Introduction

Bone defects arise following surgery for bone

tumors, traumatic injury or congenital disorders, and often require

surgical intervention using effective bone grafts. Ideal scaffolds

for bone tissue engineering usually require strong mechanical

properties as well as good biocompatibility (1), new bone-synchronizing degradation

abilities (2,3), adjustable pore structure and

osteogenesis-promoting capabilities (4). To date, the most frequently used bone

substitute materials include metal, ceramics and natural or

synthetic polymers (5). However,

metallic scaffolds may weaken bone growth due to stress shielding

as a result of excessive rigid fixation, while ceramic is

associated with brittleness and poor degradability (6–8). Due to

these issues with the current bone repair materials available,

further investigation is required in order to identify novel bone

tissue engineering scaffolds.

Poly(ε-caprolactone) (PCL) has drawn much attention

in the field of bone tissue engineering due to its excellent

biocompatibility, biodegradability, mechanical properties and

workability (9). However, the major

limitations of PCL are that it lacks a cell recognition site and is

hydrophobic, thus, it can induce in vivo fibrous

encapsulation (10). Therefore, a

number of previous studies have been performed to investigate

methods of enhancing the cell affinity of PCL, such as through

surface coating with collagen (11–13).

An ideal bone tissue engineering scaffold should be

as similar as possible to the natural bone, which is a type of

mineralized collagen composite with hierarchical structure; thus,

many previous studies have focused on using biomimetic strategies

in order to fabricate scaffolds (5,14,15). As

a completely computer aided process, three-dimensional (3D)

printing technology, also known as rapid prototyping (RP), provides

a new method to accurately design and produce scaffolds with high

porosity and connectable pore networks (8,16). In

order to build a scaffold that matches the function and structure

of natural bone, a hierarchical composite scaffold is constructed

by combining the RP technology with the bionic functional

manufacturing strategy, as applied in the present study.

Simvastatin (SIM), which is currently used

clinically to lower blood cholesterol and low-density lipoprotein,

has been hypothesized to promote osteoblast proliferation and

differentiation, inhibit osteoclast activity and support immune

cells such as macrophages; thus, it has been proposed to enhance

bone repair (17–21). A controlled drug release system is

able to provide a sustained stimulus for bone regeneration. For

this reason, the controlled release of SIM was applied in the

present study with poly(lactic-co-glycolic acid) (PLGA)

microspheres. Owing to its good biocompatibility and drug-loading

properties, PLGA has been approved by the US Food and Drug

Administration for application in pharmaceuticals, medical

materials and tissue engineering (22). Furthermore, microspheres based on

PLGA are of stable degradability and are easy to fabricate since

the size and distribution of particles are controllable; they are

therefore becoming increasingly favorable as drug carriers

(23–26).

In the present study, a PCL macro-porous framework

construct was first generated using RP technology, which had

favorable mechanical properties to support nascent bone tissue in

growth. Then, collagen (COL) incorporating SIM-loaded PLGA

microspheres was coated on to the PCL framework using the

evacuation method to formulate bone-like microporous networks and

to provide a sustained osteoinduction stimulus. The in vitro

osteogenic effect of the scaffolds was evaluated using bone

marrow-derived mesenchymal stem cells (BMSCs), and their in

vivo osteogenic potential was investigated using a rat femur

defect model.

Materials and methods

Materials

PCL was purchased from Shenzhen Esun Industrial Co.,

Ltd. (Shenzhen, China). COL was purchased from Sichuan Mingrang

Bio-Tech Co., Ltd. (Sichuan, China).

N-(3-dimethylaminopropyl)-N′-ethylcarbodiimide hydrochloride

crystalline (EDC), SIM and PLGA were purchased from Sigma Aldrich

(Merck KGaA, Darmstadt, Germany). A Cell Counting Kit-8 (CCK-8) was

obtained from Dojindo Molecular Technologies, Inc. (Kumamoto,

Japan). Polyvinyl alcohol (PVA) and dichloromethane were purchased

from Aladdin Bio-Chem Technology Co., Ltd. (Shanghai, China).

Generation of SIM-loaded PLGA

(SIM-PLGA) microspheres

SIM-PLGA microspheres were prepared by utilizing the

single emulsion solvent evaporation method, as previously described

(27). A total of 460 mg PLGA and 23

mg SIM were dissolved in 6 ml dichloromethane. The mixture was

ultrasonically shaken for 30 sec and left standing at room

temperature for 30 min. It was then slowly dropped into aqueous

solution containing 3% PVA, and stirred for 6 h until it fully

solidified into microspheres. Then the microspheres were rinsed

three times with deionized water, centrifuged at 300 × g and 4°C

for 10 min, pre-frozen at −80°C for 2 h and restored following

lyophilization for 24 h.

Encapsulation efficiency

The content of SIM in the microspheres was

determined using an ultraviolet (UV) spectrophotometer (Beckman

Coulter, Inc., Brea, CA, USA) (26,28–30). UV

scanning from 100 to 1,000 nm was used to identify the absorption

peak of SIM. It was identified that the absorbance of SIM solution

was greatly affected by its concentration at 250 nm. The standard

absorption curve of SIM was calculated according to the absorbance

of samples with known SIM concentrations at 250 nm. The SIM content

in the solution was calculated according to the standard absorption

curve. Briefly, 1 mg SIM-PLGA microspheres was dissolved in 5 ml

acetonitrile and sonicated at 40,000 Hz for 40 sec at room

temperature. The UV absorbance of the sample was examined and the

concentration of SIM was determined using the standard curve.

Encapsulation efficiency of the SIM-PLGA microspheres was

calculated according to the following formula: Encapsulation

efficiency (%)=(amount of encapsulated SIM)/(amount of total SIM)

×100%.

Release properties

A total of 1 mg of PLGA microspheres was incubated

with 5 ml PBS and placed in a vibrating screen with constant

stirring (60 rpm) at 37°C. After 1, 3, 7, 14, 21 and 28 days, 2.5

ml of the supernatant was removed and an equal volume of fresh PBS

was added. The content of SIM in the solution was quantified using

a UV spectrophotometer as aforementioned.

PCL scaffold generation and

functionalization

PCL scaffolds were generated with a fused deposition

modeling 3D printer (Glarun Technology Co., Ltd., Nanjing, China)

as previously described (5).

Briefly, a 3D porous CAD model was established and modified in stl

format using Magics software 2.1 (Materialise, Leuven, Belgium),

processed in the 0-60-120° pattern with a filament width of 500 µm,

and the final vertical and lateral pore sizes of 1,000 and 250 µm,

respectively. The PCL scaffold was then produced according to the

stl module. Firstly, the raw PCL material was heated to 120°C, so

that PCL melted to a half flow state. Using the computer controls,

according to the shape of the STL file module, PCL with a diameter

of 500 µm was squeezed from the nozzle along the X- and Y-axis,

cooled to room temperature and allowed to solidify. Then, the

nozzle was raised to a specific height along the Z-axis and the

process was repeated. The new half flow PCL was squeezed from the

nozzle and tightly bound to the lower layer after cooling and

solidifying.

Generation of the PCL/COL/SIM-PLGA

scaffold

For surface activation, the PCL scaffolds were first

alkaline-treated with 5 M NaOH solution at 37°C for 24 h, and then

subsequently immersed in COL solution (1 wt% in 0.1 M acetic acid),

vacuumed for 30 min, frozen at −80°C and freeze-dried at −50°C for

48 h in order to obtain the preliminary COL-PCL composite. The

scaffolds were then cross-linked with 5 mM EDC solution for 24 h,

thoroughly washed with 5 wt% glycine solution and distilled water

three times, and freeze-dried at −50°C for 24 h. To incorporate the

SIM-PLGA into the PCL/COL scaffolds, 7 mg of microspheres was added

to 10 ml COL solution, thoroughly mixed by manual agitation and

freeze-dried as aforementioned.

Morphology and porosity

observations

The morphologies of the scaffold and the

microspheres were observed by field-emission scanning electron

microscopy (SEM; Hitachi S-4800; Hitachi, Ltd., Tokyo, Japan) at a

beam energy of 10 and 3 keV, respectively. To evaluate the PCL/COL

scaffold, the molded samples were cut into 5×2.5×2.5 mm pieces,

which were then gold-coated prior to observation. The porosity of

the scaffolds was measured using an ethanol infiltration method.

The sample was slowly immersed into a known volume (V1)

of absolute alcohol solution (Aladdin Bio-Chem Technology Co.,

Ltd.) inside a measuring cylinder. After 1 h, the total volume of

alcohol and sample was regarded as V2. Following careful

removal of the sample, the residual volume of alcohol solution was

measured as V3. The results were determined from the

following formula: Porosity

(%)=(V1-V3)/(V2-V3)

×100%.

In vitro cell seeding, proliferation,

viability and cytotoxicity evaluations

BMSCs were obtained from newborn Sprague-Dawley rats

as described in a previous study with ethical approval from the

Animal Care and Use Committee of Shanghai Ninth People's Hospital

(Shanghai, China) (31). The

protocol conformed to the National Institutes of Health Guidelines

concerning the Care and Use of Laboratory Animals (32). The cell culture medium consisted of

89% Dulbecco's modified Eagle's medium (Invitrogen; Thermo Fisher

Scientific, Inc., Waltham, MA, USA), 10% fetal bovine serum

(Invitrogen; Thermo Fisher Scientific, Inc.) and 1%

penicillin-streptomycin (Invitrogen; Thermo Fisher Scientific,

Inc.). Passages 2–3 of BMSCs w ere used for the subsequent

experiments.

For evaluation of cell-seeding efficiency,

5×105 cells in 100 µl D10 medium were added into the

constructs (PCL, PCL/COL and PCL/COL/SIM-PLGA; n=5 each group). The

cell number was counted as W1. Following incubation for

4 h, the seeded constructs were removed and washed with PBS. Cells

that had adhered were digested with trypsin and were counted as

W2; thus, the cell seeding efficiency was calculated

according to the following formula: Cell seeding

efficiency=W2/W1.

To evaluate cytotoxicity, 1×103 BMSCs

were seeded onto a 96-well plate and incubated for 4 h in D10

medium, then the medium was replaced with fresh medium, fresh D10

medium with 5% DMSO, or the extract fluid of PCL, PCL/COL, or

PCL/COL/SIM-PLGA, which was prepared by immersing the constructs in

D10 medium for 72 h (n=5). CCK-8 assays were then performed to

assess the cytotoxicity 1 day later at a wavelength of 450 nm.

To evaluate cell proliferation, 3×104

cells in 20 µl D10 medium were seeded into the PCL, PCL/COL,

PCL/COL/SIM-PLGA, or decalcified bone matrix (DBM; cut to 5×2.5×2.5

mm) in 24-well plates and incubated in 1 ml of D10 medium for 1 h.

The procedure was then repeated on the other side of the

constructs. At 1, 3 and 7 days after seeding, cell proliferation on

the different constructs was assessed by CCK-8 assay. DBM was

prepared as described in a previous study (33).

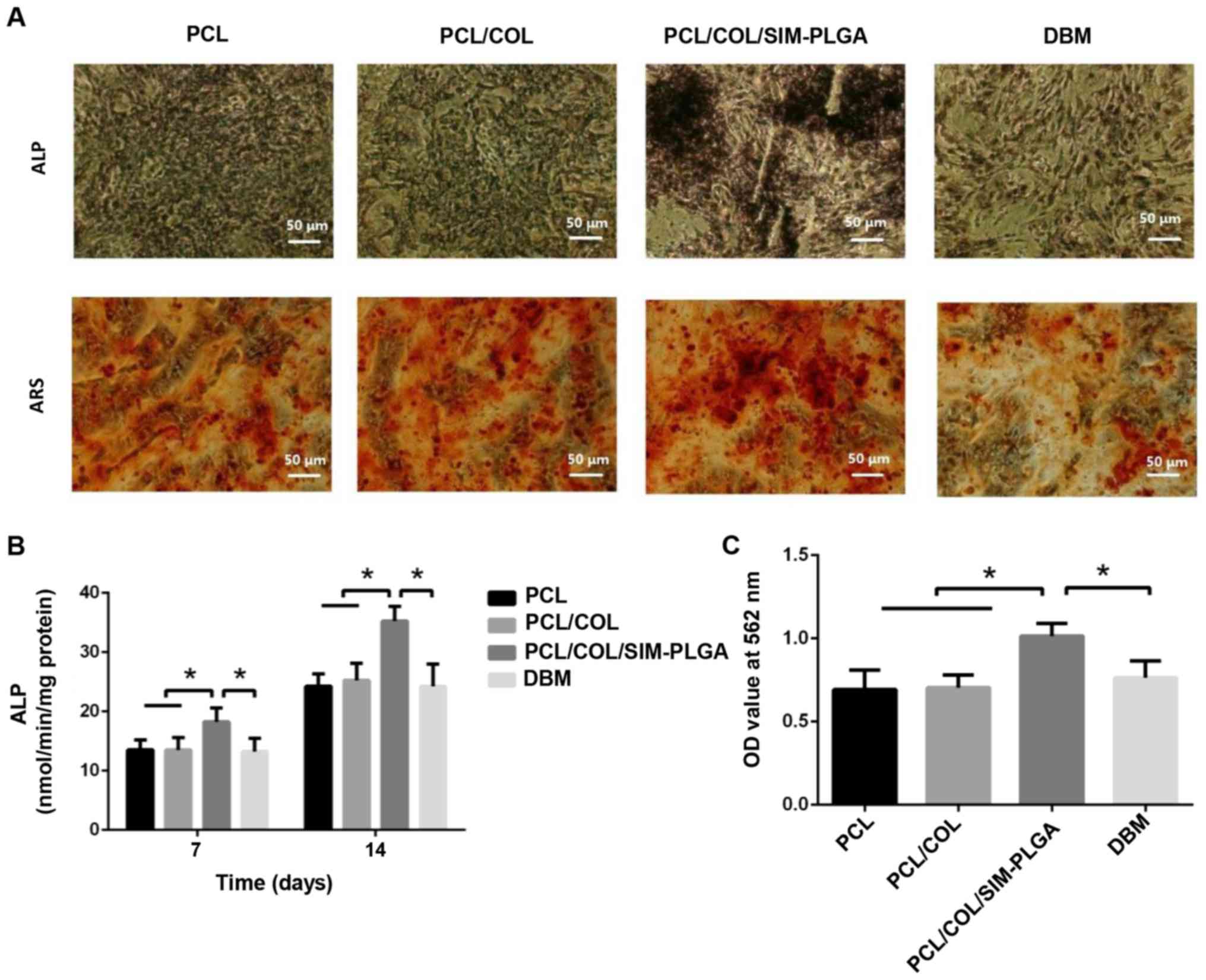

Alkaline phosphatase (ALP) and

Alizarin red staining

Since it is difficult to extract the mRNA of cells

directly cultured on scaffolds, and the blank scaffold would have

very poor osteoinduction since this property is primarily due to

the encapsulated drug, cells were cultured on the well plate and

scaffolds were placed on the Transwell membrane above the cells

(34). BMSCs (1×104) of

passage 3 were seeded in 24-well plates. After 6 h, 1 ml of

osteogenic induction medium (50 mg/ml ascorbic acid, 10 mM

β-glycerophosphate and 10 nM dexamethasone) was added. Then, the

0.8-µm-pore inserts and the different scaffolds were added to the

wells of the culture plates. On day 7 following osteogenic

induction, the cells were fixed in 4% paraformaldehyde for 20 min

at room temperature and stained in ALP staining solution (Beyotime

Institute of Biotechnology, Haimen, China) at 37°C for 10 min in

the dark. ALP activity after 7 and 14 days of culture was

quantified using the QuantiChrom™ Alkaline Phosphatase Assay kit

(BioAssay Systems; Thermo Fisher Scientific, Inc.), and the total

protein content was assessed with a BCA Protein Assay kit (Thermo

Fisher Scientific, Inc.). The mineralized matrix nodules formed by

BMSCs were evaluated using Alizarin red staining. On day 21, the

cells were washed three times with PBS, fixed in 4%

paraformaldehyde at room temperature for 30 min and incubated with

Alizarin red solution (Beyotime Institute of Biotechnology) for 10

min at room temperature. To quantify the levels of mineralization,

the mineralized matrix nodules were dissolved in 10% (w/v)

cetylpyridinium chloride (Aladdin Bio-Chem Technology Co., Ltd.)

and the absorbance was measured at 450 nm using a microplate

reader.

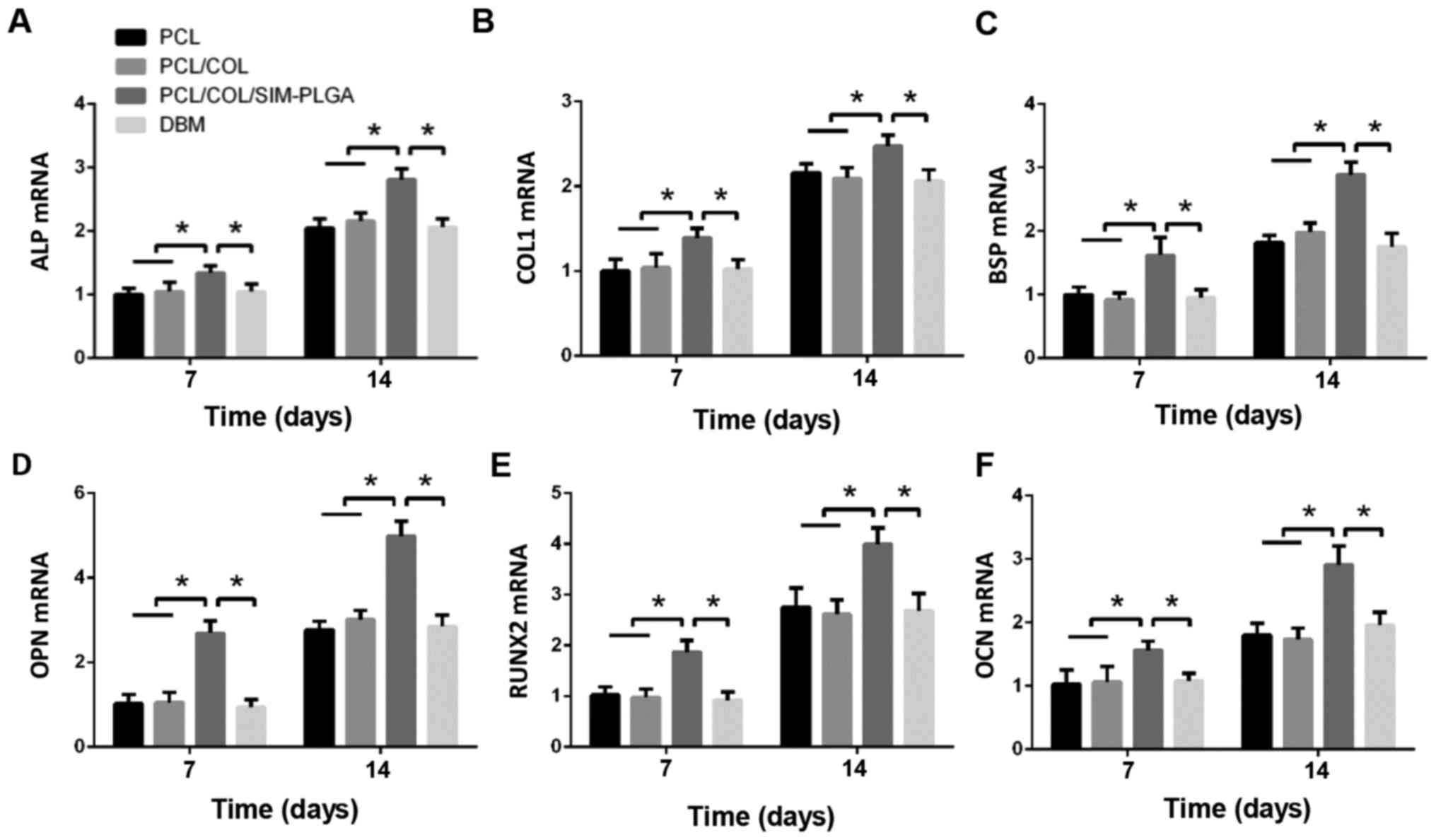

Reverse transcription-quantitative

polymerase chain reaction (RT-qPCR)

The expression of genes associated with osteogenesis

was assessed by RT-qPCR, as previously described (35). After 7 and 14 days of culture, total

RNA was prepared using TRIzol reagent (Invitrogen; Thermo Fisher

Scientific, Inc.) in order to determine the mRNA expression of ALP

and COL type 1 (COL 1), which are associated with osteogenesis.

cDNA was obtained by reverse transcription at 37°C for 1 h using

BeyoRT™ II First Strand cDNA Synthesis kit with gDNA Eraser

(Beyotime Institute of Biotechnology) from 1 µg RNA and stored at

−20°C. qPCR was conducted using SYBR GreenER qPCR SuperMix reagents

(Invitrogen; Thermo Fisher Scientific, Inc.). The following

thermocycling conditions were used for the PCR: Initial

denaturation at 95°C for 10 min; 30 cycles of 95°C for 15 sec, and

60°C for 1 min; and a final dissociation cycle at 95°C for 15 sec,

60°C for 1 min and 95°C for 15 sec. The following 5′-3′ primer

sequences were used: ALP forward, CGTGGAAACCTGATGTATGCT and

reverse, ACTCCTATGACTTCTGCGTCTG; COL 1 forward,

GAAAGAGAAAGACCCCAGTTAC and reverse, ATACCATCTCCCAGGAACAT; β-actin

forward, CCTCTATGCCAACACAGT and reverse, AGCCACCAATCCACACAG; BSP

forward, GATAGTTCGGAGGAGGAGGG and reverse, CTAACTCCAACTTTCCAGCGT;

OPN forward CCTGGACCTCATCAGCATTT and reverse TTGGAGCAAGGAGAACCC;

RUNX2 forward GCACCCAGCCCATAATAGA and reverse

GACGGTTATGGTCAAGGTGAA; OCN forward GGAGGGCAGTAAGGTGGTGAA and

reverse GAAGCCAATGTGGTCCGCTA. β-actin forward CACGAAACTACCTTCAACTCC

and reverse CATACTCCTGCTTGCTGATC. The 2−ΔΔCq method was

used to calculate the relative expression of each target gene

against the β-actin (36).

In vivo study of segmental defect

repair on rat femurs

The following animal experiments were performed with

ethical approval from the Animal Care and Use Committee of Shanghai

Ninth People's Hospital (Shanghai, China), and conformed to the

National Institutes of Health Guidelines concerning the Care and

Use of Laboratory Animals (37).

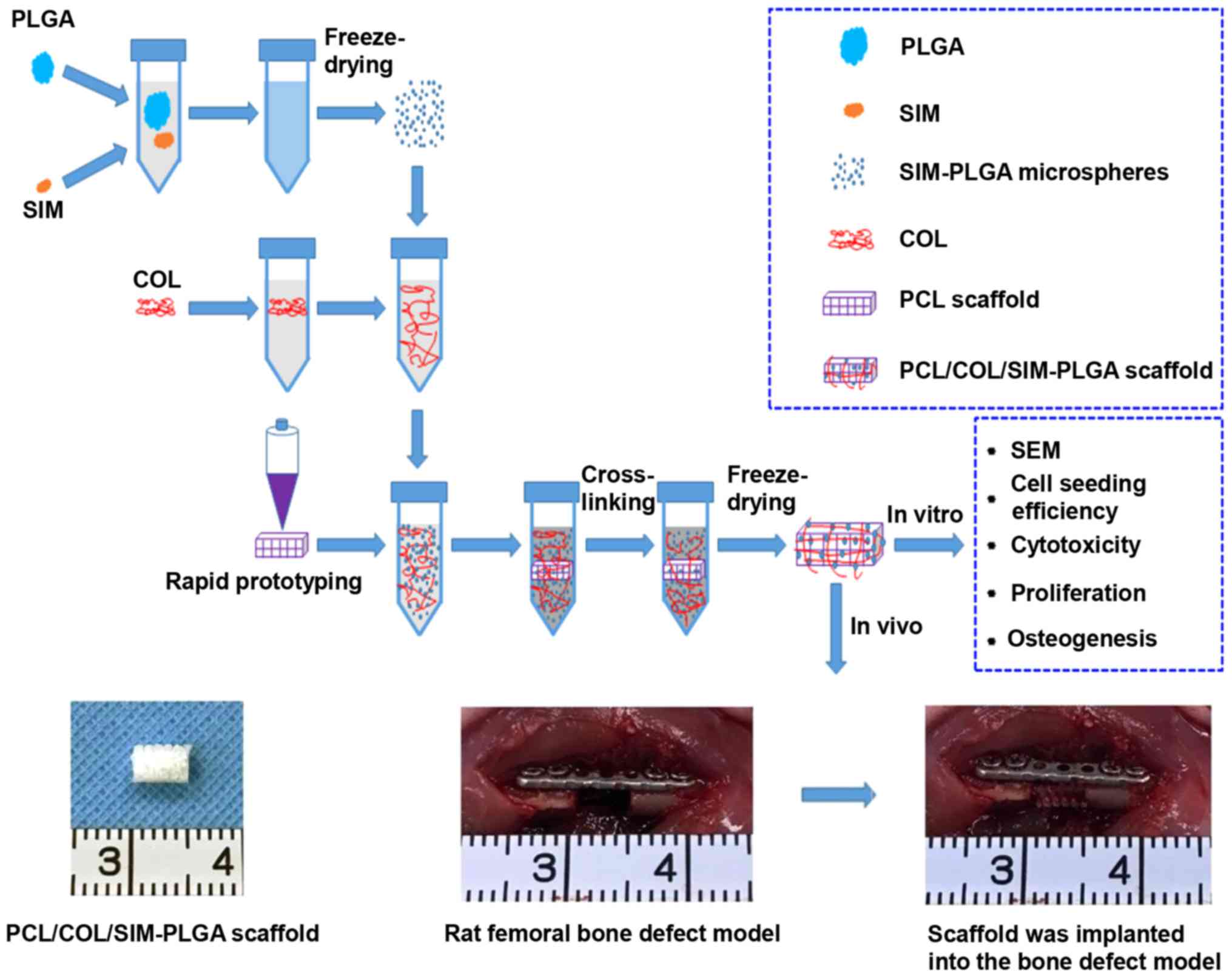

A diagram of the experimental procedure is presented

in Fig. 1. A total of 12 male

Sprague-Dawley rats aged 6–8 weeks (~200 g) were purchased from the

Shanghai Jiao Tong University Research Center of Laboratory Animal

(Shanghai, China). The animals were housed and acclimatized at the

experimental animal laboratory of Shanghai Ninth People's Hospital

(Shanghai, China) under controlled temperature (25°C) and humidity

(55%) with a 12-h light/dark cycle, with free access to food and

water. The rats were randomly divided into three groups: i) PCL

(bone defect + blank PCL scaffold); ii) PCL/COL (bone defect + PCL

scaffold coated with COL); and iii) PCL/COL/SIM-PLGA (bone defect +

PCL scaffold coated with COL and SIM-loaded PLGA microspheres; n=4

each group). Rats were anesthetized via intraperitoneal injection

of 1% pentobarbital sodium (Invitrogen; Thermo Fisher Scientific,

Inc.; 40 mg/kg). Under a standard surgical procedure, the femur was

fully exposed and holes were made on both femoral ends with a micro

bone drill. Then, a titanium plate (15×2.8 mm) was fixed along the

femur using tapping screws (1 mm in diameter, 6 mm in length).

Then, a 5 mm-long segmental defect was made in the middle position

corresponding to the plate with the bone drill, which was then

cleaned with 0.9% saline and the PCL, PCL/COL and PCL/COL/SIM-PLGA

scaffolds were transferred to the defect area respectively.

X-ray examination was performed at 4 and 12 weeks

after surgery. At 12 weeks post-surgery, the animals were

sacrificed and the femurs of rats were fixed in 4% paraformaldehyde

at room temperature for a week. The specimens were then detected by

micro-computed tomography (micro-CT; SCANCO µ-80 Micro-CT; SCANCO

Medical AG, Brüttisellen, Switzerland). 3D reconstruction and

calculation of the new bone tissue was subsequently performed with

the built-in micro-CT software. The regions of interest were

restricted to the cylindrical part covering the defect, whereas

regions with CT values of 1,300–3,500 were determined as bone

tissue.

Histological assay

Following micro-CT testing, the specimens were

decalcified with 10% EDTA, dehydrated, paraffin embedded, sectioned

into 5-µm-thick slices for hematoxylin and eosin (HE; 30 min at

room temperature) and Masson trichrome (20 min at room temperature)

staining, and examined by light microscopy.

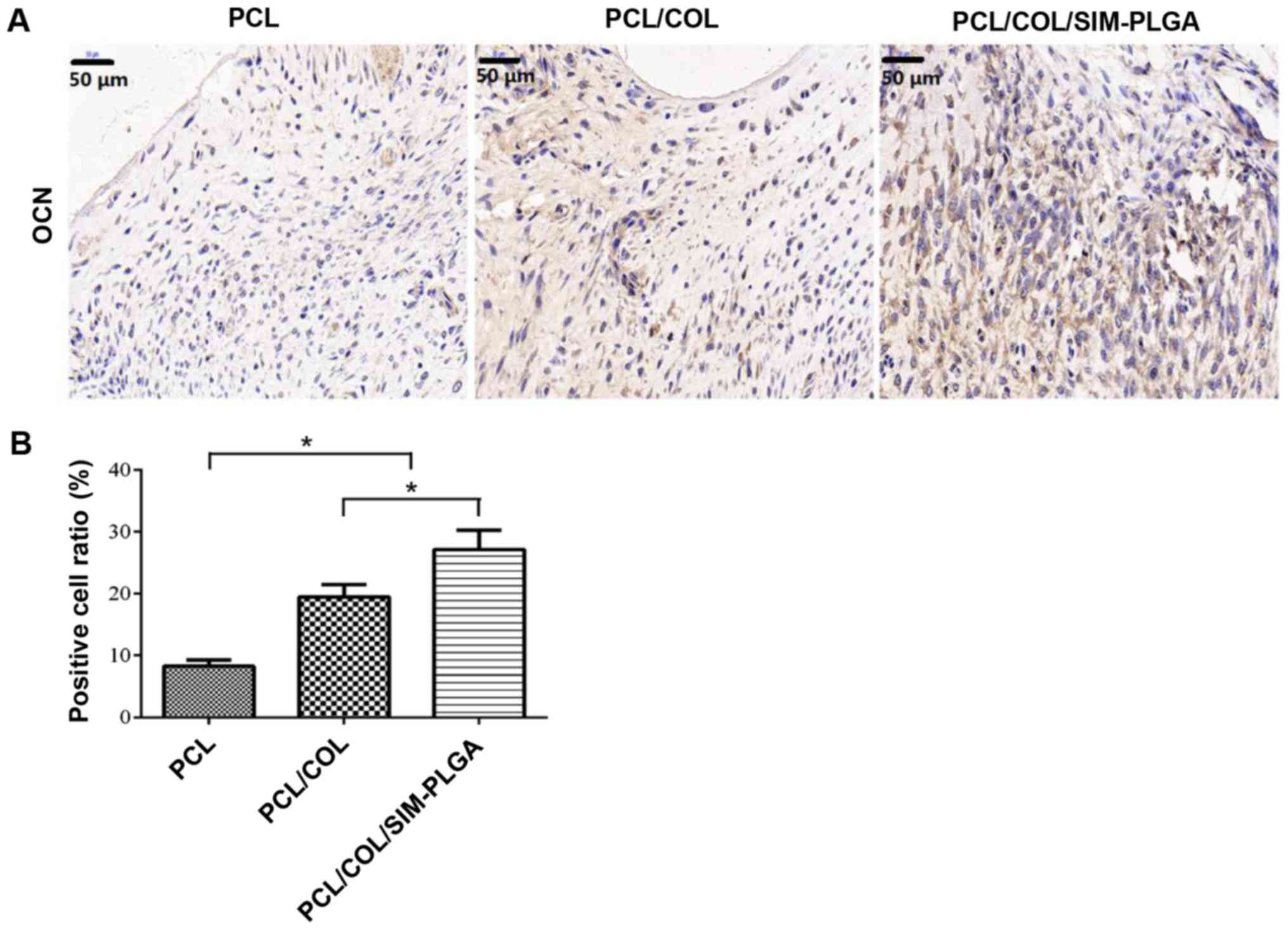

For immunohistochemistry, the sections were blocked

with 5% bovine serum albumin (Invitrogen; Thermo Fisher Scientific,

Inc.) for 30 min at room temperature and then incubated with the

anti-osteocalcin (OCN; Abcam, Cambridge, UK; cat. no. ab198228;

1:200) primary antibody overnight at room temperature. The sections

were then incubated with the horseradish peroxidase-conjugated goat

anti-rabbit IgG (H+L) secondary antibody (Beyotime Institute of

Biotechnology; cat. no. A0208) at a dilution of 1:200 for 1 h at

room temperature, visualized with 3,3-diaminobenzidine solution,

and counter-stained with hematoxylin (Beyotime Institute of

Biotechnology) for 1 h at room temperature. Image Pro Plus software

6.0 (Media Cybernetics, Inc., Rockville, MD, USA) was used to

analyze the results.

Statistical analysis

All data are expressed as the mean ± standard

deviation. The results were evaluated by one-way analysis of

variance with Tukey's post-hoc using SPSS 15.0 software for Windows

(SPSS, Inc., Chicago, IL, USA). P<0.05 was considered to

indicate a statistically significant difference.

Results

Surface characterization

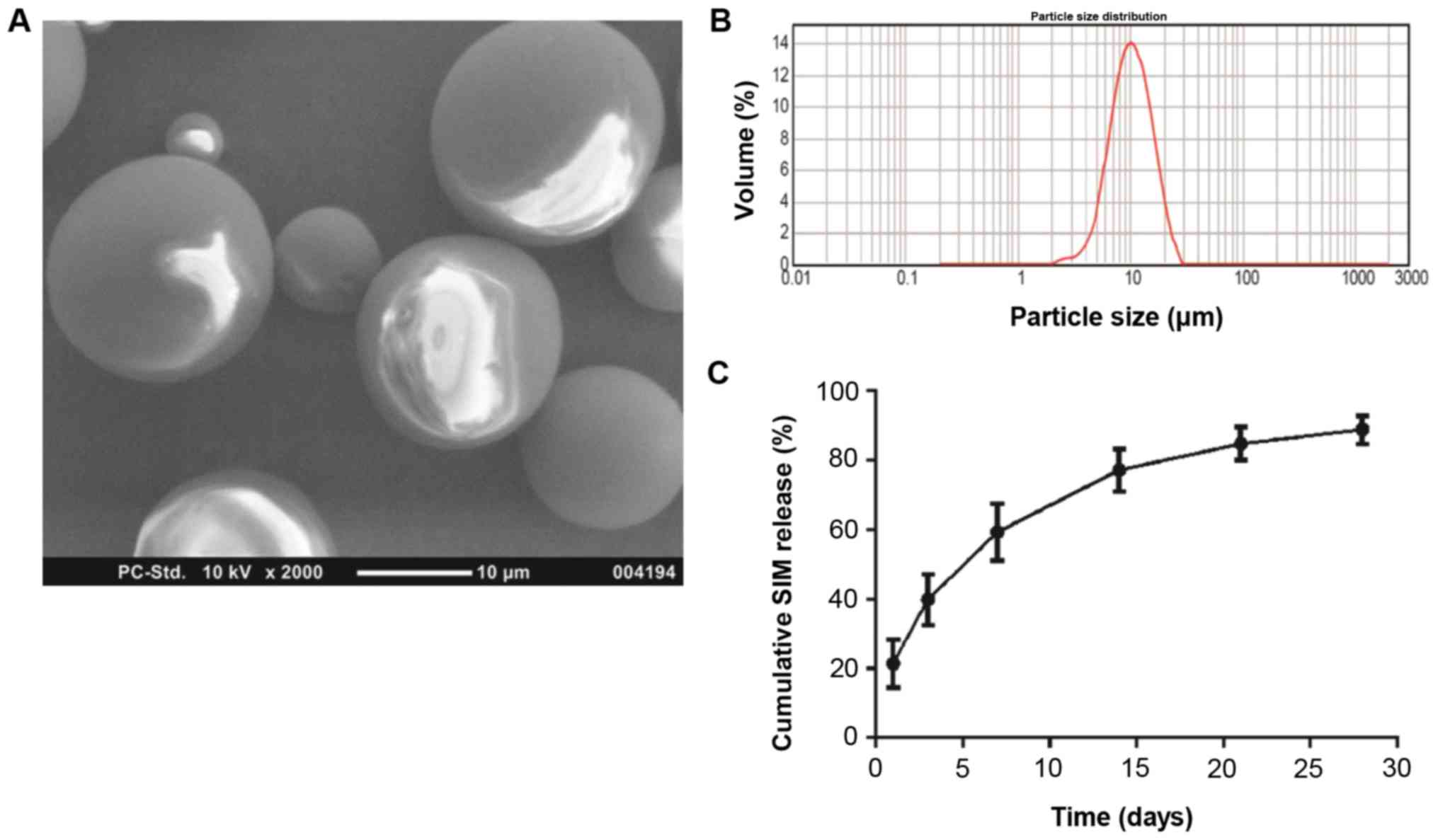

As demonstrated in the SEM images, the SIM-PLGA

microspheres assumed a configuration with a smooth, glossy surface

and regular spherical shape (Fig.

2A), indicating that the experimental conditions for the

manufacture of microspheres were stable and suitable (31,38,39). The

particle diameter (Fig. 2B) ranged

from 2–20 µm (mean, 12.11 µm). The narrow particle size

distribution suggested that the drug release from scaffolds would

be relatively stable (40,41). In addition, the encapsulation

efficiency of SIM inside the PLGA microspheres reached ~86.3%. An

initial outbreak release was detected in the first 3 days. As

indicated in the in vitro release diagram, ~40% of the

primarily integrated SIM was leaked from the PLGA microspheres

within the first 3 days, which was followed by sustained release

over 27 days (Fig. 2C). At the end

of the release assay, almost 90% of the SIM-loaded microspheres

were released (Fig. 2C), and the

cumulative drug release achieved ~86.9%.

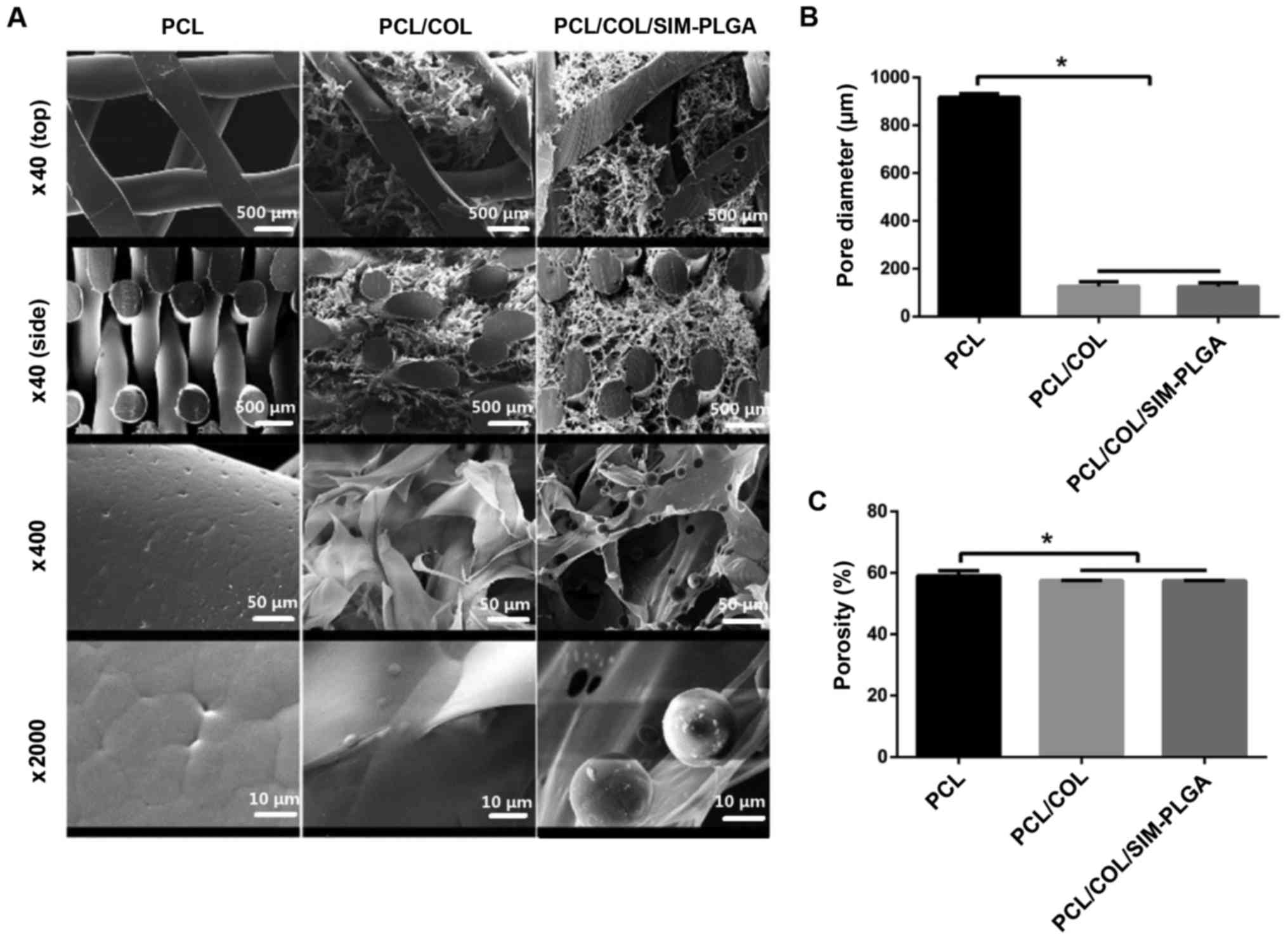

In the present study, the PCL scaffold alone

exhibited a vertical aperture at 917±14.8 µm. Porous COL with good

biological activity was well compounded onto the PCL scaffold by

vacuuming and freeze-drying, forming a thin coating layer. COL

displayed porosity with homogeneous pore sizes, filling in the

horizontal pores in a reticular pattern and covering the trabecula

of the PCL scaffold. Therefore, the PCL/COL composite possessed a

two-level pore structure, consisting of macro-porous PCL (~1,000

µm) and microporous COL (~100 µm). Following further incorporation,

PLGA microspheres were evenly distributed in the COL network

(Fig. 3A). The pore size of PCL/COL

was 126.7±18.42 µm, whereas that of PCL/COL/SIM-PLGA was

125.7±15.82 µm (Fig. 3B). In

addition, the porosity of the three constructs was 59.05±1.7,

57.5±0.1 and 57.4±0.1%, respectively (Fig. 3C). These results revealed that a

reduced but hierarchical structure was formed following COL

modification, while the incorporation of SIM-PLGA had no

significant effect on porosity.

In vitro cellular evaluation

Cell proliferation and viability

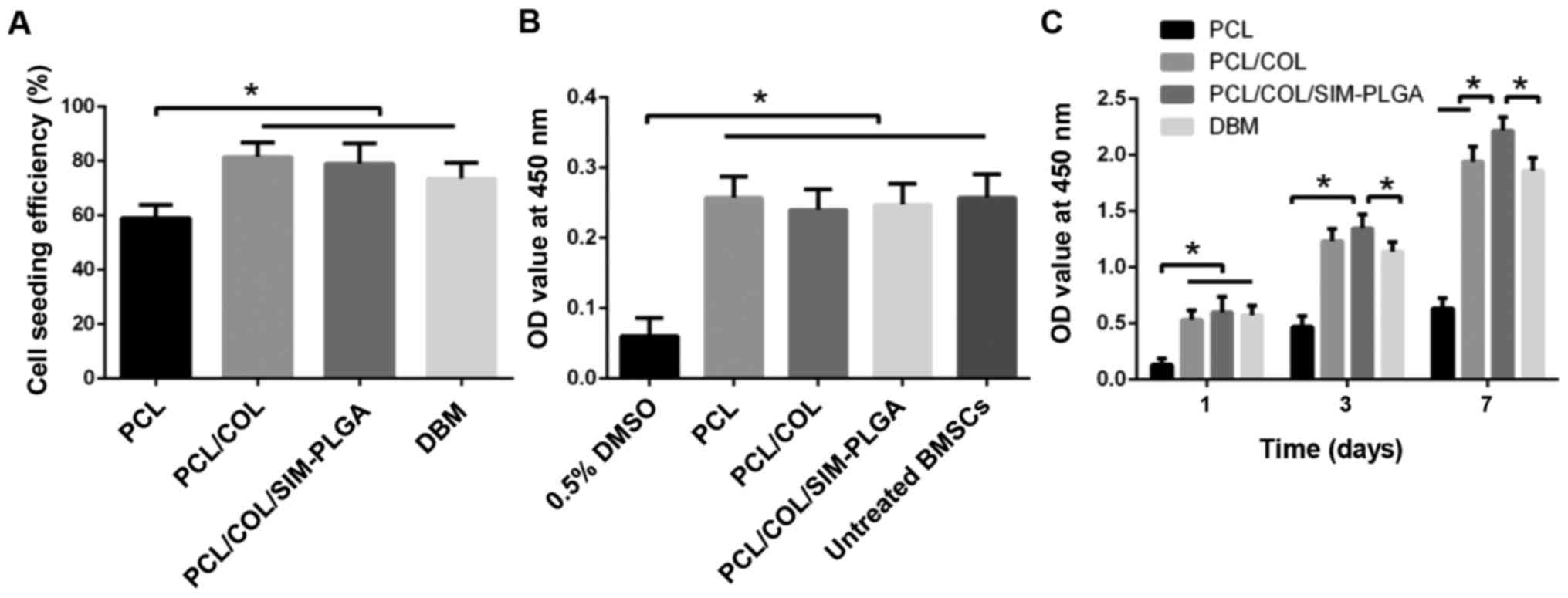

BMSCs were directly seeded on the scaffold. The

cell-seeding efficiency was revealed to be 54±2.2% for PCL,

88.6±2.0% for PCL/COL and 89±1.6% for PCL/COL/SIM-PLGA. PCL/COL and

PCL/COL/SIM-PLGA exhibited a significantly higher efficiency (1.64-

and 1.65-fold increase, respectively) when compared with PCL alone

(Fig. 4A). The improvement in cell

seeding may be attributable to the greater contact area with the

COL network and more adhesion sites from the COL matrix, while PLGA

microspheres may have exerted little influence. The extracted fluid

test demonstrated that there was no significant cytotoxicity in the

scaffolds when compared with the untreated BMSC group, indicating

that no toxic substances were identified during the COL

cross-linking process, and thus demonstrating its biosafety

(Fig. 4B). Furthermore, the greatest

levels of proliferation were produced by the SIM-PLGA group, which

may be caused by the SIM released from the scaffold (Fig. 4C).

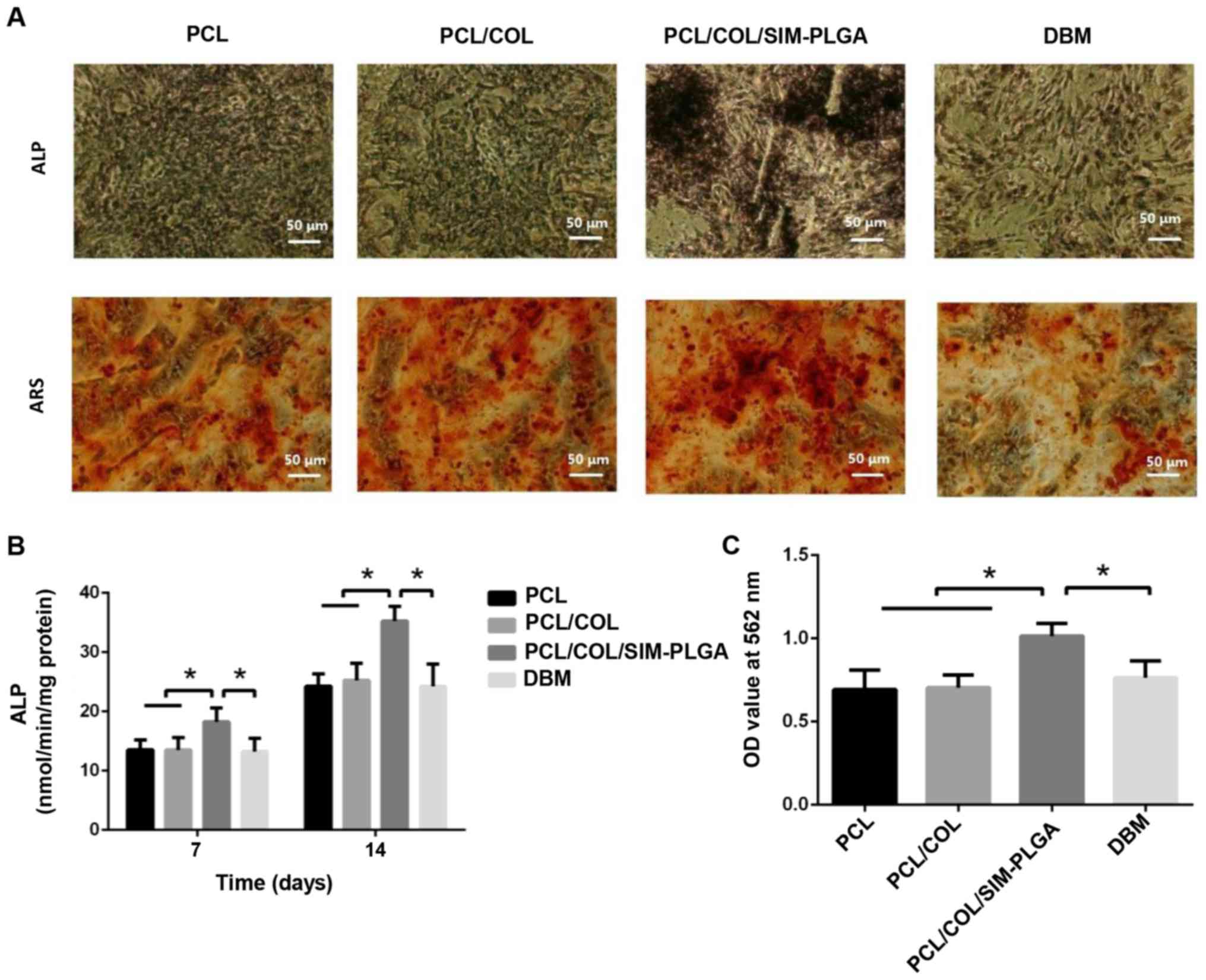

Osteogenic potency of BMSCs

To assess the osteogenic potency of BMSCs treated

with the different constructs, the present study performed Alizarin

red and ALP staining. Cells were cultured on the well plate and

scaffolds were placed on a Transwell membrane above the cells.

Typical osteogenic differentiation was observed in all three

groups. However, the SIM/PLGA group exhibited higher ALP activity

and more mineralized nodules (Fig.

5A). Despite the increase in ALP expression noted in all three

groups following 14 days of differentiation when compared with that

observed after 7 days (Fig. 5B), the

SIM-PLGA group exhibited significantly higher expression levels

when compared with the other three groups at 7 and 14 days.

Furthermore, quantitative analysis of Alizarin red staining

indicated that the OD value of the SIM/PLGA group was the highest

among the four groups, suggesting that the mineral deposition and

the osteogenic differentiation of BMSCs improved. By contrast, the

DBM group exhibited similar osteogenesis to the PCL group, as

determined by the quantitative results of Alizarin red staining

(Fig. 5C).

| Figure 5.Early and late stages of BMSC

osteogenic differentiation, as determined by ALP staining and ARS,

respectively. (A) Representative images of ALP staining after

14-day culture and ARS after 21-day culture. (B) ALP activity

results. (C) Summary of ARS results. The PCL/COL/SIM-PLGA construct

significantly promoted the osteogenic differentiation of BMSCs in

both the early and late stages. *P<0.05, as indicated. PLGA,

poly(lactic-co-glycolic acid); SIM, simvastatin; COL, collagen;

PCL, poly(ε-caprolactone); BMSC, bone marrow-derived mesenchymal

stem cells; ALP, alkaline phosphatase; ARS, Alizarin red staining;

OD, optical density. |

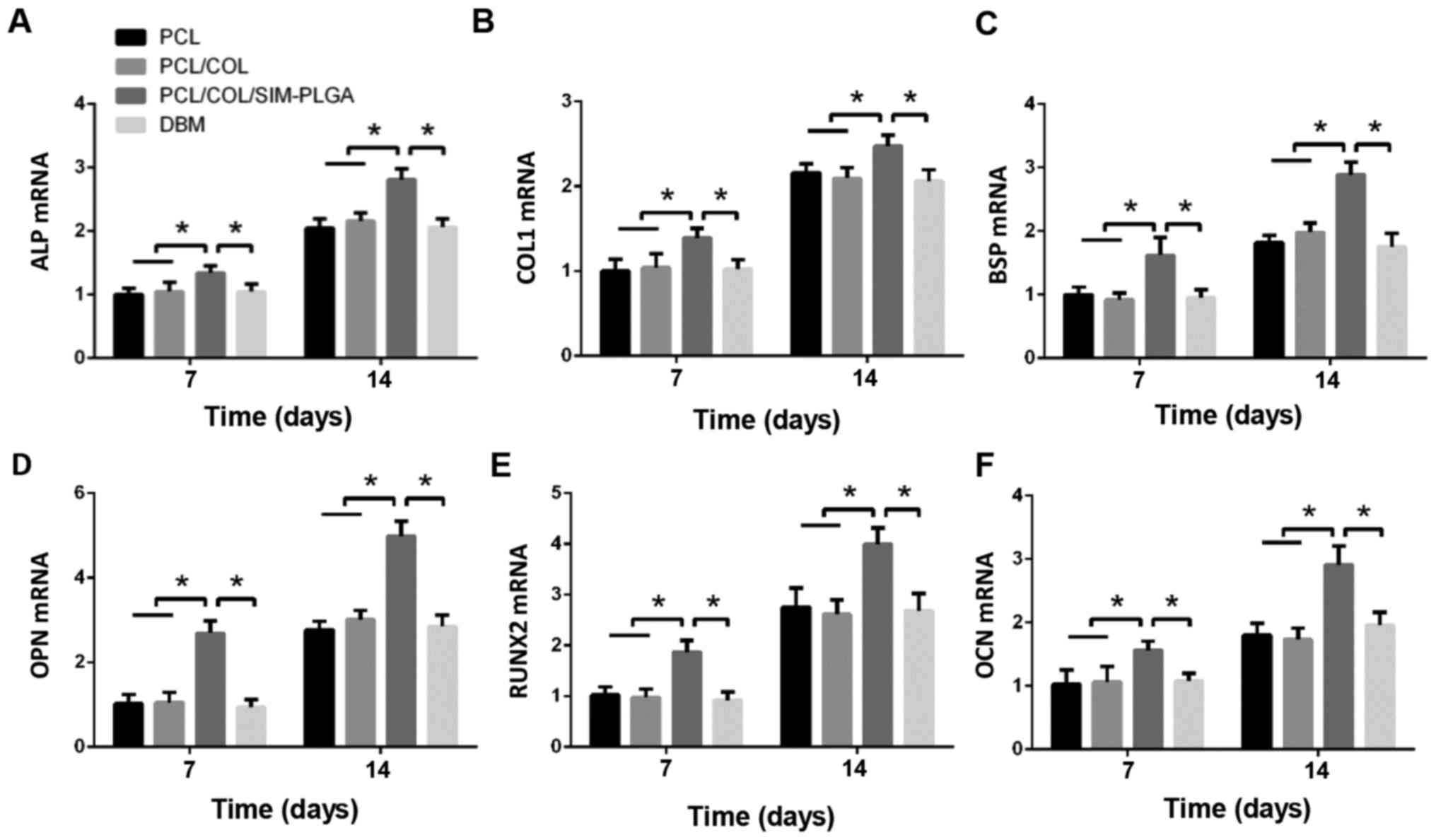

Osteogenic gene expression

RT-qPCR was performed to examine the mRNA levels of

ALP, bone sialoprotein, COL 1, runt-related transcription factor 2,

osteopontin and OCN in the BMSCs of the different groups. As

presented in Fig. 6, the SIM-PLGA

group exhibited significantly higher expression levels of all

osteogenic genes when compared with the other groups at days 7 and

14.

| Figure 6.Gene expression analyses of (A) ALP,

(B) COL 1, (C) BSP, (D) OPN, (E) RUNX2 and (F) OCN in the different

groups after 7 and 14 days of culture. The results are presented as

relative ratios to the PCL group at day 7. The expression of

osteogenic genes was greatly enhanced by the PCL/COL/SIM-PLGA

scaffold. *P<0.05, as indicated. PLGA, poly(lactic-co-glycolic

acid); SIM, simvastatin; COL, collagen; PCL, poly(ε-caprolactone);

ALP, alkaline phosphatase; COL 1, collagen type 1; BSP, bone

sialoprotein; RUNX2, runt-related transcription factor 2; OPN,

osteopontin; OCN, osteocalcin. |

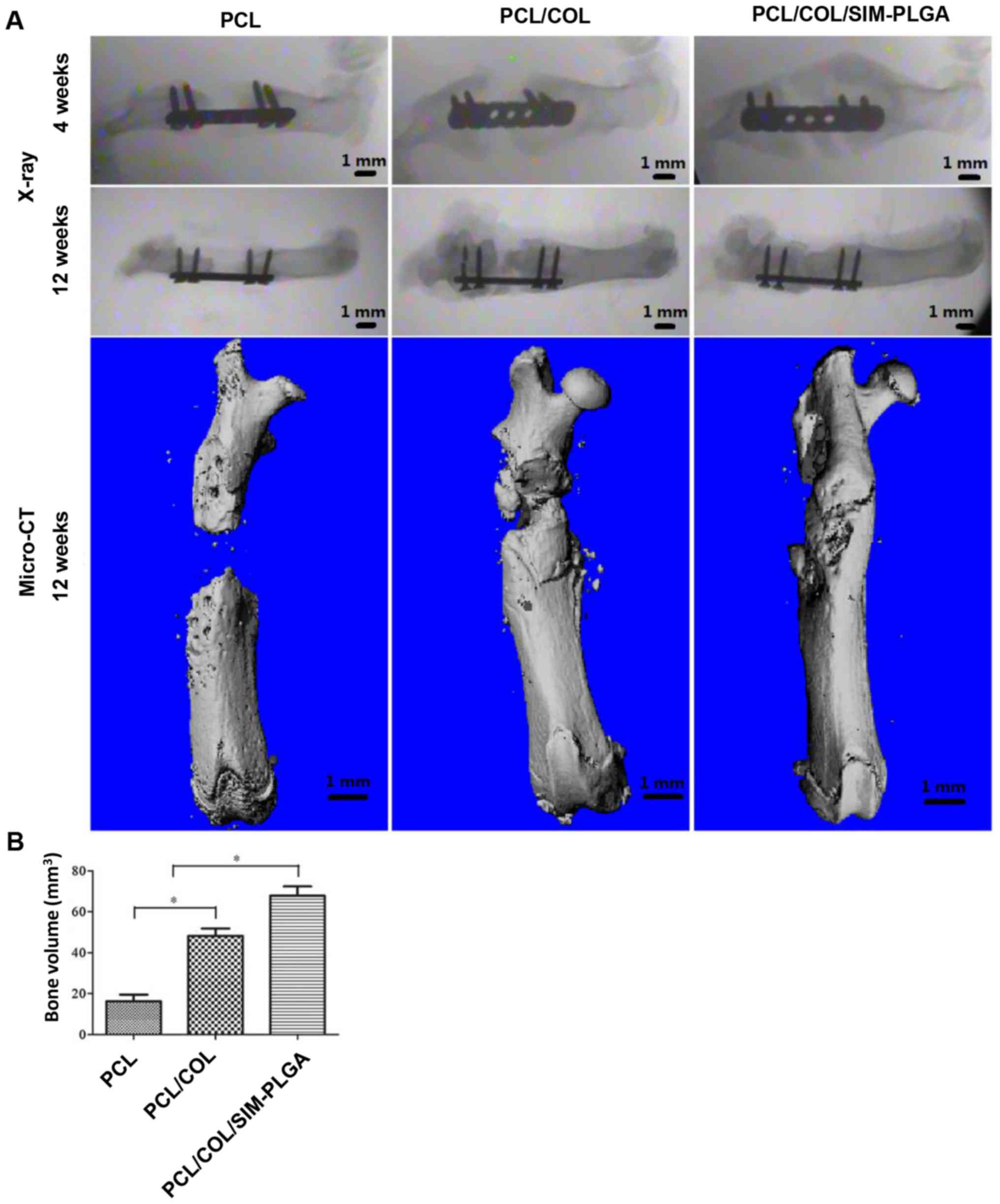

In vivo study of rat femur defects

X-ray and micro-CT examination

As indicated in Fig.

7A, at 4 weeks post-surgery, the X-ray images revealed that the

PCL group exhibited only a small amount of bone tissue growth, with

no significant increase in bone deposition at 12 weeks and no bone

fracture healing. On the other hand, significant levels of bone

tissue growth were observed at 4 weeks in the PCL/COL and

PCL/COL/SIM-PLGA groups. Notably, complete defect repair with

continuous cortical bone was achieved in the PCL/COL/SIM-PLGA group

at 12 weeks post-implantation. The results of micro-CT demonstrated

that there was scattered bone tissue near the defect edges as

opposed to obvious newly formed bone in the PCL group. As shown in

the 3D reconstructed images, new bone formation reconnected the

fractured ends, with the newly formed cortical bone enveloping the

scaffolds. Both the PCL/COL and PCL/COL/SIM-PLGA attained improved

results compared with the PCL group, and the incorporation of

SIM-PLGA further enhanced the osteogenic ability of the PCL/COL

scaffolds. Furthermore, the new bone volume calculated according to

the 3D reconstructed images indicated that the PCL/COL/SIM-PLGA

group exhibited the best bone regeneration among the three groups

(Fig. 7B).

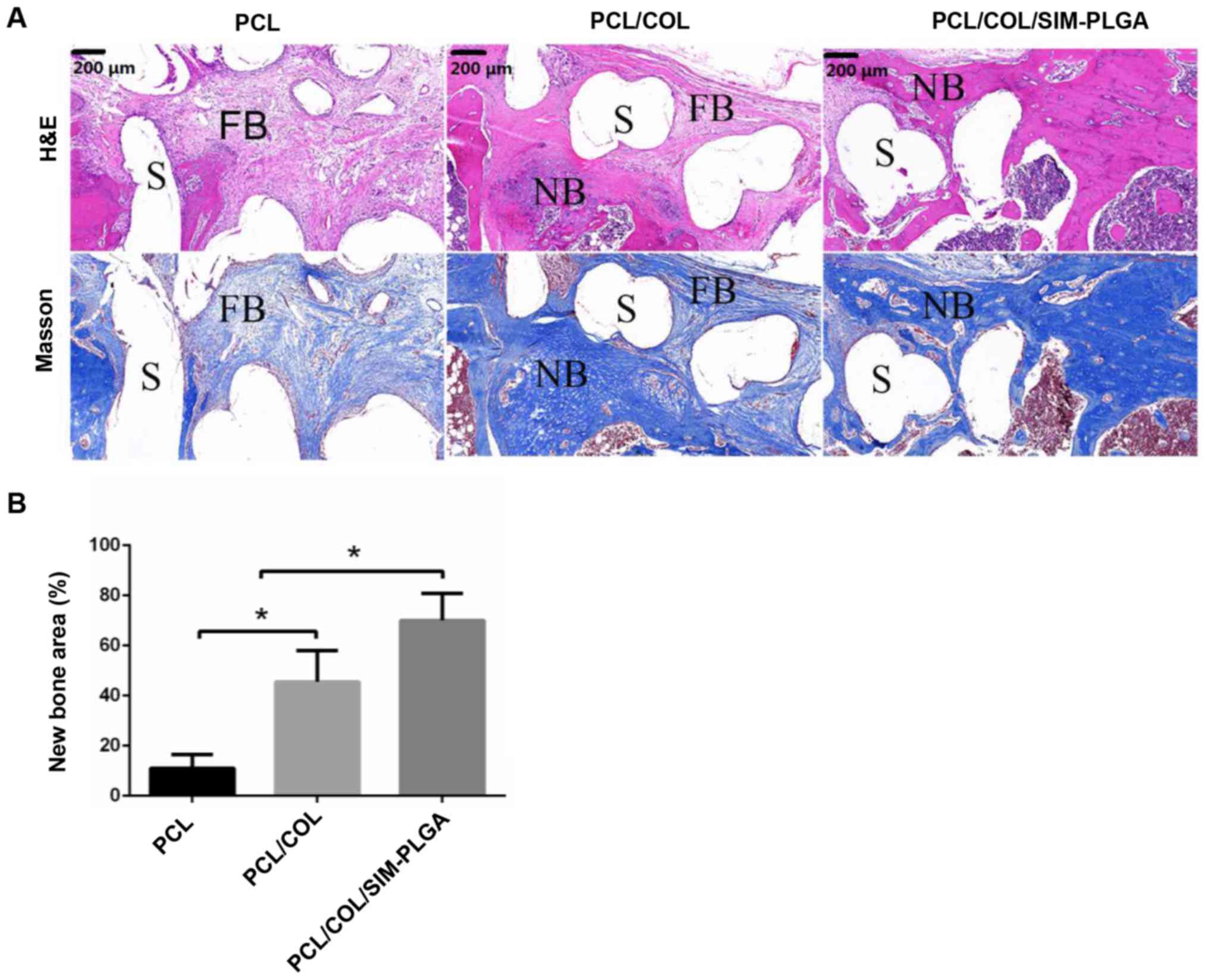

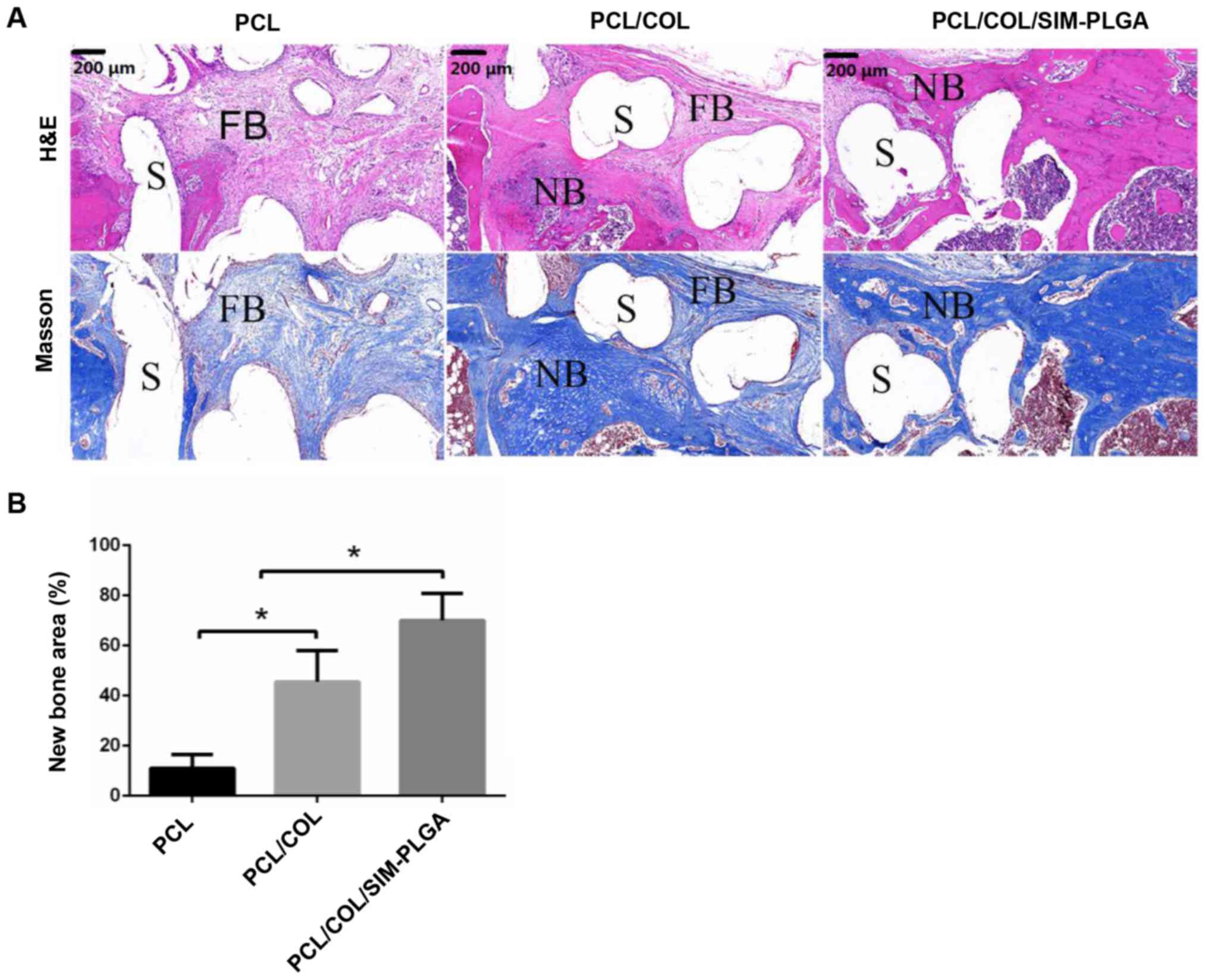

Histological qualitative and

quantitative analysis

The HE staining results revealed that the defect

area was filled with loose fibrous connective tissue, which was

stained a light red, and was wrapped around the PCL trabecula

(Fig. 8A). The results of Masson

trichrome staining were in accordance with that of HE, as the

fibrous tissue, stained a light blue, surrounded the scaffolds

forming a fibrous interface at the scaffold-bone juncture. In the

PCL/COL group, only a marginal amount of fibrous tissue formed, and

the defect was filled mostly with newly formed bone tissue; both

mature (dark blue) and immature (light blue) bone tissue was

observed. In the PCL/COL/SIM-PLGA composite scaffold group, the

bone tissue in the bone defect was further improved, and was

primarily composed of mature bone tissue stained a dark blue. The

new bone tissue directly integrated with the scaffold material by

connecting with the original bone tissue at the fracture end, which

was consistent with the results of micro-CT. Thus, the

PCL/COL/SIM-PLGA construct served well in osteogenesis. In

addition, quantitative analysis of new bone area also indicated

that the PCL/COL exhibited an improved osteoinduction ability

compared with the blank PLC scaffold and the PCL/COL/SIM-PLGA

scaffold exhibited the highest new bone area among the three

groups.

| Figure 8.Analysis of bone regeneration of the

femur defect by using HE and Masson staining. (A) HE and Masson

stained tissue sections of bone regeneration in the defect areas,

implanted with PCL, PCL/COL or PCL/COL/SIM-PLGA constructs, at 3

months after surgery. (B) The SIM-loaded scaffold demonstrated the

most robust osteogenic activity, and the majority of the defect

area in the SIM-loaded scaffold group was filled with eosin-stained

newly formed bone tissue. *P<0.05, as indicated. S, scaffolds;

NB, newly formed bone; FB, fibrosis; PLGA, poly(lactic-co-glycolic

acid); SIM, simvastatin; COL, collagen; PCL, poly(ε-caprolactone);

HE, hematoxylin and eosin. |

Immunohistochemical staining of

OCN

The immunohistochemical staining results (Fig. 9) demonstrated that the

PCL/COL/SIM-PLGA group exhibited significantly higher OCN

expression compared with the PCL/COL group, as determined by the

number of OCN-positive areas (indicated by brown staining). In

addition, the level of OCN expression in the PCL/COL and

PCL/COL/SIM-PLGA groups was significantly increased compared with

the PCL group, which suggested that the composited PCL possessed

improved osteogenic ability, with collagen facilitating the PCL to

form bone tissue and SIM-PLGA promoting further osteogenesis.

Discussion

In order to accelerate bone reconstruction, an

optimal bone implant for clinical practice requires both a porous

structure and optimal biocompatibility. The present study employed

hybrid 3D PCL scaffolds consisting of PCL, COL and SIM/PLGA, and

the results revealed two key points. Firstly, the low degradation

rate of the PCL scaffold with an interconnected porous structure

provided good mechanical strength and allowed for the delivery of

nutrients through the scaffolds. COL modification produced

scaffolds with macro/micro hierarchical structures where cells

attached and proliferated well among the COL RGD (Arg-Gly-Asp

motif) domains and integrin receptors (13). Secondly, the scaffolds conferred high

absorbability to the SIM-PLGA microspheres, enhancing osteogenesis

and the osteointegration of biomimetic PCL/COL scaffolds.

In our previous study, PCL frames that were

incorporated with a COL scaffold significantly increased the

surface area and bulk modulus, making best use of the advantages,

and bypassing the disadvantages, of using scaffold materials

(5). In the present study, in order

to further improve the biological functionalities of the composite,

SIM-PLGA was subsequently incorporated into the COL scaffold in

order to achieve controlled SIM discharge. To elucidate the impact

of SIM-PLGA incorporation, the pore size, release diagram,

mechanical structure of the scaffolds, cell activity and in

vivo bone restoration effect were measured.

As indicated in previous research, SIM enhances bone

formation by reducing apoptosis and increasing osteogenesis in MSCs

(21), as well as inhibiting bone

resorption by suppressing the proliferation and differentiation of

osteoclasts (42). In the present

study, it was also observed that SIM could augment the

proliferative and differentiative capabilities of BMSCs, indicating

its potential as a bone regenerative molecule. This was also

confirmed by the superior osteogenesis elicited by the

incorporation of SIM-PLGA in femur bone defect repair. However, it

remains difficult to systemically manipulate the uptake of SIM due

to its poor drug absorptivity. On the other hand, sufficient doses

via local injection may cause inflammation (15). To improve the efficacy of SIM and

circumvent its side effects, the present study selected PLGA

microspheres as a drug vehicle due to their agreeable

biocompatibility, low toxicity and controllable rate of degradation

(24,25,43).

Sustained release of SIM plays an essential role in bone

regeneration, as a release time of 2–3 weeks is required for growth

factors to fulfill ideal bone repair (44). As demonstrated in the release

diagram, the release of SIM from the PLGA microspheres lasted

>27 days, indicating that PLGA microspheres may serve as

appropriate carriers for growth factors.

Porosity is an important determinant of optimal

regenerative materials (45).

Osteochondral formation usually occurs in pores of a small size;

and non-chondral osteogenesis is usually present in pores of a

larger size (46,47). Based on previous work (5), the present study fabricated scaffolds

with a pore size of 1,000 µm through 3D printing. To simulate the

anatomic constitution of human cancellous bone, COL was combined

with the PCL scaffold via dry-freezing, thereby acquiring a

hierarchical porous structure with a saturated void space (48). Within the COL network, the PLGA

microspheres exhibited homogeneous distribution with the pore size

slightly diminished.

Since bones function as load-bearing parts, the

materials for bone implants must retain strong mechanical

properties in order to secure all of the osteogenic cells with

sufficient space for tissue regeneration. Due to its good

mechanical strength and low rate of degradation, PCL is widely

considered to be an appropriate candidate for osteogenic scaffolds.

Previous studies have revealed that the compressive strength and

modulus of PCL, with a hierarchical pore structure, is similar to

that of human cancellous bone (1,49) and

could be utilized for bone tissue engineering (1,4), as

demonstrated by the present study.

In conclusion, the results of the present study

provide the basis for a new strategy for bone tissue regeneration,

which incorporates polyesters and biomolecules, forming a

hierarchical structure containing a PCL scaffold of a macro-scale

filled with micro-sized COL. With the sustained release of SIM, the

present study obtained superior bone formation with sufficient

mechanical strength.

Acknowledgements

The authors would like to thank Dr Jinbing Wang and

Dr Yu Li (Shanghai Key Laboratory of Tissue Engineering, Department

of Plastic and Reconstructive Surgery, Shanghai Ninth People's

Hospital, School of Medicine, Shanghai Jiao Tong University,

Shanghai, China) for their help in the preparation of the

scaffolds.

Funding

No funding was received.

Availability of data and materials

The datasets used and/or analyzed during the present

study are available from the corresponding author on reasonable

request.

Authors' contributions

The final version of the manuscript has been read

and approved by all authors, and each author believes that the

manuscript represents honest work. ZZZ and HZZ collaborated to

design the study. ZZZ was responsible for experiments. ZZZ and ZYZ

analyzed the data. All authors collaborated to interpret results

and prepare the manuscript.

Ethics approval and consent to

participate

All procedures performed in the current study were

approved by the Ethics Committee of Shanghai Ninth People's

Hospital.

Patient consent for publication

Not applicable.

Competing interests

The authors declare that they have no competing

interests.

References

|

1

|

Weisgerber DW, Erning K, Flanagan CL,

Hollister SJ and Harley BAC: Evaluation of multi-scale mineralized

collagen-polycaprolactone composites for bone tissue engineering. J

Mech Behav Biomed Mater. 61:318–327. 2016. View Article : Google Scholar : PubMed/NCBI

|

|

2

|

Kasuya A, Sobajima S and Kinoshita M: In

vivo degradation and new bone formation of calcium phosphate

cement-gelatin powder composite related to macroporosity after in

situ gelatin degradation. J Orthop Res. 30:1103–1111. 2012.

View Article : Google Scholar : PubMed/NCBI

|

|

3

|

Zhang J, Wang L, Zhang W, Zhang M and Luo

ZP: Synchronization of calcium sulphate cement degradation and new

bone formation is improved by external mechanical regulation. J

Orthop Res. 33:685–691. 2015. View Article : Google Scholar : PubMed/NCBI

|

|

4

|

Li L, Zuo Y, Zou Q, Yang B, Lin L, Li J

and Li Y: Hierarchical structure and mechanical improvement of an

n-HA/GCO-PU composite scaffold for bone regeneration. ACS Appl

Mater Interfaces. 7:22618–22629. 2015. View Article : Google Scholar : PubMed/NCBI

|

|

5

|

Wang J, Wu D, Zhang Z, Li J, Shen Y, Wang

Z, Li Y, Zhang ZY and Sun J: Biomimetically ornamented rapid

prototyping fabrication of an apatite-collagen-polycaprolactone

composite construct with nano-micro-macro hierarchical structure

for large bone defect treatment. ACS Appl Mater Interfaces.

7:26244–26256. 2015. View Article : Google Scholar : PubMed/NCBI

|

|

6

|

Pilia M, Guda T and Appleford M:

Development of composite scaffolds for load-bearing segmental bone

defects. Biomed Res Int. 2013:4582532013. View Article : Google Scholar : PubMed/NCBI

|

|

7

|

Inzana JA, Olvera D, Fuller SM, Kelly JP,

Graeve OA, Schwarz EM, Kates SL and Awad HA: 3D printing of

composite calcium phosphate and collagen scaffolds for bone

regeneration. Biomaterials. 35:4026–4034. 2014. View Article : Google Scholar : PubMed/NCBI

|

|

8

|

Papadimitropoulos A, Riboldi SA,

Tonnarelli B, Piccinini E, Woodruff MA, Hutmacher DW and Martin I:

A collagen network phase improves cell seeding of open-pore

structure scaffolds under perfusion. J Tissue Eng Regen Med.

7:183–191. 2013. View

Article : Google Scholar : PubMed/NCBI

|

|

9

|

Zein I, Hutmacher DW, Tan KC and Teoh SH:

Fused deposition modeling of novel scaffold architectures for

tissue engineering applications. Biomaterials. 23:1169–1185. 2002.

View Article : Google Scholar : PubMed/NCBI

|

|

10

|

Siddiqui N, Asawa S, Birru B, Baadhe R and

Rao S: PCL-based composite scaffold matrices for tissue engineering

applications. Mol Biotechnol. 2018. View Article : Google Scholar : PubMed/NCBI

|

|

11

|

Kim W, Jang CH and Kim G: Optimally

designed collagen/polycaprolactone biocomposites supplemented with

controlled release of HA/TCP/rhBMP-2 and HA/TCP/PRP for hard tissue

regeneration. Mater Sci Eng C Mater Biol Appl. 78:763–772. 2017.

View Article : Google Scholar : PubMed/NCBI

|

|

12

|

Cui Z, Lin L, Si J, Luo Y, Wang Q, Lin Y,

Wang X and Chen W: Fabrication and characterization of chitosan/OGP

coated porous poly(epsilon-caprolactone) scaffold for bone tissue

engineering. J Biomater Sci Polym Ed. 28:826–845. 2017. View Article : Google Scholar : PubMed/NCBI

|

|

13

|

Kiran S, Nune KC and Misra RD: The

significance of grafting collagen on polycaprolactone composite

scaffolds: Processing-structure-functional property relationship. J

Biomed Mater Res A. 103:2919–2931. 2015. View Article : Google Scholar : PubMed/NCBI

|

|

14

|

Pek YS, Gao S, Arshad MS, Leck KJ and Ying

JY: Porous collagen-apatite nanocomposite foams as bone

regeneration scaffolds. Biomaterials. 29:4300–4305. 2008.

View Article : Google Scholar : PubMed/NCBI

|

|

15

|

Xie C, Lu X, Han L, Xu J, Wang Z, Jiang L,

Wang K, Zhang H, Ren F and Tang Y: Biomimetic mineralized

hierarchical graphene oxide/chitosan scaffolds with adsorbability

for immobilization of nanoparticles for biomedical applications.

ACS Appl Mater Interfaces. 8:1707–1717. 2016. View Article : Google Scholar : PubMed/NCBI

|

|

16

|

Wang C, Zhao Q and Wang M: Cryogenic 3D

printing for producing hierarchical porous and rhBMP-2-loaded

Ca-P/PLLA nanocomposite scaffolds for bone tissue engineering.

Biofabrication. 9:0250312017. View Article : Google Scholar : PubMed/NCBI

|

|

17

|

Yan Q, Xiao LQ, Tan L, Sun W, Wu T, Chen

LW, Mei Y and Shi B: Controlled release of simvastatin-loaded

thermo-sensitive PLGA-PEG-PLGA hydrogel for bone tissue

regeneration: In vitro and in vivo characteristics. J Biomed Mater

Res A. 103:3580–3589. 2015. View Article : Google Scholar : PubMed/NCBI

|

|

18

|

Papadimitriou K, Karkavelas G, Vouros I,

Kessopoulou E and Konstantinidis A: Effects of local application of

simvastatin on bone regeneration in femoral bone defects in rabbit.

J Craniomaxillofac Surgy. 43:232–237. 2015. View Article : Google Scholar

|

|

19

|

Montero J, Manzano G and Albaladejo A: The

role of topical simvastatin on bone regeneration: A systematic

review. J Clin Exp Dent. 6:e286–e290. 2014. View Article : Google Scholar : PubMed/NCBI

|

|

20

|

Tanigo T, Takaoka R and Tabata Y:

Sustained release of water-insoluble simvastatin from biodegradable

hydrogel augments bone regeneration. J Control Release.

143:201–206. 2010. View Article : Google Scholar : PubMed/NCBI

|

|

21

|

Park JB: The use of simvastatin in bone

regeneration. Med Oral Patol Oral Cir Bucal. 14:e485–e488.

2009.PubMed/NCBI

|

|

22

|

Mir M, Ahmed N and Rehman AU: Recent

applications of PLGA based nanostructures in drug delivery.

Colloids Surf B Biointerfaces. 159:217–231. 2017. View Article : Google Scholar : PubMed/NCBI

|

|

23

|

Li H, Liao H, Bao C, Xiao Y and Wang Q:

Preparation and evaluations of mangiferin-loaded PLGA scaffolds for

alveolar bone repair treatment under the diabetic condition. AAPS

Pharm Sci Tech. 18:529–538. 2017. View Article : Google Scholar

|

|

24

|

Hu X, Zhang J, Tang X, Li M, Ma S, Liu C,

Gao Y, Zhang Y, Liu Y, Yu F, et al: An accelerated release method

of risperidone loaded PLGA microspheres with good IVIVC. Curr Drug

Deliv. 15:87–96. 2018. View Article : Google Scholar : PubMed/NCBI

|

|

25

|

Huang J, Chen Z, Li Y, Li L and Zhang G:

Rifapentine-linezolid-loaded PLGA microspheres for interventional

therapy of cavitary pulmonary tuberculosis: Preparation and in

vitro characterization. Drug Des Devel Ther. 11:585–592. 2017.

View Article : Google Scholar : PubMed/NCBI

|

|

26

|

Li Y and Zhang Z and Zhang Z: Porous

chitosan/nano-hydroxyapatite composite scaffolds incorporating

simvastatin-loaded PLGA microspheres for bone repair. Cells Tissues

Organs. 205:20–31. 2018. View Article : Google Scholar : PubMed/NCBI

|

|

27

|

Fernández-Sánchez L, Bravo-Osuna I, Lax P,

Arranz-Romera A, Maneu V, Esteban-Pérez S, Pinilla I,

Puebla-González MDM, Herrero-Vanrell R and Cuenca N: Controlled

delivery of tauroursodeoxycholic acid from biodegradable

microspheres slows retinal degeneration and vision loss in P23H

rats. PLoS One. 12:e01779982017. View Article : Google Scholar : PubMed/NCBI

|

|

28

|

Jeong C, Kim SE, Shim KS, Kim HJ, Song MH,

Park K and Song HR: Exploring the in vivo anti-inflammatory actions

of simvastatin-loaded porous microspheres on inflamed tenocytes in

a collagenase-induced animal model of achilles tendinitis. Int J

Mol Sci. 19:E8202018. View Article : Google Scholar : PubMed/NCBI

|

|

29

|

Qiao F, Zhang J, Wang J, Du B, Huang X,

Pang L and Zhou Z: Silk fibroin-coated PLGA dimpled microspheres

for retarded release of simvastatin. Colloids Surf B Biointerfaces.

158:112–118. 2017. View Article : Google Scholar : PubMed/NCBI

|

|

30

|

Yu WL, Sun TW, Qi C, Zhao HK, Ding ZY,

Zhang ZW, Sun BB, Shen J, Chen F, Zhu YJ, et al: Enhanced

osteogenesis and angiogenesis by mesoporous hydroxyapatite

microspheres-derived simvastatin sustained release system for

superior bone regeneration. Sci Rep. 7:441292017. View Article : Google Scholar : PubMed/NCBI

|

|

31

|

Li Y and Zhang ZZ: Sustained curcumin

release from PLGA microspheres improves bone formation under

diabetic conditions by inhibiting the reactive oxygen species

production. Drug Des Devel Ther. 12:1453–1466. 2018. View Article : Google Scholar : PubMed/NCBI

|

|

32

|

Zhang W, Chang Q, Xu L, Li G, Yang G, Ding

X, Wang X, Cui D and Jiang X: Graphene oxide-copper

nanocomposite-coated porous CaP scaffold for vascularized bone

regeneration via activation of Hif-1α. Adv Healthc Mater.

5:1299–1309. 2016. View Article : Google Scholar : PubMed/NCBI

|

|

33

|

Xie H, Wang Z, Zhang L, Lei Q, Zhao A,

Wang H, Li Q, Cao Y, Zhang Jie W and Chen Z: Extracellular

vesicle-functionalized decalcified bone matrix scaffolds with

enhanced pro-angiogenic and pro-bone regeneration activities. Sci

Rep. 7:456222017. View Article : Google Scholar : PubMed/NCBI

|

|

34

|

Shen X, Zhang Y, Gu Y, Xu Y, Liu Y, Li B

and Chen L: Sequential and sustained release of SDF-1 and BMP-2

from silk fibroin-nanohydroxyapatite scaffold for the enhancement

of bone regeneration. Biomaterials. 106:205–216. 2016. View Article : Google Scholar : PubMed/NCBI

|

|

35

|

Li Y, Gao X and Wang J: Human

adipose-derived mesenchymal stem cell-conditioned media suppresses

inflammatory bone loss in a lipopolysaccharide-induced murine

model. Exp Ther Med. 15:1839–1846. 2018.PubMed/NCBI

|

|

36

|

Livak KJ and Schmittgen TD: Analysis of

relative gene expression data using real-time quantitative PCR and

the 2(-Delta Delta C(T)) method. Methods. 25:402–408. 2001.

View Article : Google Scholar : PubMed/NCBI

|

|

37

|

National Research Council Committee for

the Update of the Guide for the Care and Use of Laboratory Animals:

The National Academies Collection: Reports funded by National

Institutes of Health, . In: Guide for the Care and Use of

Laboratory Animals. th (ed). National Academies Press (US) National

Academy of Sciences; Washington (DC): 2011

|

|

38

|

Sun X, Wang J, Wang Y and Zhang Q:

Collagen-based porous scaffolds containing PLGA microspheres for

controlled kartogenin release in cartilage tissue engineering.

Artif Cells Nanomed Biotechnol. 1–10. 2017. View Article : Google Scholar

|

|

39

|

Fahimipour F, Rasoulianboroujeni M,

Dashtimoghadam E, Khoshroo K, Tahriri M, Bastami F, Lobner D and

Tayebi L: 3D printed TCP-based scaffold incorporating VEGF-loaded

PLGA microspheres for craniofacial tissue engineering. Dent Mater.

33:1205–1216. 2017. View Article : Google Scholar : PubMed/NCBI

|

|

40

|

Ramazani F, Chen W, van Nostrum CF, Storm

G, Kiessling F, Lammers T, Hennink WE and Kok RJ: Strategies for

encapsulation of small hydrophilic and amphiphilic drugs in PLGA

microspheres: State-of-the-art and challenges. Int J Pharm.

499:358–367. 2016. View Article : Google Scholar : PubMed/NCBI

|

|

41

|

Giteau A, Venier-Julienne MC,

Aubert-Pouëssel A and Benoit JP: How to achieve sustained and

complete protein release from PLGA-based microparticles? Int J

Pharm. 350:14–26. 2008. View Article : Google Scholar : PubMed/NCBI

|

|

42

|

Oryan A, Kamali A and Moshiri A: Potential

mechanisms and applications of statins on osteogenesis: Current

modalities, conflicts and future directions. J Control Release.

215:12–24. 2015. View Article : Google Scholar : PubMed/NCBI

|

|

43

|

Du L, Yang S, Li W, Li H, Feng S, Zeng R,

Yu B, Xiao L, Nie HY and Tu M: Scaffold composed of porous

vancomycin-loaded poly(lactide-co-glycolide) microspheres: A

controlled-release drug delivery system with shape-memory effect.

Mater Sci Eng C Mater Biol Appl. 78:1172–1178. 2017. View Article : Google Scholar : PubMed/NCBI

|

|

44

|

Guelcher SA, Brown KV, Li B, Guda T, Lee

BH and Wenke JC: Dual-purpose bone grafts improve healing and

reduce infection. J Orthop Trauma. 25:477–482. 2011. View Article : Google Scholar : PubMed/NCBI

|

|

45

|

Liu H, Yang L, Zhang E, Zhang R, Cai D,

Zhu S, Ran J, Bunpetch V, Cai Y, Heng BC, et al: Biomimetic tendon

extracellular matrix composite gradient scaffold enhances

ligament-to-bone junction reconstruction. Acta Biomater.

56:129–140. 2017. View Article : Google Scholar : PubMed/NCBI

|

|

46

|

Du Y, Liu H, Yang Q, Wang S, Wang J, Ma J,

Noh I, Mikos AG and Zhang S: Selective laser sintering scaffold

with hierarchical architecture and gradient composition for

osteochondral repair in rabbits. Biomaterials. 137:37–48. 2017.

View Article : Google Scholar : PubMed/NCBI

|

|

47

|

Amini AR, Wallace JS and Nukavarapu SP:

Short-term and long-term effects of orthopedic biodegradable

implants. J Long Term Eff Med Implants. 21:93–122. 2011. View Article : Google Scholar : PubMed/NCBI

|

|

48

|

Nezu T and Winnik FM: Interaction of

water-soluble collagen with poly(acrylic acid). Biomaterials.

21:415–419. 2000. View Article : Google Scholar : PubMed/NCBI

|

|

49

|

Hollister SJ: Porous scaffold design for

tissue engineering. Nat Mater. 4:518–524. 2005. View Article : Google Scholar : PubMed/NCBI

|