phospholipids

(X1) exhibited a significant quadratic effect

(P<0.01). In addition, an interaction between the ultrasound

time and the ratio of phospholipids to ACEI peptides for the

entrapment efficiency (P<0.05) was also observed. The linear

effects of X1, quadratic effect of

X62 and interaction effects of

X1X5 and X1X6 were

demonstrated to be non-significant on the entrapment efficiency of

liposomal ACEI peptides.

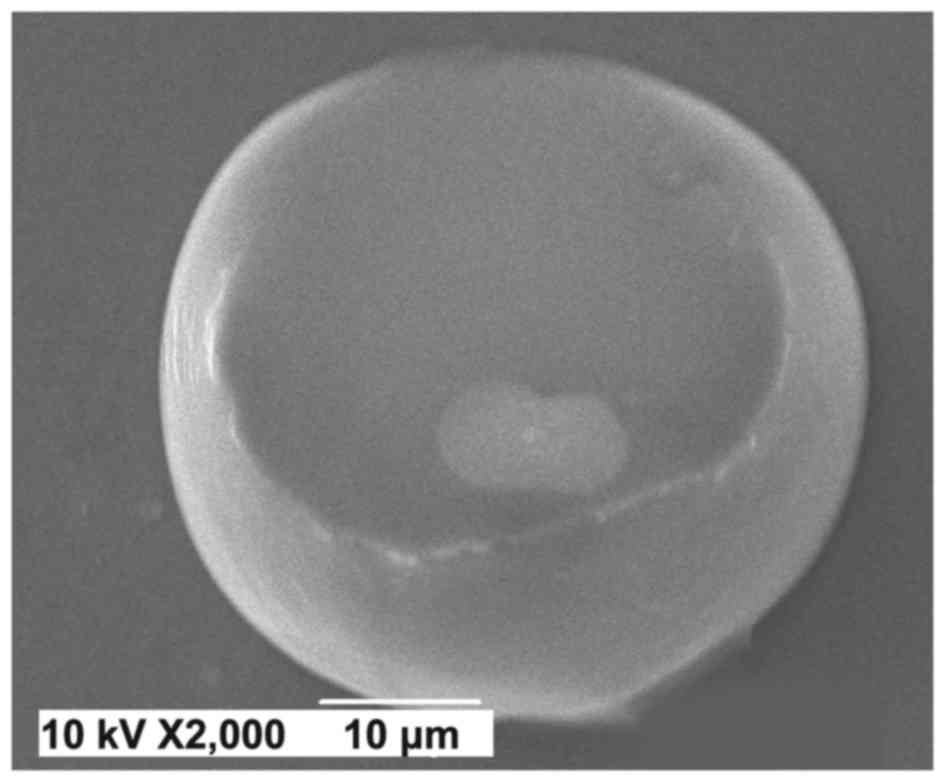

To illustrate the interaction of the ratio of

phospholipids to cholesterol, ultrasound time and ratio of

phospholipids to ACEI peptides and to efficiently optimize the

variables, 3D response surface plots and the 2D contour plots were

obtained. As shown in Fig. 3, a

visual interpretation of the interactions between the two

independent variables on the entrapment efficiency was observed,

while the third variable was held at zero level. The circular

contour plots of response surfaces suggest that the interaction is

negligible among the corresponding variables. An elliptical or

saddle nature of the contour plots indicates the significance of

the interactions between the corresponding variables. In the case

of saddle contour plots, the optimum values are obtained at the

point of intersection of lines, which are formed by joining the

locus (30).

Fig. 3A and B

demonstrate that entrapment efficiency of liposomal ACEI peptides

was increased with the increase of ultrasound time from 5 to 10

min, while it was decreased when the ultrasound time was >10

min. The result was similar to a previous publication (31). The entrapment efficiency was

increased with the ratio of phospholipids to cholesterol until a

peak was detected at ~3:1 (w:w). In Fig. 3B, the saddle contour plots

demonstrated that interactions between phospholipids to cholesterol

ratio and phospholipids to ACEI peptides ratio also reached optimum

levels. Fig. 3C shows that the

entrapment efficiency of liposomal ACEI peptides increased with the

decrease of the ratio of phospholipids to ACEI peptides from 25:1

to 15:1 (w:w) when the ratio of phospholipids to cholesterol was

set. There was a saddle in the contour plot (Fig. 3C), indicating the significance of

interactions between ultrasound time and the ratio of phospholipids

to ACEI peptides.

Validation of the experimental

design

The optimum conditions for the entrapment efficiency

of liposomal ACEI peptides were calculated based on the data

obtained using the ‘response optimizer’ option of Design-Expert

software. The optimal values of each variable in coded units were

as follows: X1=0.55, X5=−0.39 and

X6=−1. Their actual values were 4.1:1 (w:w) of

phospholipids to cholesterol ratio (X1), 8.05 min of

ultrasound time (X5) and 15:1 (w:w) of phospholipids to

ACEI peptides ratio (X6), respectively. The model

predicted that the entrapment efficiency of liposomal ACEI peptides

could reach 90.86% by using the above optimized condition of the

variables. The experiments were repeated three times to validate

the suitability of the model equations. The entrapment efficiency

(91.25±0.182%, n=3) was obtained from the real experiments,

indicating validation of the RSM model.

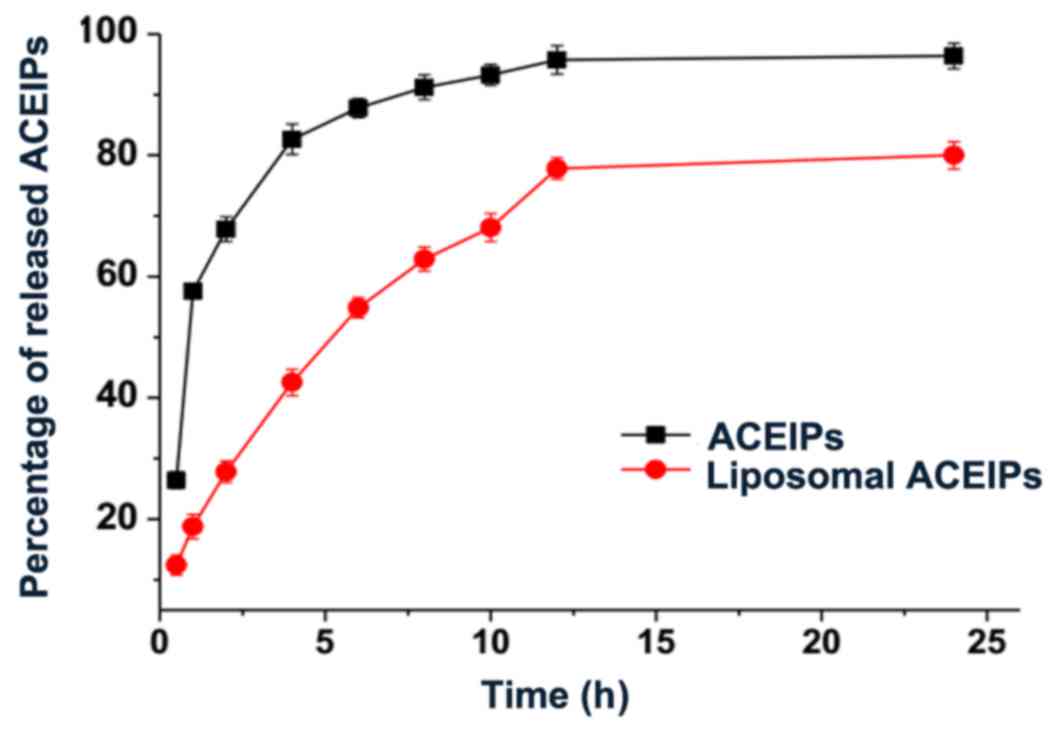

ACEI peptides release assay

The liposomal ACEI peptides were subjected to

release experiments in vitro in order to provide information

about the efficiency of release of ACEI peptides from liposome. As

reported in Fig. 4, the percentage

of ACEI peptides released in phosphate buffer was 95.74% after 12

h, whereas it was 77.83% after 12 h for liposomal ACEI peptides.

The release of liposome-entrapped ACEI peptides was significantly

delayed compared with ACEI peptides in phosphate buffer.

Furthermore, the fitted equation of the percentage of ACEI peptides

released vs. release time was calculated based on different release

models (zero-order dynamic, one-order dynamic, Korsmeyer-Peppas,

Higuchi, logistic) (32,33). The logistic model and one-order

dynamic model were well-fitted with the release percentage of ACEI

peptides (adjusted R2 of 0.9883 and 0.9841,

respectively).

In conclusion, liposomal ACEI peptides derived from

sunflower protein hydrolysates were prepared with the aims of

improving entrapment efficiency and sustaining release. The ratio

of phospholipids to cholesterol, ultrasound time and the ratio of

phospholipids to ACEIPs were notable factors affecting entrapment

efficiency. Under optimal experimental conditions, the entrapment

efficiency of liposomal ACEIPs was 91.25±0.182%. The percentage of

released of liposomal ACEIPs was reduced by 17.91% compared with

ACEIPs in phosphate buffer after 12 h. However, there are some

limitations of the present study. The release of liposome-entrapped

ACEIPs in simulated gastric fluid and simulated intestinal fluid

was not investigated, and the stability of liposomes was also not

analyzed under long durations of preservation; further

investigation is required.

Acknowledgements

The present study was partially supported by a grant

of College Students' Innovative Training Program of China (grant

no. 201410759048).

References

|

1

|

Ogihara T, Mikami H, Katahira K and Otsuka

A: Comparative study of the effects of three angiotensin converting

enzyme inhibitors on the cough reflex. Am J Hypertens. 4:46S–51S.

1991. View Article : Google Scholar : PubMed/NCBI

|

|

2

|

Ong L and Shah NP: Influence of probiotic

Lactobacillus acidophilus and L. helveticus on proteolysis, organic

acid profiles and ACE-inhibitory activity of cheddar cheeses

ripened at 4, 8 and 12 degrees C. J food sci. 73:M111–M120. 2008.

View Article : Google Scholar : PubMed/NCBI

|

|

3

|

Ong L and Shah NP: Release and

identification of angiotensin-converting enzyme-inhibitory peptides

as influenced by ripening temperatures and probiotic adjuncts in

cheddar cheeses. LWT-Food Sci Technol. 41:1555–1566. 2008.

View Article : Google Scholar

|

|

4

|

Hwang JS: Impact of processing on

stability of angiotensin I-converting enzyme (ACE) inhibitory

peptides obtained from tuna cooking juice. Food Res Int.

43:902–906. 2010. View Article : Google Scholar

|

|

5

|

Chen J, Liu S, Ye R, Cai G, Ji B and Wu Y:

Angiotensin-I converting enzyme (ACE) inhibitory tripeptides from

rice protein hydrolysate: Purification and characterization. J

Functional Foods. 5:1684–1692. 2013. View Article : Google Scholar

|

|

6

|

Gu Y and Wu J: LC-MS/MS coupled with QSAR

modeling in characterising of angiotensin I-converting enzyme

inhibitory peptides from soybean proteins. Food Chem.

141:2682–2690. 2013. View Article : Google Scholar : PubMed/NCBI

|

|

7

|

White BL, Sanders TH and Davis JP:

Potential ACE-inhibitory activity and nanoLC-MS/MS sequencing of

peptides derived from aflatoxin contaminated peanut meal. LWT-Food

Sci Technol. 56:537–542. 2014. View Article : Google Scholar

|

|

8

|

Ngo DH, Ryu B and Kim SK: Active peptides

from skate (Okamejei kenojei) skin gelatin diminish angiotensin-I

converting enzyme activity and intracellular free radical-mediated

oxidation. Food Chem. 143:246–255. 2014. View Article : Google Scholar : PubMed/NCBI

|

|

9

|

Udenigwe CC, Lin YS, Hou WC and Aluko RE:

Kinetics of the inhibition of renin and angiotensin I-converting

enzyme by flaxseed protein hydrolysate fractions. J Functional

Foods. 1:199–207. 2009. View Article : Google Scholar

|

|

10

|

Vaštag Ž, Popović L, Popović S, Krimer V

and Peričin D: Production of enzymatic hydrolysates with

antioxidant and angiotensin-I converting enzyme inhibitory activity

from pumpkin oil cake protein isolate. Food Chem. 124:1316–1321.

2011. View Article : Google Scholar

|

|

11

|

Megias C, del Mar Yust M, Pedroche J,

Lquari H, Girón-Calle J, Alaiz M, Millán F and Vioque J:

Purification of an ACE inhibitory peptide after hydrolysis of

sunflower (Helianthus annuus L.) protein isolates. J agric food

chem. 52:1928–1932. 2004. View Article : Google Scholar : PubMed/NCBI

|

|

12

|

Megias C, Pedroche J, Yust Mdel M, Alaiz

M, Girón-Calle J, Millan F and Vioque J: Affinity purification of

angiotensin converting enzyme inhibitory peptides using immobilized

ACE. J Agric Food Chem. 54:7120–7124. 2006. View Article : Google Scholar : PubMed/NCBI

|

|

13

|

Du B, Li Y, Li XAY, Chen C and Zhang Z:

Preparation, characterization and in vivo evaluation of

2-methoxyestradiol-loaded liposomes. Int J Pharm. 384:140–147.

2010. View Article : Google Scholar : PubMed/NCBI

|

|

14

|

Milla P, Dosio F and Cattel L: PEGylation

of proteins and liposomes: A powerful and flexible strategy to

improve the drug delivery. Current Drug Metab. 13:105–119. 2012.

View Article : Google Scholar

|

|

15

|

Vemuri S and Rhodes CT: Preparation and

characterization of liposomes as therapeutic delivery systems: A

review. Pharm Acta Helv. 70:95–111. 1995. View Article : Google Scholar : PubMed/NCBI

|

|

16

|

Andrade CA, Correia MT, Coelho LC,

Nascimento SC and Santos-Magalhaes NS: Antitumor activity of

Cratylia mollis lectin encapsulated into liposomes. Int J Pharm.

278:435–445. 2004. View Article : Google Scholar : PubMed/NCBI

|

|

17

|

Pereira-Lachataignerais J, Pons R, Panizza

P, Courbin L, Rouch J and Lopez O: Study and formation of vesicle

systems with low polydispersity index by ultrasound method. Chem

Phys Lipids. 140:88–97. 2006. View Article : Google Scholar : PubMed/NCBI

|

|

18

|

Silva R, Little C, Ferreira H and

Cavaco-Paulo A: Incorporation of peptides in phospholipid

aggregates using ultrasound. Ultrason Sonochem. 15:1026–1032. 2008.

View Article : Google Scholar : PubMed/NCBI

|

|

19

|

Shaw GJ, Meunier JM, Huang SL, Lindsell

CJ, McPherson DD and Holland CK: Ultrasound-enhanced thrombolysis

with tPA-loaded echogenic liposomes. Thromb Res. 124:306–310. 2009.

View Article : Google Scholar : PubMed/NCBI

|

|

20

|

Villanueva A, Vioque J, Sánchez-Vioque R,

Clemente A, Pedroche J, Bautista J and Millán F: Peptide

characteristics of sunflower protein hydrolysates. J Amer Oil Chem

Soc. 76:1455–1460. 1999. View Article : Google Scholar

|

|

21

|

Dadzie R, Ma H, Abano E, Qu W and Mao S:

Optimization of process conditions for production of angiotensin

I-converting enzyme (ACE) inhibitory peptides from vital wheat

gluten using response surface methodology. Food Sci Biotechnol.

22:1531–1537. 2013. View Article : Google Scholar

|

|

22

|

Yu Z, Liu B, Zhao W, Yin Y, Liu J and Chen

F: Primary and secondary structure of novel ACE-inhibitory peptides

from egg white protein. Food Chem. 133:315–322. 2012. View Article : Google Scholar : PubMed/NCBI

|

|

23

|

Ferreira H, Lúcio M, Lima JL, Matos C and

Reis S: Interaction of clonixin with EPC liposomes used as membrane

models. J Pharm Sci. 94:1277–1287. 2005. View Article : Google Scholar : PubMed/NCBI

|

|

24

|

Cortesi R, Argnani R, Esposito E, Dalpiaz

A, Scatturin A, Bortolotti F, Lufino M, Guerrini R, Cavicchioni G,

Incorvaia C, et al: Cationic liposomes as potential carriers for

ocular administration of peptides with anti-herpetic activity. Int

J Pharm. 317:90–100. 2006. View Article : Google Scholar : PubMed/NCBI

|

|

25

|

Jeong JM, Chung YC and Hwang JH: Enhanced

adjuvantic property of polymerized liposome as compared to a

phospholipid liposome. J Biotechnol. 94:255–263. 2002. View Article : Google Scholar : PubMed/NCBI

|

|

26

|

Huang YZ, Gao JQ, Liang WQ and Nakagawa S:

Preparation and characterization of liposomes encapsulating

chitosan nanoparticles. Biol Pharm Bull. 28:387–390. 2005.

View Article : Google Scholar : PubMed/NCBI

|

|

27

|

Moeller EH, Holst B, Nielsen LH, Pedersen

PS and Østergaard J: Stability, liposome interaction and in vivo

pharmacology of ghrelin in liposomal suspensions. Int J Pharm.

390:13–18. 2010. View Article : Google Scholar : PubMed/NCBI

|

|

28

|

McDonald DB, Grantham WJ, Tabor WL and

Murphy MJ: Global and local optimization using radial basis

function response surface models. Applied Math Model. 31:2095–2110.

2007. View Article : Google Scholar

|

|

29

|

Dong X, Pan R, Zou S, He M and Wang C:

Oxidative degradation of the sulfated polysaccharide isolated from

sea cucumber Holothuria nobilis. Process Biochem. 50:294–301. 2015.

View Article : Google Scholar

|

|

30

|

Murthy MSRC, Swaminathan T, Rakshit SK and

Kosugi Y: Statistical optimization of lipase catalyzed hydrolysis

of methyloleate by response surface methodology. Bio Eng. 22:35–39.

2000. View Article : Google Scholar

|

|

31

|

Chang L and Zhao Y: Studies on preparation

and properties of Vc nano liposomes. J Appli Sci Eng Innov.

1:237–240. 2014.

|

|

32

|

Nounou MM, El-Khordagui LK, Khalafallah NA

and Khalil SA: In vitro release of hydrophilic and hydrophobic

drugs from liposomal dispersions and gels. Acta Pharm. 56:311–324.

2006.PubMed/NCBI

|

|

33

|

Boyd BJ, Whittaker DV, Khoo SM and Davey

G: Lyotropic liquid crystalline phases formed from glycerate

surfactants as sustained release drug delivery systems. Int J

Pharm. 309:218–226. 2006. View Article : Google Scholar : PubMed/NCBI

|