Introduction

The future use of titanium alloys as implant

materials is predicted to increase due to their good

biocompatibility, mechanical properties and chemical stability

(1). Titanium alloys are also

lightweight, possess high toughness and tensile ductility, a high

corrosion resistance and the ability to withstand extreme

temperatures (2). Titanium alloys

are roughly classified into four categories depending on their

purity and crystal structures: commercially pure titanium (CP-Ti);

α alloy (body-centered cubic structure, BCC); β alloy (hexagonal

close-packed structure, HCP) and α + β dual-phase alloy (3). Compared with α and α + β types,

β-type titanium alloy offers a more advantageous material for

dental implants due to its improved mechanical properties, higher

corrosion resistance and a lower modulus of elasticity (4). Ti-6Al-4V, an α + β type titanium

alloy, is the most widely used titanium alloy for medical implants,

including orthopedic, dental and cardiovascular implants (5). However, the elastic modulus of

Ti-6Al-4V alloy is 4–10 times that of human bone, and an elastic

modulus mismatch between bone and implant material has often been

cited as a cause of implant failure (6). Furthermore, the elements Al and V of

Ti-6Al-4V alloy are capable of being released into tissue cells by

passive film dissolution, which may induce Alzheimer’s disease,

neuropathy, osteomalacia and allergic reactions. Therefore, novel

titanium alloys containing non-toxic and non-allergic elements,

including Nb, Ta, Zr, Mo and Sn, have been designed and constructed

for biomedical applications (7).

The novel β-type titanium alloy Ti-24Nb-4Zr-8Sn (Ti2448) has

attracted considerable attention due to its high strength, high

fatigue resistance and a low elastic modulus (8). An in vivo study of Ti2448 in

New Zealand white rabbits demonstrated that the low elastic modulus

of Ti2448 leads to significant improvements in new bone formation

following a tibial shaft fracture compared with a Ti-6Al-4V alloy

(9). These results suggest that

intramedullary nails constructed of low modulus Ti2448 alloy

improve new bone formation in the marrow cavity during the initial

stages of bone healing.

Since titanium is biologically inert and does not

bond directly nor immediately to the bone following implantation,

electrochemical anodic oxidation has been applied to improve a

number of the surface characteristics of titanium, including

corrosion resistance, cell proliferation, cell adhesion and cell

viability (10). Anodic oxidation

is generally considered as a useful method for modifying the

surface structure of titanium in several ways, including corrosion

protection, aspect improvement and bonding of polymers (11). The anodic oxidation technique is

capable of forming a nanoporous titanium oxide film of controllable

pore size, good uniformity and conformability over large areas at

low cost (12). Titanium oxide

films with nanoporous structures are desirable for these

applications due to their large surface areas and high reactivity

(13). It has also been reported

that the interactions between osteoblasts and titanium oxide films

involve chemical reactions (14).

Greater surface roughness and surface energy, more surface hydroxyl

groups and the presence of fibronectin or vitronectin are important

elements for the adhesion, spreading and proliferation of

osteoblasts on titanium surfaces (14,15).

However, the majority of studies have focused on osteoblast

adhesion using a sol-gel derived hydroxyapatite coating on

Ti-6Al-4V alloy (16–18). Few studies have been published with

regard to nanoporous titanium oxide films on Ti2448 alloy formed by

anodic oxidation with a typical pore size <100 nm. Therefore, we

hypothesize that nanostructured oxide films may enhance osteoblast

cell adhesion on Ti2448 alloys.

In the present study, the effects of the surface

characteristics of nanoporous titanium oxide films on the initial

adhesion of osteoblast-like MG-63 cells was investigated.

Nanoporous titanium oxide films with two different pore sizes (30

and 90 nm) were formed by anodization in NH4F solution

on Ti2448 alloy. Titanium surface roughness was examined using a

Surftest Formtracer and field emission scanning electron microscopy

(FESEM). Cells were evaluated for cell viability at different time

points using the

3-(4,5-dimethylthiazol-2-yl)-2,5-diphenyltetrazolium bromide (MTT)

assay. To investigate the regulatory mechanisms involved in the

focal adhesion of osteoblasts to Ti2448 alloys, the expression

levels of integrin β1 and paxillin mRNAs in response to the surface

structure of nanoporous titanium oxide films during the initial

osteoblast adhesion were quantified using real-time RT-PCR. The

present study may serve as a foundation for the development and

clinical application of Ti2448 alloy as a novel implant

material.

Materials and methods

Preparation of nanoporous titanium oxide

films on Ti2448 alloys

Ti2448 alloys were purchased from Shenyang National

Laboratory for Materials Science, Institute of Metal Research,

Chinese Academy of Sciences (Shenyang, China). Disks of 10-mm

diameter [used for scanning electron microscopy (SEM) analysis and

in the MTT assay] and 30-mm diameter (used for real-time RT-PCR

analysis) were cut from Ti2448 alloys using a diamond cut-off wheel

(Struers, Glasgow, UK). Prior to electrochemical anodization, the

sheets were ground using 2400-grit emery paper (Softflex, Bad

Säckingen, Germany) and polished with diamond paste (6 μm).

The samples were then degreased by sonication for 10 min in

acetone, isopropanol and methanol; following this, the samples were

rinsed with deionized water, dried in a nitrogen stream and stored

covered under UV light (19).

Anodic oxidation treatment of Ti2448 alloys was

performed at room temperature in a neutral electrolyte with 1 mol/l

(NH4)2SO4 and 0.15 mol/l

NH4F (pH 6.7) prepared from analytical grade chemicals

and deionized water. A direct current power supply was used to keep

the potential at a constant value. On several occasions, the

potential was swept from the open circuit potential to the desired

final potential with a sweep rate of 0.5 V/sec. A two-electrode

system, with stainless steel as a cathode and sample as an anode,

was used to form the nanoporous titanium oxide films under

non-stirred conditions. All samples were cleaned using deionized

water following the anodization process.

Anodic oxidation was performed at potentials of 10

and 25 V, and TiO2 nanotubes with diameters of 30 and 90

nm were formed in turn. The anodized samples were named as the 30-

and 90-nm groups, respectively. Samples without anodic oxidation

treatment were used as the control. All samples were cleaned

ultrasonically in acetone, alcohol and deionized water (each for 10

min), and sterilized by cobalt-60 irradiation prior to cell culture

(20,21).

Surface morphology

The anodized specimens were uniformly coated with a

layer of gold for electric conductivity and the morphology of the

nanoporous titanium oxide films was observed using FESEM (LEO model

Supra 35, Oberkochen, Germany) (22). Roughness was measured using a

Surftest Formtracer (Surftest SV-402; Mitutoyo Instruments, Tokyo,

Japan) on three samples of each group. For each sample, five

profiles were recorded (23).

ANOVA was performed to test the homogeneity of the anodization

process of each sample and the reproducibility of this process

between samples of each group. ANOVA was then applied to the usual

roughness parameters (Ra, arithmetic mean deviation of

the roughness profile; Rz, mean peak-to-valley height;

Ry, maximum height of the roughness).

Cell culture

Osteoblast-like MG-63 cells (CRL-1427; American Type

Culture Collection, Manassas, VA, USA) were cultured in Dulbecco’s

modified Eagle’s medium (DMEM) (Invitrogen Life Technologies,

Carlsbad, CA, USA), supplemented with 2 mM L-glutamine (Invitrogen

Life Technologies), 10% fetal calf serum (FCS; Eurobio, Paris,

France) and 50 μg/ml gentamicin sulfate (Sigma, St. Louis,

MO, USA). Cultures were maintained at 37°C in a humidified

incubator in the presence of 5% CO2 and subcultures were

performed using a 0.01% trypsin solution in phosphate-buffered

saline (PBS) at pH 7.4. The cultures were observed daily under an

inverted microscope (magnification, ×400). Media were changed every

other day. The cells were routinely passaged until they reached 80%

confluency (14).

The titanium disks were placed in a 24-well plate

with a cell density of 5,000/cm2 (for SEM analysis and

in the MTT assay) or a 6-well plate with a cell density of

50,000/cm2 (for real-time RT-PCR analysis). The cells

were cultured for different incubation periods according to the

study design.

Cell morphology

Following 48 h incubation, the cultured disks were

rinsed three times with PBS and fixed with 2.5% glutaraldehyde

diluted in 0.1 M PBS for 2 h at 4°C, postfixed in 1% osmium

tetroxide, dehydrated in graded ethanol series, treated with

hexamethyldisilazane (Sigma) and then subjected to critical point

drying. A thin layer of palladium-gold was sputter coated onto the

samples prior to examination by FESEM (24).

MTT assay

MTT is transformed by mitochondrial dehydrogenases

into formazan, enabling mitochondrial activity and cell viability

to be assessed. Following incubation, the samples were washed with

PBS and transferred to a new 24-well plate. Then, 300 μl

culture medium and 300 μl MTT reagent (5 mg/ml in PBS;

Sigma) were added to each well. Following 4 h incubation in a 5%

CO2 incubator at 37°C, the medium was replaced with 500

μl dimethyl sulfoxide to dissolve formazan. The plate was

shaken for 10 min and then the solution in each well was

transferred to a 96-well ELISA plate. The optical density (OD)

value of the dissolved solute was measured using an ELISA reader

(Tecan, Grödig, Austria) at 570 nm (n=9 for each group). The common

OD value of the blank group was subtracted from the OD value in

each group at each time point (n=9). The blank group was treated

with the same methods and incubated for the same time as those in

the above three groups (25).

Real-time RT-PCR assay

Following 24 and 48 h incubation, the samples were

washed with PBS and transferred to a new 6-well plate. Total RNA

was extracted from the cultured cells using the TRIzol™

reagent (Invitrogen Life Technologies) according to the

manufacturer’s instructions. First strand cDNA was synthesized from

10 μg total RNA using the PrimeScript™ first

strand cDNA synthesis kit (Takara Bio, Inc., Osaka, Japan). PCR

primers were designed using Primer Express 2.0 software (Applied

Biosystems, Foster City, CA, USA). The primer sequences and

products of selected genes for real-time PCR are summarized in

Table I. Real-time PCR was used to

quantify the gene expression levels of integrin β1 and paxillin

when the cells had been cultured for 24 and 48 h, and the standard

PCR cycle threshold (Ct) method was performed using the Roche

Molecular Biochemicals LightCycler instrument (Roche Diagnostics

GmbH, Mannheim, Germany).

| Table I.Real-time PCR primer sequences. |

Table I.

Real-time PCR primer sequences.

| Gene | Access number (Gene

Bank) | PCR primer

sequences | Length

(nucleotides) | Cycle number | PCR products

(bp) |

|---|

| Integrin β1 | X07979 |

5′-TTACGATGACGGTCTGGG-3′ | 18 | 46 | 122 |

|

3′-AAATGGCTTGTGCTTGTT-5′ | 18 | | |

| Paxillin | P49023 |

5′-CTGCTGGCGGACTT-3′ | 14 | 23 | 120 |

|

3′-TGGCACGGCAATCT-5′ | 14 | | |

| GAPDH | M32599 |

5′-GAGCCACATCGCTCAGACAC-3′ | 20 | 24 | 150 |

|

3′-CATGTAGTTGAGGTCAATGG-5′ | 20 | | |

Statistical analysis

Data are presented as mean ± SD, median with

interquartile ranges (IQR) or frequencies. A χ2 test was

used to compare frequencies. One-way ANOVA and the Student’s t-test

were used for normally distributed variables, and the Mann-Whitney

U test was used for non-normal distributed variables. Comparisons

between two groups for nominal variables were performed by Fisher’s

exact test. P<0.05 was considered to indicate a statistically

significant result. All statistical analyses were performed using

SPSS 18.0 software (SPSS, Inc., Chicago, IL, USA).

Results

Morphology and roughness

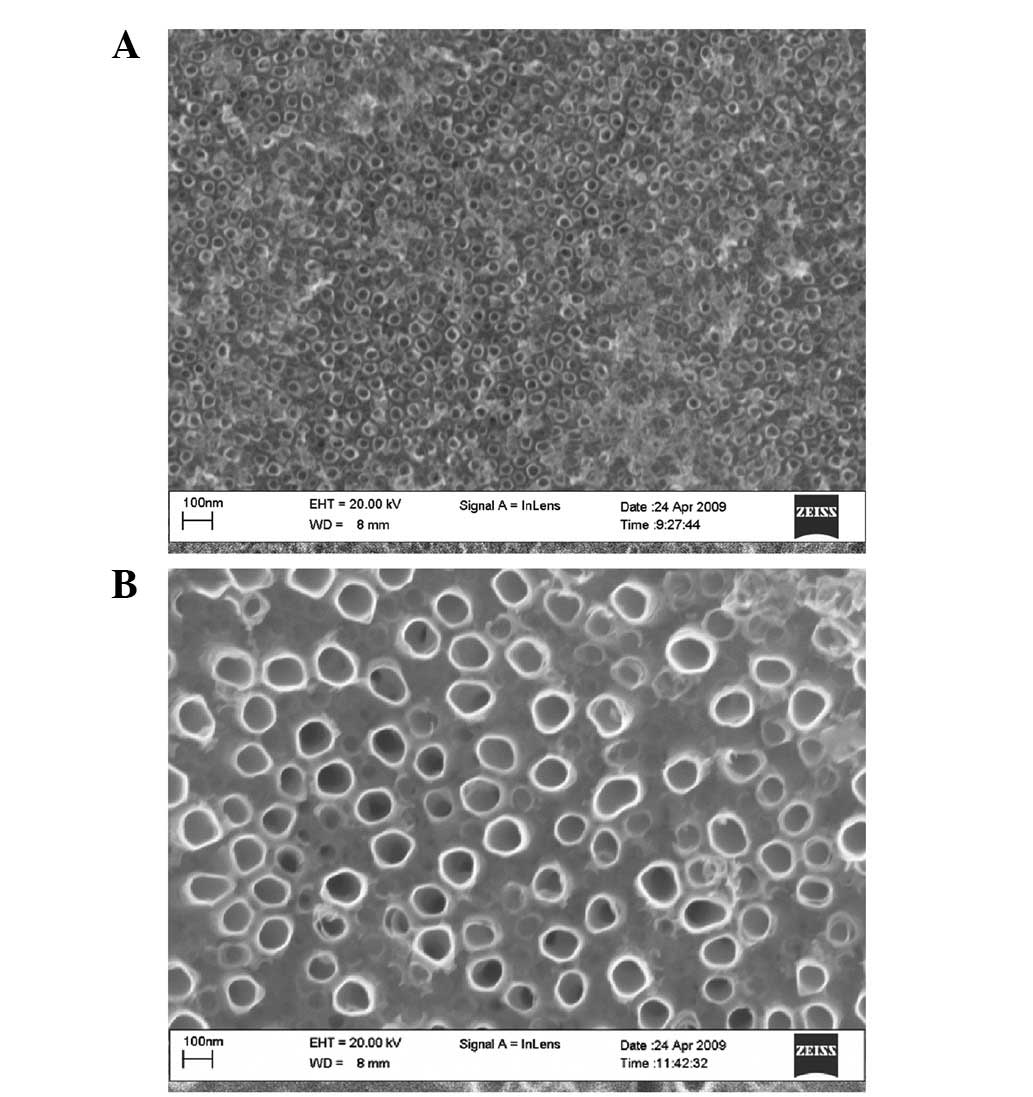

Representative FESEM micrographs of the 30- and

90-nm nanoporous titanium oxide films on Ti2448 alloys are shown in

Fig. 1. Samples with a 30-nm

nanoporous film exhibited a greater number of overlapping

microporous structures with microprojections than samples with a

90-nm nanoporous film. As shown in Table II, the anodized titanium surfaces

(30 and 90 nm) were rougher in comparison with the unanodized

control titanium surface (P<0.05). However, no significant

difference was observed in surface roughness between the 30- and

90-nm nanoporous films (P<0.05).

| Table II.Surface roughness for each group. |

Table II.

Surface roughness for each group.

| Group | Roughness |

|---|

|

|---|

| Ra

(μm) | Rz

(μm) | Ry

(μm) |

|---|

| Control group | 0.28±0.11 | 1.37±0.26 | 1.88±0.17 |

| 30-nm group | 0.76±0.03a | 5.13±0.41a | 6.14±0.29a |

| 90-nm group | 0.71±0.04a | 4.97±0.51a | 5.79±0.56a |

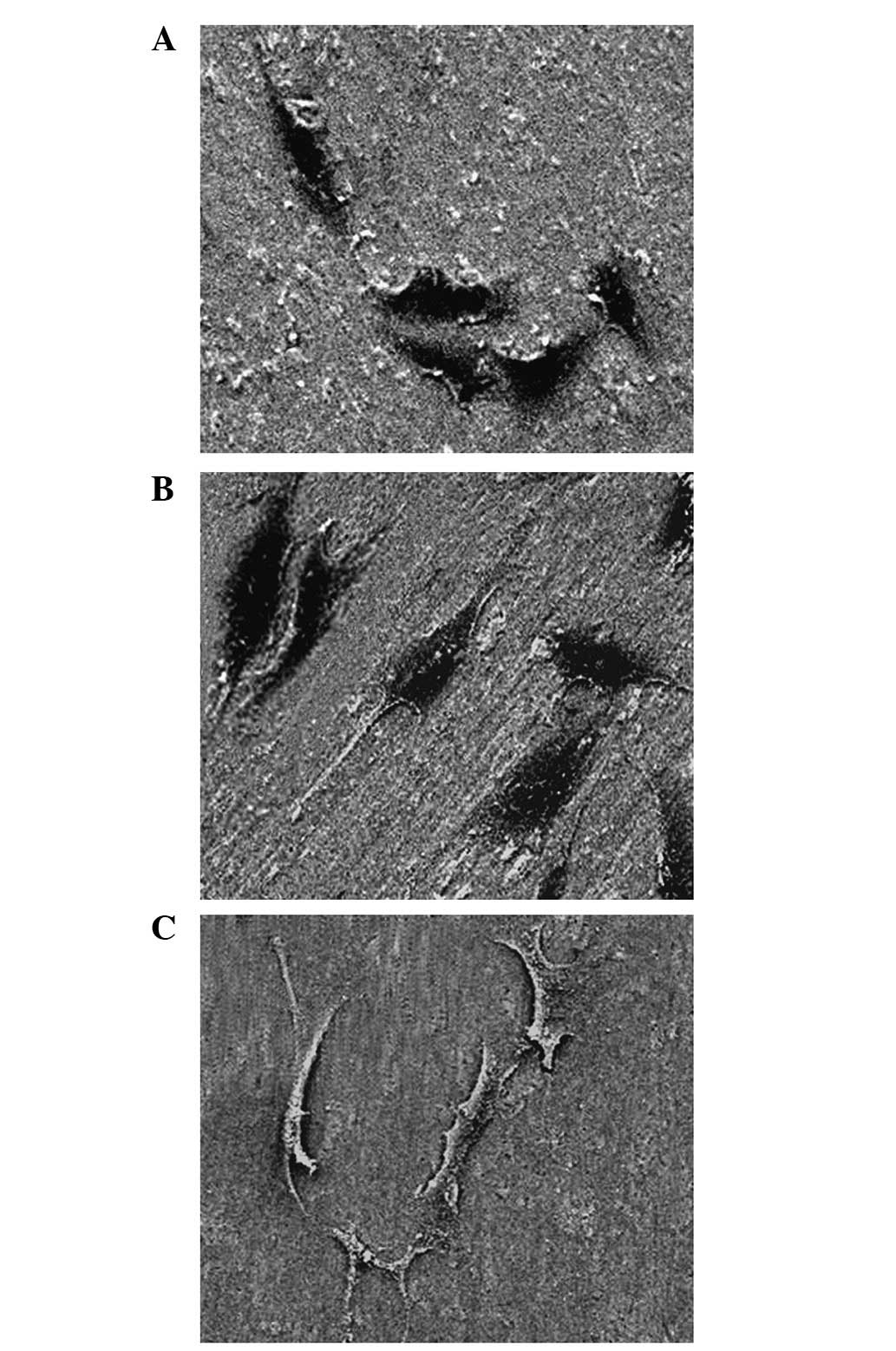

Cell adhesion and morphology

The morphology of the osteoblasts following cell

culture in each group for 48 h is shown in Fig. 2. On the 30-nm nanoporous surface,

the cells were densest on the overlapping structures and formed a

polygonal shape without an evident wrapped edge. On the 90-nm

nanoporous surface, cell adhesion was weaker than that observed on

the unanodized control and 30-nm nanoporous surfaces, and a wrapped

edge was evident. In addition, the cells exhibited a distorted and

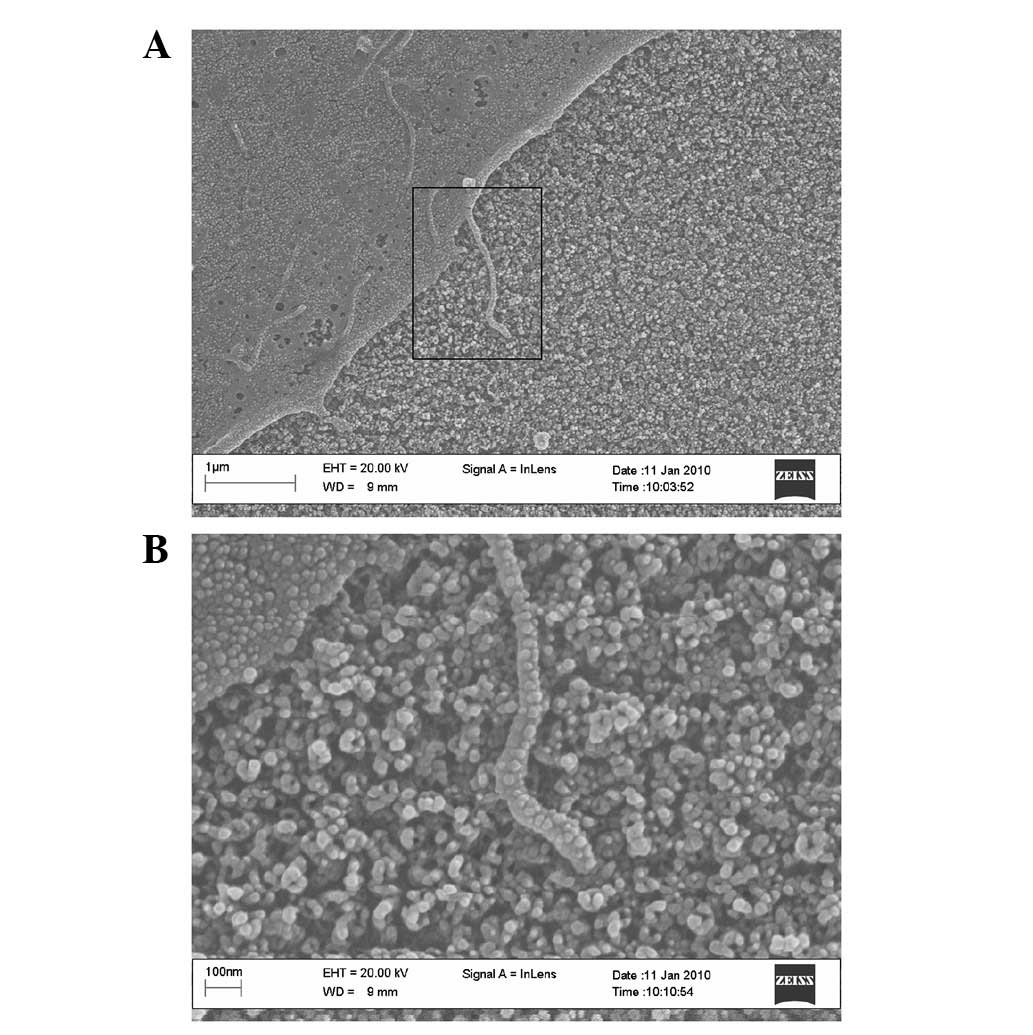

irregular shape. Under a high-magnification microscope, we observed

that the extracellular matrix (ECM) protein adhered densely to the

top wall surface of the 30-nm nanoporous surface (Fig. 3) and adhered sparsely to the 90-nm

nanoporous surface (Fig. 4). We

also observed the extension of filopodias from cells adhered to the

nanoporous surface, which was mediated by ECM proteins, and that

filopodias deviated around the nanoporous openings which were not

covered by ECM proteins.

MTT analysis

As shown in Table

III, the MTT assay indicated that the viabilities of the cells

on the 30-nm nanoporous surface were higher than those on the

unanodized control and 90-nm nanoporous surfaces following 24 and

48 h of culture (P<0.05). The cell viabilities on the 90-nm

nanoporous surface were lower than those on the control unanodized

surface following 48 h of culture (P<0.05), while there was no

significant difference between the cell viabilities of the 90-nm

and control groups following 24 h of culture (P>0.05).

| Table III.Optical density of each group at

different time points examined using the MTT assay. |

Table III.

Optical density of each group at

different time points examined using the MTT assay.

| Group | Time points |

|---|

|

|---|

| 12 h | 24 h | 48 h |

|---|

| Control group | 0.015 | 0.062 | 0.093 |

| 30-nm group | 0.017 | 0.133a,b | 0.184a,b |

| 90-nm group | 0.014 | 0.053 | 0.068a |

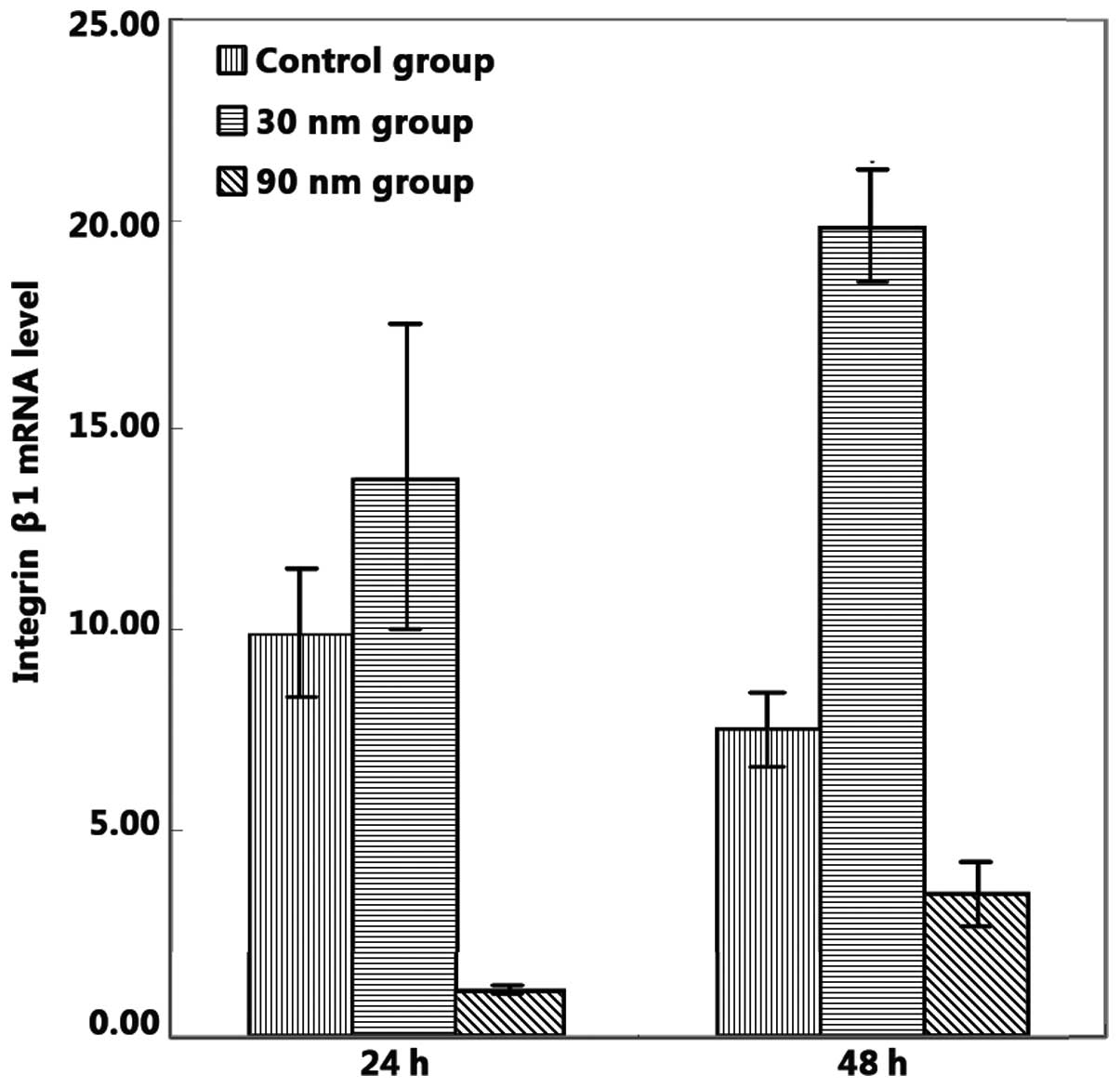

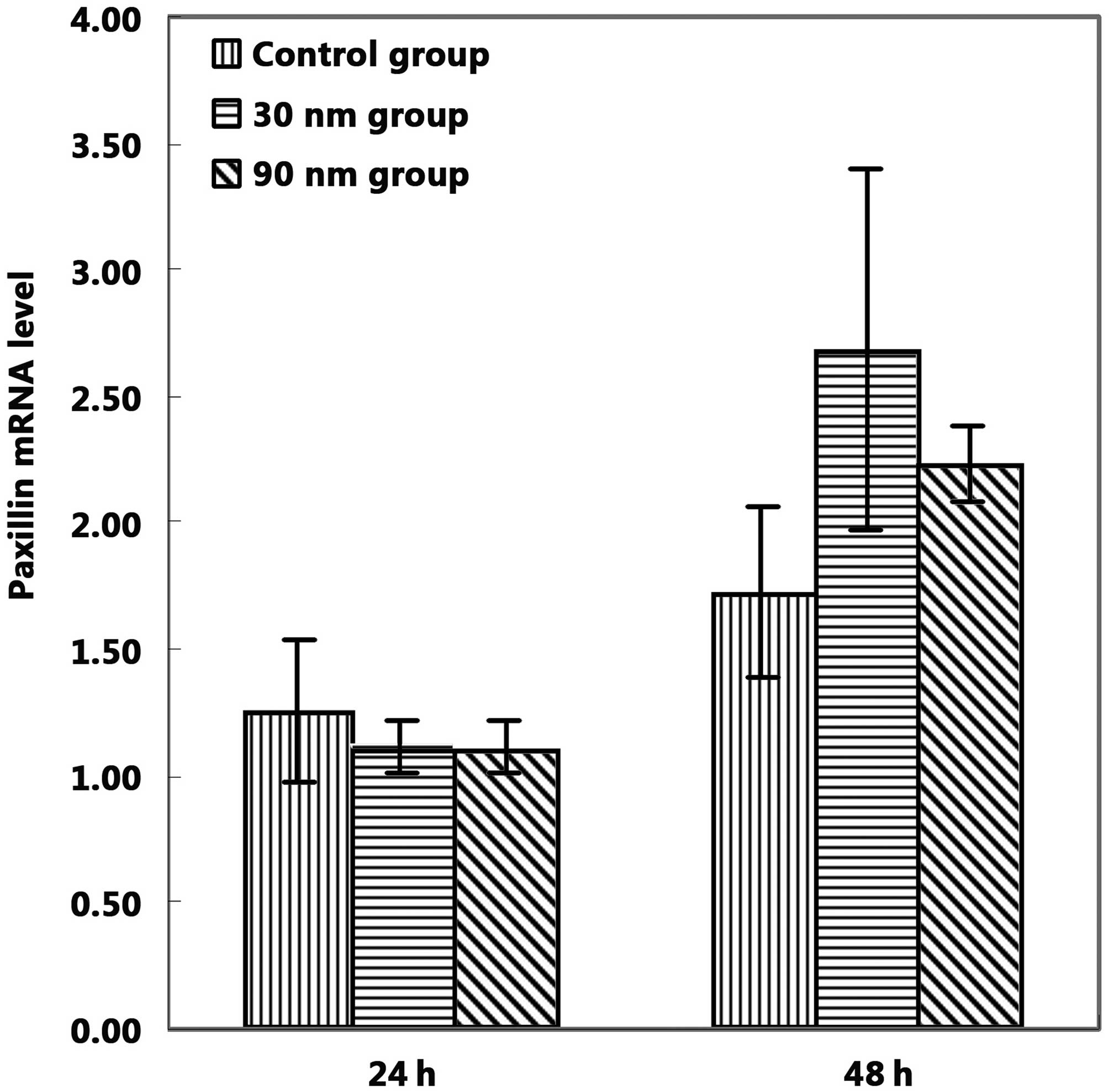

Quantitative real-time RT-PCR

analysis

Integrin β1 mRNA expression levels on the 30-nm

nanoporous surface were significantly higher than those observed on

the unanodized control and 90-nm nanoporous surfaces, following 48

h of cell culture (P<0.05; Fig.

5); however, no significant difference in the integrin β1 mRNA

expression levels between the unanodized control and 30-nm

nanoporous surfaces were observed following 24 h of cell culture

(P>0.05). However, integrin β1 expression levels on the 90-nm

nanoporous surface were evidently lower than those on the

unanodized control surface following 24 and 48 h of cell culture

(P<0.05). No statistically significant differences were observed

in the expression levels of paxillin mRNA between the unanodized

and anodized groups following 24 and 48 h of cell culture (Fig. 6).

Discussion

In the last few decades, titanium metal and its

alloys have been widely used as orthopedic and dental implants due

to their good biocompatibility, mechanical properties and neutral

interference with modern imaging techniques (26–28).

To accelerate the initial rate of osseointegration, the topographic

and chemical properties of implant surfaces should be considered

and modified. The surface structure of the titanium implants is

responsible for a good healing process. Therefore, numerous methods

have been used to produce a rough implant surface, including

titanium plasma spraying, blasting with aluminum oxide or other

ceramic particulate materials, strong acid etching, and the

potentiostatic or galvanostatic anodization of titanium (29). The majority of methods aim to form

a micro/nanoporous structure, which may promote bone bonding or

apposition of the implant surface (30).

In the present study, nanoporous titanium oxide

films with two different pore sizes (30 and 90 nm) on Ti2448 alloy

were formed by anodization in NH4F solution. The effects

of the surface characteristics of different nanoporous titanium

oxide films on the initial adhesion of osteoblasts was

investigated. Following anodization, the surface morphology was

examined using a Surftest Formtracer and FESEM. The roughness of

the anodized titanium surfaces (30 and 90 nm) was significantly

higher that of the unanodized titanium control surface. FESEM

images demonstrated that the number of adhered cells on the 30-nm

nanoporous surface was higher than those on the unanodized control

and 90-nm nanoporous surfaces following 48 h of cell culture. In

addition, cell adhesion on the 90-nm nanoporous surface was weaker

than that on the unanodized control surface, indicating that the

effects of surface micromorphology on initial cell adhesion may be

more significant than the surface roughness. Our data provide

strong evidence that the roughened surface of the 30-nm nanoporous

film was more favorable for the initial adhesion of osteoblasts.

Furthermore, we observed that the overlapped cells on the 30-nm

nanoporous surface were the densest, suggesting that the surface

demonstrated the characteristics of a typical bioactive surface

with high surface energy. Results of the MTT assay indicated that

cell viability on the 30-nm nanoporous surface following 24 and 48

h of cell culture was higher than those on the unanodized control

and 90-nm nanoporous surfaces, which may have resulted from greater

numbers of adhered osteoblasts and higher cell activities. This is

in agreement with previous studies (7,9).

In vivo studies have demonstrated an improved bone fixation

on implants with a rough surface structure compared with implants

with a smooth surface (27). A

previous study has shown that integrin β1 is an important bridge

for osteoblast adhesion on biomaterials (31). Zreiqat et al also

demonstrated that higher expression levels of integrin β1 may

contribute to the initial adhesion of osteoblastic cells to implant

surfaces (31). Our results are in

agreement with previously published studies with regard to the

influence of integrin β1 on cell adhesion properties. Using

real-time RT-PCR, we identified that integrin β1 mRNA expression

levels on the 30-nm nanoporous surface following 24 h of cell

culture were significantly higher than those on the control

unanodized and 90-nm nanoporous surfaces. However, the 90-nm

nanoporous surface demonstrated lower integrin β1 mRNA expression

levels compared with the unanodized control surface following 24

and 48 h of cell culture. These results provide support for our

hypothesis that nanoporous oxide films on Ti2448 alloy,

particularly 30-nm nanoporous films, have a significant influence

on osteoblast cell adhesion.

In conclusion, the results of the current study

indicate that 30-nm nanoporous titanium oxide films on Ti2448

alloys may provide the optimum bioactive implant surface for the

initial adhesion of osteoblasts. The 30-nm nanoporous film

exhibited the characteristics of a typical bioactive surface. Thus,

a Ti2448 alloy with a 30-nm nanoporous film is a promising

implant-coating material for the promotion of bone formation, as

well as for meeting the immediate implantation and early clinical

load requirements. Further studies are required to determine

whether the 30-nm nanoporous film on Ti2448 alloy has a strong

effect on osteoblast cell proliferation, migration and

differentiation.

Acknowledgements

This study was supported by the

National Natural Science Foundation of China (no. 51071152 and no.

50901080) and by the Ministry of Science and Technology of China

(no. 2011AA030106).

References

|

1.

|

Biesiekierski A, Wang J, Gepreel MA and

Wen C: A new look at biomedical Ti-based shape memory alloys. Acta

Biomater. 8:1661–1669. 2012. View Article : Google Scholar : PubMed/NCBI

|

|

2.

|

Fragou S and Eliades T: Effect of topical

fluoride application on titanium alloys: a review of effects and

clinical implications. Pediatr Dent. 32:99–105. 2010.PubMed/NCBI

|

|

3.

|

Lu X, Hiraki T, Nakajima K, et al:

Thermodynamic analysis of separation of alloying elements in

recycling of end-of-life titanium products. Sep Purif Technol.

89:135–141. 2012. View Article : Google Scholar

|

|

4.

|

Özcan M and Hämmerle C: Titanium as a

reconstruction and implant material in dentistry: Advantages and

pitfalls. Materials. 5:1528–1545. 2012.

|

|

5.

|

Gomes CC, Moreira LM, Santos VJ, et al:

Assessment of the genetic risks of a metallic alloy used in medical

implants. Genet Mol Biol. 34:116–121. 2011. View Article : Google Scholar : PubMed/NCBI

|

|

6.

|

Barbas A, Bonnet AS, Lipinski P, Pesci R

and Dubois G: Development and mechanical characterization of porous

titanium bone substitutes. J Mech Behav Biomed Mater. 9:34–44.

2012. View Article : Google Scholar : PubMed/NCBI

|

|

7.

|

Bai Y, Li SJ, Prima F, Hao YL and Yang R:

Electrochemical corrosion behavior of Ti-24Nb-4Zr-8Sn alloy in a

simulated physiological environment. Appl Surf Sci. 258:4035–4040.

2012. View Article : Google Scholar

|

|

8.

|

Zheng K, Li X, Fu J, et al: Effects of

Ti2448 half-pin with low elastic modulus on pin loosening in

unilateral external fixation. Journal of materials science J Mater

Sci Mater Med. 22:1579–1588. 2011. View Article : Google Scholar : PubMed/NCBI

|

|

9.

|

Guo Z, Fu J, Zhang YQ, et al: Early effect

of Ti-24Nb-4Zr-7.9Sn intramedullary nails on fractured bone. Mat

Sci Eng C Mater Biol Appl. 29:963–968. 2009. View Article : Google Scholar

|

|

10.

|

Gordin DM, Gloriant T, Chane-Pane V, et

al: Surface characterization and biocompatibility of titanium

alloys implanted with nitrogen by Hardion+ technology. J Mater Sci

Mater Med. 23:2953–2966. 2012.PubMed/NCBI

|

|

11.

|

Yu XF, Li YX, Ge WY, Yang QB, Zhu NF and

Kalantar-Zadeh K: Formation of nanoporous titanium oxide films on

silicon substrates using an anodization process. Nanotechnology.

17:808–814. 2006. View Article : Google Scholar

|

|

12.

|

Zhuang HF, Lin CJ, Lai YK, Sun L and Li J:

Some critical structure factors of titanium oxide nanotube array in

its photo-catalytic activity. Environ Sci Technol. 41:4735–4740.

2007. View Article : Google Scholar : PubMed/NCBI

|

|

13.

|

Gong D, Grimes CA, Varghese OK, et al:

Titanium oxide nanotube arrays prepared by anodic oxidation. J

Mater Res. 16:3331–3334. 2001. View Article : Google Scholar

|

|

14.

|

Feng B, Weng J, Yang BC, Qu SX and Zhang

XD: Characterization of surface oxide films on titanium and

adhesion of osteoblast. Biomaterials. 24:4663–4670. 2003.

View Article : Google Scholar : PubMed/NCBI

|

|

15.

|

Zhu X, Chen J, Scheideler L, Reichl R and

Geis-Gerstorfer J: Effects of topography and composition of

titanium surface oxides on osteoblast responses. Biomaterials.

25:4087–4103. 2004. View Article : Google Scholar : PubMed/NCBI

|

|

16.

|

Neoh KG, Hu X, Zheng D and Kang ET:

Balancing osteoblast functions and bacterial adhesion on

functionalized titanium surfaces. Biomaterials. 33:2813–2822. 2012.

View Article : Google Scholar : PubMed/NCBI

|

|

17.

|

Shtansky DV, Zhitnyak IY, Bashkova IA,

Pogozhev YS, Sheveiko AN and Gloushankova NA: The influence of

elemental composition and surface topography on adhesion,

proliferation and differentiation of osteoblasts. English Biochem

(Mosc) Suppl Ser A Membr Cell Biol. 4:272–276. 2010.

|

|

18.

|

Rosales-Leal JI, Rodríguez-Valverde MA,

Mazzaglia G, et al: Effect of roughness, wettability and morphology

of engineered titanium surfaces on osteoblast-like cell adhesion.

Colloid Surface A. 365:222–229. 2010. View Article : Google Scholar

|

|

19.

|

Macak JM, Tsuchiya H, Taveira L, Ghicov A

and Schmuki P: Self-organized nanotubular oxide layers on

Ti-6Al-7Nb and Ti-6Al-4V formed by anodization in NH4F

solutions. J Biomed Mater Res A. 75:928–933. 2005. View Article : Google Scholar : PubMed/NCBI

|

|

20.

|

Yasuda K and Schmuki P: Formation of

self-organized zirconium titanate nanotube layers by alloy

anodization. Adv Mater. 19:1757–1760. 2007. View Article : Google Scholar

|

|

21.

|

Taveira LV, Macak JM, Tsuchiya H, Dick LFP

and Schmuki P: Initiation and growth of self-organized

TiO2 nanotubes anodically formed in

NH4F/(NH4)2SO4

electrolytes. J Electrochem Soc. 152:B405–B410. 2005.

|

|

22.

|

Zhu X, Kim KH and Jeong YS: Anodic oxide

films containing Ca and P of titanium biomaterial. Biomaterials.

22:2199–2206. 2001. View Article : Google Scholar : PubMed/NCBI

|

|

23.

|

Zhu XL, Son DW, Ong JL and Kim K:

Characterization of hydrothermally treated anodic oxides containing

Ca and P on titanium. J Mater Sci Mater Med. 14:629–634.

2003.PubMed/NCBI

|

|

24.

|

van den Dolder J, Spauwen PH and Jansen

JA: Evaluation of various seeding techniques for culturing

osteogenic cells on titanium fiber mesh. Tissue Eng. 9:315–325.

2003.PubMed/NCBI

|

|

25.

|

Suh JY, Jang BC, Zhu XL, Ong JL and Kim K:

Effect of hydrothermally treated anodic oxide films on osteoblast

attachment and proliferation. Biomaterials. 24:347–355. 2003.

View Article : Google Scholar : PubMed/NCBI

|

|

26.

|

Langhoff JD, Voelter K, Scharnweber D, et

al: Comparison of chemically and pharmaceutically modified titanium

and zirconia implant surfaces in dentistry: a study in sheep. Int J

Oral Maxillofac Surg. 37:1125–1132. 2008. View Article : Google Scholar : PubMed/NCBI

|

|

27.

|

Ohkubo C, Shimura I, Aoki T, Hanatani S,

Hosoi T and Okabe T: In vitro wear assessment of titanium alloy

teeth. J Prosthodont. 11:263–269. 2002. View Article : Google Scholar : PubMed/NCBI

|

|

28.

|

Deligianni DD, Katsala N, Ladas S,

Sotiropoulou D, Amedee J and Missirlis YF: Effect of surface

roughness of the titanium alloy Ti-6Al-4V on human bone marrow cell

response and on protein adsorption. Biomaterials. 22:1241–1251.

2001. View Article : Google Scholar : PubMed/NCBI

|

|

29.

|

Le Guéhennec L, Soueidan A, Layrolle P and

Amouriq Y: Surface treatments of titanium dental implants for rapid

osseointegration. Dent Mater. 23:844–854. 2007.PubMed/NCBI

|

|

30.

|

Gittens RA, Olivares-Navarrete R,

McLachlan T, et al: Differential responses of osteoblast lineage

cells to nanotopographically-modified, microroughened

titanium-aluminum-vanadium alloy surfaces. Biomaterials.

33:8986–8994. 2012. View Article : Google Scholar

|

|

31.

|

Zreiqat H, Howlett CR, Zannettino A, et

al: Mechanisms of magnesium-stimulated adhesion of osteoblastic

cells to commonly used orthopaedic implants. J Biomed Mater Res.

62:175–184. 2002. View Article : Google Scholar : PubMed/NCBI

|