Introduction

Seed cells and scaffold material are two main issues

that are addressed in cartilage tissue engineering. Bone marrow

mesenchymal stem cells (BMMSCs), being among the most commonly used

seed cells in tissue engineering, have the ability to differentiate

multi-directionally and can be generously amplified in

vitro. Therefore, BMMSCs may be induced to differentiate into

chondroblasts through various methods in order to construct

cartilage-engineered tissue and provide seed cells.

BMMSCs in vivo mostly exist in the bone

marrow at a static state, but when stimulated by physiological and

pathological factors, their proliferation ability is demonstrated

and BMMSCs differentiate into fat cells, bone cells and

chondroblasts (1). Studies have

shown that during the differentiation process from BMMSCs to

chondrocytes, TGF-β1, one of the most important growth factors

(2), can induce BMMSCs to

differentiate into chondrocytes and promote the secretion of type

II collagen and the synthesis and accumulation of extracellular

matrix (3,4). Therefore, the TGF-β1 gene can be

transferred into BMMSCs using gene transfer technology to ensure

stable expression of TGF-β1, and BMMSCs can be persistently

induced. This has become an ideal method in cartilage tissue

engineering. Transcriptional enhancer factor TAZ (transcriptional

coactivator with PDZ-binding motif) is one type of side line gene

of the Yes-associated protein (YAP) that can regulate the

transcription expression of Smad, BMP-2 and Runx, while the

induction of TGF-β1 in BMMSCs is closely related to Smad, BMP-2,

Runx and others (5,6). After transfection of TGF-β1, during

the differentiation of BMMSCs to phenotypic chondrocytes, the

method for effectively altering TAZ expression is still

questionable. The present study was designed for a preliminarily

investigation of this issue.

Most cell growth in vivo is wrapped in a

three-dimensional environment similar as a niche box. For example,

wrapped chondrocytes in vivo grow in cartilage matrix. At

present, the antilinear of prepared and applicated porous scaffolds

are usually much larger than that of cells; the cells are planted

in such materials and can only spread and grow in an adherent

manner, which is actually a two-dimensional (monolayer) culture

model. This two-dimensional (monolayer) culture is not an effective

manner to simulate cell growth in vivo in a

three-dimensional micro-environment. Studies have shown that a

three-dimensional environment is crucial for the maintenance of

cell morphology and biological activity. Gel material has

hydrophilicity which is suitable for cell embedding. It highly

simulates the in vivo environment of cell growth, and

provides a space similar to the natural substrate and chemical

structure and signal transduction environment for cell growth

(7). Alginate calcium is a type of

saccharan composed of a different number of gulonic and mannuronic

acids. Alginate calcium itself is biodegradable and biocompatible.

This study was designed to investigate the feasibility of

constructing tissue-engineered cartilage in a three-dimensional

culture in vitro after embedding hTGF-β1 gene-transferred

BMMSCs in alginate gel material.

Materials and methods

Experimental animals

Wistar rats, 120±15 g, male or female, were

purchased from the Experimental Animal Center of Wuhan University

(Wuhan, China).

Reagents

Fetal calf serum, L-DMEM medium containing 10% fetal

calf serum, tryptase, rat anti-human TGF-β1 and collagen II

polyclonal antibody were obtained. Goat anti-rat IgG secondary

antibody, an immunohistochemistry kit, TRIzol reagent and a western

blotting kit were obtained. The adenovirus with the EGFP gene

(Ad-EGFP) and adenovirus with human transforming growth factor

(Ad-hTGF)-β1 gene were constructed and preserved in our laboratory.

Sodium alginate, calcium chloride and PCR primers were synthesized

by Shanghai Biological Engineering Company.

Procurement and culture of BMMSCs

After ether anesthesia, the rats were sacrificed and

soaked in 75% ethanol degeneration for 10 min. The femur was

removed and the soft tissues were cleanly shaved. Both sides of the

bone were opened with a rongeur, and the two femurs were placed in

10 ml L-DMEM medium containing 10% fetal calf serum. The bone

marrow cavity was repeatedly flushed until turning white using

medium in a 5-ml sterile syringe. The obtained cell suspension was

repeatedly pipetted and mixed, and then the cell suspension was

seeded in 60-mm sterile Petri dishes, and placed in a 95%

humidified incubator at 37°C in 5% CO2 for incubation.

The medium was replaced every 3–4 days, when the cells covered

70–80% of the dish. The cells were subsequently digested and

subcultured with trypsin containing 0.25% EDTA. Third-generation

cells were selected for use in the experiment.

Cell transfection and experimental

groups

The third generation cells were seeded in 12-well

plates at 1×105/ml (400 μl/well). When the cells

reached 60% confluence, the cells were divided into three groups:

the Ad-hTGF-β1-transfected group [serum-free medium with Ad-hTGF-β1

(MOI value of 200)], the Ad-EGFP-transfected group [serum-free

medium with Ad-EGFP (MOI value of 200)]. The media in the two

groups were replaced by complete medium after >48 h. The control

group was cultured in complete medium with no treatment. The three

groups of cells were placed in a 95% humidified incubator at 37°C

in 5% CO2.

mRNA expression of TGF-β1 and TAZ in

BMMSCs in the three groups as detected by real-time PCR

The various cultured cells were obtained 7 days

after transfection, and total-RNA was extracted with TRIzol reagent

according to the manufacturer’s instructions. β-actin was used as

the housekeeping gene. Embedded dye SYBR-Green I was used for

real-time quantitative PCR amplification. The primers were: TGF-β1

upstream primer, CGCAACAACGCAATCTATG and downstream primer,

ACCAAGGTAACGCCAGGA, base length 204 bp. The PCR amplification

system (25 μl) contained 2.5 μl Plus solution, 12.5

μl SYBR-Green mix, 1 μl of each of the upstream and

downstream primer (5 pmol/μl), 2.5 μl cDNA and 5.5

μl deionized water. Amplification conditions were: 50°C for

2 min, 95°C for 2 min, then a 95°C denaturation for 15 sec, and

58°C annealing for 15 sec, a 72°C extension for 45 sec, for a total

of 40 cycles, then 72°C for 10 min.

Western blotting for the detection of

TGF-β1 protein expression in the transfected BMMSCs

The cultured cells were obtained 7 days after

transfection and were rinsed three times with cold PBS at 4°C. The

lysis buffer-containing cocktail (1 ml lysis buffer plus 20

μl cocktail, prepared 5 min prior to use) was added at 4°C

and schizolysis was performed for 30 min. Percussion was carried

out with a pipette 10 times every 5 min to collect the cell

lysates. After centrifugation at 12,000 rpm for 10 min, the

supernatant was collected at room temperature. Fifteen microliters

was added/lane in an SDS-polyacrylamide gel electrophoresis tank,

in Tris-glycine electrophoresis buffer for electrophoresis and was

transferred to acetate film. The film was blocked with non-fat dry

milk for 2 h in room temperature. Then blocking fluid and rat

anti-human TGF-β1 (dilution 1:200) polyclonal antibody was added

and oscillated for 2 h at 4°C and washed three times with PBS.

Tris-Cl solution was added and incubated for 10 min at room

temperature, then blocking solution and goat anti-rat IgG secondary

antibody were added and incubated at room temperature for 1 h. The

membrane was then transferred to Tris-Cl and incubated for 10 min.

Horseradish peroxidase was added to produce the color images.

Results were repeated three times, and GAPDH was used as a

housekeeping gene.

Preparation of the cell-calcium alginate

gel compound

Preparation of the sodium

polymannuronate suspension

The sodium alginate powder (Sigma) was dissolved in

double distilled water at 12 g/l at room temperature agitated with

a magnetic stirrer overnight. To fully dissolve the sodium alginate

solution, the pH was adjusted to 7.0–8.0, and eas then reserved

after high temperature and high pressure sterilization.

Preparation of compound cell-calcium

alginate gel

The successfully transfected BMMSCs were digested,

centrifugated and counted, and were separately and thoroughly mixed

with sterile sodium alginate suspension at a final concentration of

1.0×107 cells/ml. Excess calcium chloride was added at

102 mmol/l solution, and was kept standing for 20–30 min. Then the

cells were washed 3–4 times with D-Hank’s solution, and the

formative cell-calcium alginate gel compound was suspended in

culture medium at 37°C in a 95% humidified incubator for culture.

The culture medium was replaced every 3–4 days, and the cells were

determined after 10 days of culture.

Proliferation of transfected cells

determined by MTT assay and the number of BMMSCs in the calcium

alginate gel material

The transfected cells in each group were obtained

and digested with pancreatic enzyme containing 0.25% EDTA into a

single-cell suspension, and the cell concentration was adjusted to

1×105/ml and cells were seeded into a 96-well cell

culture plate (200 μl/well). At the same time point at 1, 2,

3, 4, 5, 6 days after transfection, the cells from three wells were

randomly selected from the cells in each group, the culture medium

was discarded, 20 μl MTT was added (5 g/l) and culturing was

carried out for 4 h. After removal of the supernatant, 150

μl DMSO was added and oscillated for approximately 10 min.

The extinction A value (OD) of each well was determined at 490 nm

wavelength in a microplate reader, and the cell growth curve was

drawn according to the measured values.

At the same time points 1, 2, 3, 4, 5, 6 days after

cells were seeded in the alginate gel material, the cells were

extracted and suspensed, and the cell concentration was adjusted to

1×105/ml. The cells from the three wells were randomly

selected from the cells in each group, the culture medium was

discarded, 20 μl MTT was added (5 g/l) and culturing was

carried out for 4 h. After removing the supernatant, 150 μl

DMSO was added and oscillated for approximately 10 min. The

extinction A value (OD) in each well was determined at 490 nm

wavelength in the microplate reader and the cell growth curve was

drawn according to the measured values.

Histological and histochemical

staining

Ten days after the culture of the cell-calcium

alginate gel compound in vitro, the compound was extracted

and washed with PBS. The compound was fixed in 4% paraformaldehyde

and embedded in paraffin according to the conventional method. It

was cut into 4-μm slices, and H&E, Masson’s and

toluidine blue staining were performed, respectively, according to

conventional methods, amd the results were examined under an

inverted optical microscope.

Collagen II protein determined by

immunohistochemistry

After the 10-day culture in vitro, the

cell-calcium alginate gel compound was extracted and washed with

PBS. The compound was fixed in 4% paraformaldehyde and embedded in

paraffin according to a conventional method. It was cut into

4-μm slices. SABC assay was used to detect collagen II

expression. The primary antibody of collagen II was rat anti-human

collagen II polyclonal antibody (1:100), and the secondary antibody

was goat anti-rat IgG (1:200). The protocol was according to the

manufacturer’s instructions, and the results were observed and

tested under an inverted optical microscope and photographed.

Data analysis

Data are expressed as the means ± SD, said the

group. The comparison of group differences was carried out using

the analysis of variance. SPSS13.0 statistical software was used

for statistical analysis, and P<0.05 indicated a significant

difference.

Results

Morphology of BMMSC in primary culture

and cells cultured in calcium alginate gel

After 72 h of primary culture, BMMSCs were observed

to exhibit adherence and colony formation. The cells were

spindle-shaped and polygonal-based which continued for the 7- to

9-day culture. When the cells reached 80–90% confluence, the speed

of cell proliferation was significantly rapid after passage. The

cells were uniform and continued to grow. After 2–3 days, the cells

reached 80–90% confluence, and the cells exhibited a long

spindle-shape (Fig. 1). After

BMMSCs were grown in calcium alginate gel, they were evenly

distributed in the gel layer, and their shape was spherical

(Fig. 2).

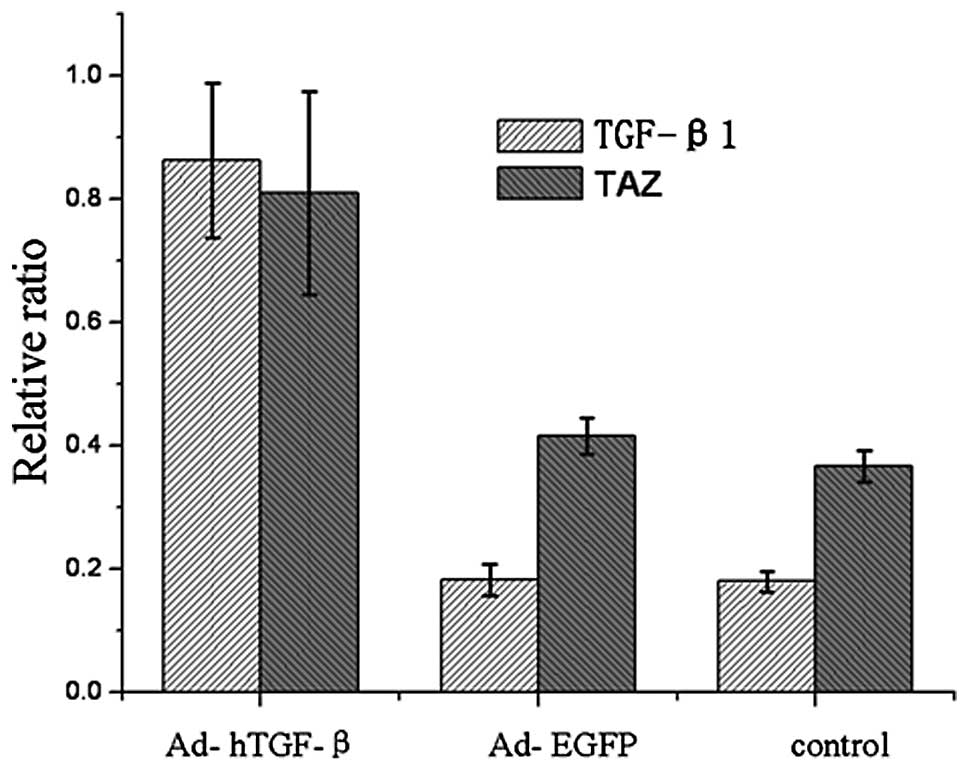

mRNA expression of TAZ and TGF-β1 in

the transfected cells as determined by real-time PCR

As shown in Fig. 3,

7 days after transfection, the

mRNA expression of TGF-β1 and TAZ in the Ad-hTGF-β1-transfected

group was significantly higher than levels in the

Ad-EGFP-transfected and the control groups.

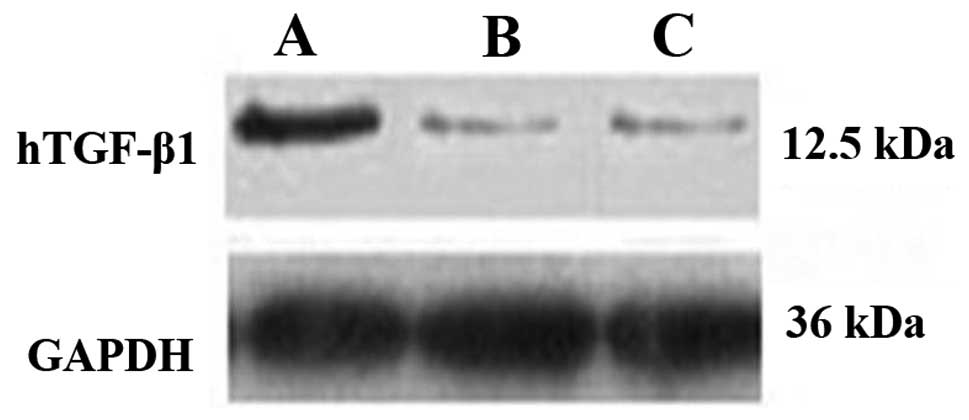

Protein expression of TGF-β1 in the

transfected BMMSCs as determined by western blotting

As shown in Fig. 4,

7 days after transfection, the

protein expression of TGF-β1 in the Ad-hTGF-β1-transfected group

was significantly higher than that of the Ad-EGFP-transfected and

control groups (Fig. 4).

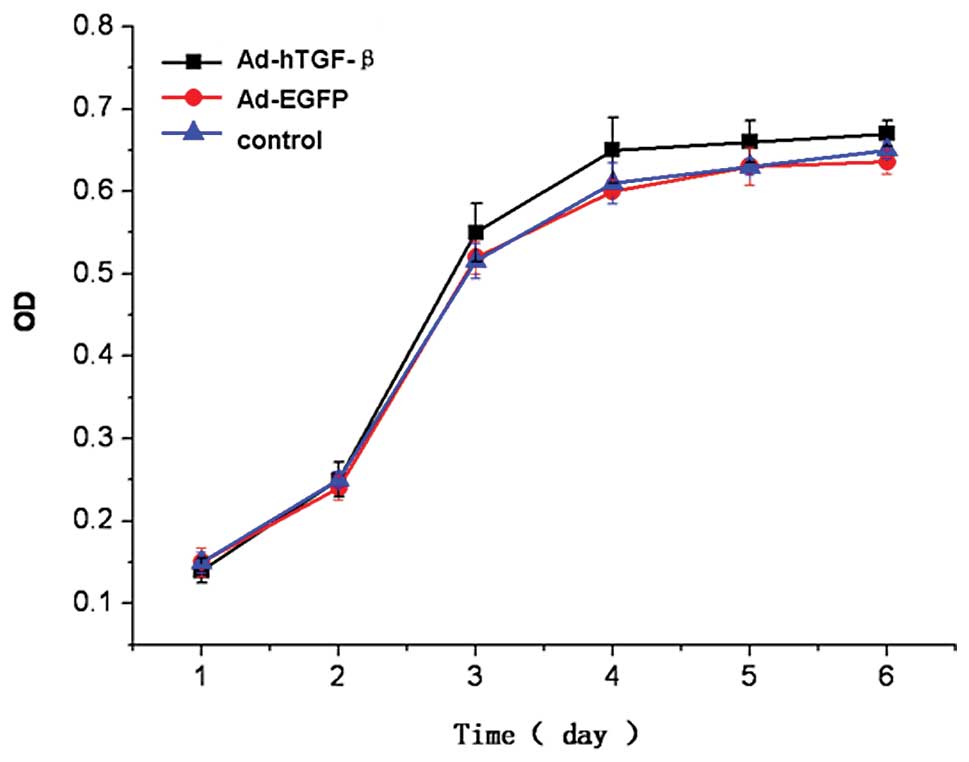

Cell proliferation ability in the

transfected BMMSCs as determined by MTT assay

The results from the MTT colorimetric assay showed

that after transfection, days 1 and 2 after cell seeding in the

three groups was considered to be a period of delitescence, day 3

was considered as the logarithmic growth phase, day 4 was

considered as the platform phase. The cell growth curves for the

three groups were similar, and the difference in absorbance (OD) at

each time point was not statistically significant (P=0.718, 0.670,

0.246, 0.192, 0.172, 0.094) (Fig.

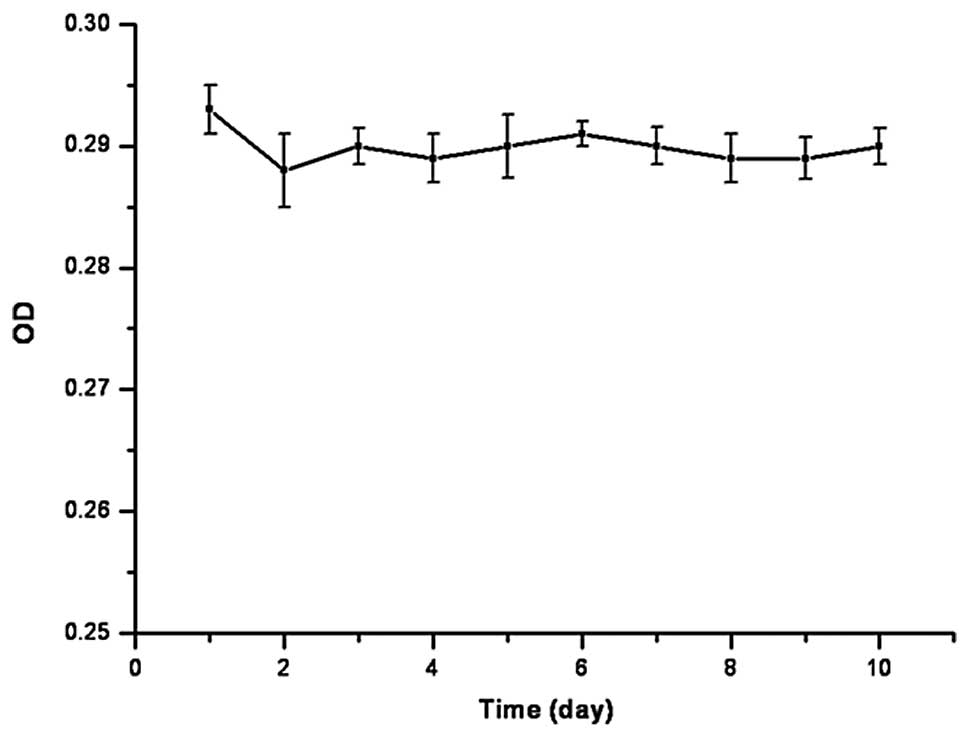

5). At the same time, after the cells were seeded on the

calcium alginate gel, the cell growth curve did not change

significantly, and difference in the absorbance (OD) at each time

point was not statistically significant (P=0.473) (Fig. 6)

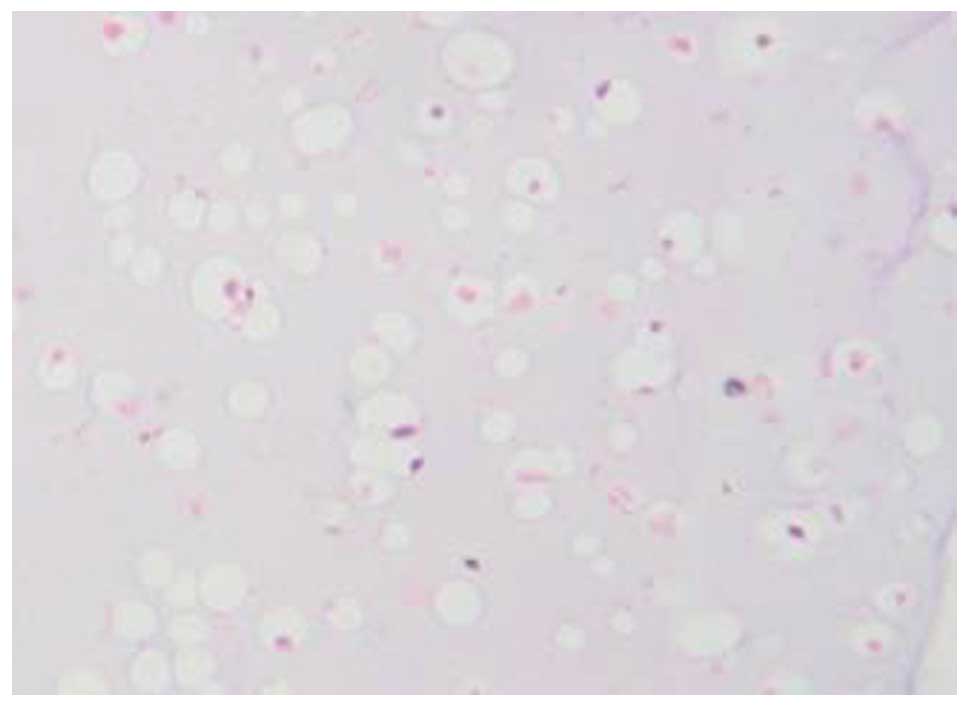

Histological and histochemical

observations

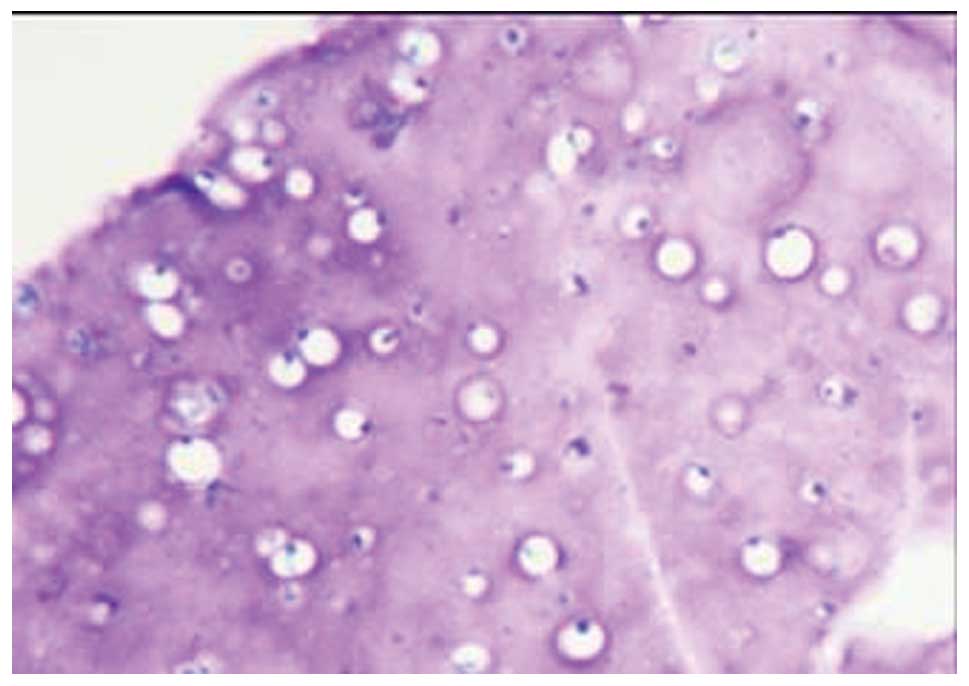

H&E staining showed that a large number of

cartilage lacunae were formed in the gel material, and the

nucleolus was clearly visible (Fig.

7). Masson staining showed the synthesis and secretion of type

II collagen in the gel material (Fig.

8). Toluidine blue staining confirmed the synthesis and

secretion of proteoglycan in the gel material (Fig. 9).

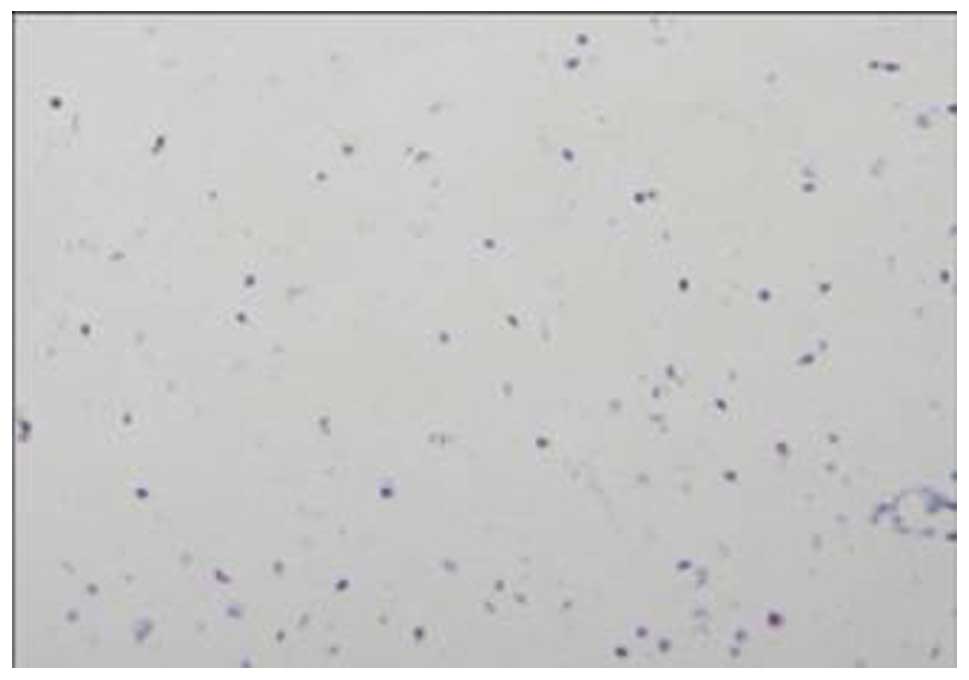

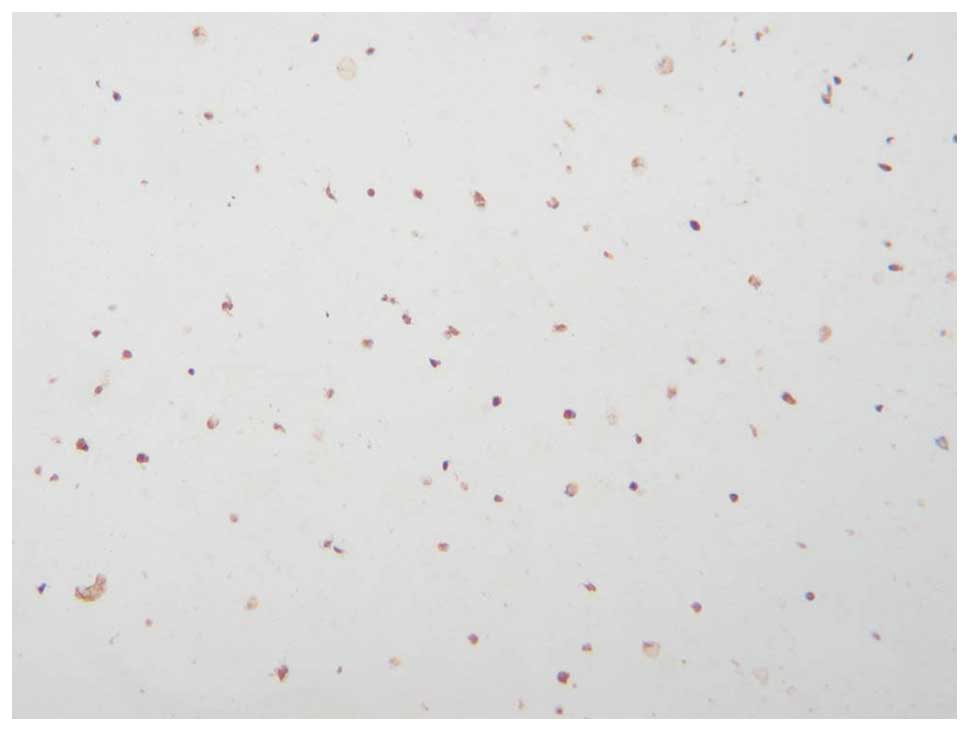

Type II collagen determined by

immunohistochemistry

The results from type II collagen determined by

immunohistochemistry showed that 10 days of culture in vitro

after the Ad-hTGF-β1-transfected cells were seeded in the gel

material, brown particles were present in the gel material. This

indicated that BMMSCs synthesized and secreted type II collagen

(Fig. 10).

Discussion

Seed cells for application in the tissue engineering

of cartilage include chondrocytes and mesenchymal stem cells, yet

autologous chondrocytes are not easily obtained, the source is

limited and their use easily leads to cartilage damage of draw

material parts. Previous studies have shown that only

1.8–4.5×105 chondrocytes can be extracted from a trauma

patient with knee injury with a single femoral condyle articular

cartilage (2), which is not enough

for chondrocyte transplantation (3). In contrast, mesenchymal stem cells

are easily obtained, can be amplified in vitro and have a

strong ability to differentiate into cartilage cells, particularly

mesenchymal stem cells. Thus, we chose bone marrow mesenchymal stem

cells as seed cells in this study. TGF-β1 is known to be a growth

factor in bone that can induce BMMSCs to differentiate into

chondrocytes, TGF-β1 is also one of the most important factors

causing BMMSCs to differentiate into cartilage (4). In view of these facts, gene transfer

technology was used to transfer the TGF-β1 gene into BMMSCs using a

standard method. TGF-β1 can steadily induce BMMSC differentiation

but does not affect the proliferation rate of BMMSCs. In this

study, after BMMSCs were transfected with Ad-hTGF-β1, the results

from real-time PCR and western blotting showed that TGF-β1

expression in the Ad-hTGF-β1-transfected cells was significantly

higher than levels in the Ad-EGFP-transfected and control group

cells; a fact indicating that we successfully constructed BMMSCs

with high expression of TGF-β1.

The role of TGF-β1 in the differentiation of BMMSCs

was found to be affected by Smad, BMP-2 and Runx genes (5). TAZ is one of the YAP sideline genes,

and regulates the expression of Smad, BMP-2 and Runx at the

transcription level, and it also affects the life of BMMSCs

(6). In this study, we designed

primer sequences to detect TAZ mRNA, and the expression differences

of TAZ mRNA were detected between the experimental and control

groups through real-time quantitative PCR. The results showed that

the level of TAZ mRNA in the Ad-hTGF-β1-transfected cell group was

significantly higher than levels in the Ad-EGFP-transfected and

control groups (P<0.05). This indicates that BMMSCs transfected

by Ad-hTGF-β1 induced BMMSC differentiation into chondrocytes due

to the increased expression of TGF-β1, while the mRNA level of TAZ

was also increased in this process. Therefore, we speculated that

TAZ may play a regulatory role in the process of TGF-β1-induced

BMMSC differentiation to chondrocyte phenotype. However, several

studies have also demonstrated that in the process of

TGF-β1-induced BMMSC differentiation into osteoblasts, the

expression level of TAZ is increased (7,8).

Therefore, it remains to be investigated how TAZ regulates the

process of TGF-β1-induced BMMSC differentiation to chondrocytes and

osteoblasts.

In a healthy organism, in addition to blood cells in

the circulatory system, other cells are grown in a relatively

stable three-dimensional space structure. In this structure, the

cells are packaged in the extracellular matrix, and soluble growth

factors distributed in the extracellular matrix are able to bind to

receptors on the cell surface and play a role in regulating the

activity of cell biology (9). At

the same time, interactions between cells also play a regulatory

role in the biological activity of cells. For mesenchymal stem

cells, the extracellular matrix and cell interactions also play an

important role in maintaining the morphology of mesenchymal stem

cells, a fact that directly affects the proliferation and

differentiation activity of mesenchymal stem cells themselves

(10,11). These features require us to take

into account the in vivo environment of the mesenchymal stem

cells in the study of tissue engineering, and thus we tried to

simulate the three-dimensional spatial structure for the growth of

cells in order to maintain the biological activity of mesenchymal

stem cells when constructing tissue-engineering scaffolds.

Research has revealed that a two-dimensional (single

layer) condition is not a good method for maintaining the

biological and biochemical properties of cells (1), particularly those of mesenchymal stem

cells. If the cells are placed in a single- or two-dimensional

culture environment, the ability of cells to differentiate into

cartilage is difficult to maintain. Therefore, material chemistry,

structure, processing technology and bioauxology can be used to

design a three-dimensional cell culture matrix for tissue

engineering with an adequate geometric and chemical composition

similar to the natural extracellular matrix signaling system. In

addition, this unique structure is conducive to the transmission of

soluble molecules, as well as the exchange of nutrients and cell

metabolism waste (12). The

traditional material for cartilage tissue engineering mainly

includes polyvinyl alcohol, polyglycolic acid, polylactic acid,

chitosan and a mixture according to different proportions. The

porous structure of the scaffolds is ensured by a freeze-drying

method, and the seed cells are then seeded in this scaffold.

Concerning the porous scaffold prepared using this method, the pore

size is generally between 200–400 μm (13), while the diameter of the cell is

only a few microns; much smaller than the pore size of the

scaffold. The cells seeded to grow in material with such pores

inevitably make the cells spread and attach to the surface of the

material in an adherent manner, which is actually a two-dimensional

(single) model. It is difficult to maintain the spherical shape of

cells, and the latter is an indispensable condition for mesenchymal

stem cells exerting their biological properties (14). In contrast, gel-like material is

prepared according to the physical and chemical properties of the

biological material itself rather than by a freeze-drying method.

The pore of this material is very small, while a large number of

charged groups are on the surface of gel, which makes the material

highly hydrophilic. This precisely simulates the body’s natural

growth environment of cartilage cells (15). This is extremely beneficial for the

differentiation of mesenchymal stem cells to cartilage cells.

Alginate (e.g. sodium alginate), which is a type of

anionic polysaccharide without a side chain derived from brown

algae, exists as a solid when it interacts with polyvalent cations

(e.g. calcium) (1,16). Alginate displays outstanding

biocompatibility with the host and seed cells in condition of

maintaining their own invariant characteristics (1). In animal experiments, gel complexes

with cartilage cells and alginate has been successfully used in

cartilage transplantation (17,18).

Alginate calcium arises from the crosslink of sodium alginate and

calcium chloride. It has superior biocompatible and absorptive

abilities, and has a porous structure that contributes to material

exchange required by the metabolism (19). In addition, the hydrophilic ability

of alginate makes cells difficult to attach to the surface of

alginate material, a fact that helps to maintain the spherical

structure and stabilize the differentiation of cells (2). A number of studies have shown that

alginate can be used as a three-dimensional material to culture

chondrocytes, since alginate material can simulate the environment

of articular cartilage and induce cartilage cells to secrete

proteoglycans and maintain the surrounding chondrocytes (20). However, it is still unclear whether

BMMSCs gene-modified using an alginate calcium-gel complex can be

used to successfully construct tissue engineered cartilage in

vitro. In the present study, after BMMSCs were successfully

transfected by Ad-hTGF-β1, they were generously amplified in

vitro. The cells at 1.0×107/ml were mixed in sodium

alginate (17) to become a cell

suspension, and calcium chloride was added and fully cross-linked

with the sodium alginate-cell suspension and finally made into a

hydrogel combined with calcium alginate-cells. BMMSCs were observed

in the gel material in a uniformly distributed manner under an

inverted microscope and grew in a spherical state (Fig. 2), which is required to maintain the

stability of the cell morphology, and simulate the grow morphous of

cells in the body to ensure the biological and biochemical

characteristics of cells. It effectively avoids the shortcoming of

adherent growth of cells cultured in a common two-dimensional

(single) manner. We used MTT assay in vitro, to detect the

cell number and found that the number of cells in the alginate gel

at different times was not significantly different (P=0.473). This

suggests that the cells embedded in the alginate gel can obtain the

required nutrients from the medium in vitro to ensure the

required energy of normal cells and maintain the cell activity, yet

at the same time, the cells do not undergo rapid proliferation in

the gel material as the gel material is unable to provide adequate

space for cell proliferation.

To confirm the differentiation of cartilage cells in

gel using BMMSCs modified by hTGF-β1 combined with alginate

calcium, after 10 days of culture in vitro, we adopted

H&E, toluidine blue and Masson’s staining for application to

the alginate-cells combined with gel materials. The results showed

that a large number of lacunae and a great amount of cartilage

proteoglycans and collagen was found in the gel material. The

results from immunohistochemistry showed that type II collagen can

be produced in the cultured cells from gel material. This indicates

that after the Ad-TGF-β1-transfected mesenchymal stem cells were

cultured in alginate calcium gel they were steadily differentiated

into cartilage.

Our preliminarily experimental results showed that

BMMSCs modified by the hTGF-β1 gene can be used as seed cells for

the tissue engineering of cartilage, while calcium alginate gel

material provides the required three-dimensional structure for

cartilage differentiation of seed cells. Alginate gel can be used

as a suitable carrier material for cartilage tissue engineering.

However, a key defect of gel material is that the mechanical

properties cannot reach the requirements of vito-dynamics. We

expect that in future studies, three-dimensional alginate gel

materials will be able to be combined with the superior mechanical

ability of a porous scaffold to develop more comprehensive tissue

engineering scaffolds. In addition, the detailed mechanism involved

in the three-dimensional culture environment affecting stem cell

proliferation and differentiation remains to be further

investigated.

Acknowledgements

This study was supported by the

National Natural Science Foundation of China (grants 30770574) as

well as by the Science and Technology Foundation of Hubei Health

Department (JX3B21).

References

|

1

|

Ghidoni I, Chlapanidas T, Bucco M, et al:

Alginate cell encapsulation: new advances in reproduction and

cartilage regenerative medicine. Cytotechnology. 58:49–56. 2008.

View Article : Google Scholar : PubMed/NCBI

|

|

2

|

Lin YJ, Yen CN, Hu YC, et al: Chondrocytes

culture in three-dimensional porous alginate scaffolds enhanced

cell proliferation, matrix synthesis and gene expression. J Biomed

Mater Res A. 88:23–33. 2009. View Article : Google Scholar : PubMed/NCBI

|

|

3

|

Kanda C, Barry WO and Marie-Paule I:

Effects of growth factors on cell proliferation and matrix

synthesis of low-density, primary bovine chondrocytes cultured in

collagen I gels. J Orthop Res. 20:1070–1078. 2002. View Article : Google Scholar : PubMed/NCBI

|

|

4

|

Yao Xiawan, Wei Liu, Tianyi Liu, et al:

Application of bone marrow stromal cells in vitro tubular cartilage

tissue engineering experiments. Chin J Microsurg. 28:328–330.

2005.

|

|

5

|

Jian Zhao and Wei Xu: Bone marrow

mesenchymal stem cells and embryonic stem cells into cartilage

cells into possible molecular mechanisms [J]. Tissue Eng

Reconstructive Surg. 2:53–57. 2006.PubMed/NCBI

|

|

6

|

Hong JH, Hwang ES, McManus MT, et al: TAZ,

a transcriptional modulator of mesenchymal stem cell

differentiation. Science. 309:1074–1078. 2005. View Article : Google Scholar : PubMed/NCBI

|

|

7

|

Zhao L, Jiang S and Hantash BM: TGF-beta1

induces osteogenic differentiation of murine bone marrow stromal

cells. Tissue Eng Part A. 16:725–733. 2010. View Article : Google Scholar : PubMed/NCBI

|

|

8

|

Hong JH and Yaffe MB: TAZ: a

beta-catenin-like molecule that regulates mesenchymal stem cell

differentiation. Cell Cycle. 5:176–179. 2006. View Article : Google Scholar : PubMed/NCBI

|

|

9

|

Lund AW, Yener B, Stegemann JP and Plopper

GE: The natural and engineered 3D microenvironment as a regulatory

cue during stem cell fate determination. Tissue Eng Part B Rev.

15:371–380. 2009. View Article : Google Scholar : PubMed/NCBI

|

|

10

|

Purpura KA, Aubin JE and Zandstra PW:

Sustained in vitro expansion of bone progenitors is cell density

dependent. Stem Cells. 22:39–50. 2004. View Article : Google Scholar : PubMed/NCBI

|

|

11

|

McBeath R, Pirone DM, Nelson CM, et al:

Cell shape, cytoskeletal tension, and RhoA regulate stem cell

lineage commitment. Dev Cell. 6:483–495. 2004. View Article : Google Scholar : PubMed/NCBI

|

|

12

|

Liu WF and Chen CS: Cellular and

multicellular form and function. Adv Drug Deliv Rev. 59:1319–1328.

2007. View Article : Google Scholar : PubMed/NCBI

|

|

13

|

Burg KJ, Porter S and Kellam JF:

Biomaterial developments for bone tissue engineering. Biomaterials.

21:2347–2359. 2000. View Article : Google Scholar : PubMed/NCBI

|

|

14

|

Benya PD and Shaffer JD: Dediferentiated

chondrocytes reexpress the differentiated collagen phenotype when

cultured in agarose gels. Cell. 30:215–224. 1982. View Article : Google Scholar : PubMed/NCBI

|

|

15

|

Vinatier C, Guicheux J, Daculsi G, et al:

Cartilage and bone tissue engineering using hydrogels. Biomed Mater

Eng. 16:S107–S113. 2006.PubMed/NCBI

|

|

16

|

Dobratz EJ, Kim SW, Voglewede A and Park

SS: Injectable cartilage: using alginate and human chondrocytes.

Arch Facial Plast Surg. 11:40–47. 2009. View Article : Google Scholar : PubMed/NCBI

|

|

17

|

Chang SC, Rowley JA, Tobias G, et al:

Injection molding of chondrocyte / alginate constructs in the shape

of facial implants. J Biomed Mater Res. 55:503–511. 2001.

View Article : Google Scholar : PubMed/NCBI

|

|

18

|

Chang SC, Tobias G, Roy AK, Vacanti CA and

Bonassar LJ: Tissue engineering of autologous cartilage for

craniofacial reconstruction by injection molding. Plast Reconstr

Surg. 112:793–799. 2003. View Article : Google Scholar : PubMed/NCBI

|

|

19

|

Yi Guoquan and Shibi Lu: Alginate

properties and applications in cartilage tissue engineering. Chin J

Orthopaedic Surg. 14:216–218. 2006.

|

|

20

|

Kamishina H, Miyabayashi T, Clemmons RM,

et al: Three-dimensional culture of feline articular chondrocytes

in alginate microspheres. J Vet Med Sci. 68:1239–1242. 2006.

View Article : Google Scholar : PubMed/NCBI

|