Introduction

Bone grafting is performed on millions of patients

suffering from bone trauma and bone defects caused by wars, traffic

accidents, sports injuries, diseases and natural disasters. Bone

grafting is the second most frequently performed type of tissue

transplant following blood transfusion (1). In 1995, Crane et al (2) proposed the concept of using bone tissue

engineering for the repair of bone defects. Since then, this

technology has achieved marked progress, in fundamental research

and clinical application in repairing bone defects (3,4) and in

total joint replacement (5,6). There are three types of scaffold

materials used in bone tissue engineering: Natural, artificially

synthesized inorganic, and artificially synthesized polymers.

Generally, a single type of scaffold material does not satisfy the

current requirements for an extracellular scaffold, which are as

follows: Enhanced mechanical strength, improved degradation time

and increased biological activity. Therefore, numerous studies have

investigated the use of two or more materials in the composition of

scaffold materials (7–9). By selecting appropriate components and

adjusting the proportion of each, composite materials with

adjustable degradation characteristics and mechanical properties

may be produced.

It has been widely recognized that, following

autogenous bone, allograft bone is the best substitute material for

bone grafting. Demineralized bone matrix (DBM), prepared for

allograft cortical bone through grinding, washing and

decalcification, is a natural sustained-release carrier of bone

morphogenetic proteins with favorable bone induction, bone

conduction and biocompatibility properties (10,11).

However, DBM has poor mechanical properties and is difficult to

model (12). The most widely applied

artificially synthesized polymer scaffold material is polylactic

acid (PLA), which has useful mechanical properties and is easy to

model, but has no biological activity and poor cellular affinity

(13). Therefore, a composite of DBM

and PLA together may exhibit advantages compared with either

material alone.

With effective utilization of antibiotics,

concurrent infection of bone defects are well controlled. However,

the postoperative infection rate of bone defects caused by open

injuries remains as high as 20%, even when debridement is conducted

early in the procedure (14). The

prevention and treatment of infected bone defects is more difficult

compared with that of a simple bone defect (15). When a bone defect is infected, bone

grafting in the first stage does not facilitate the union of the

defect, but rather exacerbates the infection (16). Furthermore, single-dose

administration of antibiotics at the site of bone grafting may not

be effective, as systemic antibiotic administration cannot provide

an effective concentration of antibiotics at the bone grafting site

and can also have potential adverse side effects (17). One solution to this problem is to

combine antibiotics with a scaffold material to prepare an

anti-infective tissue-engineered bone material that is able to

maintain a high local concentration of antibiotics at the bone

grafting position, and a low concentration in the circulation. This

may reduce the infection rate by increasing antibacterial activity

locally at the bone grafting site (18).

With these considerations, the present study

investigated the effect of a novel gentamicin sulfate (GS)/DBM/PLA

porous composite for the treatment of an infected femoral condyle

defect in a rat model.

Materials and methods

Preparation of DBM and PLA

The ethics committee of Shanxi Medical University

(Taiyuan, China) approved the present study. Human cortical bones

from numerous healthy and certified donors were ground and sifted

to prepare bone powder with a diameter of 200–300 µm. The bone

powder was frozen, ultrasonically washed with distilled water for 3

days, decalcified in 0.6 N HCl at 4°C for 48 h and lyophilized. A

1-g sample of 0.5×105, 1×105 or 5

×105 Da PLA (Daigang Biomaterial Co., Ltd., Jinan,

China) was mixed with 2 g NaCl (diameter, 200–300 µm, determined by

molecular sieve), at a PLA-to-NaCl ratio of 1:2. The mixed

composition was put into a 10-ml supercritical cylinder reactor

vessel linked to supercritical (SC)-CO2 reaction

apparatus (SFE-2; Applied Separations, Inc., Allentown, PA, USA).

The pressure of the container was gradually raised to 20 MPa and

the temperature was increased to 37°C, and was maintained at

37±1°C, with the pressure variation kept within 0.1 MPa of this.

After maintaining the temperature and pressure for 30 min, they

were decreased slowly over 15 min to room temperature and pressure.

PLA samples were then removed from the vessel and leached with

distilled water for 48 h to completely remove the NaCl. Following

lyophilization, the samples were packed in a three-layer aseptic

package (Fuhua Medical Packing Co., Ltd., Nantong, China) and

irradiated with 20 kGy 60Co (China Nuclear Power

Engineering Co., Ltd, Beijing, China) for sterilization.

Preparation of porous GS/DBM/PLA

composite biomaterial

To produce the biomaterial, 0.6 g DBM (particle

size, 200–300 µm; Shanxi Provincial Tissue Bank, Taiyuan, China)

and 0.4 g PLA (molecular weight, 1×105; Daigan

Biological Materials, Jinan, China) were weighed at a DBM-to-PLA

ratio of 3:2, in addition to 0.5 g GS powder (BBI Life Sciences

Corporation, Shanghai, China) and 2 g NaCl (diameter, 200–300 µm).

These materials were all white powders and were mixed thoroughly

prior to being placed into the 10-ml supercritical reactor vessel.

The vessel was then linked to the supercritical CO2

reaction apparatus and the preparation proceeded as described for

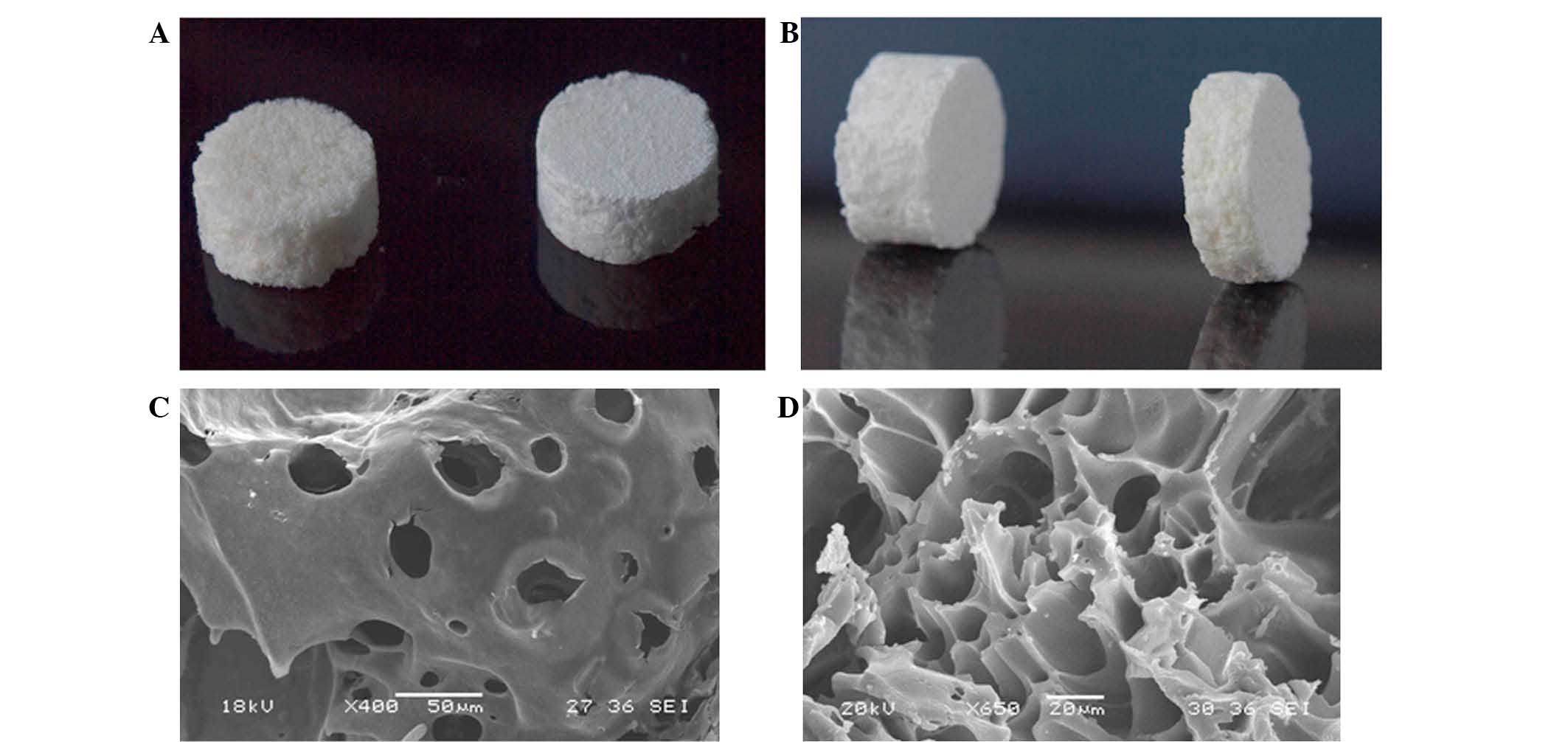

the DBM and PLA. Optical and scanning electron microscope

(JSM-6360LVV; JEOL, Ltd., Tokyo, Japan) images of the composite

biomaterial are presented in Fig. 1.

GS/DBM/PLA was prepared to a ratio of 5:3:2.

Characteristics of the porous

GS/DBM/PLA composite biomaterial

For the evaluation of the biomechanical properties

of the composite biomaterials, specific gravity was measured as an

indication of porosity, and compressive strength and elastic

modulus were determined using an RGT-20A microcomputer-controlled

electronic universal testing machine (Shenzhen Reger Instrument Co.

Ltd., Shenzhen, China). Cytotoxicity was detected in the mouse

fibroblast cell line L-929 (Shanxi Provincial Tissue Bank) using an

MTT assay. Briefly, mouse fibroblast cells at passage 3 were

cultured together with extracts of GS/DBM/PLA and DBM/PLA in

96-well culture plates, with DMEM medium serving as a control.

After culturing for 1, 2, 3, 4, 5, 6 and 7 days, MTT solution

(Sigma-Aldrich, St. Louis, MO, USA) was added to each well and the

cells were cultured for an additional 4 h. Subsequent to this, 150

µl DMSO was added to each well and the optical density was examined

using a Model 680 microplate reader (Bio-Rad Laboratories, Inc.,

Hercules, CA, USA) at a wavelength of 570 nm to determine cell

viability in the presence of these compounds. Next, the prepared

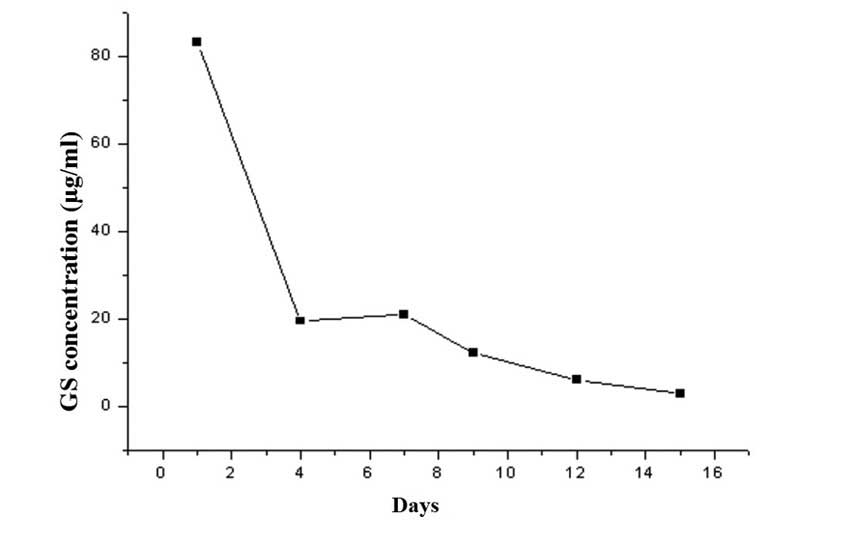

GS/DBM/PLA composite was trimmed to uniform size (10 × 5 mm).

Fifteen test tubes were prepared and 10 ml normal saline was added

to each under sterile conditions. The prepared GS/DBM/PLA materials

were put into test tube 1, soaked for 4 h at 37°C and the next day

removed to test tube 2. Then, the process was repeated from tube 2

to tube 3, successively up to tube 15 (day 15). During this time,

the gentamicin in the GS/DBM/PLA composite gradually leached into

the normal saline. A microbial inhibitory concentration test was

then conducted on the saline in each of the tubes to determine the

antibacterial concentration at different times and to produce an

in vitro release curve of gentamicin (Fig. 2). Subsequent to this, prepared

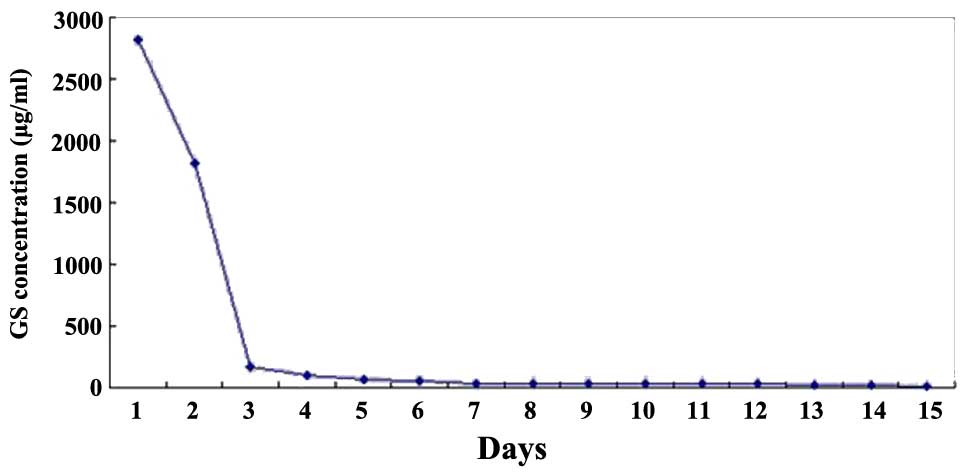

GS/DBM/PLA composite was trimmed to uniform size (5 × 5 mm), and

placed into the muscle of rats (described below). At postoperative

days 1, 4, 7, 9, 12 and 15, 3 mm muscular tissue around the

implanted materials was removed and 2 mm blood was collected from

the abdominal aorta [using heparin anticoagulant (Sigma-Aldrich)].

The biological samples were stored in a cryogenic refrigerator

(DW-25L92; Haier Group, Qindao, China) at −20°C. Then, under

sterile conditions, the preserved muscle tissue and blood were

homogenized in phosphate-buffered saline solution, centrifuged for

10 min at 37°C, 2,300 × g, and the supernatant was collected.

Microbial inhibitory concentration was detected in this saline by a

golden Staphylococcus microbiological test, based on flat

colony counting methods (Shanxi Medical University), and an in

vivo release curve was mapped (Fig.

3).

Preparation of the animal model

A total of 84 Wistar rats were used (Shanxi Medical

University Medical Laboratory Animal Center). These were kept at

26°C, in pathogen-free conditions with a 12–12 h light-dark cycle.

The body weight of rats was ~300 g, and the sample included male

and female rats. The requisite approval was obtained from the local

ethics committee. The rats were divided into four groups, as

follows: The control group, in which no experiment was conducted;

the GS/DBM/PLA plus Staphylococcus aureus (SA) group; the

DBM/PLA plus SA group; and the DBM/PLA without SA group, with 21

rats per group. The rats were anesthetized with 0.6% pentobarbital

sodium (30 mg/100 g; Merck Millipore, Darmstadt, Germany) and fixed

prostrate to the operating platform. Following depilation and

sterilization around the femoral condyle, with drapes covering the

skin, subcutaneous tissue and deep fascia were incised by layer.

The muscles were bluntly dissected to prepare for a bilateral

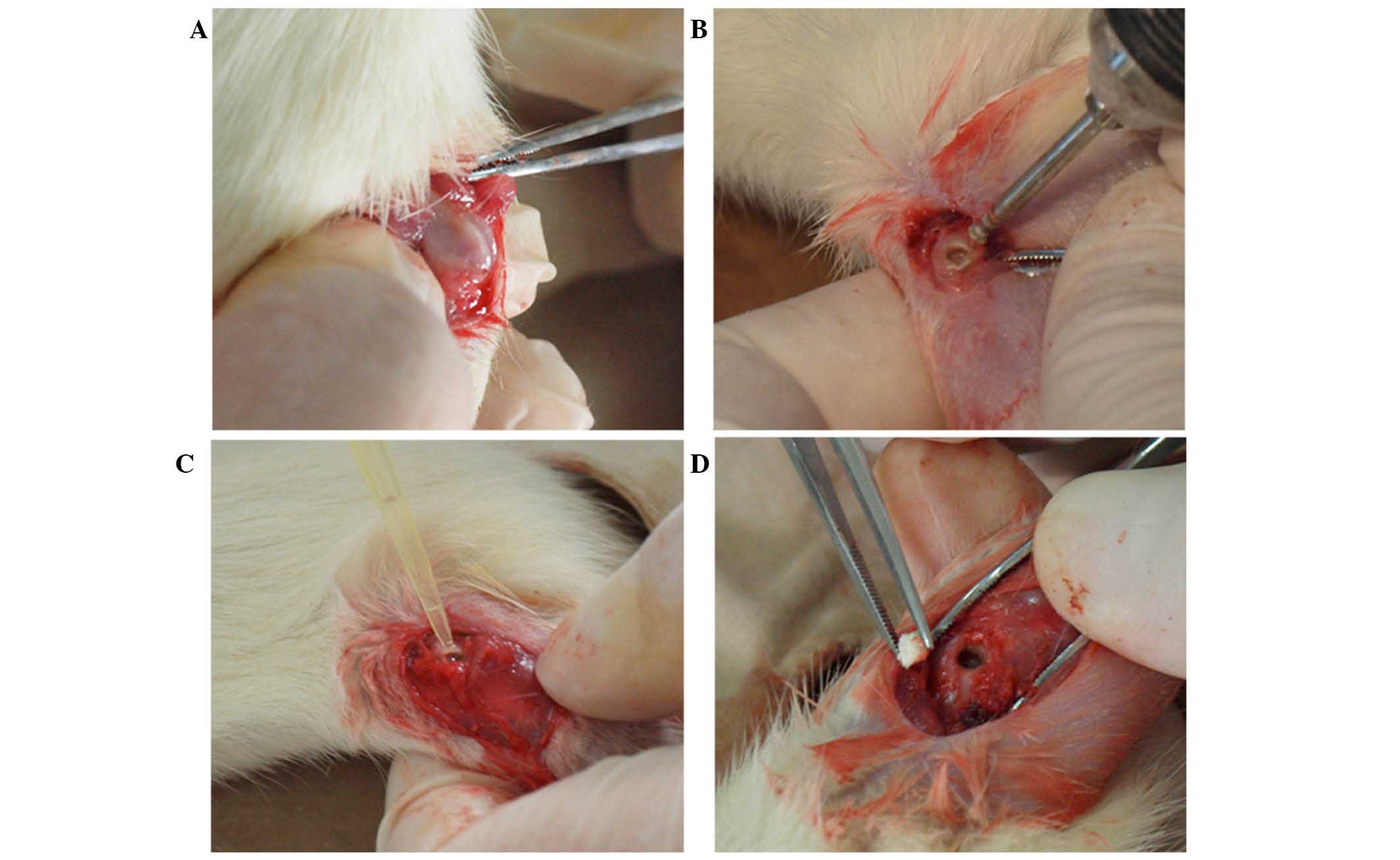

femoral condyle defect. A 1-cm incision on the lateral femoral

condyle was made to expose the lower end of the femur. The incision

did not penetrate into the articular cavity in order to protect the

articular cartilage (Fig. 4A). A

dental ball drill (diameter, 1.6 mm) was applied to drill in from

the lateral side of the femoral condyle along the bone shaft axis

(Fig. 4B), reaching the bone cortex

on the opposite side but not damaging it. Then, the defect in the

condyle was enlarged until it was 60–70% of the volume of the

femoral condyle (Fig. 4C). The

defect was washed with sterile saline and dried with a sterile

gauze. Then, 10 µl SA standard solution (1×1011 CFU/ml;

Shanxi Medical University) was injected into the defect by pipette

(Fig. 4D). After 30 min, ~80 mg

GS/DBM/PLA or DBM/PLA was implanted into the defect. Following

suturing, the incision was tightly covered, but the operated limb

was not fastened. The rats were fed conventionally following the

operation. Rats were sacrificed prior to the following experiments

using an injected overdose of pentobarbital sodium (40–60 mg/100

g), at 4, 6 or 8 weeks after the first operation.

Radiographic observation and bone

density analysis

Three rats (six sites of femoral condyle defects) in

each group were selected and anesthetized with 0.6% pentobarbital

sodium (30 mg/100 g) at 4, 6 and 8 weeks after the operation

described above. To investigate new bone growth and reconstruction

of bone, radiographs were captured using an SMX-1000 Plus X-ray

inspection system (Shimadzu, Kyoto, Japan). The grayscale value per

unit area of defect was measured using image analysis software

(Image-Pro Plus version 5.0; Media Cybernetics, Inc., Rockville,

MD, USA) to evaluate the bone repair condition instead of bone

mineral density.

Biomechanical compression tests

Four rats from each group were selected and the left

femoral condyles were inspected at 4, 6, and 8 weeks after the

operation. For comparison, the left femoral condyles of the Wistar

rats in the control group with normal age and weight were inspected

at the same position. The femoral condyles were fixed onto the

biomechanics machine (WD-P4204; Jinan Test Machine Co., Ltd.,

Jinan, China) table and compressed at a rate of 5 mm/min. During

the process, the femoral condyle displacement/time and

displacement/load were determined. A displacement of 2 mm (femoral

condyle thickness, ~5 mm) was defined as structural damage and this

pressure (the breaking load) was used to evaluate the carrying

capacity (compression area, ~24 mm2).

Histological observation

Four rats from each group were selected and the

right femoral condyles were inspected at 4, 6 and 8 weeks after the

operation. The bone at the bilateral femoral condyle (weight, ~2 g)

was excised until sterile conditions. The samples were then fixed

in 10% neutral buffered formalin for 24 h, decalcified in 50%

formic acid, dehydrated in an 80–100% ethyl alcohol series, a

95–100% hyaline xylene series and prepared for paraffin embedding.

The samples were sectioned longitudinally at 5 µm and stained with

hematoxylin and eosin (Sigma-Aldrich). The bone union in the

grafted area was then observed under an optical microscope (IX73;

Olympus Corporation, Tokyo, Japan).

Statistical analysis

Data analysis was performed using SPSS version 18.0

statistical software (SPSS, Inc., Chicago, IL, USA). Data are

presented as the mean ± standard deviation. The porosity was

analyzed by rank correlation, and intergroup comparisons were

carried out by one-way analysis of variance using the multi-sample

average. If the homogeneity of variance was satisfied, the

intergroup multiple comparisons were conducted with the method of

least significance difference, and for heterogeneity, Tamhanes T2

post hoc test was applied to the intergroup multiple comparisons.

Comparisons between two group were performed using the Students

t-test or t-test (for heterogeneity of variance) using the

independent sample average. The optical density value measured by

the cytotoxicity test was analyzed through factorial design

variance analysis. P<0.05 was considered to indicate a

statistically significant difference.

Results

Physical and chemical properties of

GS/DBM/PLA and DBM/PLA

The porosity of the composite biomaterials

GS/DBM/PLA (5:3:2) and DBM/PLA (3:2) were evaluated using a t-test.

The porosity of GS/DBM/PLA (77.08%) was significantly reduced

compared with DBM/PLA (79.71%) (t=2.877; P=0.021; Table I). The compressive strength and

elastic modulus of the GS/DBM/PLA and DBM/PLA materials were

evaluated using a t-test (Table

II). The t-values were 2.056 and 2.028, and the P-values were

0.074 and 0.077, respectively. Thus, there was no significant

difference between the two groups with regards to compressive

strength or elastic modulus, although the compressive strength and

elastic modulus of GS/DBM/PLA was slightly inferior to that of

DBM/PLA. Table III presents the

data demonstrating the effects of GS/DBM/PLA and DBM/PLA composite

gentamicin leachate on cellular proliferation and Table IV presents the cytotoxicity rating

of GS/DBM/PLA and DBM/PLA composites. There are significant

differences in the cell optical density values at different time

points (F=1376.194; P<0.001), and the difference is also

significant between GS/DBM/PLA and DBM/PLA (F=2.983; P<0.001).

From days 3 to 7, there is no statistical difference among the

control, DBM/PLA and GS/DBM/PLA groups. The relative rate of

cellular proliferation from days 3 to 7 was >90% following

treatment with GS/DBM/PLA composite leachate and the cell toxicity

rating was 0 or 1, indicating that the GS/DBM/PLA composite was

almost non-cytotoxic relative to the DBM/PLA composite

material.

| Table I.Porosity of GS/DBM/PLA and DBM/PLA

composite biomaterials (n=5). |

Table I.

Porosity of GS/DBM/PLA and DBM/PLA

composite biomaterials (n=5).

| Composite

material | Porosity (%) |

|---|

| GS/DBM/PLA |

77.08±1.63a,b |

| DBM/PLA |

79.71±1.23a,b |

| Table II.Compressive strength and elastic

modulus of GS/DBM/PLA and DBM/PLA composite biomaterials (n=5). |

Table II.

Compressive strength and elastic

modulus of GS/DBM/PLA and DBM/PLA composite biomaterials (n=5).

| Composite

material | Compressive

strength | Elastic

modulus |

|---|

| GS/DBM/PLA |

100.99±7.28a,b |

13.82±2.00c,d |

| DBM/PLA |

108.71±4.19a,b |

11.82±0.94c,d |

| Table III.OD values for the proliferation of

mouse fibroblast L929 cells in the presence of composite

biomaterials (n=5). |

Table III.

OD values for the proliferation of

mouse fibroblast L929 cells in the presence of composite

biomaterials (n=5).

|

| Composite

biomaterial |

|

|

|

|---|

|

|

|

|

|

|

|---|

| Day | Control | DBM/PLA | GS/DBM/PLA | Mean OD | F-value | P-value |

|---|

| 1 | 0.392±0.040 | 0.515±0.022 | 0.395±0.051 | 0.434±0.070 | 15.618 | <0.001 |

| 2 | 0.474±0.060 | 0.577±0.027 | 0.457±0.044 | 0.503±0.069 | 10.152 | 0.003 |

| 3 | 0.582±0.019 | 0.546±0.044 | 0.584±0.019 | 0.570±0.033 | 2.616 | 0.114 |

| 4 | 0.716±0.081 | 0.744±0.047 | 0.702±0.040 | 0.721±0.057 | 0.651 | 0.539 |

| 5 | 1.306±0.053 | 1.272±0.043 | 1.282±0.066 | 1.287±0.053 | 0.504 | 0.616 |

| 6 | 1.388±0.045 | 1.346±0.029 | 1.392±0.037 | 1.375±0.041 | 2.328 | 0.140 |

| 7 | 1.325±0.027 | 1.304±0.036 | 1.316±0.035 | 1.315±0.032 | 0.478 | 0.632 |

| Mean |

0.883±0.415a,b |

0.901±0.366a,b |

0.876±0.413a,b | 0.886±0.394 | 4.318 | <0.001 |

| F | 380.161 | 562.808 | 498.743 | 1376.194 | – | – |

| Table IV.Cell toxicity of GS/DBM/PLA and

DBM/PLA leachates. |

Table IV.

Cell toxicity of GS/DBM/PLA and

DBM/PLA leachates.

|

| Day |

|---|

|

|

|

|---|

| Group | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

|---|

| GS/DBM/PLA | 0 | 1 | 0 | 1 | 1 | 0 | 1 |

|

DBM/PLAa | 0 | 0 | 1 | 0 | 1 | 1 | 1 |

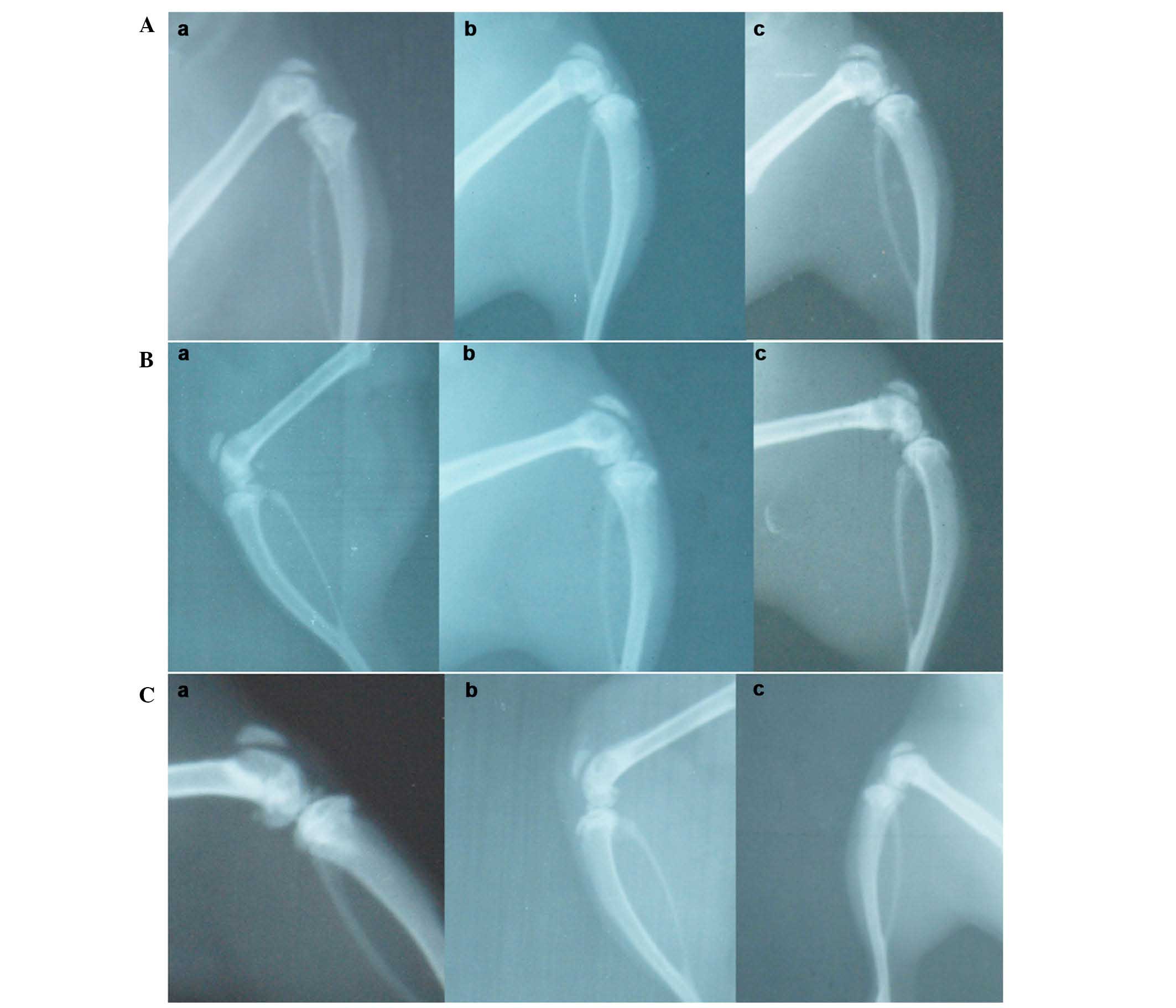

X-ray observation

Representative X-rays of the three different groups

are presented in Fig. 5. In the

GS/DBM/PLA group containing SA, at 4 weeks following implantation,

the defect repair area appeared cloudy, and the density of this was

highest at the center of the repair area (Fig. 5A). At 6 weeks after implantation, the

flocculent resistance projection grew denser (Fig. 5A). At 8 weeks following implantation,

the resistance projection at the defect region was nearly as dense

as normal bone (Fig. 5A). In the

DBM/PLA group containing SA, at 4 weeks following implantation

there was clear and uniform flocculent resistance projection in the

defect repair area and the defect center was radiolucent (Fig. 5B). At 6 weeks following implantation,

the flocculent resistance projection grew denser and more uniform,

but there remained a large area of transparent zones that could be

observed in the defect area (Fig.

5B). At 8 weeks following implantation, the flocculent

resistance projection was more dense and the transparent zones in

the center of the defect were smaller and irregular (Fig. 5C). In the DBM/PLA group without SA,

at 4 weeks following implantation, there was flocculent resistance

projection in the defect repair area and the transparent zones in

the center of defect were not obvious (Fig. 5A). At 6 weeks following implantation,

the flocculent resistance projection was uniform and dense

(Fig. 5B). At 8 weeks following

implantation, the defect region was nearly as dense as normal bone

(Fig. 5C).

Analysis of bone density

measurement

Variance analysis was conducted to evaluate the gray

values (bone mineral density) of materials collected at 4, 6 and 8

weeks post-operation, and there was significant difference recorded

at each point (Table V). At 4 weeks,

F=56.248, P<0.001; at 6 weeks, F=57.704, P<0.001; and at 8

weeks, F=25.793, P<0.001. Further intergroup comparisons

demonstrated statistical differences between each pair of groups

(P<0.001). The grey value of the DBM/PLA group without SA was

highest, and that of the DBM/PLA group containing SA was the

lowest. In addition, the grey value of the GS/DBM/PLA group

containing SA was significantly higher compared with the DBM/PLA

group containing SA. These results suggest that the DBM/PLA

material could promote the repair of bone defects and that

GS/DBM/PLA was beneficial to bone defect repair as a result of its

ability to reduce local infection.

| Table V.Bone mineral density (pixels; gray

value) of bone repair in the area surrounding the composite

material (n=6). |

Table V.

Bone mineral density (pixels; gray

value) of bone repair in the area surrounding the composite

material (n=6).

|

| Gray value

(pixels) |

|---|

|

|

|

|---|

| Composite

material | Week 4a | Week 6b | Week 8c |

|---|

| Non-operated

control | 2.223±0.328 | 2.505±0.574 | 3.993±0.597 |

| GS/DBM/PLA |

1.230±0.265d |

1.693±0.296d |

2.850±0.555d |

| DBM/PLA |

3.333±0.420d,e |

4.520±0.494d,e |

5.968±1.035d,e |

Biomechanical compression tests

Variance analysis was conducted to evaluate the

breaking load and breaking strength of composite materials at 6 and

8 weeks following operation, and there was significant difference

between these values (Table VI). At

6 weeks, F=50.381, P<0.001, and at 8 weeks, F=93.291,

P<0.001. Further intergroup comparison demonstrated that, except

for the GS/DBM/PLA group containing SA and the DBM/PLA group

without SA at 6 weeks (P=0.097), there was statistical difference

among the other groups (P<0.05). The analysis indicated that the

breaking load and breaking strength were highest in the normal

control group, followed by the DBM/PLA group without SA, and that

the breaking load and breaking strength were lowest in the DBM/PLA

group containing SA, which was lower than those in the GS/DBM/PLA

group containing SA. These differences were statistically

significant and suggest that the DBM/PLA material can promote the

repair of bone defects and that GS/DBM/PLA supported bone defect

repair applying its anti-infection properties.

| Table VI.Anti-compression biomechanical

evaluation of the femoral condyle in the presence of a composite

material with, or without, SA (n=4). |

Table VI.

Anti-compression biomechanical

evaluation of the femoral condyle in the presence of a composite

material with, or without, SA (n=4).

|

| Week 6a | Week 8b |

|---|

|

|

|

|

|---|

| Composite

material | Load (N) | Strength (MPa) | Load (N) | Strength (MPa) |

|---|

| GS/DBM/PLA (with

SA) | 288.284±31.255 | 12.012±1.302 | 363.029±23.828 | 15.126±0.993 |

| DBM/PLA (with

SA) |

192.376±15.811c |

8.01±0.659c |

248.687±21.465c |

10.362±0.894c |

| DBM/PLA (without

SA) |

322.530±32.802d |

13.439±1.367d |

412.902±11.748a,d |

17.204±0.490c,d |

| Normal control

group |

88.696±22.174c,d,e |

17.651±1.012c,d,e |

527.878±33.655c,d,e |

21.995±1.402c,d,e |

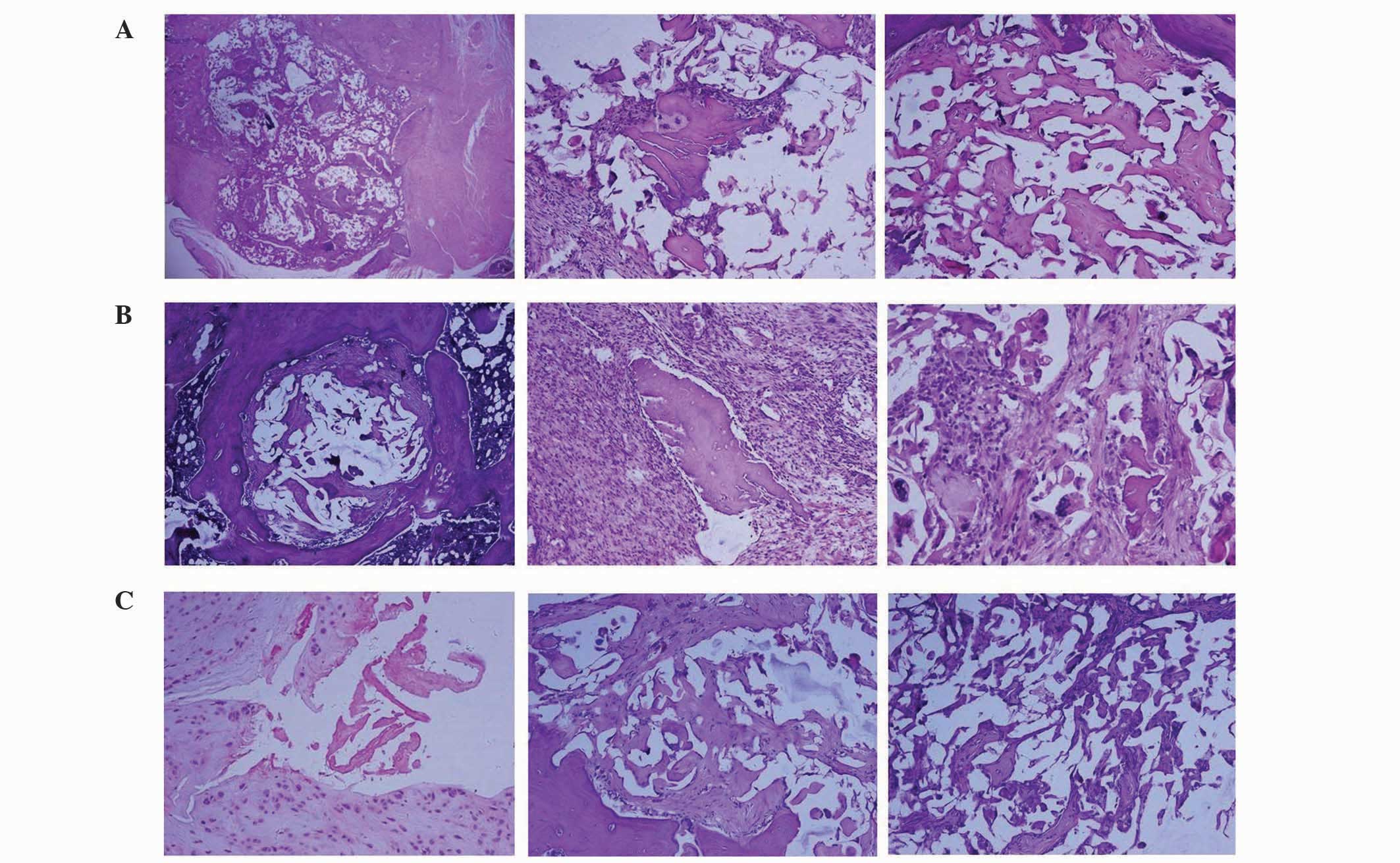

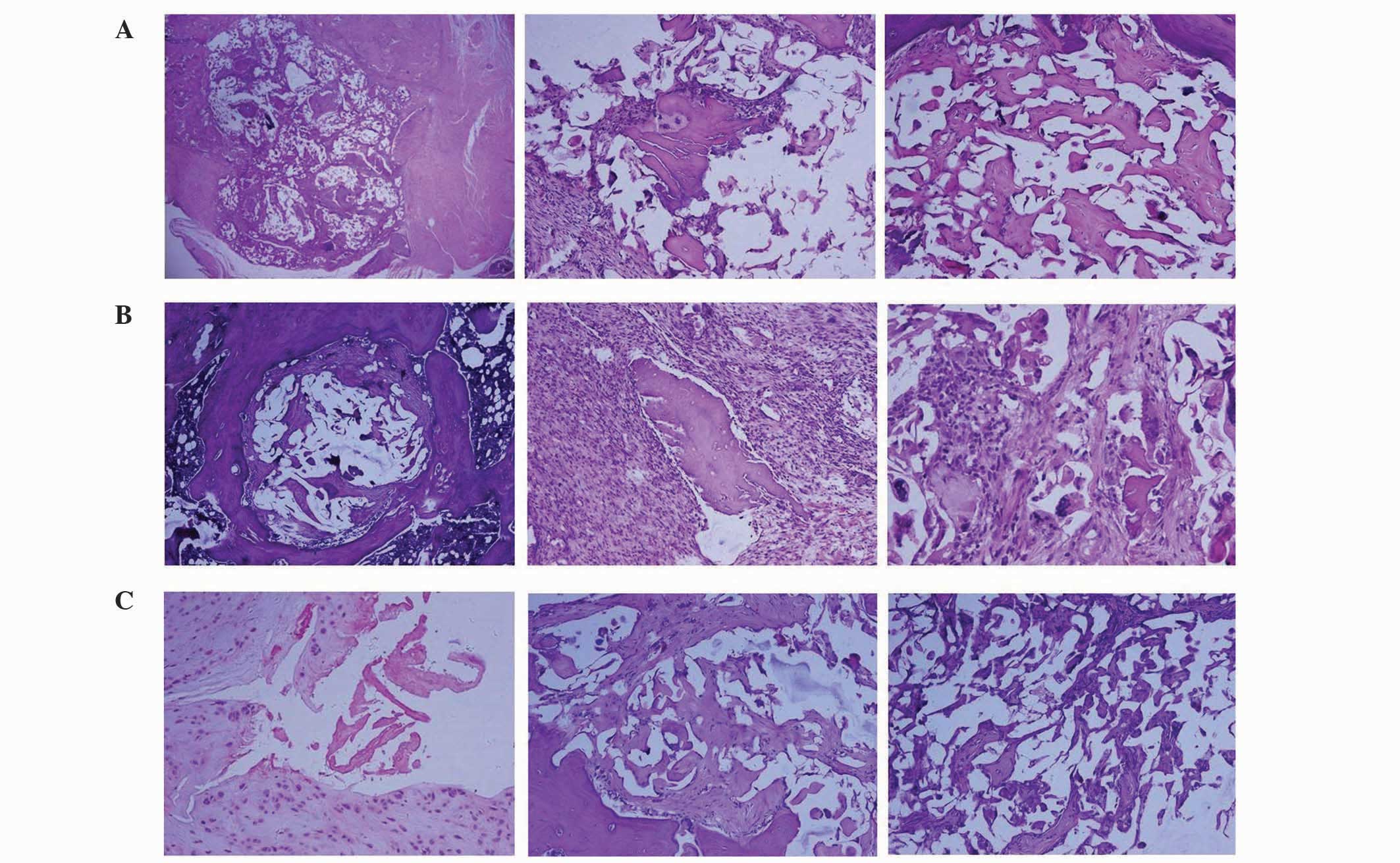

Histological observation

In the GS/DBM/PLA group containing SA, after 4

weeks, a small area of inflammatory tissue was observed among the

implanted biomaterial (Fig. 6).

After 6 weeks, mesenchymal cells grew into the implanted bone, and

a number of inflammatory cells and polykaryocytes were also

observed. Osteoblasts could be seen around the implanted material.

After 8 weeks, the implanted area was completely substituted by new

bone tissue and the condition of bone union was similar to that of

the DBM/PLA group without SA at 8 weeks. In the DBM/PLA group

containing SA after 4 weeks, the implanted material was covered by

inflammatory fibrous tissue in which a large amount of inflammatory

cells were observed. After 8 weeks, the implanted material was

almost absorbed by the inflammatory fibrous tissue, despite some

DBM fragments, and the implanted area was saturated with

inflammatory fibrous tissue.

| Figure 6.Histological images, stained with

hematoxylin and eosin, of biomaterial implanting (A) after 4 weeks,

displaying a small area of inflammatory tissue among the implanted

biomaterial, (B) after 6 weeks, displaying mesenchymal cells

growing into the implanted bone with a number of inflammatory

cells, multinucleated cells around the demineralized bone matrix

and osteoblasts in the lacuna, and (C) after 8 weeks, when the

implanting area was fully covered with new-borne bone tissue,

showing complete dissipation of inflammation (magnification,

×100). |

Discussion

In the present study, the GS/DBM/PLA porous

composite was prepared using a SC-CO2 fluid technique,

and DBM/PLA was the sustained-release carrier for GS. It was

observed that the porous GS/DBM/PLA composite material accelerated

repair of bone defects while controlling infection in the rat

model.

Poly(methyl methacrylate) (PMMA) was the earliest

sustained-release drug material applied in clinical practice, and

it achieves evident curative effect in the treatment of bone

infections and bone defect repairs. However, PMMA has a number of

limitations, including poor histocompatibility, heat release during

polymerization, toxicity of its monomer, a second operation

required to remove it and inadequate drug release (19). These disadvantages of PMMA impose

many restrictions on its clinical application (20,21).

A number of studies have been conducted on the

materials that can provide sustained-release of antibiotics. For

anti-infective bone defect repair, studies have investigated

composites to contain antibiotics including allogeneic bone

(22,23), alginates (24), hydroxyapatites (25) and beta tricalcium phosphate (26). However, appropriate biological

activity, degradability and mechanical strength cannot be satisfied

by a single material, and therefore creating an anti-infective

material that contains two different methods of producing

sustained-release of antibiotic with desirable properties is a

vital area of research. The DBM/PLA material prepared in the

present study was demonstrated to have favorable biocompatibility,

bone inductive activity and mechanical properties. When composited

with GS, it exhibited good anti-infective ability, effectively

inhibiting the growth of SA and promoting the union of bone

defects.

After grafting, degradable material may fill the

cavity of the bone defect and release a high concentration of

antibiotics. Compared with systemic administration, this method

avoids adverse antibiotic side effects as well as bacterial drug

resistance (27). In addition,

degradable material does not require a second operation to remove

it; space for bone growth is provided as the material degrades

(28). The degradable

sustained-release materials PLA, polyglycolic acid and their

copolymer poly(glycolide-co-lactide) have numerous advantages,

including high local drug concentration, long maintenance time,

lack of toxic and allergic reactions and acceptable compatibility

with most antibiotics (29,30). In addition, these materials can

usually be metabolized in the human body and their decomposition

products, carbon dioxide and water, have no toxic or other adverse

side effects in humans (31).

The GS/DBM/PLA porous composite prepared in the

current study combined the advantages of its three components: The

easy modelling and good biomechanical properties of PLA, the

biocompatibility and bone induction properties of DBM and the

broad-spectrum antibacterial activity of GS. As a result, the

composite has the favorable properties required to treat infected

bone defects. As previously reported, when the porosity of a

biomaterial is >60%, new bone tissue can grow from the surface

inwards along the intercommunicated pores, forming a network

structure (32). The porosity of the

GS/DBM/PLA porous composite in the present study was 77.1%, and its

compressive strength and elasticity modulus were 101.0±7.3 and

13.8±2.0 MPa, respectively. Cell compatibility is another important

indicator affecting bone tissue engineering material. The

cytotoxicity grade of the GS/DBM/PLA porous composite in this study

was rated as 0 or 1, which is almost nontoxic. This satisfies the

essential requirements for bone tissue engineering scaffold

material.

In the present study, the materials were processed

at <37°C to ensure bioactivity during compositing. During the

SC-CO2 reaction process, low pressure may lead to

oversized and uneven pores, while excessive pressure may cause

complete swelling of the material and collapse of the pores

(33). The reaction pressure in the

present study was 20 MPa and ideal porosity was obtained; the

porosity of the DBM/PLA composite was >65% and increased with

the proportion of DBM, reaching 79.7% at the optimal composite

proportion of DBM/PLA (3:2). High porosity enlarges the contact

area between the scaffold material and cells, thus promoting the

cell adhesive growth and facilitating the entrance of oxygen and

nutrients, and the excretion of metabolic products.

Response time is another crucial factor that

influences the size of pores in PLA material. The porosity of the

material formed from pure PLA after 30 min of SC-CO2

reaction is relatively high and the pore size is ~300 µm; a

reaction that is much shorter or longer is not beneficial to the

formation of pores on the PLA surface (34). If the reaction time is too short the

segmental motion will be incomplete, and if the reaction time is

too long the chain segments will rearrange and there will be fewer

pores. Adequate infiltration time ensures that carbon dioxide will

infiltrate the sample sufficiently, and after pressure reduction

and foaming, a porous scaffold material with high porosity will be

obtained (35,36). Therefore, in the present study the

reaction time was set to 30 min.

The pressure reduction time also has a marked

influence on the porosity of the composite material. If the

pressure reduction time is too short, the PLA will rapidly separate

from the supercritical system and the curing speed will be high.

Furthermore, the speed of CO2 overflowing out of the PLA

will be high, leading to a low expansion rate (37). If the pressure reduction time is

prolonged to 15 min, the curing speed of the PLA and the overflow

speed of the carbon dioxide will reduce, leaving sufficient time

for a uniform foam to form and solidify, resulting in a microporous

structure of relatively large diameter (38). On this basis, the current study

adopted 15 min as the pressure reduction time.

Bucholz (39)

proposed that the pore diameter of bone substitute material should

not be <100 µm, in order to avoid stunting the growth of bone.

However, if the pore diameter is >500 µm, the strength and cell

adhesion rate of the material would be adversely affected. Porter

et al (40) considered that a

pore diameter of >200 µm is essential for bone conduction, and a

pore diameter between 200 and 400 µm is ideal for bone growth.

Therefore, the pore diameter of the DBM/PLA porous composite

prepared in the present study was between 200 and 400 µm. Thus, the

material was able to promote the growth of bone tissue into the

material and facilitate cell adhesion and nutrient diffusion. In

addition, there were small pores (diameter, 20–30 µm) on the pore

wall of the material which may assist the growth of bone tissue and

blood vessels.

In conclusion, the GS/DBM/PLA porous composite

prepared by the SC-CO2 fluid technique has favorable

porosity, mechanical properties, bone induction/conduction ability,

local antibacterial ability and bone defect repair efficacy.

Therefore, the GS/DBM/PLA porous composite is a potentially viable

bone tissue engineering material for the repair of infective bone

defects.

Acknowledgments

The present study was supported by a grant from the

Shenzhen Governmental Basic Research Grant (no.

JCYJ20120617115010496), the State Key Laboratory of Bioelectronics

of Southeast University (Nanjing, China) and the Doctor Startup

Foundation of Zunyi Medical College (no. F-746).

References

|

1

|

Roberts TT and Rosenbaum AJ: Bone grafts,

bone substitutes and orthobiologics: The bridge between basic

science and clinical advancements in fracture healing.

Organogenesis. 8:114–124. 2012. View Article : Google Scholar : PubMed/NCBI

|

|

2

|

Crane GM, Ishaug SL and Mikos AG: Bone

tissue engineering. Nat Med. 1:1322–1324. 1995. View Article : Google Scholar : PubMed/NCBI

|

|

3

|

Won YH, Kim SG, Oh JS and Lim SC: Clinical

evaluation of demineralized bone allograft for sinus lifts in

humans: A clinical and histologic study. Implant Dent. 20:460–464.

2011. View Article : Google Scholar : PubMed/NCBI

|

|

4

|

Lima CE, Calixto JC and Anbinder AL:

Influence of the association between simvastatin and demineralized

bovine bone matrix on bone repair in rats. Braz Oral Res. 25:42–48.

2011. View Article : Google Scholar : PubMed/NCBI

|

|

5

|

Zhang HY, Luo JB, Zhou M, Zhang Y and

Huang YL: Biotribological properties at the stem-cement interface

lubricated with different media. J Mech Behav Biomed Mater.

20:209–216. 2013. View Article : Google Scholar : PubMed/NCBI

|

|

6

|

Zhang H, Zhang S, Luo J, Liu Y, Qian S,

Liang F and Huang Y: Investigation of protein adsorption mechanism

and biotribological properties at simulated stem-cement interface.

J Tribol. 135:0323012013. View Article : Google Scholar

|

|

7

|

Liu H, Zhang L, Shi P, Zou Q, Zuo Y and Li

Y: Hydroxyapatite/polyurethane scaffold incorporated with

drug-loaded ethyl cellulose microspheres for bone regeneration. J

Biomed Mater Res B Appl Biomater. 95:36–46. 2010. View Article : Google Scholar : PubMed/NCBI

|

|

8

|

Xu C, Su P, Wang Y, Chen X, Meng Y, Liu C,

Yu X, Yang X, Yu W, Zhang X, et al: A novel biomimetic composite

scaffold hybridized with mesenchymal stem cells in repair of rat

bone defects models. J Biomed Mater Res A. 95:495–503. 2010.

View Article : Google Scholar : PubMed/NCBI

|

|

9

|

Thomas DB, Brooks DE, Bice TG, DeJong ES,

Lonergan KT and Wenke JC: Tobramycin-impregnated calcium sulfate

prevents infection in contaminated wounds. Clin Orthop Relat Res.

441:366–371. 2005. View Article : Google Scholar : PubMed/NCBI

|

|

10

|

Agarwal A, Goyal RK and Pruthi KK: Fate of

calcium hydroxyapatite blocks with cortico-cancellous autogenous

bone grafting in gap non-union of long bones along with LCP. J Clin

Orthop Trauma. 6:72–73. 2015. View Article : Google Scholar

|

|

11

|

Ajiboye RM, Hamamoto JT, Eckardt MA and

Wang JC: Clinical and radiographic outcomes of concentrated bone

marrow aspirate with allograft and demineralized bone matrix for

posterolateral and interbody lumbar fusion in elderly patients. Eur

Spine J. 24:2567–2572. 2015. View Article : Google Scholar : PubMed/NCBI

|

|

12

|

Tavakol S, Khoshzaban A, Azami M, Kashani

IR, Tavakol H, Yazdanifar M and Sorkhabadi SM: The effect of

carrier type on bone regeneration of demineralized bone matrix

in vivo. J Craniofac Surg. 24:2135–2140. 2013. View Article : Google Scholar : PubMed/NCBI

|

|

13

|

Turner TM, Urban RM, Hall DJ, Chye PC,

Segreti J and Gitelis S: Local and systemic levels of tobramycin

delivered from calcium sulfate bone graft substitute pellets. Clin

Orthop Relat Res. 437:97–104. 2005. View Article : Google Scholar : PubMed/NCBI

|

|

14

|

Bakhshalian N, Hooshmand S, Campbell SC,

Kim JS, Brummel-Smith K and Arjmandi BH: Biocompatibility and

microstructural analysis of osteopromotive property of allogenic

demineralized dentin matrix. Int J Oral Maxillofac Implants.

28:1655–1662. 2013. View Article : Google Scholar : PubMed/NCBI

|

|

15

|

Jimi E, Hirata S, Osawa K, Terashita M,

Kitamura C and Fukushima H: The current and future therapies of

bone regeneration to repair bone defects. Int J Dentistry.

1482612012.

|

|

16

|

Chen ZW, Liu H and Zhai WL and Zhai WL:

Treatment of infected bone defect with one stage open cancellous

bone grafting. Zhongguo Gu Shang. 21:377–378. 2008.(In Chinese).

PubMed/NCBI

|

|

17

|

García-Gareta E, Coathup MJ and Blunn GW:

Osteoinduction of bone grafting materials for bone repair and

regeneration. Bone. 81:112–121. 2015. View Article : Google Scholar : PubMed/NCBI

|

|

18

|

Li XD and Hu YY: The treatment of

osteomyelitis with gentamicin-reconstituted bone

xenograft-composite. J Bone Joint Surg Br. 83:1063–1068. 2001.

View Article : Google Scholar : PubMed/NCBI

|

|

19

|

Hautamäki MP, Aho AJ, Alander P, Rekola J,

Gunn J, Strandberg N and Vallittu PK: Repair of bone segment

defects with surface porous fiber-reinforced polymethyl

methacrylate (PMMA) composite prosthesis: Histomorphometric

incorporation model and characterization by SEM. Acta Orthop.

79:555–564. 2008. View Article : Google Scholar : PubMed/NCBI

|

|

20

|

Zheng J, Su Q, Wang C, Cheng G, Zhu R, Shi

J and Yao K: Synthesis and biological evaluation of PMMA/MMT

nanocomposite as denture base material. J Mater Sci Mater Med.

22:1063–1071. 2011. View Article : Google Scholar : PubMed/NCBI

|

|

21

|

Li Z, Kawamura K, Kawashita M, Kudo TA,

Kanetaka H and Hiraoka M: In vitro assessment of

poly(methylmethacrylate)-based bone cement containing magnetite

nanoparticles for hyperthermia treatment of bone tumor. J Biomed

Mater Res A. 100:2537–2545. 2012. View Article : Google Scholar : PubMed/NCBI

|

|

22

|

Fong N, Poole-Warren LA and Simmons A:

Development of sustained-release antibacterial urinary biomaterials

through using an antimicrobial as an organic modifier in

polyurethane nanocomposites. J Biomed Mater Res B Appl Biomater.

101:310–319. 2013. View Article : Google Scholar : PubMed/NCBI

|

|

23

|

Quaglino P, Nardò T, Fierro MT, Massaia M,

Orsucci L, Fava P, Marenco F, Marra E, Savoia P, Vitolo U, et al:

Clinicopathologic spectrum of cutaneous diseases in patients with

hematologic malignancies with or without allogeneic bone marrow

transplantation: An observational cohort study in 101 patients. G

Ital Dermatol Venereol. 148:453–463. 2013.PubMed/NCBI

|

|

24

|

Anal AK and Stevens WF: Chitosan-alginate

multilayer beads for controlled release of ampicillin. Int J Pharm.

290:45–54. 2005. View Article : Google Scholar : PubMed/NCBI

|

|

25

|

Buranapanitkit B, Srinilta V, Ingviga N,

Oungbho K, Geater A and Ovatlarnporn C: The efficacy of a

hydroxyapatite composite as a biodegradable antibiotic delivery

system. Clin Orthop Relat Res. 424:244–252. 2004. View Article : Google Scholar : PubMed/NCBI

|

|

26

|

Silverman LD, Lukashova L, Herman OT, Lane

JM and Boskey AL: Release of gentamicin from a tricalcium phosphate

bone implant. J Orthop Res. 25:23–29. 2007. View Article : Google Scholar : PubMed/NCBI

|

|

27

|

Pandey M, Amin M, Ahmad N and Abeer MM:

Rapid synthesis of superabsorbent smart-swelling bacterial

cellulose/acrylamide-based hydrogels for drug delivery. Int J Polym

Sci. 9054712013.

|

|

28

|

Corden TJ, Jones IA, Rudd CD, Christian P,

Downes S and McDougall KE: Physical and biocompatibility properties

of poly-epsilon-caprolactone produced using in situ polymerisation:

A novel manufacturing technique for long-fibre composite materials.

Biomaterials. 21:713–724. 2000. View Article : Google Scholar : PubMed/NCBI

|

|

29

|

Ambrose CG, Clyburn TA, Louden K, Joseph

J, Wright J, Gulati P, Gogola GR and Mikos AG: Effective treatment

of osteomyelitis with biodegradable microspheres in a rabbit model.

Clin Orthop Relat Res. 421:293–299. 2004. View Article : Google Scholar : PubMed/NCBI

|

|

30

|

Mäkinen TJ, Veiranto M, Lankinen P, Moritz

N, Jalava J, Törmälä P and Aro HT: In vitro and in

vivo release of ciprofloxacin from osteoconductive bone defect

filler. J Antimicrob Chemother. 56:1063–1068. 2005. View Article : Google Scholar : PubMed/NCBI

|

|

31

|

Stiller M, Kluk E, Bohner M, Lopez-Heredia

MA, Muller-Mai C and Knabe C: Performance of β-tricalcium phosphate

granules and putty, bone grafting materials after bilateral sinus

floor augmentation in humans. Biomaterials. 35:3154–3163. 2014.

View Article : Google Scholar : PubMed/NCBI

|

|

32

|

Yoshikawa T, Ohgushi H, Uemura T, Nakajima

H, Ichijima K, Tamai S and Tateisi T: Human marrow cells-derived

cultured bone in porous ceramics. Biomed Mater Eng. 8:311–320.

1998.PubMed/NCBI

|

|

33

|

Hile DD, Amirpour ML, Akgerman A and

Pishko MV: Active growth factor delivery from

poly(D,L-lactide-co-glycolide) foams prepared in supercritical

CO(2). J Control Release. 66:177–185. 2000. View Article : Google Scholar : PubMed/NCBI

|

|

34

|

Zhang YM, Li BX, Li J, Ma HQ, Zhao YP and

Yuan L: Preparation of porous polylactic-acid/ bone matrix gelatin

composite as scaffold materials for bone-tissue engineering. Nan

Fang Yi Ke Da Xue Xue Bao. 26:1745–1748. 2006.(In Chinese).

PubMed/NCBI

|

|

35

|

Link DP, van den Dolder J, Jurgens WJ,

Wolke JG and Jansen JA: Mechanical evaluation of implanted calcium

phosphate cement incorporated with PLGA microparticles.

Biomaterials. 27:4941–4947. 2006. View Article : Google Scholar : PubMed/NCBI

|

|

36

|

Yandrapu SK, Upadhyay AK, Petrash JM and

Kompella UB: Nanoparticles in porous microparticles prepared by

supercritical infusion and pressure quench technology for sustained

delivery of bevacizumab. Mol Pharm. 10:4676–4686. 2013. View Article : Google Scholar : PubMed/NCBI

|

|

37

|

Nofar M, Tabatabaei A and Park CB: Effects

of nano-/micro-sized additives on the crystallization behaviors of

PLA and PLA/CO2 mixtures. Polymer. 54:2382–2391. 2013. View Article : Google Scholar

|

|

38

|

Li Z, Ramay HR, Hauch KD, Xiao D and Zhang

M: Chitosan-alginate hybrid scaffolds for bone tissue engineering.

Biomaterials. 26:3919–3928. 2005. View Article : Google Scholar : PubMed/NCBI

|

|

39

|

Bucholz RW: Nonallograft osteoconductive

bone graft substitutes. Clin Orthop Relat Res. 395:44–52. 2002.

View Article : Google Scholar : PubMed/NCBI

|

|

40

|

Porter NL, Pilliar RM and Grynpas MD:

Fabrication of porous calcium polyphosphate implants by solid

freeform fabrication: A study of processing parameters and in

vitro degradation characteristics. J Biomed Mater Res.

56:504–515. 2001. View Article : Google Scholar : PubMed/NCBI

|