Introduction

Titanium (Ti) and its alloys are frequently used as

orthopedic implant materials, due to their mechanical strength,

chemical stability and biocompatibility (1,2). It

has been demonstrated that the biocompatibility of Ti is closely

related to the properties of the surface oxide layer (predominantly

titanium dioxide, TiO2), with regard to its structure,

morphology and composition. However, TiO2 does not

exhibit sufficient bioactivity to form a direct bond with the

juxtaposed bone, and this may translate into a lack of

osseointegration, leading to the long-term failure of the implant

(3–5). Combining the TiO2 with

bioactive materials is recognized to be an effective method of

overcoming this drawback.

There has recently been an increased focus on the

effects of trace elements on biological processes, particularly in

the field of bone formation and in the study of essential elements.

With regard to the divalent cations, there have, to date, been a

variety of studies on manganese (Mn) (6–9). Mn

is an essential trace element in the human body, and it has the

most potent capacity for binding to integrins, and for mediating

the binding of ligands to various integrins, at low concentrations

(6,10–12).

Previous studies have endeavored to use Mn to enhance the

osteoconductivity of a bioinert Ti substrate, by means of its

potent cell adhesion-promoting effect (7,9,13,14).

However, there have not been any studies into Mn-containing

TiO2 ceramics or coatings, and the effects of Mn on the

composition, microstructure and biological responses of

TiO2 have not been elucidated. Moreover, the signal

transduction pathway that mediates the effects of Mn on

osteoblastic adhesion has not been studied. Therefore, the aim of

the present study was to investigate the preparation and

characterization of Mn-containing TiO2 coatings.

Plasma electrolytic oxidation (PEO), also known as

microarc oxidation, is a relatively convenient and effective

technique for the preparation of TiO2-based coatings on

a Ti substrate (15–17). PEO coatings are, in general, porous

and nanostructured, and this has been demonstrated to be beneficial

to osteoblast adhesion and proliferation (15,17).

At present, the PEO process is widely applied to the

biofunctionalization of titanium, in order to create bioactive

porous oxide coatings (18). In

addition, many biological elements, for example calcium (Ca) and

phosphorus (P), may be effectively incorporated into the PEO-evoked

TiO2 coating through the supplementation of the

electrolyte (19,20). In the present study, a porous

Mn-TiO2 coating was prepared by PEO in an electrolyte

containing Ca, P and Mn. In addition, the adhesion behavior of

osteoblast-like MG63 cells onto the Mn-TiO2 coating, and

the corresponding signal transduction pathway, were

investigated.

Materials and methods

Preparation of samples

The study used commercially pure Ti plates with

dimensions of 10×10×1 mm. The Ti was mechanically polished using

silicon carbide (SiC) abrasive sandpaper. For the TiO2

coatings, the Ti plates were anodized in an electrolyte containing

0.05 mol/l glycerophosphate disodium salt pentahydrate

(C3H7Na2O6P.5H2O,

GP) and 0.1 mol/l calcium acetate monohydrate

[(CH3COO)2Ca.H2O, CA], while for

the Mn-TiO2 coatings, 0.04 mol/l manganese acetate

[Mn(CH3COO)2·2H2O] was added into

the electrolyte. The current density, frequency, duty cycle and

duration time were fixed at 16.5 A/dm2, 800 Hz, 10% and

4 min, respectively. Following the PEO treatment, the samples were

washed with deionized water, and dried in air.

The surface characterization of the PEO-treated

samples was performed using scanning electron microscopy (SEM),

with a S-4200 scanning electron microscope (Hitachi, Tokyo, Japan),

X-ray diffraction (XRD), with a D/MAX-2550 diffractometer (Rigaku

Corporation, Tokyo, Japan) and energy-dispersive X-ray spectrometry

(EDS) attached to an electron probe X-ray microanalysis system

(EPMA), using an XA-8100 microprobe (Hitachi, Tokyo, Japan). The

surface roughness (Ra) of the samples was measured using a surface

profiler (Hommel Tester T8000; Hommelwerke GmbH,

Villingen-Schwennigen, Germany) with a scan distance of 4.8 mm and

a scan rate of 0.5 mm/sec. The scan was performed on each sample

three times at different locations on the sample.

Cell culture

The osteoblastic MG63 cells were cultured in

α-minimum essential medium (MEM), supplemented with 100 mg/ml

penicillin G, 50 mg/ml gentamicin, 3 mg/ml amphotericin B and 15%

newborn bovine serum, at 37°C in a humidified atmosphere of 95% air

and 5% CO2. The osteoblasts were trypsinized (0.25%

trypsin, 0.1% glucose, citrate-saline buffer; pH 7.8) prior to

confluent growth, in order to avoid post-confluence differentiation

effects, counted electronically with a cell counter (Coulter

Electronics Ltd., Luton, UK) and plated onto the test and control

surfaces at a density of 30,000–100,000 cells/ml. A total of 31.5

mg/ml sodium-β-glycerol phosphate and 0.58 mg/ml L-ascorbic acid

phosphate magnesium salt n-hydrate were added to the supplemented

α-MEM over the course of the experiments. Cells were not used above

passage number 20.

MTT assay

An MTT assay was used to determine the cell

attachment. The cells were seeded at a concentration of

2×105 cells/cm2 onto the disks of the Ti

plates, and the TiO2 and Mn-TiO2 coatings,

and were cultured on the disks for 1, 8, 16 and 24 h, respectively,

in a 37°C incubator with 5% CO2. At the pre-determined

time points, each disk was transferred to a well in a new 24-well

plate, and 1.5 ml medium was added to each disk. A total of 150 μl

freshly prepared 5 mg/ml MTT was added to each well where a disk

was present. The plates were then placed in an incubator at 37°C

for 3 h, prior to the supernatant of each well being removed, and

replaced with acidified isopropanol (0.04 M HCl in isopropanol).

This was subsequently mixed thoroughly to dissolve the dark-blue

crystals. The absorbance was measured with a spectrophotometer at a

wavelength of 570 nm, with a subtraction of the absorbance at 650

nm. The cell number was determined using a linear correlation

between the absorbance and MG63 cell concentration.

Cell morphology

The cells were seeded onto the Ti plates and the

TiO2 and Mn-TiO2 coatings at a density of

1×104/cm2 in α-MEM supplemented with 10%

phosphate-buffered saline (PBS), and were cultured under standard

cell culture conditions for 16 h. The specimens were then separated

from the medium, washed twice in PBS and fixed with 2.5%

glutaraldehyde in PBS for 1 h at room temperature. Following this,

the samples were dehydrated in a graded ethanol series of 50, 70,

80 and 95% ethanol for 5 min, as well as twice with 100% ethanol

for 15 min. Subsequently, the samples were stored overnight in a

thermo-ventilated oven at 37°C, prior to undergoing gold

metallization using Emscope SC500 apparatus (Quorum Technologies

Ltd., Ashford, UK), and SEM analysis with a Philips XL30 FEG

scanning electron microscope (Philips, Amsterdam, the

Netherlands).

Quantitative polymerase chain reaction

(qPCR) analysis

The gene expression of the integrin subunits

β1, β3, α1 and α3, as

well as FAK, ERK1 and ERK2, were determined using qPCR analysis.

The cells were seeded onto Mn-TiO2 and TiO2

coatings, in addition to Ti plates, in 24-well plates at a density

of 2×104 cells/well, and cultured for 1, 8, 16 and 24 h,

respectively. The total cellular RNA was extracted using

TRIzol® reagent (Invitrogen Life Technologies, Carlsbad,

CA, USA), in accordance with the manufacturer’s instructions. To

obtain first-strand cDNAs, 1 μg total RNA extract was used for

reverse transcription. The reactions were performed using a

RevertAid™ First Strand cDNA Synthesis kit (Thermo Fisher

Scientific, Inc., Waltham, MA, USA), in a final volume of 20 μl, at

42°C for 60 min, and were then terminated by heating at 70°C for 5

min. Glyceraldehyde-3-phosphate dehydrogenase (GAPDH) was used as

the housekeeping gene. The primer sequences utilized are displayed

in Table I.

| Table IPrimer pairs used in the present

study. |

Table I

Primer pairs used in the present

study.

| Target | Primer

sequence |

|---|

| Integrin

α1 | F:

5′-TCGCTCCGTGGCCTTGTGGAA-3′ |

| R:

5′-CCCATTTCAGTAACCACGCCC-3′ |

| Integrin

α3 | F:

5′-TGGGTCATAGACCGGTATAC-3′ |

| R:

5′-ATCCACTCATAGCAAACAGT-3′ |

| Integrin

β3 | F:

5′-TGCTGACGGGAGGAACGGTA-3′ |

| R:

5′-CGGGATCAGATGTGTCTGGG-3′ |

| Integrin

β1 | F:

5′-GTCTTTGCGTAGGCTTACTT-3′ |

| R:

5′-ACCCGTGGGTACGATGCATC-3′ |

| FAK | F:

5′-GCGAGAGGTGTGGTAATATCAGGTGAA-3′ |

| R:

5′-ACACGTATTCACTGTTCAACTATTGAC-3′ |

| ERK1 | F:

5′-ACACACGCCCAAACCATG-3′ |

| R:

5′-TCCACTCGCGCATTCGTA-3′ |

| ERK2 | F:

5′-TTTACCATAGGACTCAACCT-3′ |

| R:

5′-GGGCATGGTGTCCTGCAGAA-3′ |

| GAPDH | F:

5′-CGCGTCGCGCTCGATGTCAC-3′ |

| R:

5′-GGTAAGTGACATGCTGAGTT-3′ |

The amplification process was performed using a

Maxima SYBR-Green qPCR Master Mix in an Applied Biosystems 7500

RT-PCR system (Applied Biosystems, Foster City, CA, USA). The

reaction volume was 25 μl, containing 12.5 μl SYBR-Green qPCR

Master Mix, 1 μl each primer (0.3 μM), 2 μl template DNA and 8.5 μl

nuclease-free water. The initial denaturation was carried out at

95°C for 600 sec, with denaturation at 95°C for 15 sec, annealing

at 60°C for 30 sec and then 40 cycles of extension at 72°C for 30

sec. At the end of the PCR cycles, a melting curve analysis was

performed to determine the specificity of the PCR product. The mRNA

content of each gene was normalized to the quantity of GAPDH mRNA,

and the average threshold cycle (CT) values were used to quantify

the gene expression in each sample: ΔCT =

ΔCT(experiment)-ΔCT(control). The relative gene expression (fold

change) was obtained by transforming the logarithmic values into

absolute values using 2−ΔΔct.

Statistical analysis

One way analysis of variance (ANOVA) and Tukey’s

multiple comparison tests were performed to detect any significant

effects that occurred as a result of the experimental variables.

The results were analyzed using the Student’s t-test, with a sample

number including ≥4 samples. The error bars represent mean ±

standard deviation. P<0.05 was considered to indicate a

statistically significant difference.

Results

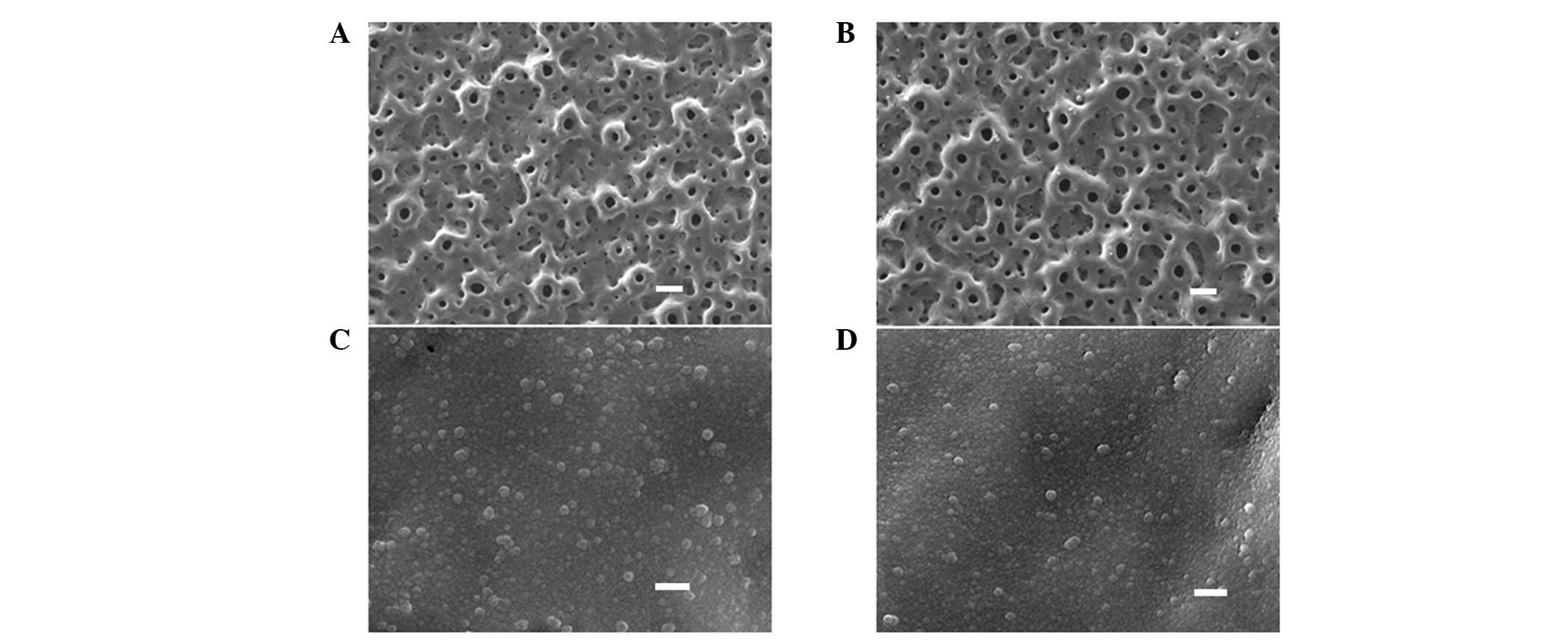

As demonstrated in Fig.

1, the low magnification views (x1,000) revealed that the

TiO2 (Fig. 1A) and

Mn-TiO2 (Fig. 1B)

coatings were porous, with a pore size of <5 μm. The pores were

well separated, and homogeneously distributed over the coating

surfaces. The high magnification views (x50,000) indicated that the

TiO2 (Fig. 1C) and

Mn-TiO2 (Fig. 1D)

coatings were covered by nanograins of ~30–50 nm. No obvious

differences in morphology were observed between the TiO2

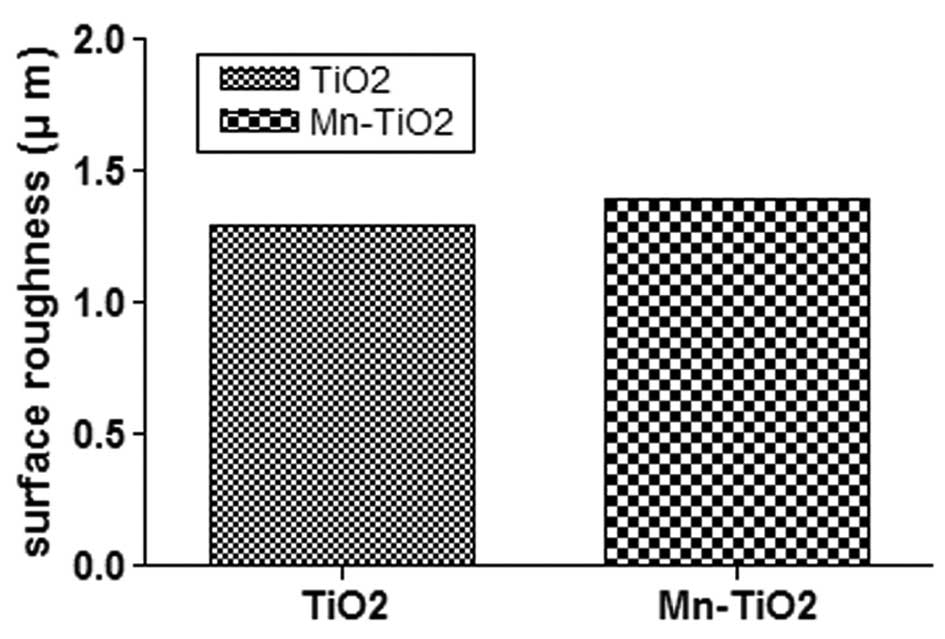

and Mn-TiO2 coatings. Fig.

2 indicates that there was no significant difference between

the Ra of the TiO2 and Mn-TiO2 coatings

(1.3±0.1 μm and 1.4±0.2 μm, respectively).

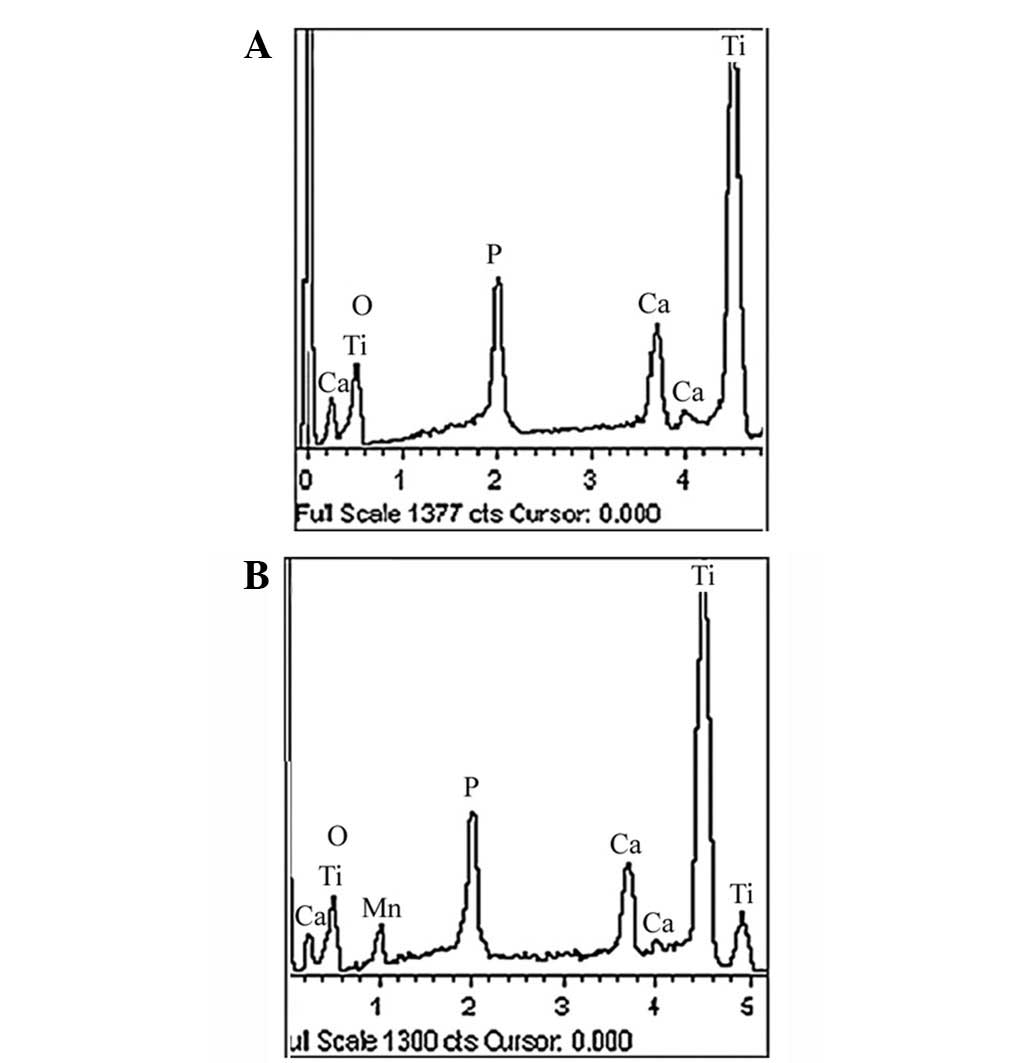

Fig. 3 displays the

elemental compositions of the surfaces of the TiO2 and

Mn-TiO2 coatings, as determined by EDS. Ti, oxygen (O),

Ca and P were detected in the TiO2 coating, while in the

Mn-TiO2 coating, Mn was detected in addition to Ti, O,

Ca and P. This indicated that Mn had been successfully incorporated

into the coating. Table II

summarizes the elemental compositions of the TiO2 and

Mn-TiO2 coatings, and reveals that the Mn content was

2.41±0.08 wt% in the Mn-TiO2 coating. Following the Mn

incorporation, the P content increased from 7.47±0.25 to 8.06±0.24

wt%, while the Ca content decreased from 7.09±0.21 to 6.04±0.19

wt%.

| Table IIElemental compositions of the

TiO2 and Mn-TiO2 coatings, detected by

EDS. |

Table II

Elemental compositions of the

TiO2 and Mn-TiO2 coatings, detected by

EDS.

| Elemental

composition (weight %) |

|---|

|

|

|---|

| Samples | Ca | P | Ti | O | Mn |

|---|

|

TiO2 | 7.09±0.21 | 7.47±0.25 | 43.55±0.44 | 41.89±0.42 | - |

|

Mn-TiO2 | 6.04±0.19 | 8.06±0.24 | 37.31±0.36 | 46.18±0.49 | 2.41±0.08 |

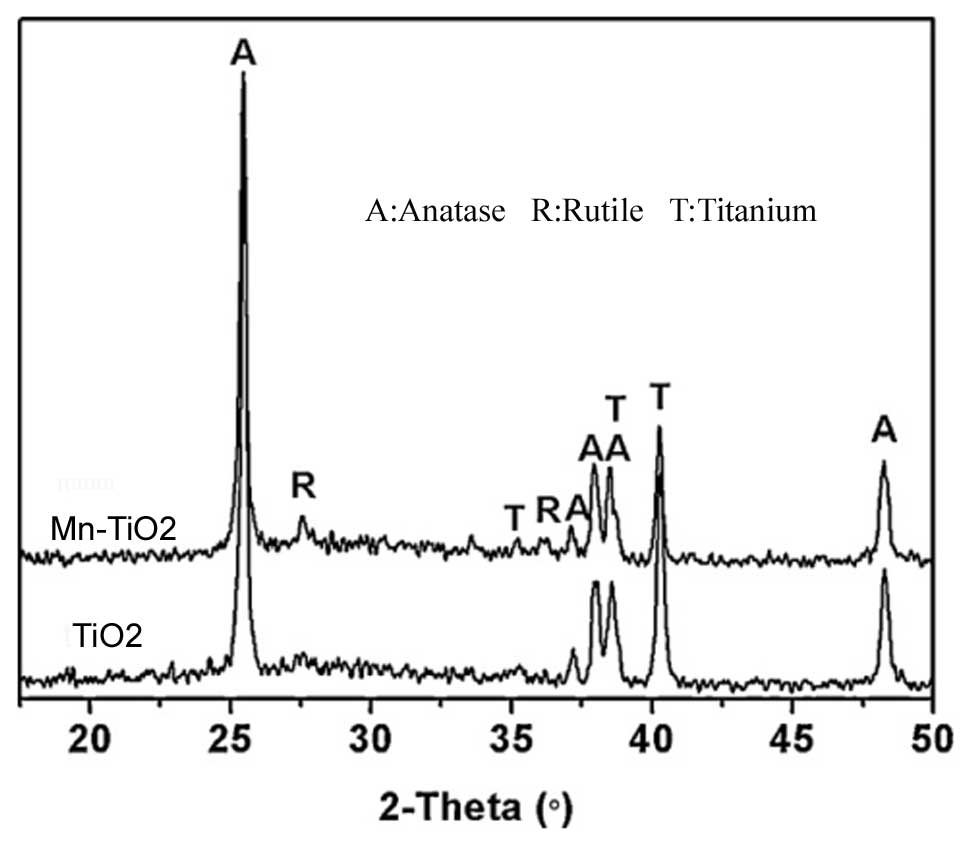

The XRD patterns of the TiO2 and

Mn-TiO2 coatings are displayed in Fig. 4. The two coatings primarily

consisted of the anatase phase, while small peaks of the rutile

phase were also detected in the XRD patterns of the Mn-incorporated

sample. The incorporation of Mn only marginally altered the phase

compositions of the TiO2 coating.

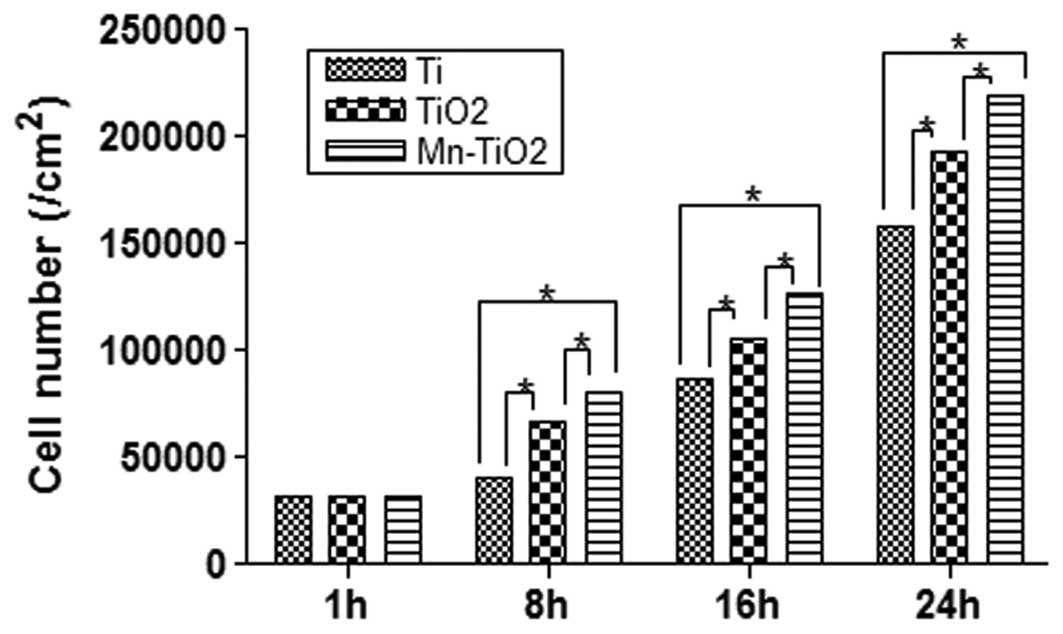

Fig. 5 displays the

results of the MTT assay used to determine the attachment of the

MG63 cells cultured on the Ti plates, and the TiO2 and

Mn-TiO2 coatings at 1, 8, 16 and 24 h. During the

initial 1 h of the incubation, the majority of the cells attached

onto each of the substrates, and no significant differences were

detected between them (P>0.05). However, the MTT assay indicated

that there was a more rapid increase in cell attachment on the

Mn-TiO2 coating, as compared with the Ti plates and

TiO2 coating. At 8, 16 and 24 h, it was observed that

the number of cells on the TiO2 coating was

significantly greater than that on the Ti plates (P<0.05), but

significantly less than that on the Mn-TiO2 coating

(P<0.05). Therefore, the Mn-TiO2 coating appeared to

provide a more favorable surface for the attachment of

osteoblasts.

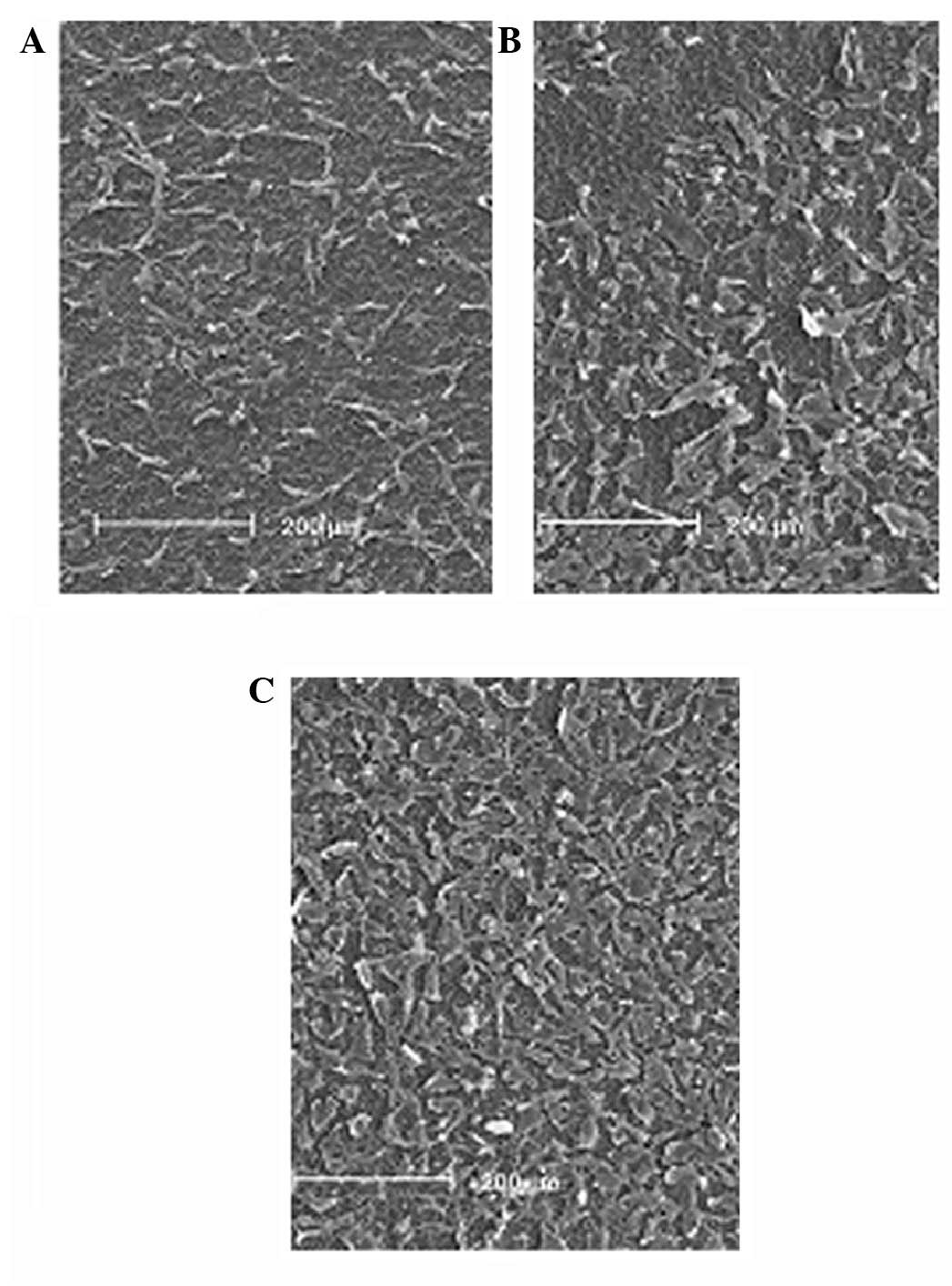

Fig. 6 reveals the

osteoblastic morphology of the cells on the three substrates. The

micrographs demonstrate that, following 16 h of culture on the

Mn-TiO2 and TiO2 coatings, and the Ti plates,

the MG63 cells exhibited different morphologies. In comparison with

the cells seeded on the TiO2 coating and the Ti plates,

those seeded on the Mn-TiO2 coating displayed a

particularly spread-out morphology, with numerous connections to

the surface.

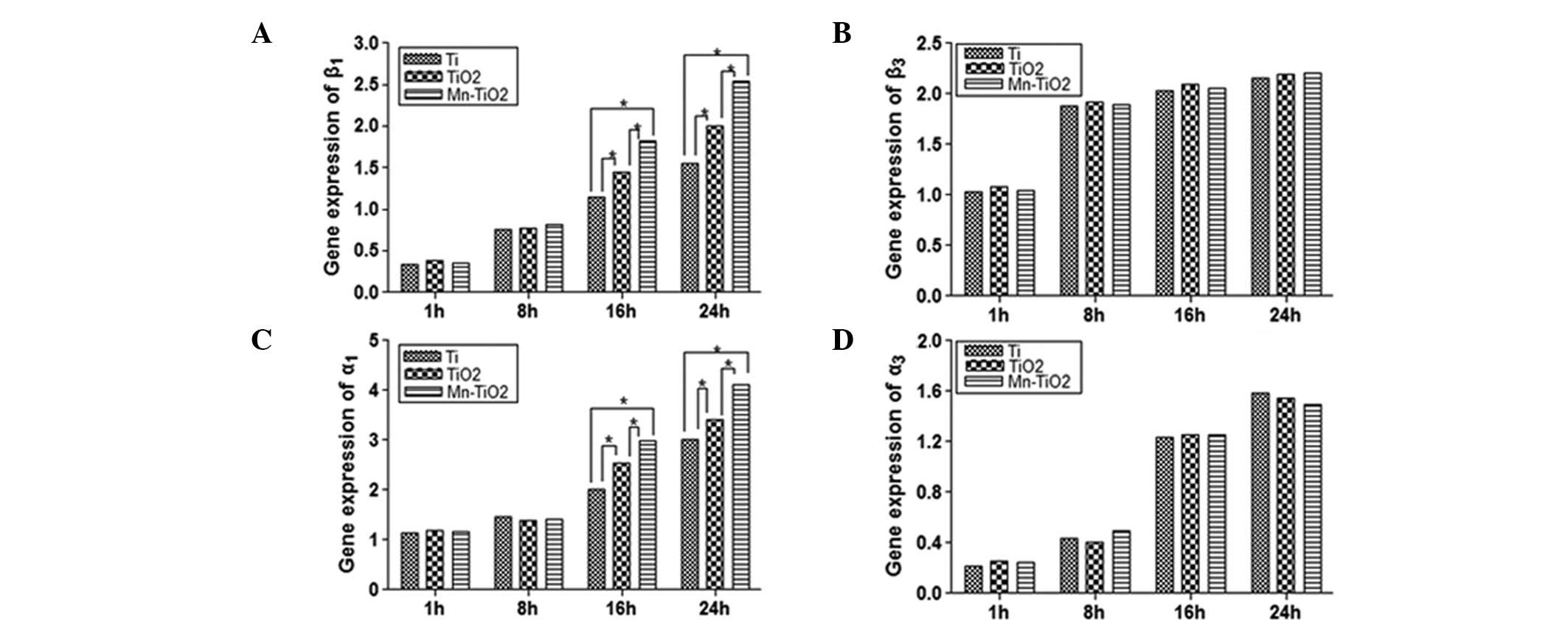

The expression of adhesion-specific genes, including

integrins (subunits β1, β3, α1 and

α3), FAK and ERK (ERK1 and −2), were measured at 1, 8,

16 and 24 h using qPCR. It was observed that the MG63 cells

cultured on the Mn-TiO2 coating expressed higher levels

of the mRNA of integrin (subunits β1 and α1),

FAK and ERK2 compared with the cells seeded on the TiO2

coating and Ti plates. Integrins, as transmembrane heterodimeric

receptors consisting of an α- and β-subunit, are important in

mediating osteoblast adhesion onto biomaterials. Fig. 7 displays the integrin gene

expression of MG63 cells cultured on Ti plates, and TiO2

and Mn-TiO2 coatings. The integrin β1

(Fig. 7A) and α1

(Fig. 7C) gene expression of the

MG63 cells increased gradually with culture time, on each of the

substrates. During the initial 8 h, the MG63 cells seeded on the

three substrates demonstrated no significant differences in

integrin β1 and α1 gene expression

(P>0.05). When the MG63 cells were cultured on the substrates

for ≥16 h, the gene expression of integrin β1 and

α1 became significantly different, depending on the

substrate. The Mn-TiO2 coating appeared to promote

integrin β1 and α1 gene expression more

effectively than the TiO2 coating and Ti plates, and

resulted in the highest level of gene expression (P<0.05). There

were no significant differences in the gene expression of integrin

β3 or α3 between the cells seeded on the

three substrates at any time; however, as the experiment

progressed, the cells on each of the substrates demonstrated a

marked upregulation in gene expression, which persisted throughout

the course of the experiment (Figs. 7B

and D).

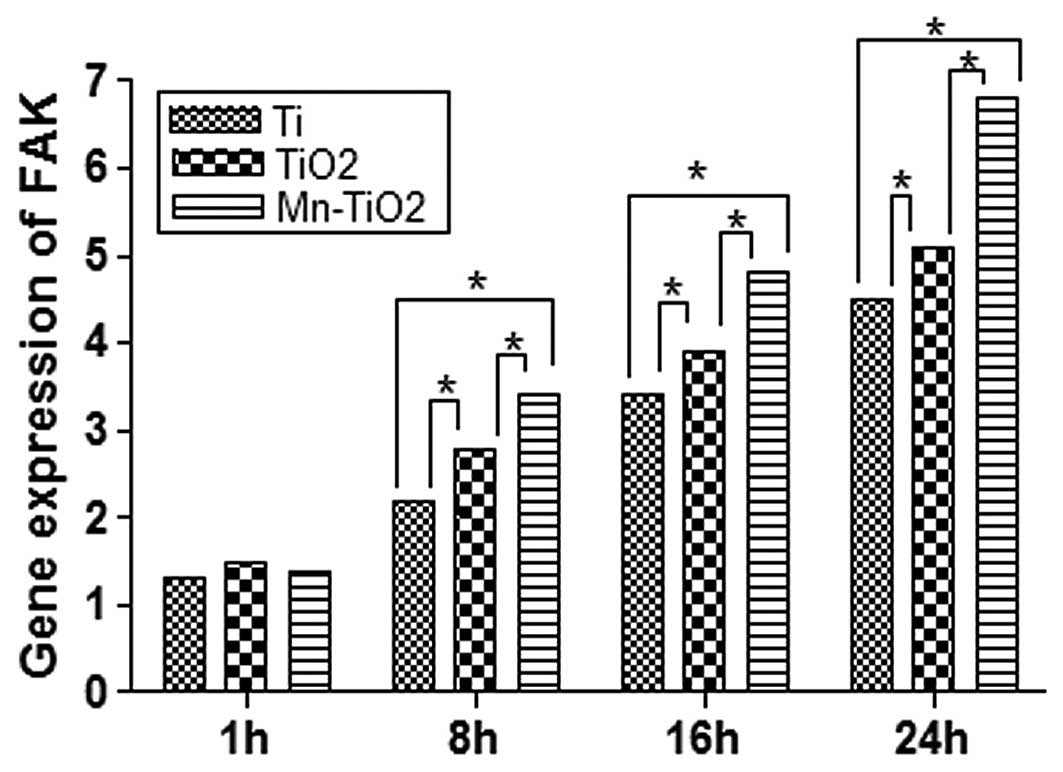

FAK, an integrin receptor, is important in the

integrin-mediated signal transduction pathway, which mediates

osteoblastic adhesion onto biomaterials. Fig. 8 demonstrates that at 1 h, the

differences in FAK gene expression were not statistically

significant (P>0.05). When the incubation time was ≥8 h, the FAK

gene expression of the MG63 cells seeded on the TiO2 and

Mn-TiO2 coatings was markedly upregulated. It was

observed that the MG63 cells seeded on the Mn-TiO2

coating had a significantly higher level of FAK gene expression

than those cultured on the TiO2 coating and Ti plates

(P<0.05). The trend in FAK gene expression was similar to that

of the cell attachment activity indicated in Fig. 5.

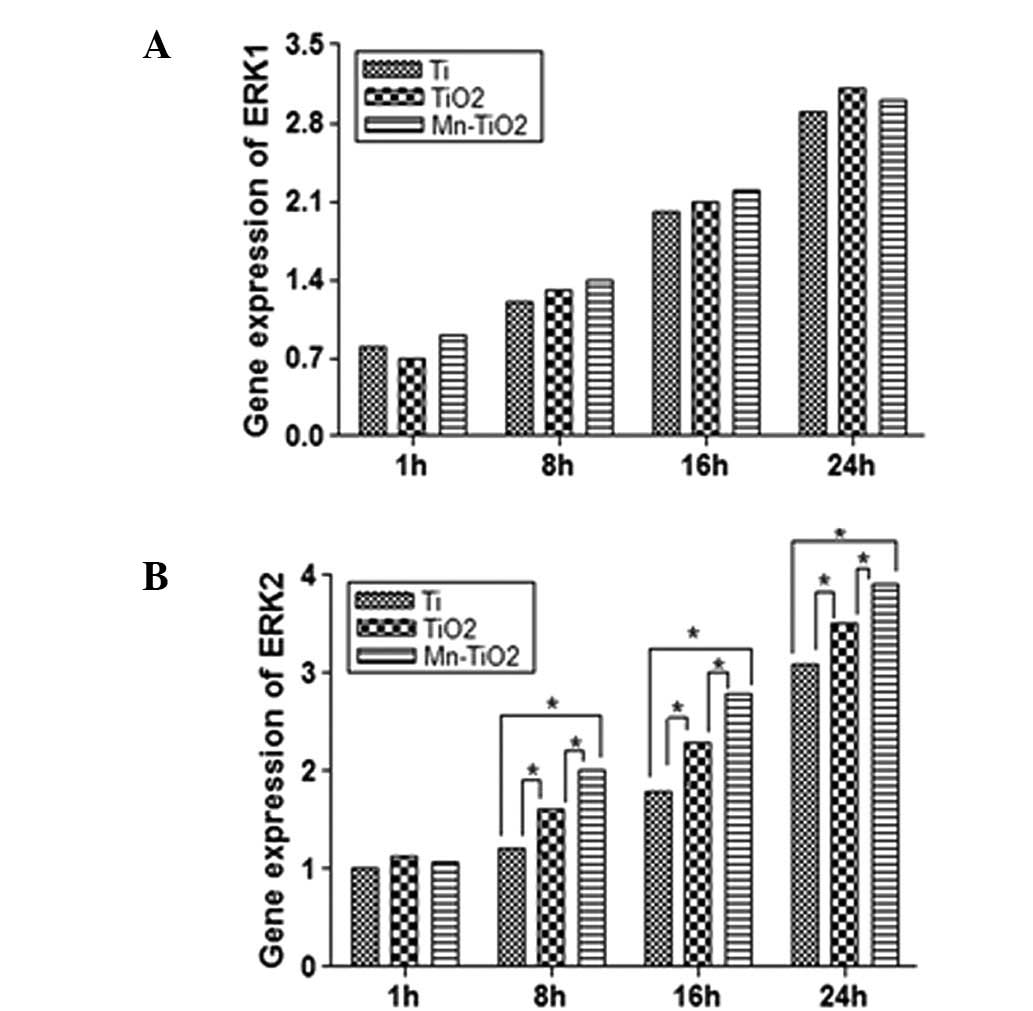

ERK (including ERK1 and −2), a member of the

mitogen-activated protein kinase (MAPK) family, is essential in the

regulation of osteoblastic adhesion, and may be stimulated as a

result of FAK activation. The gene expression of ERK1 and −2 is

displayed in Fig. 9. The results

demonstrated that the ERK2 gene expression of the MG63 cells

cultured on the Mn-TiO2 coating was upregulated at all

time points, and became significantly greater than that of the

cells on the TiO2 coating and Ti plates at 8, 16 and 24

h (Fig. 9B). With regard to the

ERK1 gene expression, there were no significant differences between

the three substrates at any of the time points, although the gene

expression was upregulated continuously throughout the experiment

(Fig. 9A).

Discussion

The initial adhesion and spreading activities of

osteoblasts characterize the first phase of cell-material

interactions, and the quality of this stage influences the capacity

of the cells to proliferate and differentiate on contact with the

implant (21,22). Preclinical and clinical studies

have demonstrated that osteoblastic adhesion on implant contact is

significantly influenced by the surface properties of the implant,

including the surface chemistry and topography (2,21,23).

In the present study, we evaluated the adhesion of MG63 cells on

three substrates (Ti plates, and TiO2 and

Mn-TiO2 coatings), and investigated the relationship

between the material of the substrate and the cell behavior.

As indicated by the MTT assay (Fig. 5), the attachment of a significantly

greater number of cells to the Mn-TiO2 coating, compared

with the TiO2 coating and the Ti plates, has certain

implications for the long-term success of this material, due to the

fact that the cell-surface integration is critical for the

incorporation of the material into the new bone. Surface chemistry

is an important factor affecting osteoblastic attachment to

biomaterials (2,21). The Mn released from

Mn-TiO2 coatings has been demonstrated to contribute to

extracellular pH changes, which alter the structure of

transmembrane proteins (9,10,11,14).

This alteration of the transmembrane proteins has been revealed to

facilitate the interaction and bonding of the transmembrane

proteins with proteins adsorbed onto the Mn-TiO2

coatings from the culture medium, which promotes the attachment of

MG63 cells onto the surface (7,10,11).

In addition to surface chemistry, the attachment of osteoblasts is

also affected by surface topography (21,24–27).

Although a variety of studies (21,25,27–30)

have revealed few consistent trends in the effects of surface

topography on initial osteoblastic attachment, the most commonly

observed trend has been that a porous structure is beneficial to

cell attachment (15,17, 21,25,28,29).

When the Mn-TiO2 coating is placed into the culture

medium, the porous nanostructured surface facilitates the

adsorption of proteins from the culture medium, by providing a

larger contact area at the sample-medium interface. This promotes

cell recruitment, and may be one of the reasons for the enhanced

osteoblastic attachment on Mn-TiO2 coatings.

Osteoblastic spreading on the biomaterial is a

process that is essential in establishing the biological properties

of the cells (21,31,32),

and may be significantly influenced by the surface chemistry of the

biomaterial (2,21,33–35).

It has been observed that incorporating Mn into a hyaluronan

coating may promote the spreading of osteoblasts (8,9). In

addition, Li et al(8)

demonstrated that osteoblasts displayed a significantly flatter

morphology on an Mn-containing coating. In the present study, we

observed that following seeding on a Mn-TiO2 coating for

16 h, MG63 cells displayed a flatter morphology, and exhibited

numerous connections to the surface, in comparison with cells on a

TiO2 coating and Ti plates (as indicated in Fig. 6). The Mn released from the

Mn-TiO2 coating may have bonded to oxygen, forming a Mn

network structure on the surface of the coating, which was capable

of holding elements of the proteins together in an organized

fashion, thus contributing to the architecture of the connective

tissue (6,8,10–12).

It is possible that these proteins may have been adsorbed onto the

Mn network structure, promoting enhanced osteoblastic spreading via

interactions with the integrins on the MG63 cells and, in turn,

triggering certain specific signals, which may have then had a

stimulatory effect on the bone mineralization process. However,

further investigation into the precise mechanism by which Mn

affects osteoblastic spreading is required. The surface topography

of the biomaterial is another factor that is important in

osteoblastic spreading (21,24,26,27).

Several studies have observed that bone cells spread and flattened

with greater efficacy on nanostructured porous coatings, compared

with rough coatings (21,36,37).

However, contrary conclusions have been drawn in other studies

(38,39), and, as a result, it has been

difficult to establish a simple conclusion with regard to the

correlation between the surface topography and osteoblastic

spreading. In the present study, we demonstrated that the spreading

of MG63 cells cultured on porous TiO2 and

Mn-TiO2 coatings for 16 h was more pronounced than that

on polished Ti plates (Fig. 6),

suggesting that the spreading was promoted by the surrounding

porous nanostructures.

When a biomaterial is placed in culture medium,

proteins adsorb to its surface. This protein layer subsequently

regulates the interaction of the biomaterial with the osteoblasts

arriving from the surrounding tissue. Integrins are essential

transmembrane molecules that are involved in the process of

osteoblastic adhesion (1). It has

been demonstrated that Mn increases the ligand-binding affinity of

integrins, thus affecting cellular interactions with the

extracellular matrix (ECM), and activating cell adhesion (10,11,13).

The present study investigated the gene expression of the integrin

subunits β1, β3, α1 and

α3. We observed a significantly higher expression of the

integrin β1 and α1 genes in the cells on the

Mn-TiO2 coating compared with those on the

TiO2 coating and Ti plates (Figs. 7A and C), following 16 h of

culture, while no significant differences were observed with regard

to the integrin β3 and α3 gene expression

(Figs. 7B and D). The results

indicated that the integrin β1 and α1

subunits may have been partially responsible for the enhanced

osteoblastic adhesion on the Mn-TiO2 coating. However, a

comparison of Fig. 5 and Fig. 7, revealed that although at 8 h a

significantly greater number of MG63 cells were attached on the

Mn-TiO2 coating than on the TiO2 coating or

Ti plates, the levels of integrin β1 and α1

gene expression were approximately equal, irrespective of the

substrate. This implied that alternative integrin subunits, in

addition to β1 and α1, may have had an

earlier effect on the process of MG63 cell attachment onto

Mn-TiO2 coatings.

Following the binding of a ligand, integrins cluster

together into focal contacts (1,40,41).

This is an area of close contact between a cell and the ECM, and

consists of additional cytoskeletal proteins, adapter molecules,

and kinases (42). Subsequent to

the clustering, cytoskeletal elements and signaling molecules are

recruited and activated, in a process known as outside-in signaling

(41,42). The signaling pathway inside the

cell is complex, and involves the accumulation of several proteins,

including FAK, Src, and cytoskeletal proteins (43). The activation of FAK initiates

intracellular signal transduction cascades, including those

involved in the MAPK effector cascades and the remodeling of the

cytoskeleton. These effects, in turn, regulate cellular processes

such as adhesion, growth, and differentiation (43). In the present study, it was

observed that the FAK gene expression in the MG63 cells cultured on

the Mn-TiO2 coating was significantly higher compared

with that of the cells cultured on a TiO2 coating or Ti

plates at 8, 16, and 24 h (Fig.

8). This revealed a similar trend to that of the gene

expression of the integrin β1 and α1

subunits, indicating that these subunits may have been involved in

stimulating FAK activation at 16 and 24 h. It is possible that

alternative integrin subunits may have contributed to the

activation of FAK, leading to the higher expression of FAK in the

cells on the Mn-TiO2 coating at 8 h.

Integrin and FAK molecules may provide a platform

for intracellular signaling; however, they are not able to exhibit

intrinsic enzymatic activity in their cytoplasmic domains.

Downstream signaling, following integrin binding, is regulated by

non-receptor tyrosine kinases (43), and one such pathway is the ERK/MAPK

signaling cascade (44). Several

studies have demonstrated that integrin engagement and FAK

activation stimulated ERK expression (43,44).

In the current study, we observed that the gene expression of ERK2

(Fig. 9B) was similar to that of

the integrin β1, α1 subunits (Fig. 7A and C) and FAK (Fig. 8), which implied that integrin

β1 and α1-mediated activation of FAK may have

been responsible for the enhanced ERK2 expression on the

Mn-TiO2 coating at 16 and 24 h. The increased ERK2 gene

expression at 8 h on the Mn-TiO2 coating may have been

induced by alternative integrin subunits, in addition to

β1 and α1.

In conclusion, the present study prepared a porous

and nanostructured Mn-TiO2 coating by PEO, using a novel

Mn-containing electrolyte, which successfully incorporated Mn into

the coating. The microstructure, Ra and phase composition of the

TiO2 coating were not altered following the

incorporation of Mn; however, the Mn-incorporated TiO2

coating was demonstrated to exhibit biological activity in

promoting the adhesion of MG63 cells. Moreover, the present study

indicated that Mn-TiO2 coatings may modulate

osteoblastic proliferation and differentiation, a process regulated

by the ERK/MAPK signaling pathway, through integrin-FAK mediated

cellular adhesion. There are limitations to using an evaluation of

initial cell adhesion as an end point for a screening assay of

potential material surfaces; however, further studies involving

in vitro cellular calcification and mineralization assays,

along with in vivo histological observations are currently

in progress.

References

|

1

|

Hamilton DW and Brunette DM: The effect of

substratum topography on osteoblast adhesion mediated signal

transduction and phosphorylation. Biomaterials. 28:1806–1819. 2007.

View Article : Google Scholar : PubMed/NCBI

|

|

2

|

Chen J, Ulerich JP, Abelev E, Fasasi A, et

al: An investigation of the initial attachment and orientation of

osteoblast-like cells on laser grooved Ti-6Al-4V surfaces. Mat Sci

Eng C. 29:1442–1452. 2009. View Article : Google Scholar

|

|

3

|

von Wilmowsky C, Bauer S, Lutz R, Meisel

M, et al: In vivo evaluation of anodic TiO2 nanotubes:

an experimental study in the pig. J Biomed Mater Res B Appl

Biomater. 89:165–171. 2009.PubMed/NCBI

|

|

4

|

Aita H, Hori N, Takeuchi M, Suzuki T, et

al: The effect of ultraviolet functionalization of titanium on

integration with bone. Biomaterials. 30:1015–1025. 2009. View Article : Google Scholar : PubMed/NCBI

|

|

5

|

Advincula MC, Rahemtulla FG, Advincula RC,

Ada ET, et al: Osteoblast adhesion and matrix mineralization on

sol-gel-derived titanium oxide. Biomaterials. 27:2201–2212. 2006.

View Article : Google Scholar : PubMed/NCBI

|

|

6

|

Bracci B, Torricelli P, Panzavolta S,

Boanini E, et al: Effect of Mg2+, Sr2+, and

Mn2+ on the chemico-physical and in vitro biological

properties of calcium phosphate biomimetic coatings. J Inorg

Biochem. 103:1666–1674. 2009.

|

|

7

|

Park JW, Kim YJ and Jang JH: Surface

characteristics and in vitro biocompatibility of a

manganese-containing titanium oxide surface. Appl Surf Sci.

258:977–985. 2011. View Article : Google Scholar

|

|

8

|

Li Y, Widodo J, Lim S and Ooi CP:

Synthesis and cytocompatibility of manganese (II) and iron (III)

substituted hydroxyapatite nanoparticles. J Mater Sci. 47:754–763.

2012. View Article : Google Scholar

|

|

9

|

Paluszkiewicz C, Œlósarczyk A, Pijocha D,

Sitarz M, et al: Synthesis, structural properties and thermal

stability of Mn-doped hydroxyapatite. J Mol Struct. 976:301–309.

2010. View Article : Google Scholar

|

|

10

|

Dormond O, Ponsonnet L, Hasmim M, Foletti

A and Rüegg C: Manganese-induced integrin affinity maturation

promotes recruitment of alpha V beta 3 integrin to focal adhesions

in endothelial cells: evidence for a role of phosphatidylinositol

3-kinase and Src. Thromb Haemost. 92:151–161. 2004.

|

|

11

|

Legler DF, Wiedle G, Ross FP and Imhof BA:

Superactivation of integrin αvβ3 by low antagonist concentrations.

J Cell Sci. 114:1545–1553. 2001.

|

|

12

|

Lüthen F, Lange R, Becker P, Rychly J, et

al: The influence of surface roughness of titanium on beta1- and

beta3-integrin adhesion and the organization of fibronectin in

human osteoblastic cells. Biomaterials. 26:2423–2440.

2005.PubMed/NCBI

|

|

13

|

Lüthen F, Bulnheim U, Müller PD, Rychly J,

et al: Influence of manganese ions on cellular behavior of human

osteoblasts in vitro. Biomol Eng. 24:531–536. 2007.PubMed/NCBI

|

|

14

|

Zreiqat H, Howlett CR, Zannettino A, Evans

P, et al: Mechanisms of magnesium-stimulated adhesion of

osteoblastic cells to commonly used orthopaedic implants. J Biomed

Mater Res. 62:175–184. 2002. View Article : Google Scholar

|

|

15

|

Hu H, Zhang W, Qiao Y, Jiang X, et al:

Antibacterial activity and increased bone marrow stem cell

functions of Zn-incorporated TiO2 coatings on titanium.

Acta Biomater. 8:904–915. 2012. View Article : Google Scholar : PubMed/NCBI

|

|

16

|

Li Y, Lee IS, Cui FZ and Choi SH: The

biocompatibility of nanostructured calcium phosphate coated on

micro-arc oxidized titanium. Biomaterials. 29:2025–2032. 2008.

View Article : Google Scholar : PubMed/NCBI

|

|

17

|

Han Y, Chen DH, Sun J, Zhang Y and Xu K:

UV-enhanced bioactivity and cell response of micro-arc oxidized

titania coatings. Acta Biomater. 4:1518–1529. 2008. View Article : Google Scholar : PubMed/NCBI

|

|

18

|

Sul YT, Johansson C, Byon E and

Albrektsson T: The bone response of oxidized bioactive and

non-bioactive titanium implants. Biomaterials. 26:6720–6730. 2005.

View Article : Google Scholar : PubMed/NCBI

|

|

19

|

Lee JM, Lee JI and Lim YJ: In vitro

investigation of anodization and CaP deposited titanium surface

using MG63 osteoblast-like cells. Appl Surf Sci. 256:3086–3092.

2010. View Article : Google Scholar

|

|

20

|

Wei D, Zhou Y and Yang C: Characteristic,

cell response and apatite-induction ability of microarc oxidized

TiO2-based coating containing P on Ti6Al4V before and

after chemical-treatment and dehydration. Ceram Int. 35:2545–2554.

2009. View Article : Google Scholar

|

|

21

|

Anselme K: Osteoblast adhesion on

biomaterials. Biomaterials. 21:667–681. 2000. View Article : Google Scholar

|

|

22

|

Silva GA, Coutinho OP, Ducheyne P, Shapiro

IM and Reis RL: The effect of starch and starch-bioactive glass

composite microparticles on the adhesion and expression of the

osteoblastic phenotype of a bone cell line. Biomaterials.

28:326–334. 2007. View Article : Google Scholar : PubMed/NCBI

|

|

23

|

Kennedy SB, Washburn NR, Simon CG Jr and

Amis EJ: Combinatorial screen of the effect of surface energy on

fibronectin-mediated osteoblast adhesion, spreading and

proliferation. Biomaterials. 27:3817–3824. 2006. View Article : Google Scholar : PubMed/NCBI

|

|

24

|

Kang IC, Kim TS, Ko KK, Song HY, et al:

Microstructure and osteoblast adhesion of continuously porous

Al2O3 body fabricated by fibrous monolithic

process. Mater Lett. 59:69–73. 2005. View Article : Google Scholar

|

|

25

|

Linez-Bataillon P, Monchau F, Bigerelle M

and Hildebrand HF: In vitro MC3T3 osteoblast adhesion with respect

to surface roughness of Ti6Al4V substrates. Biomol Eng. 19:133–141.

2002. View Article : Google Scholar : PubMed/NCBI

|

|

26

|

Zinger O, Anselme K, Denzer A, Habersetzer

P, et al: Time-dependent morphology and adhesion of osteoblastic

cells on titanium model surfaces featuring scale-resolved

topography. Biomaterials. 25:2695–2711. 2004. View Article : Google Scholar : PubMed/NCBI

|

|

27

|

Bacakova L, Grausova L, Vacik J, Fraczek

A, et al: Improved adhesion and growth of human osteoblast-like MG

63 cells on biomaterials modified with carbon nanoparticles. Diam

Relat Mater. 16:2133–2140. 2007. View Article : Google Scholar

|

|

28

|

Rodil SE, Ramírez C, Olivares R, Arzate H,

et al: Osteoblasts attachment on amorphous carbon films. Diam Relat

Mater. 15:1300–1309. 2006. View Article : Google Scholar

|

|

29

|

Huang HH, Ho CT, Lee TH, Lee TL, et al:

Effect of surface roughness of ground titanium on initial cell

adhesion. Biomol Eng. 21:93–97. 2004. View Article : Google Scholar : PubMed/NCBI

|

|

30

|

Dalby MJ, Kayser MV, Bonfield W and Di

Silvio L: Initial attachment of osteoblasts to an optimised HAPEX

topography. Biomaterials. 23:681–690. 2002. View Article : Google Scholar : PubMed/NCBI

|

|

31

|

Finke B, Luethen F, Schroeder K, Mueller

PD, et al: The effect of positively charged plasma polymerization

on initial osteoblastic focal adhesion on titanium surfaces.

Biomaterials. 28:4521–4534. 2007. View Article : Google Scholar : PubMed/NCBI

|

|

32

|

Tang ZG and Hunt JA: The effect of PLGA

doping of polycaprolactone films on the control of osteoblast

adhesion and proliferation in vitro. Biomaterials. 27:4409–4418.

2006. View Article : Google Scholar : PubMed/NCBI

|

|

33

|

Hillberg AL, Holmes CA and Tabrizian M:

Effect of genipin cross-linking on the cellular adhesion properties

of layer-by-layer assembled polyelectrolyte films. Biomaterials.

30:4463–4470. 2009. View Article : Google Scholar : PubMed/NCBI

|

|

34

|

Pallu S, Bourget C, Bareille R, Labrugère

C, et al: The effect of cyclo-DfKRG peptide immobilization on

titanium on the adhesion and differentiation of human

osteoprogenitor cells. Biomaterials. 26:6932–6940. 2005. View Article : Google Scholar : PubMed/NCBI

|

|

35

|

Feng B, Weng J, Yang BC, Qu SX and Zhang

XD: Characterization of titanium surfaces with calcium and

phosphate and osteoblast adhesion. Biomaterials. 25:3421–3428.

2004. View Article : Google Scholar : PubMed/NCBI

|

|

36

|

Xue WC, Krishna BV, Bandyopadhyay A and

Bose S: Processing and biocompatibility evaluation of laser

processed porous titanium. Acta Biomater. 3:1007–1018. 2007.

View Article : Google Scholar : PubMed/NCBI

|

|

37

|

Yun KD, Yang YZ, Lim HP, Oh GJ, et al:

Effect of nanotubular-micro-roughened titanium surface on cell

response in vitro and osseointegration in vivo. Mat Sci Eng C.

30:27–33. 2010. View Article : Google Scholar

|

|

38

|

Randeniya LK, Bendavid A, Martin PJ, Amin

MS, et al: Thin-film nanocomposites of diamond-like carbon and

titanium oxide; Osteoblast adhesion and surface properties. Diam

Relat Mater. 19:329–335. 2010. View Article : Google Scholar

|

|

39

|

Liu XM, Lim JY, Donahue HJ, Dhurjati R, et

al: Influence of substratum surface chemistry/energy and topography

on the human fetal osteoblastic cell line hFOB 1.19: Phenotypic and

genotypic responses observed in vitro. Biomaterials. 28:4535–4550.

2007. View Article : Google Scholar : PubMed/NCBI

|

|

40

|

Rouahi M, Champion E, Hardouin P and

Anselme K: Quantitative kinetic analysis of gene expression during

human osteoblastic adhesion on orthopaedic materials. Biomaterials.

27:2829–2844. 2006. View Article : Google Scholar : PubMed/NCBI

|

|

41

|

Rubin J, Rubin C and Jacobs CR: Molecular

pathways mediating mechanical signaling in bone. Gene. 367:1–16.

2006. View Article : Google Scholar : PubMed/NCBI

|

|

42

|

Siebers MC, ter Brugge PJ, Walboomers XF

and Jansen JA: Integrins as linker proteins between osteoblasts and

bone replacing materials. A critical review. Biomaterials.

26:137–146. 2005. View Article : Google Scholar : PubMed/NCBI

|

|

43

|

Wilson CJ, Clegg RE, Leavesley DI and

Pearcy MJ: Mediation of biomaterial-cell interactions by adsorbed

proteins: a review. Tissue Eng. 11:1–18. 2005. View Article : Google Scholar : PubMed/NCBI

|

|

44

|

Prasadam I, Friis T, Shi W, van Gennip S,

et al: Osteoarthritic cartilage chondrocytes alter subchondral bone

osteoblast differentiation via MAPK signalling pathway involving

ERK1/2. Bone. 46:226–235. 2010. View Article : Google Scholar : PubMed/NCBI

|