Introduction

In bone tissue engineering, the use of composite

carriers that encapsulate bioactive components is a key strategy

for drug delivery. Carriers may contain drugs, small molecules or

even nanomaterials (1,2). Electrospun nanofibers are effective

biocompatible drug carriers because of their ability to repair bone

tissue. These fibers can deliver significant amounts of

therapeutics and have, therefore, attracted attention as potential

drug delivering scaffolding materials (3,4). In

addition, nanofibers are highly porous, providing an artificial

milieu that is structurally comparable to the naturally occurring

extracellular matrix (ECM) (1,5). As

such, electrospun nanofibers are frequently utilized in tissue

engineering (1,6,7).

Electrospinning can also produce nanofibers with high bioactivity.

These are based on natural polymers, including gelatin (Gt),

chitosan and hyaluronic acid, and synthetic polymers, including

poly-D, L-lactide-coglycolide (PLGA), polycaprolactone (PCL) and

polyurethane. These polymers are all highly biocompatible and

biodegradable (5).

Guided bone regeneration (GBR) has been demonstrated

to be effective in periodontal therapy (8) and is an important strategy in bone

tissue engineering (9). In GBR, the

typical barrier membrane consists of two surfaces: The porous

surface that faces the osseous bone defect, to guide bone

formation, and the dense surface that faces the soft tissue, to

prevent non-osteogenic cells (such as fibroblasts) from interfering

with bone healing (10). Thus, the

barrier membrane plays a crucial role in bone regeneration

(8). In recent years,

co-electrospinning has been used to generate hybrid nanofibers with

specific features, such as its interconnected porous structures,

broad surface areas and capability of delivering drugs (11-13).

These nanofibers have the features of both naturally occurring and

synthetic polymers, which improve their ability to induce bone

tissue repair. Multi-layered scaffolds are also useful for vascular

tissue engineering (14-16).

The structural diversity of these scaffolds is more advantageous

than homogeneous structures due to their enhanced mechanical

features, biodegradability and biocompatibility (14,17,18).

Unfortunately, complications such as delamination (poor

biomechanics and operability) and difficulty in molding

three-dimensional structures (compact structure that can impede

cell migration) with many constituents have restricted the

widespread development of multi-layered scaffolds (19,20).

Simvastatin, a cholesterol-lowering drug, can

promote bone growth and this is hypothesized to be through

stimulation of BMP-2 expression (21,22).

Simvastatin has also been successfully integrated into drug

delivery vehicles consisting of a methylcellulose gel surrounded by

a polylactic acid (PLA) membrane. Using this system, a single

administration of 2.2 mg of simvastatin was demonstrated to induce

bone growth in vivo, however, soft-tissue inflammation was

observed (23).

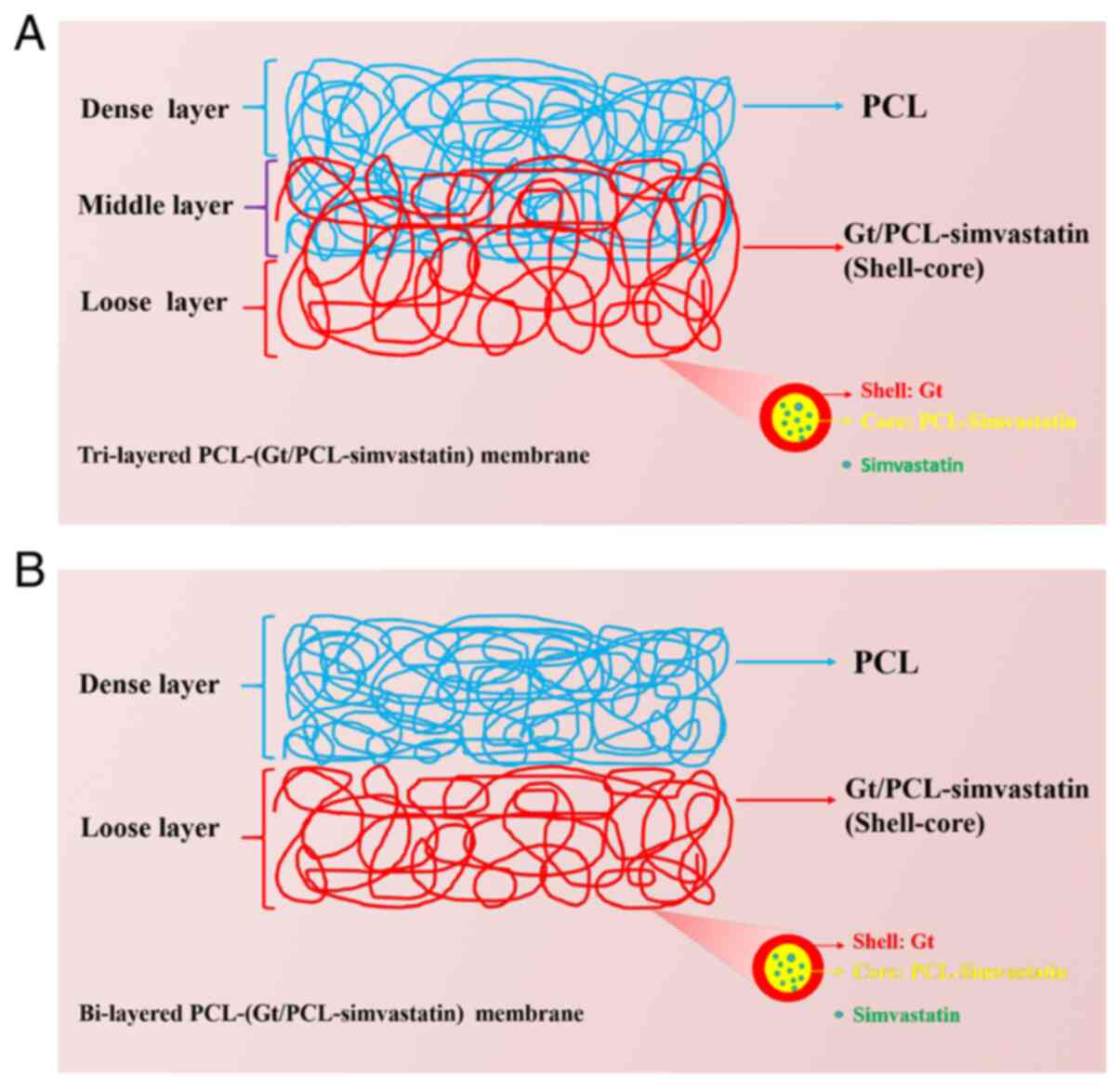

In the present study, two multi-layered

co-electrospun nanofibers membranes made of natural (Gt) and

synthetic (PCL) polymers were designed. These membranes have both

porous and dense layers to improve their osteogenic efficacy and

barrier function. In addition, these membranes were loaded with

simvastatin to promote bone growth (Fig. 1). These membranes were designed to

promote osteoinduction and act as a barrier against cells but not

against water and molecules in order to promote guided bone

regeneration (GBR). The in vitro biological function of the

membranes was then evaluated. In order to verify the osteogenic and

barrier effects of the membranes, bone marrow mesenchymal stem

cells (BMMSCs) and human fibroblasts were seeded on the surface of

the porous and dense layers, respectively. The cell distribution on

the different surfaces was observed using a confocal laser scanning

microscope (CLSM). The osteogenic effects of simvastatin on

critically-sized calvarial defects in rabbits were evaluated to

assess the membrane's potential for GBR.

Materials and methods

Materials

PCL (85 kDa) and histopaque-1077 were obtained from

Sigma-Aldrich (Merck KGaA). 2,2,2-trifluroroethanol (TFE) was

obtained from the Weihai Newera Chemical Co., Ltd. Gelatin (Gt, 200

Bloom) was supplied by the Department of Polymer Science and

Engineering, Zhejiang University (China). Simvastatin was purchased

from BioSino Biotechnology & Science, Inc. 0.05% trypsin-5 Mm

EDTA was from Biochrom GmbH (Merck KGaA). Human foreskin

fibroblasts (HFFs-1) were obtained from the American Type Culture

Collection. Culture media and other cell culture medium supplements

were obtained from Thermo Fisher Scientific, Inc.

Preparation of the multilayered

nanofibers

Simvastatin was dissolved in a PCL (20% w/w in TFE)

solution to obtain a final concentration of 3.5%. Gt was dissolved

in TFE to obtain a 12% solution. Coaxial electrospinning was

conducted with reference to a previous study (24). The Gt/TFE solution was used to

create the outer shell, while the PCL/TFE solution containing

simvastatin was used to create the inner core. All feed rates were

set at 1 ml/h. The spinning electrode and the collector were

separated by 16 cm, with a voltage of 9-10 kV/cm. Collection was

carried out over 3 h to obtain the Gt/PCL-simvastatin membrane. A

single jet was used to electrospin the PCL mat on the

Gt/PCL-simvastatin membrane. The spinning electrode and the

collector were 17 cm apart, with a voltage of 11-12 kV/cm. The

duration of electrospinning was 4 h, and the feed rate was 1 ml/h.

Finally, a bi-layered PCL-Gt/PCL-simvastatin membrane (membrane A)

was obtained. The layers were 100-150 µm thick.

The tri-layered PCL-Gt/PCL-simvastatin membrane

(membrane B) was fabricated in a similar manner to membrane A.

First, the coaxial Gt/PCL-simvastatin fibers were electrospun for 2

h, followed by the introduction of PCL nanofibers onto the coaxial

membrane by simultaneous spinning using another electrode. The

position of the spray nozzle for the PCL nanofibers was adjusted to

ensure maximum overlap of the receiving area of the core-shell and

PCL fibers. The two nanofibers were collected for 1.5 h, before

coaxial electrospinning was stopped. The electrospinning of the PCL

nanofibers was continued for 2 h. The structure of the

multiple-layered nanofibrous membranes is shown in Fig. 1. The membranes were stored at room

temperature.

Scaffold characterization

A scanning electron microscope (SEM; model no.

JSM-5300; JEOL, Ltd.) was used to assess the surface and morphology

of the nanofibers under x1,000 magnification. Image-Pro Plus v6.0

(Media Cybernetics, Inc.) was used to measure the average fiber

diameter and pore size (n=100) of the materials. The samples used

for SEM were subjected to vacuum drying and were sputter-coated

with gold-palladium for 60 sec.

In order to evaluate nanofiber degradation, three

membrane pieces were immersed in 10 ml phosphate-buffered saline

(PBS, pH 7.2±0.1) and placed in a 37˚C water bath for 1 and 3

months, with PBS refreshed monthly. Sample degradation was examined

by SEM observation.

The membranes were cut into squares (10x10 mm; n=3)

and used to assess the in vitro release of simvastatin over

one month. After sterilization using Cobalt-60 (2 h), the specimens

were immersed in PBS (1 ml) and incubated at 37˚C under rotation

(150 RPM). Supernatants were obtained daily and stored at -20˚C,

with the addition of fresh PBS (1 ml). The amount of released

simvastatin was assessed by high-performance liquid chromatography

(HPLC), and the cumulative release of simvastatin was plotted.

Culture of bone marrow mesenchymal

stem cells (BMMSCs)

BMMSCs were isolated from iliac crest marrow

aspirates of human donors (aged 20-25 years) with no known disease

(n=4). Informed consent was obtained and signed by the donors and

the study was approved by the Research Ethics Committee of The

First Affiliated Hospital, College of Medicine, Zhejiang University

(Hangzhou, China; Reference number 2013-273). The human samples

were collected in the operating room of The First Affiliated

Hospital of Zhejiang University School of Medicine between November

2014 and October 2020.

The isolation and culture procedure of BMMSCs were

performed as described in our previous study (25). Histopaque-1077 density gradient

centrifugation was used for BMMSC isolation. The collected

mononuclear cells (MNCs) underwent PBS washes and resuspension in

Dulbecco's modified Eagle's medium (DMEM) containing 10% fetal

bovine serum (FBS) and 100 U/ml penicillin/streptomycin and were

plated at a density of 2x106 MNCs/cm2.

Incubation was carried out at 37˚C in a humidified environment

containing 5% CO2, and the medium was replenished at

3-4-day intervals. At 80% confluency, BMMSCs were passaged after

trypsinization.

Seeding and culturing of cells on the

membranes

BMMSCs at passage 3 were seeded on the coaxial

surface of the membranes (10x10 mm) after sterilization (Cobalt-60,

2 h), placed in a 24-well culture plate under pressure (glass

column), and incubated overnight in a humid environment containing

5% CO2 at 37˚C, as previously described (25,26).

For seeding, cells at 5.4x106 cells/ml were added drop

by drop onto the membrane, with approximately 3.2x105

cells per membrane. Third-passage HFFs-1 were added to the PCL

surface of the membranes, as described above, at 5.4x106

cells/ml. Membrane A was used as the control group and membrane B

as the experimental group. Constructs were incubated for 2.5-3 h to

ensure cell adhesion to the membrane. Incubation was performed at

37˚C, as described above, with the medium refreshed at 3-4-day

intervals. At defined time points, triplicates per seeding group

were obtained for cell adhesion, distribution and differentiation

assessment.

Cell morphology, proliferation, and

distribution on membranes

To assess cell adhesion and morphology, cell-loaded

membranes at 10, 30 and 60 min post-seeding were submitted to two

PBS washes, glutaraldehyde fixation (2.5%; 2 h; 4˚C), and two

additional PBS washes. Graded ethanol solutions (30, 50, 70, 80,

90, 95 and 100%) were used for dehydration, followed by sputter

coating with gold and SEM analysis.

Cell proliferation was estimated with the Cell

Counting Kit-8 (CCK-8; Dojindo Molecular Technologies, Inc.) after

the cells were cultured on the membranes for 1, 3, 5 and 7 days.

Cell proliferation was compared to cells seeded on Petri dishes as

control. CCK-8 solution (10 µl) was added to each well (three wells

for each group) and the cells were incubated at 37˚C for 4 h.

Absorbance at 450 nm was determined using a microplate reader

(Bio-Tek Instruments, Inc.).

For cell distribution assessment, PBS-washed

cell-loaded membranes were incubated with

4',6-diamidino-2-phenylindole (DAPI; Invitrogen; Thermo Fisher

Scientific, Inc.) for 30 min, washed, and further incubated in

fresh medium for 1 h. These procedures were performed at 37˚C in a

humidified 5% CO2 atmosphere. Laser confocal scanning

microscopy was performed and raw 3D images were analyzed using

NIS-Elements Basic Research v3.0 (Nikon Instruments Inc.) for cell

distribution.

Reverse transcription-quantitative PCR

(RT-qPCR) for the determination of osteogenic gene expression

Total RNA from cell-membrane samples was obtained

using the RNeasy micro kit (Qiagen GmbH). RNA amounts and purity

were assessed on a Bio-Photometer (Eppendorf). First-strand cDNA

(in 100-µl reaction volumes) synthesis was performed with a

QuantiTect Reverse Transcription kit (Qiagen GmbH) based on 100 ng

of total RNA, as recommended by the manufacturer (37˚C for 15 min

and 85˚C for 5 sec). qPCR was carried out on an Applied Biosystems

7500 Real-Time PCR System (Life Technologies; Thermo Fisher

Scientific, Inc.) with a QuantiTect SYBR Green PCR kit (Qiagen

GmbH). Reactions contained 1 µl of cDNA, 4.5 µl of Real Master

Mix/SYBR solution (Qiagen GmbH), 1 µl of each primer and 2.5 µl of

RNase-free water. The early-stage osteogenic differentiation gene

core-binding factor-α1 (Cbf-α1) (27,28)

and alkaline phosphatase (ALP) (29), the middle-to-late stage osteogenic

marker osteonectin (ON) (30), and

the late stage markers osteocalcin (OCN) and osteopontin (OPN)

(31) were assessed using

glyceraldehyde-3-phosphate dehydrogenase (GAPDH) for normalization.

Cells cultured without a membrane constituted the control group for

assessing target gene expression. The primer sequences used are

listed in Table I. Amplification

was carried out for 40 cycles in a real-time PCR device, with a

program consisting of HotstarTaq DNA polymerase activation (2 min,

95˚C), denaturation (15 sec, 95˚C) and annealing for 15 sec at 62˚C

(ON, OCN, OPN), 63˚C (Cbf-α1) or 59˚C (GAPDH), with a final

extension (20 sec, 68˚C). Cycle threshold (Ct) values and melting

curves were assessed. The analysis was performed as described by

Pfaffl (32).

| Table IPrimer sequences of target and

housekeeping genes that were utilized in the study. |

Table I

Primer sequences of target and

housekeeping genes that were utilized in the study.

| Gene | Primer Sequence

(5'-3') |

|---|

| Cbf-α1 | F:

TTCCAGACCAGCAGCACTC |

| | R:

CAGCGTCAACACCATCATT |

| ON | F:

CGAGCTGGATGAGAACAACA |

| | R:

AAGTGGCAGGAAGAGTCGAA |

| ALP | F:

GTCACTGCGGACCATTCC |

| | R:

GGCTGCATACGCCATCAC |

| OCN | F:

CAGCCACCGAGACACCATG |

| | R:

CAGAGCGACACCCTAGACC |

| OPN | F:

CAGTTGTCCCCACAGTAGACAC |

| | R:

GTGATGTCCTCGTCTGTAGCATC |

| GAPDH | F: GGAGCG

AGATCCCTCCAAAAT |

| | R:

GGCTGTTGTCATACTTCTCATGG |

Assessment of in vivo implants

Surgery

Critical-size defects were surgically created on the

calvaria of 8-month-old New Zealand white rabbits (male, 2.0-2.5

kg; n=24) (21,31-38)

purchased from the Laboratory Animal Center of Zhejiang Province.

The rabbits were assigned to three groups: Control group (no

membrane), group A (bi-layered PCL-Gt/PCL-simvastatin membrane) and

group B (tri-layered PCL-Gt/PCL-simvastatin membrane). The Animal

Experimental Ethical Committee of the First Affiliated Hospital,

College of Medicine, Zhejiang University (Reference no. 2013-273)

approved the protocols for animal experiments. The implantation

procedures in these rabbits were performed under general anesthesia

using fentanyl/fluanison (Hypnorm®, fentanyl citrate

0.315 mg/ml, fluanisone 10 mg/ml, Janssen Pharmaceuticals, Inc.;

Johnson + Johnson; 0.3 ml/kg intramuscular) combined with an

intravenous injection of 1 mg/kg diazepam. During surgery,

full-thickness flaps were made to reveal the cranial bone, and

critical size (15 mm) defects, as previously described (23,33-40),

were generated with trephines under irrigation with chilled saline.

For the membrane groups, the membranes were implanted and fixed

onto the defects at this stage. A resorbable suture was used for

closure of the soft tissues in layers. The rabbits underwent

euthanasia with an overdose (100 mg/kg) of intravenous

pentobarbital sodium at 4 or 12 weeks following implantation (n=4)

and were assessed for bone regeneration.

Micro-computed tomography (µ-CT)

At 4 or 12 weeks after implantation, the tissues

surrounding the membranes were harvested and fixed in 10% formalin

at room temperature for 24 h. Imaging was carried out on an animal

micro-CT scanner (SCANCO Medical AG) in high-resolution scanning

mode using 70 kV, 200 µA, a field of view of 15 mm and 34.4-µm

resolution. Data analysis was performed with the micro-CT image

analysis software (NRecon v.1.6.9; Bruker micro-CT; Bruker

Corporation) to determine the mean new bone volume (BV), bone

mineral density (BMD) and bone volume/total volume (BV/TV).

Histological analysis

Half of the samples underwent fixation with 10%

formalin at room temperature for 24 h, decalcification,

dehydration, paraffin embedding and hematoxylin and eosin (H&E)

staining (26). The remaining half

of the samples were fixed in 4% formalin (Formafix, Global

Technologies Ltd.) at room temperature for 7 days and dehydrated

for 14 days with increasing concentrations of alcohol (70, 80, 96

and 100%). Over a period of 28 days, the sections were

block-embedded in polymethyl methacrylate (PMMA;

Technovit® 7200 VLC; Kulzer GmbH), after which the

samples were ground in the sagittal direction and sliced into

250-µm thick sections with a microtome (EXAKT Technologies, Inc.).

The sections were further reduced to 15 µm, polished and stained

with Van Gieson and toluidine blue, as described previously

(41). Images were captured using

an IX 70 light microscope (Olympus Corporation; magnification,

x25). Three fields of view were observed for each section.

Statistical analysis

SPSS v11.5 (SPSS, Inc.) was used for the statistical

analyses. Values are presented as the mean ± standard deviation

(SD). Groups were compared by one-way analysis of variance (ANOVA)

with Tukey's post hoc test/P<0.05 was considered to indicate

statistical significance.

Results

Morphological and structural

features

The preparation process of the tri-layered

PCL-Gt/PCL-simvastatin membrane (membrane B) is shown in Fig. 1. The middle layer of membrane B was

generated by the simultaneous spinning of uniaxial PCL and coaxial

Gt/PCL-simvastatin nanofibers using two nozzles. As a control, the

bi-layered PCL-(Gt/PCL-simvastatin) membrane (membrane A) was made

with two separated fibrous mats by sequential electrospinning. As

shown in Fig. 1A, the

Gt/PCL-simvastatin and PCL nanofibers resulted in the porous and

dense layers, respectively, while the middle layer of membrane B

contained both types of fibers.

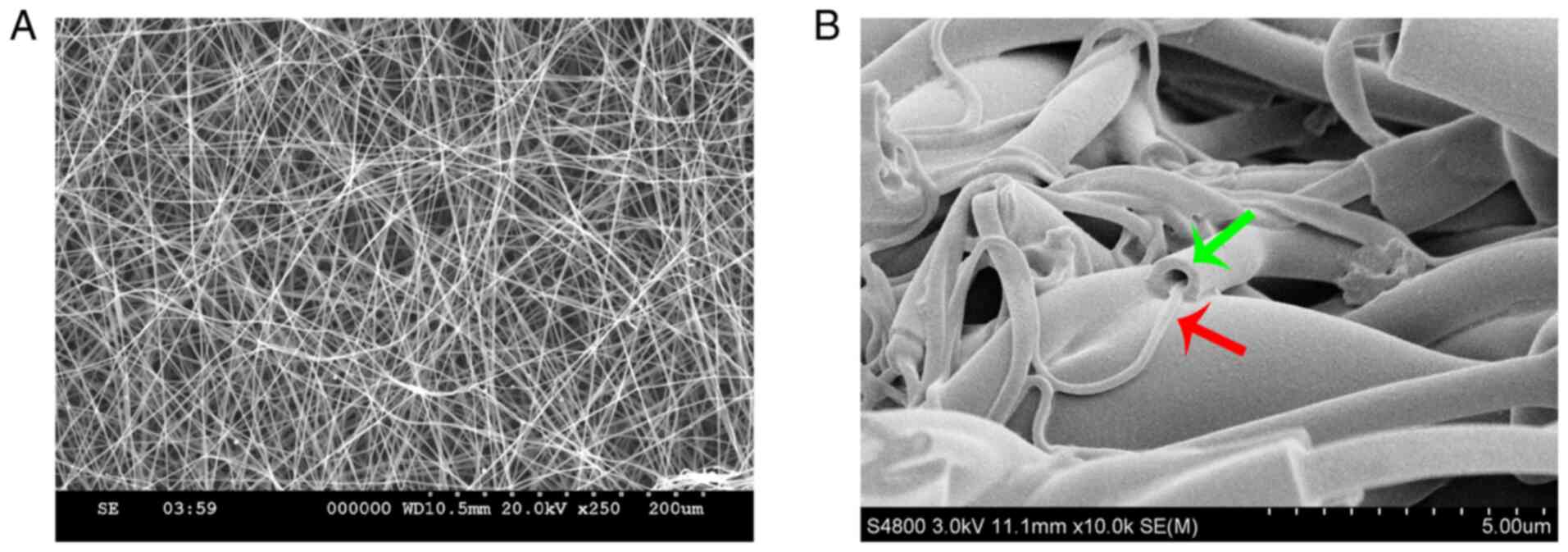

As indicated by the SEM images, electrospun

nanofibers were smooth. This indicates that both PCL and

Gt/PCL-simvastatin fibers could be generated under all flow rates

and methods used (Fig. 2A). The two

types of nanofibers had different morphologies. The pore sizes of

the Gt/PCL-simvastatin nanofibers (porous layer) were 30.27±4.23 µm

(membrane A) and 31.84±4.43 µm (membrane B), while the fiber

diameters were 419.28±59.23 nm (membrane A) and 444.62±96.53 nm

(membrane B). The pore sizes of the PCL nanofibers (dense layer)

were 13.88±4.38 µm (membrane A) and 14.75±2.96 µm (membrane B),

while the fiber diameters were 228.58±98.12 nm (membrane A) and

254.73± 0.68 nm (membrane B). Fig.

2B demonstrates the general structure of the Gt/PCL fibers. The

shell was composed of the natural polymer Gt, and the core was

composed of the synthetic polymer PCL containing simvastatin.

Fig. 2B does not represent the

final structure of the membrane, nor its evolution in time.

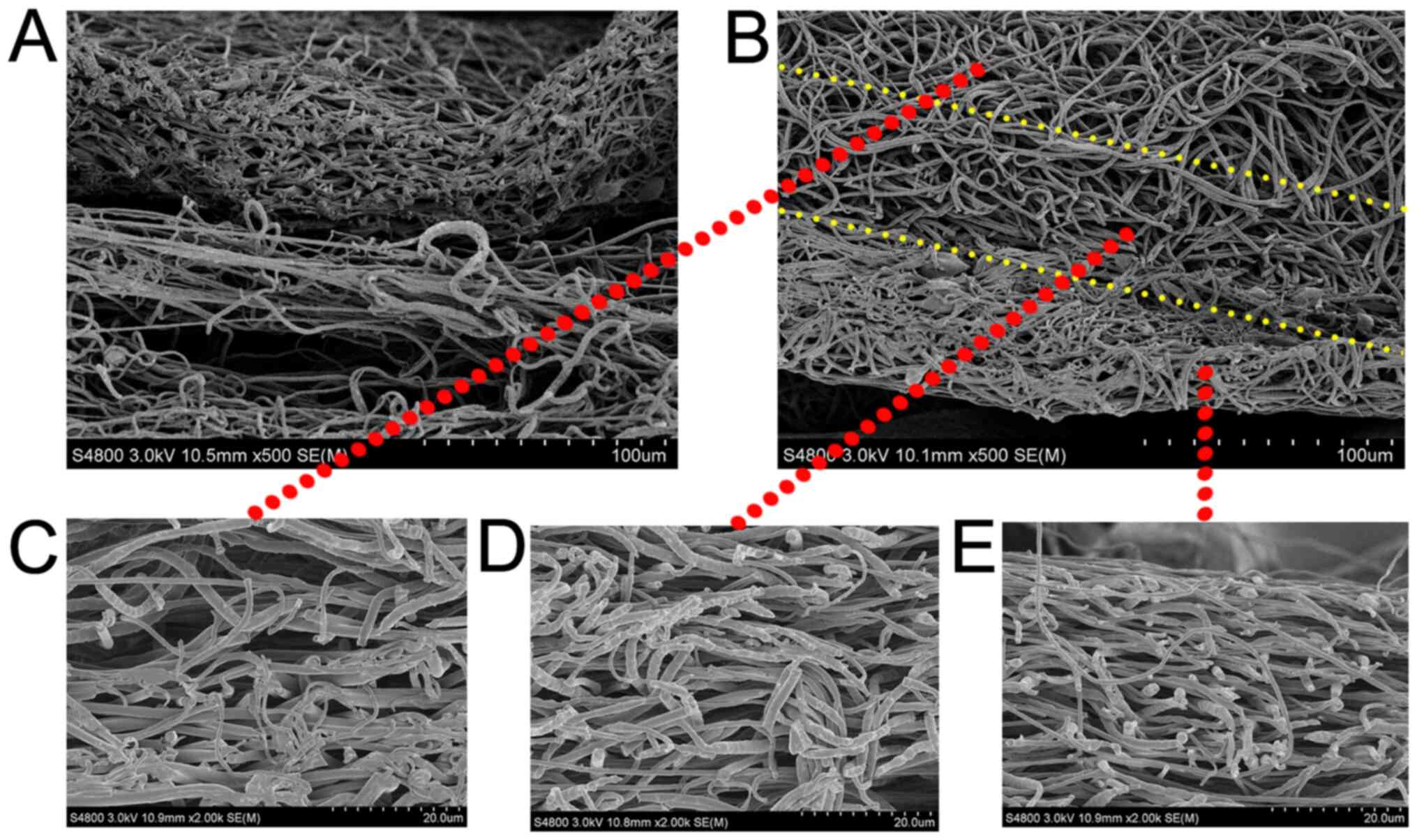

The structural details of the membranes are shown in

Fig. 3. Obvious delamination

appeared in membrane A with the PCL mat on the top and

Gt/PCL-simvastatin membrane on the bottom (Fig. 3A), while no delamination was

observed in membrane B (Fig. 3B).

SEM images demonstrating the morphology in membrane B are also

shown. The changes in structure and morphology in the different

layers indicated a distribution of multiple layers in the membrane.

The upper layer was composed of coaxial electrospun fibers with a

smooth surface (Fig. 3C). The layer

between the dense and porous layers is the middle layer (Fig. 3D), while the lower PCL layer

comprised greater corrugation nanofibers (Fig. 3E).

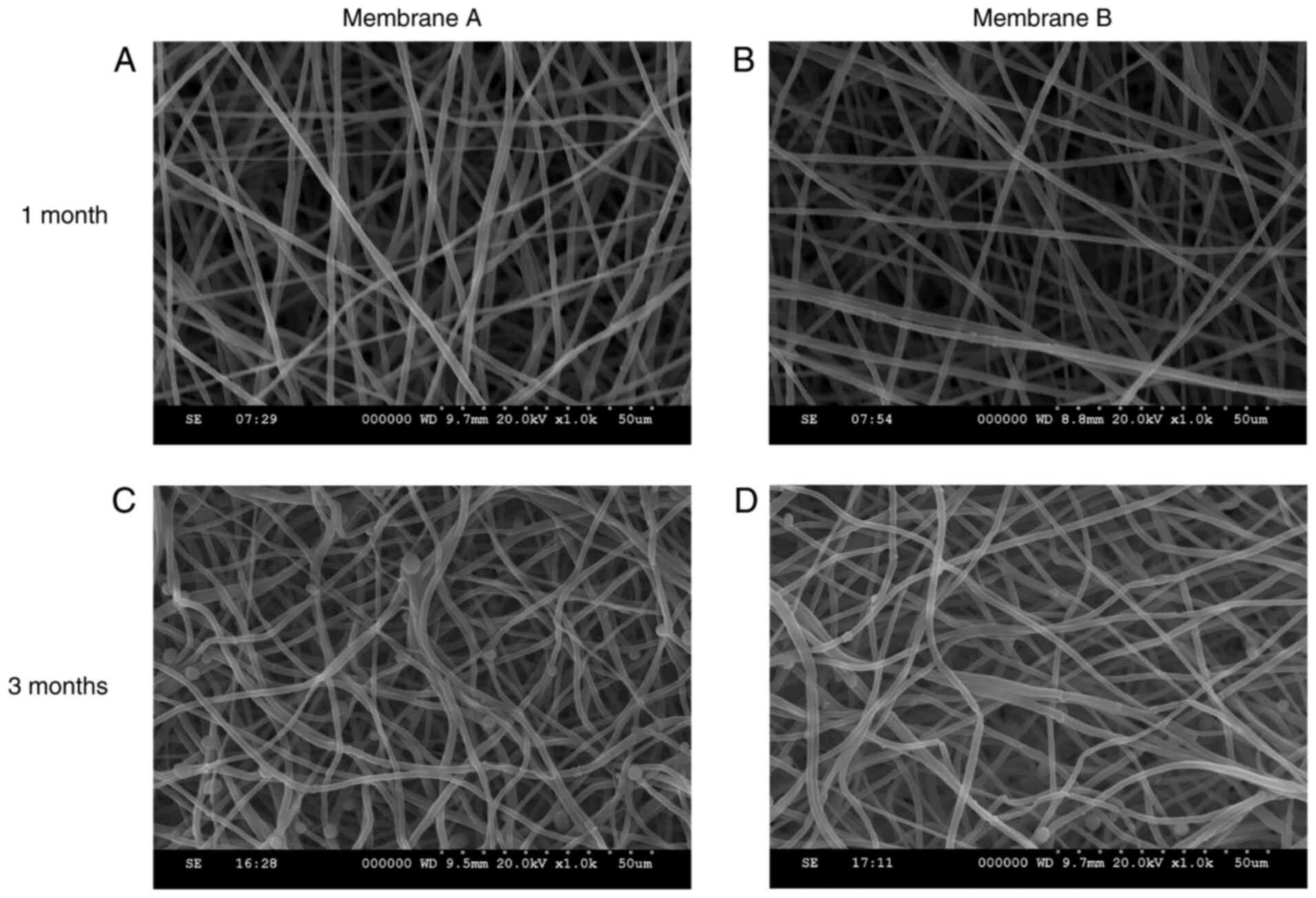

Biodegradability in vitro

SEM micrographs of the electrospun membranes during

degradation are shown in Fig. 4.

The porous layer of the nanofibrous membranes was morphologically

intact during the first month. After 3 months, the coaxial

nanofibers were partially dissolved, but the overall integrity of

the fiber structure was maintained.

Simvastatin release from the

electrospun fibers

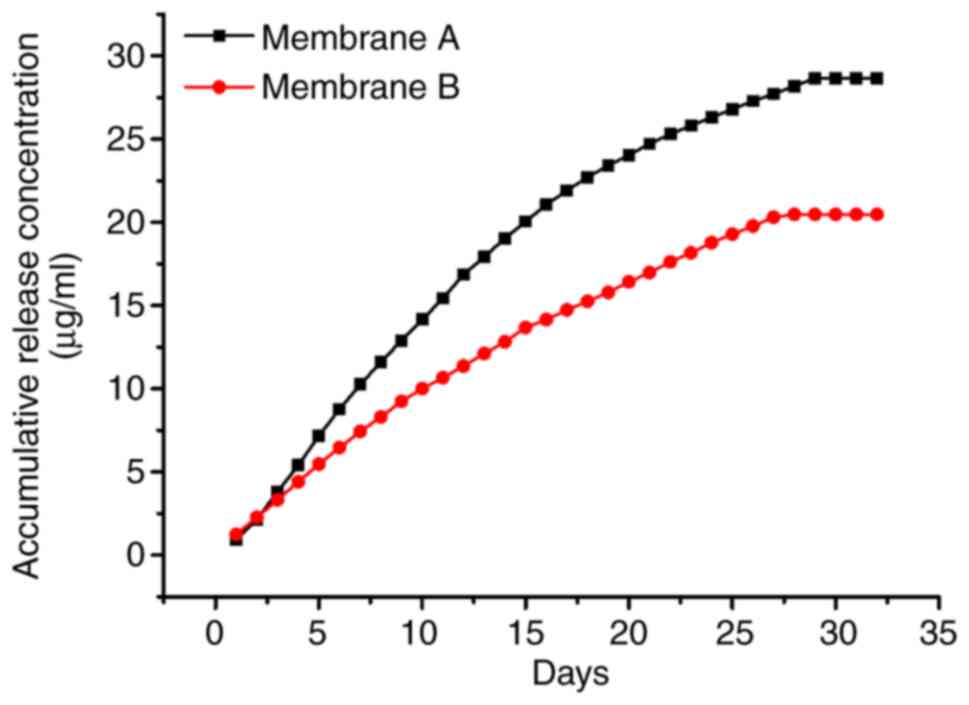

The release profile of simvastatin from the

core-shell structured fibers is shown in Fig. 5. Samples for assessing simvastatin

release into the solution were obtained every day for 32 days, and

the total simvastatin amounts were evaluated by HPLC. Approximately

28.66 µg of simvastatin was released per membrane within the first

25 days. The cumulative release of simvastatin was linearly

correlated with the incubation time at the early stage (about 15

days) and approached a plateau after 25 days.

Adhesion of BMMSCs to electrospun

membranes

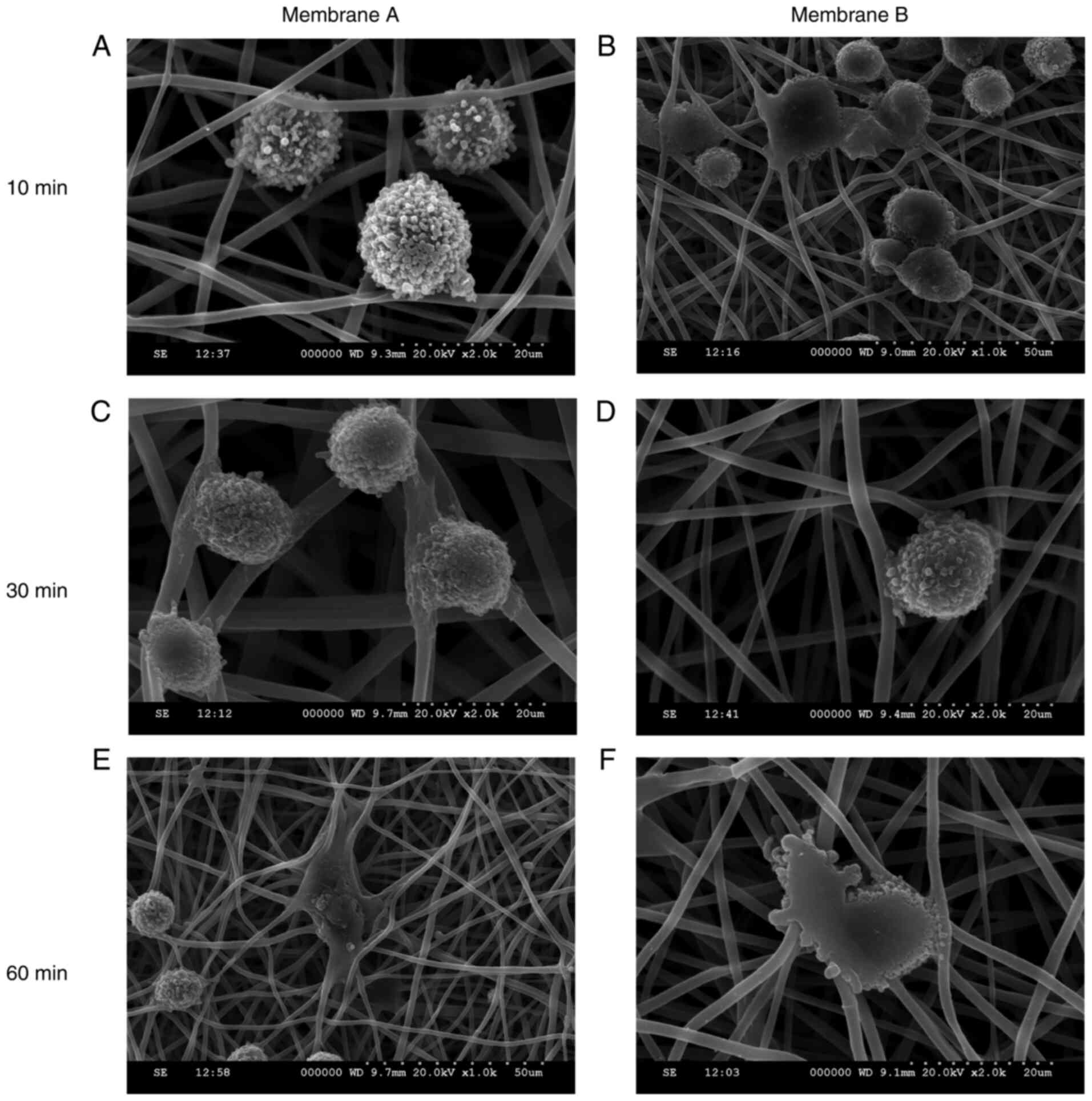

The adhesion of BMMSCs to the porous layer of the

membranes is shown in Fig. 6. BMMSC

adhesion was highly prominent at 10 min post-seeding. The cells

stretched out along the fiber processes on the membrane in all

directions, particularly at 60 min after seeding. No obvious

differences were found between membranes A and B.

Cell proliferation on the

membranes

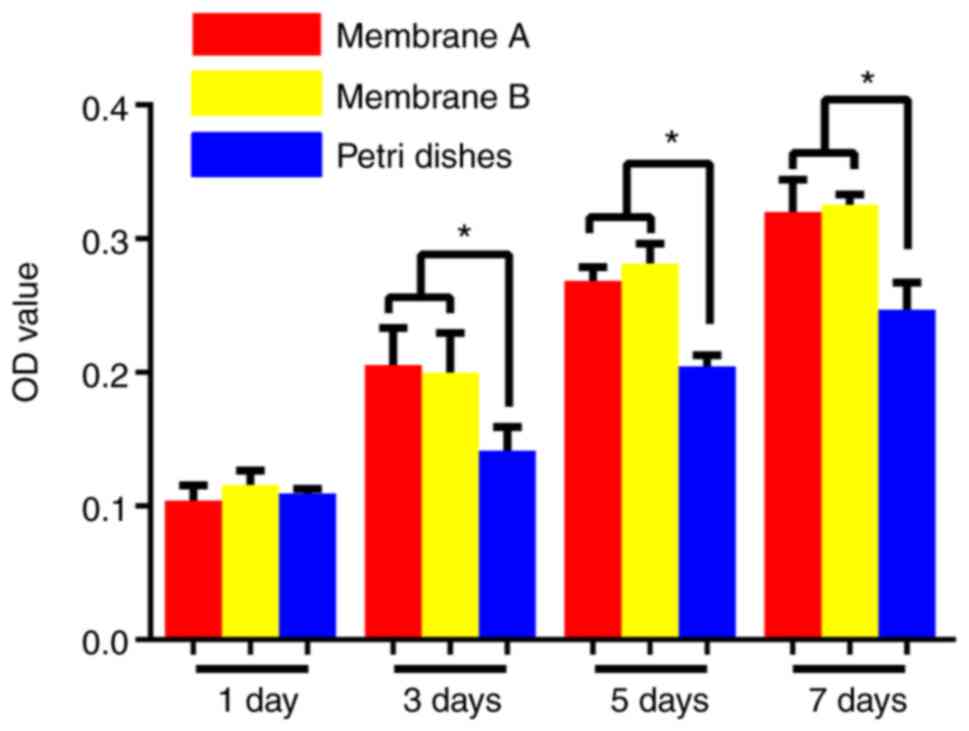

The cell proliferative activity on the membranes was

evaluated over 7 days (Fig. 7).

Compared to the control group, the numbers of BMMSCs from the

membrane groups were significantly higher than the numbers in the

control group throughout the 7 days (P<0.05). However, there

were no significant differences between the two membranes

(P>0.05).

Cell distribution on the electrospun

fibers

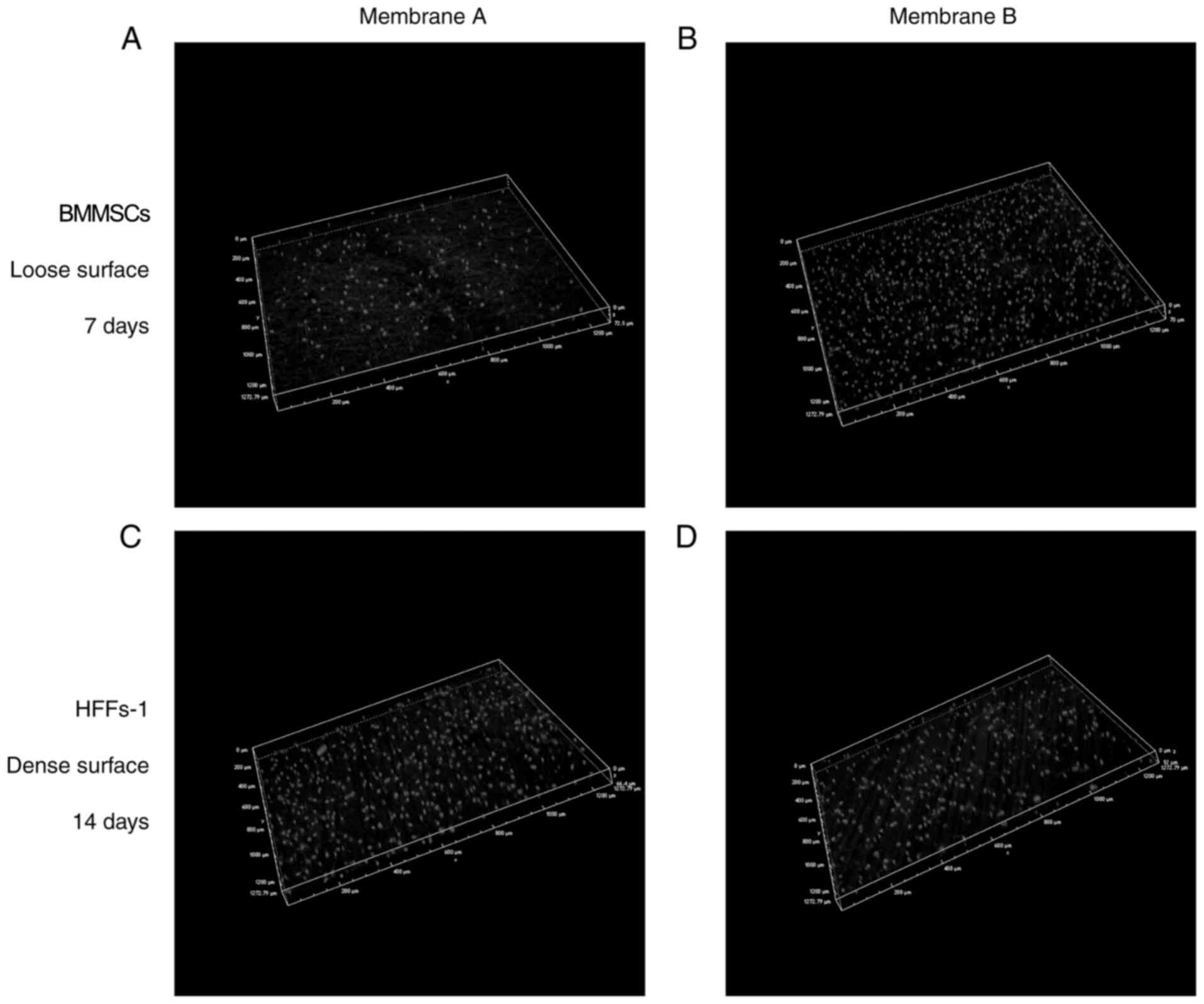

Confocal images showing cells on the fibers after

culturing for 7 and 14 days are shown in Fig. 8. At 7 days, the porous surface of

the membrane was covered by a continuous and structured MSC

monolayer. The dense surface was covered by HFFs-1 at 14 days. The

3D image shows that the MSCs seeded on the porous surface of the

membrane penetrated as deeply as 70 µm after 7 days, while HFFs-1

seeded on the dense surface of membrane penetrated as deeply as 60

µm after 14 days, indicating that the dense layer could act as an

effective barrier to prevent cell invasion. No cells were observed

to cross the membranes completely.

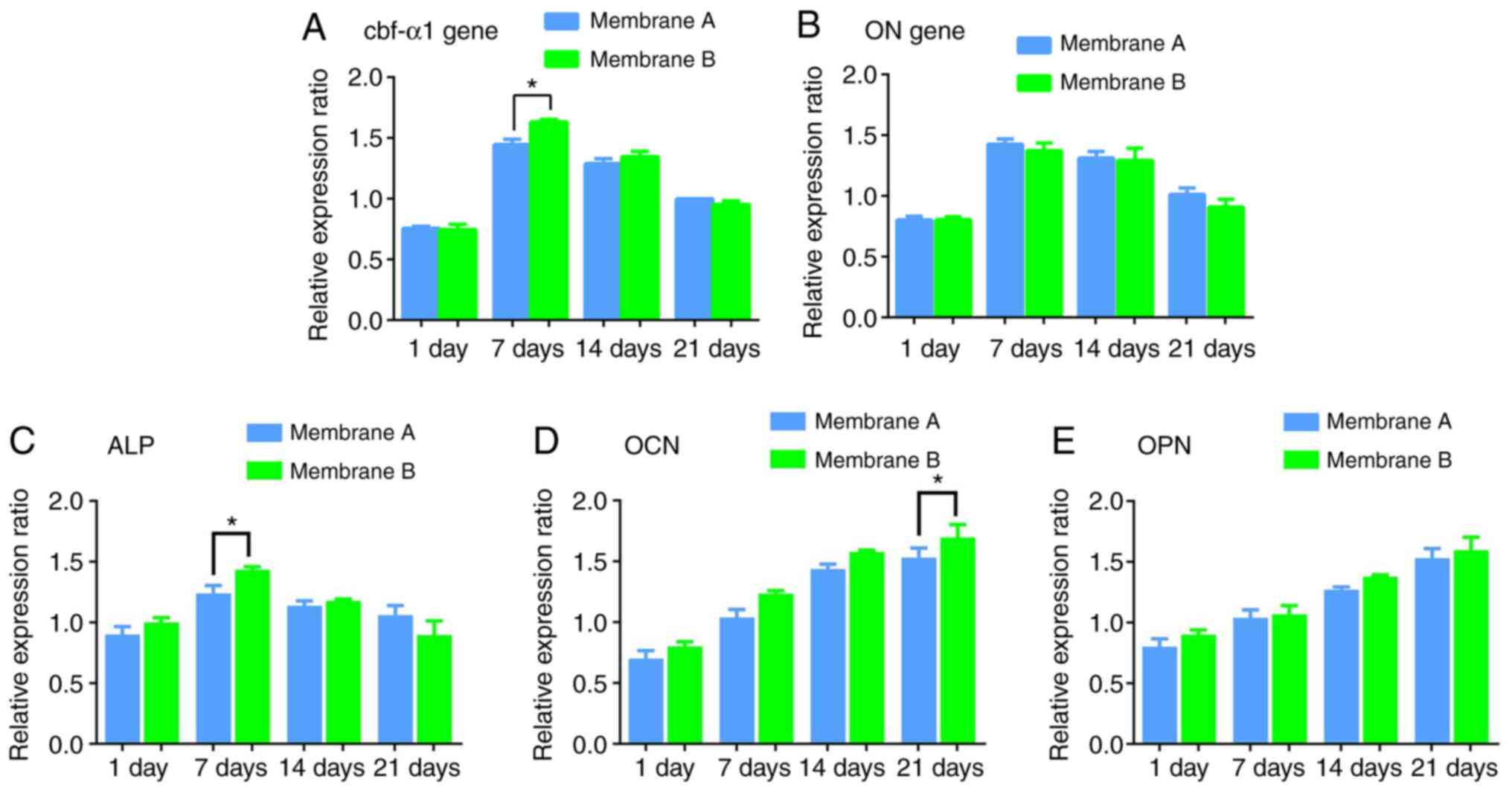

Osteogenic gene expression in BMMSCs

on the fibers

While continuously co-culturing the MSC-membrane

composite, osteogenic gene expression levels were comparable in

groups A and B after 1, 7, 14 or 21 days (all P>0.05; Fig. 9), with peaks at 7 days. An exception

was Cbf-α1 gene expression in MSCs grown on tri-layered

PCL-Gt/PCL-simvastatin fibers, which was significantly increased at

7 days (P<0.05). ALP was also higher in membrane B than in

membrane A at 7 days (P<0.05), while OCN was higher in membrane

B at 21 days (P<0.05). There were no differences in OPN

expression between the two membranes (P>0.05).

In vivo implantation

To assess the osteogenic defect of nanofibers in

vivo, 15-mm complete calvarial defects were generated in

rabbits. During the experiment, no necrosis was observed in the

animals.

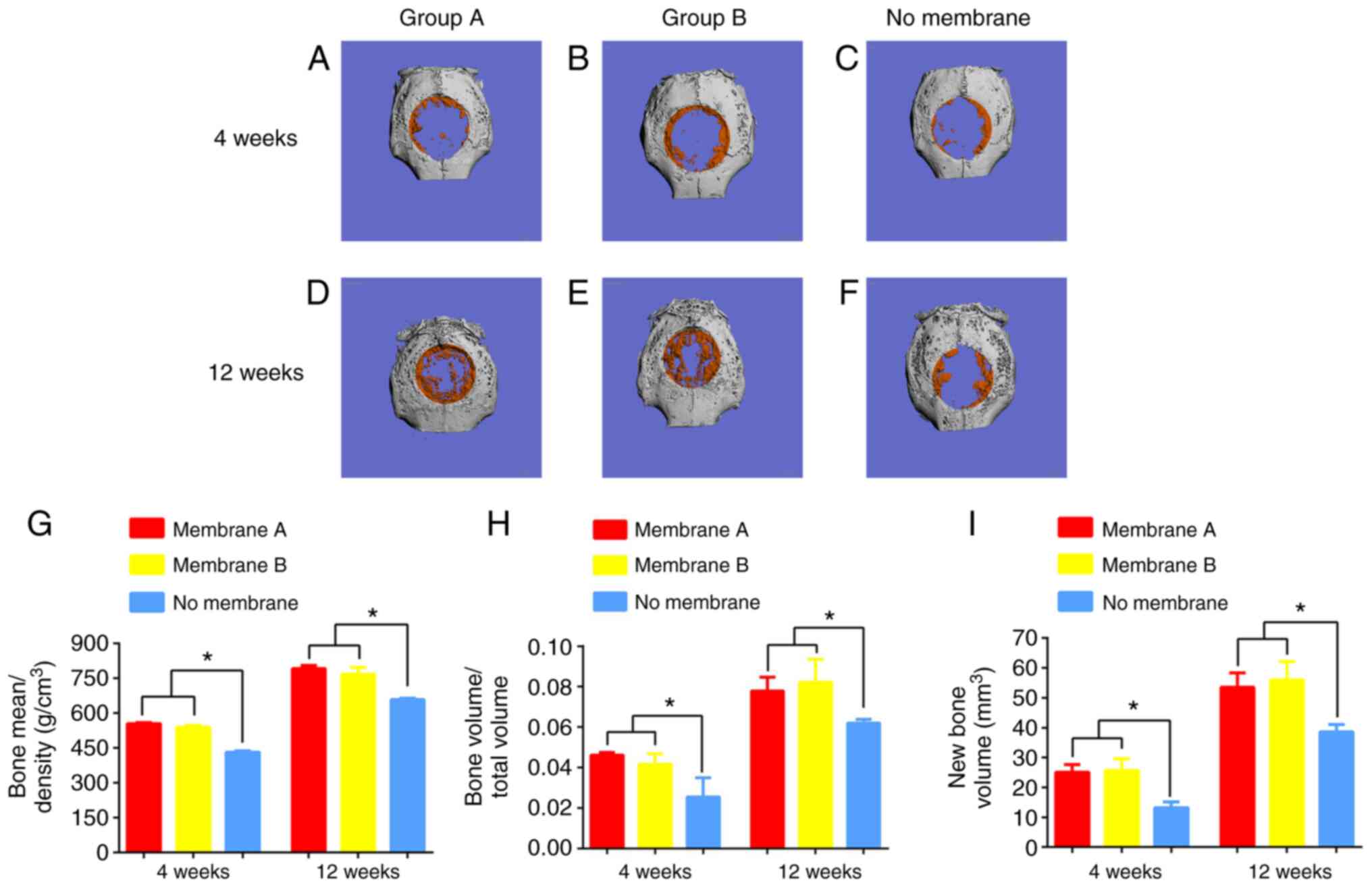

Micro-CT analysis

Bone formation was increased in the nanofiber groups

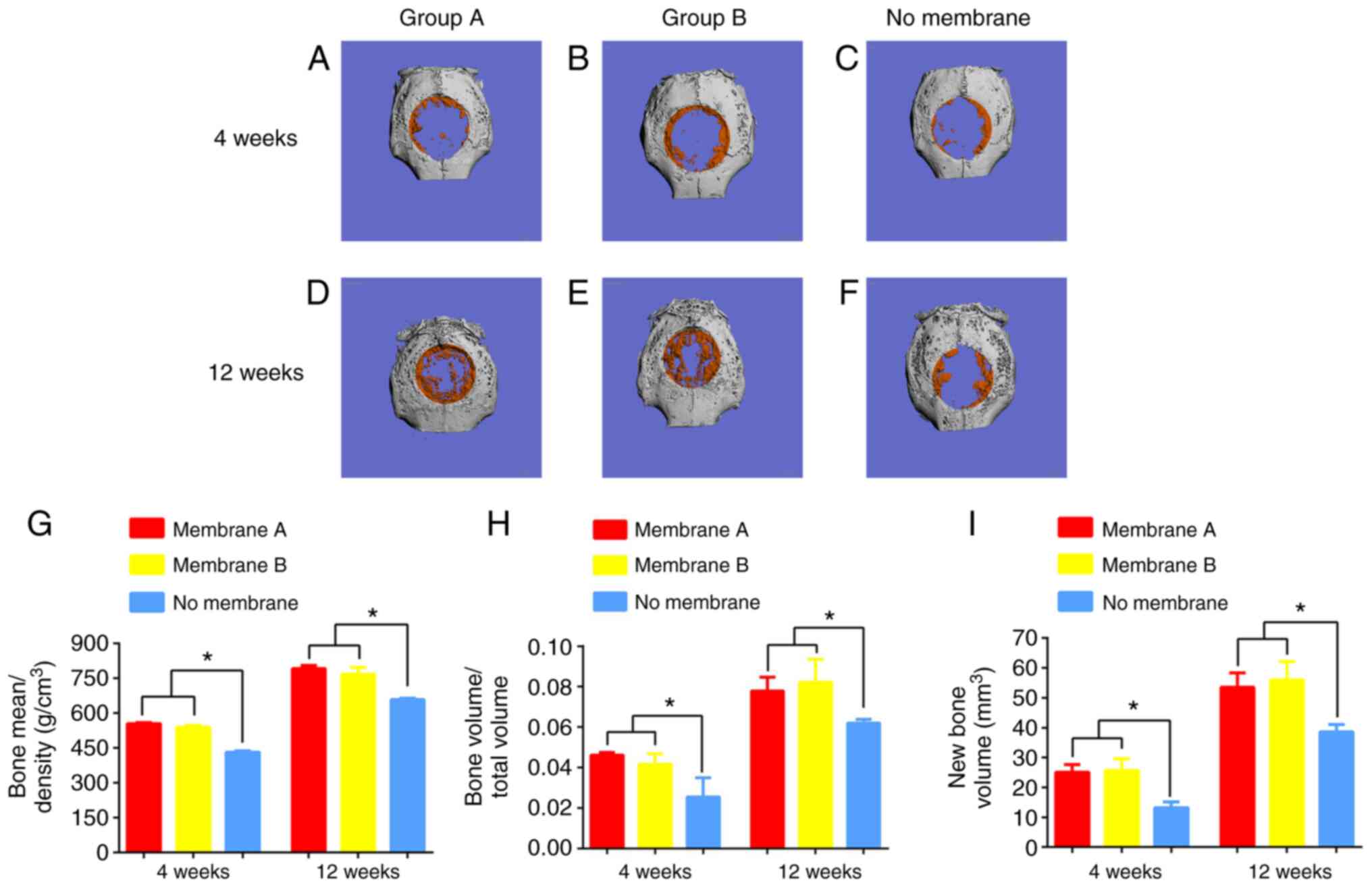

compared with the control group at 4 and 12 weeks (Fig. 10A-F). Quantitation of µ-CT imaging

data was carried out by assessing BV, BMD and BV/TV of the defects

(Fig. 10G-I). Defects treated with

membrane B showed healing with BV, BMD and BV/TV of 25.13±2.50

mm3, 539.74±8.38 mg/mm3 and 4.17±0.51%,

respectively, at 4 weeks following implantation. New bone formation

was similar in groups A and B and almost inexistent in the control

group. At 12 weeks, new bone was found in the three groups. In

comparison with controls, group B had markedly increased healing,

with BV, BMD and BV/TV of 56.05±60.15 mm3, 767.83±29.10

mg/mm3 and 8.22±1.17%. In group B, bone formation

covered most of the defects. By contrast, healing was only observed

in the center or at the edges in controls. These findings

demonstrated that the released simvastatin had in vivo

activity.

| Figure 10Micro-CT results of surgical defects

treated with membranes A or B, or a no membrane (control group) at

4 and 12 weeks. Osteogenesis effects were seen in (A) group A and

(B) group B in repair of the defect in comparison to (C) the

control at 4 weeks. A greater extent of defect repair was also seen

in (D) group A and (E) group B in repair of the defect in

comparison to (F) the control at 12 weeks. There were more blue

areas in the control group and more orange areas in groups A and B,

where blue represents fibrous tissue, and orange represents new

mineralized bone. At 12 weeks, the greatest extent of repair

appeared in group B, and the defect region was mainly covered by

orange. (G) BMD (mg/mm3), (H) BV/TV (%) and (I) BV

(mm3) within the defects were calculated. BV, BMD, and

BV/TV of groups A and B were significantly higher than in the

control group at both 4 and 12 weeks. Data are presented as the

mean ± SD; n=4; *P<0.05. BMD, bone mineral density;

BV/TV, bone volume/total volume; new bone volume. |

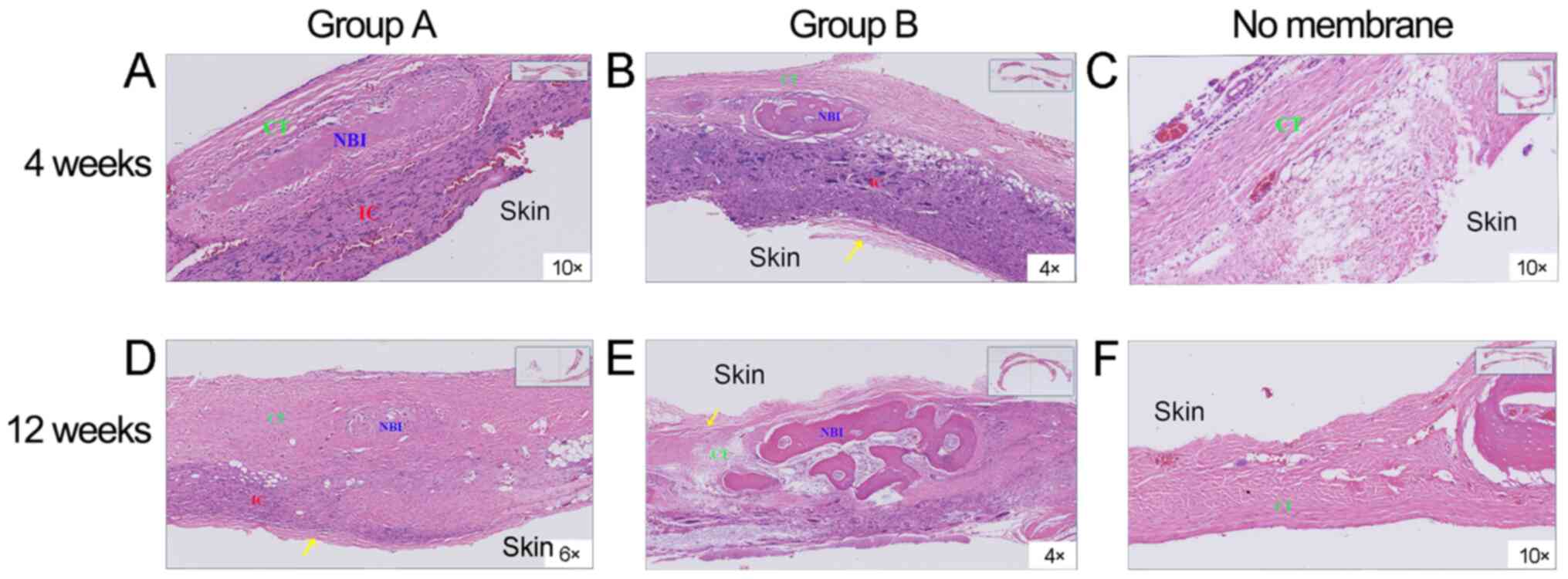

Histological properties

Using eosin ethanol staining, new bone generation

was observed in groups A and B at 4 weeks after surgery, whereas in

the control group, only soft tissues and limited new bone were

observed (Fig. 11). At 12 weeks,

the new bone area was markedly elevated in group B in comparison

with the two other groups. The control group only showed minimal

fibrous-connective tissue. At the initial stage (4 weeks) of bone

healing, an overt immunologic response with inflammatory signs were

recorded. At 12 weeks, there were slight inflammatory signs in both

membrane groups, indicating that the membranes were gradually

degraded. Over time, residual membrane materials were observed in

both membrane groups.

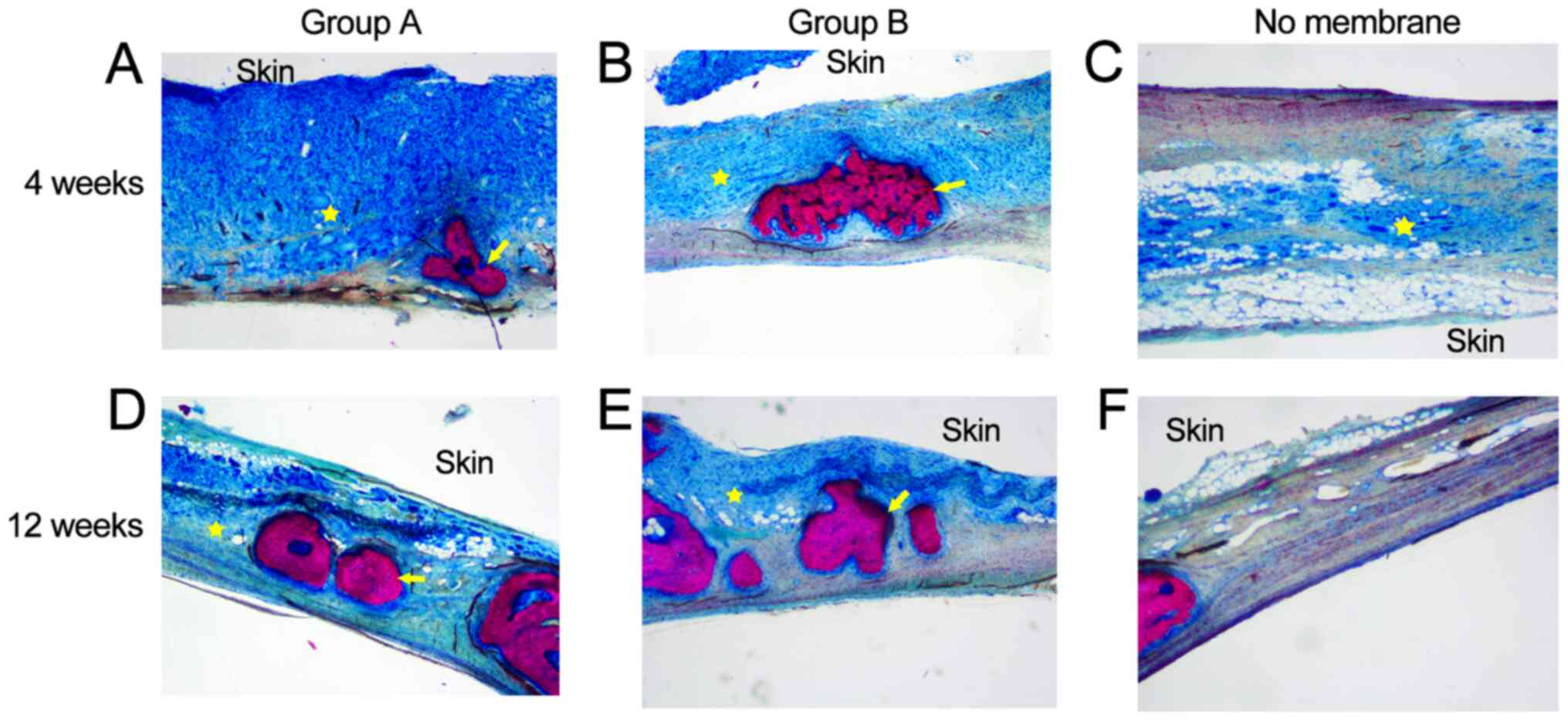

The results of Van Gieson and toluidine blue stain

were consistent with the H&E staining results (Fig. 12). New bone formation in groups A

and B occurred to a greater extent than in the control group at 4

and 12 weeks. In the control group, only a large amount of

connective tissue was observed.

Discussion

Our previous studies demonstrated that the diameter

of electrospinning nanofibers could be affected by flow rate and

receiving distance (42,43). The parameters for the present study

were optimized during our earlier studies (42,43).

SEM revealed that the membranes were nano-scaled and that the

co-axial electrospun Gt/PCL-simvastatin fibers had a distinct

core-shell structure. Using a sequential quantity gradient

co-electrospinning approach, PCL markedly improved the mechanical

features of the nanofibers. The membrane structure was similar to

that of the ECM, and the pore size of the PCL surface was

significantly smaller than that of the coaxial surface. The present

study demonstrated that the designed membrane had good

morphological, physicochemical and mechanical features that enable

it to serve as a barrier membrane. Cross-sectional images of

membrane B showed that the Gt/PCL-simvastatin and PCL nanofibers

were well-mixed and integrated between the membrane layers. By

contrast, membrane A was observed to have two layers without

connection and could be easily separated.

An ideal drug delivery system should supply

effective product amounts, avoid systemic undesired reactions, and

convey products into target areas at fixed rates (44). The generation of a distinct boundary

could be theoretically assessed (45,46).

Studies by both our group (25) and

others (47) have indicated that

coaxial electrospinning can achieve effective product loading as

well as continuous and controlled local drug delivery. In the

present study, simvastatin was embedded in the core (PCL) of a

coaxial structure. The mechanism of simvastatin release at a

controlled rate can be explained by diffusion and polymer

degradation (48,49). Simvastatin is first released by

diffusion onto the fiber's surface. Subsequently, when the membrane

is incubated with the medium, the small pores on the shell (Gt) of

the fibers undergo gradual polymer degradation. This allows the

slow and constant release of the drug through the pores. Both

membranes in the present study demonstrated constant and continuous

drug release, with membrane B demonstrating a more controlled drug

release, due to its gradient structure.

Implantable materials should undergo in vivo

degradation at a controlled rate to maintain and provide space for

new bone formation (50). Material

degeneration speed is critical in tissue engineering (51-54).

If the membrane is degraded too fast, cell proliferation may be

hampered, with insufficient secretion of the new matrix (51). Conversely, if degradation is too

slow, residual materials could adversely affect new bone's

homogeneity and function (55).

Furthermore, the optimal time for degradation of materials in the

skull or maxillofacial bones is 3-6 months, whereas the scaffold

used in spinal fusion should be degraded after 9 months or longer

(50). In the present study, an

artificial synthetic material (PCL) was used to provide controlled

release kinetics (47) and an

appropriate degradation rate. The results of degradation testing

in vitro suggested that the fiber surface became

increasingly rough within 3 months, consistent with the optimal

time of 3-6 months. Nevertheless, the complete degradation time of

PCL is about 2 years, and future studies should examine for how

long a PCL-based membrane retains its support and barriers effects.

H&E staining also suggested that new bone islands and osteoid

tissue had replaced the degraded membrane material at this time

point. Furthermore, the timing coincides well with the release of

simvastatin.

Electrospun nanofibers have high surface-to-volume

ratios and are potential ECM substitutes that improve cell

attachment (56,57). Simultaneously, high porosity confers

optimal permeability for nutrient and gas exchange in the newly

formed tissue (58). SEM of BMMSCs

seeded membranes showed that cells were firmly attached to fibers,

with cytoplasmic processes spreading throughout. This suggests that

such membranes are an optimal scaffold for cell attachment. CCK-8

testing revealed that the membranes could promote cell adhesion and

proliferation, with no cytotoxicity in vitro. The confocal

microscopy results established that MSCs proliferated on the

coaxial fibrous surface and the superficial layer of the internal

part of the membrane. HFFs-1 with poorer adhesion and more

superficial invasive depth also showed an excellent barrier

function in membrane B. The same results were obtained from

histological assessment of in vivo samples, with group B

showing less fibrous tissue in the defect lending itself to ideal

barrier function.

In order to assess the clinical usefulness of

membrane B, a critical-sized defect in rabbit calvaria was created,

based on previous studies (23,33-40).

Micro-CT revealed an elevated BV/TV ratio, suggesting new bone

generation, for both membrane groups compared with controls. Both

membrane groups showed comparable values. In vivo

histological data demonstrated that both membranes enhanced bone

regeneration in comparison with controls. Meanwhile, in

vitro testing of osteoinduction of simvastatin released from

the membrane fibers revealed that osteogenic genes were upregulated

in culture. Thus, simvastatin released from the membrane increases

new bone generation and accelerates bone healing in the

calvarial-defect model, but osteoinductive effects were comparable

in both membrane groups.

The present study demonstrated that a novel

multi-layered PCL-Gt/PCL-simvastatin membrane promoted osteogenesis

in cultured BMMSCs and repaired bone defects in rabbits. As the

sole bioactive agent, simvastatin could be successfully delivered

and in a controlled manner. The role of multi-layered structured

membranes in GBR technology remains unclear. These results suggest

that the novel gradient nanofibrous membrane could be a candidate

for an ideal barrier membrane, which is the primary end goal for

current GBR technologies.

Inflammation could be seen in the specimens from the

rabbits that received the membranes. Gelatin and PCL are

widely-used polymers in the field of tissue engineering and are

highly biocompatible and biodegradable (5). However, though simvastatin has been

shown to induce bone growth in vivo, pronounced soft-tissue

inflammation was observed (23). It

can be hypothesized that this inflammation is the result of

simvastatin, which was suggested by a previous study (59). Why simvastatin induces inflammation

and how it might participate in the osteogenesis process remain to

be examined.

The barrier membrane developed in this study is a

guide for tissue regeneration. It has a loose surface and a dense

surface. The loose surface faces the bone tissue to facilitate the

crawling of bone cells or stem cells and guide bone tissue

regeneration. The dense surface has a small pore size to prevent

fibrosis. Since the regenerative cells invade the bone defect area

while the fibrotic cells invade from the connective tissues, the

stem cells were inoculated on the loose surface and fibroblasts on

the dense surface to observe the barrier function of the barrier

membrane and guide the regeneration ability of totipotent stem

cells. The differential impact of different cell types will have to

be examined in a future study.

There are several limitations to this study.

Multilayered membranes without simvastatin as controls were not

included. Indeed, the main research focus of this article was on

the structural innovation of the barrier membrane, rather than the

bone-promoting function of simvastatin, which is relatively

well-known (21,22). In addition, it has previously been

shown that coaxial electrospinning can achieve effective product

loading as well as continuous and controlled local drug delivery

(26). The present study

demonstrates the potential application of novel multilayered

electrospun membranes for GBR with simvastatin in the treatment of

bone regeneration.

The characteristics of cell donor may influence the

results, however all donors in this study were 20-25 years of age

and healthy, and the effect of age difference on BMMSCs should be

minimal (60-62).

In a published Master's degree thesis (entitled Osteogenic ability

and differential gene expression profile of human bone marrow

mesenchymal stem cells of different ages), BMMSCs from the fetal

group (20-24 weeks of age), youth group (16-30 years), and elderly

group (60+ years) showed consistent characteristics within their

respective groups, but the osteogenic properties clearly decreased

with age (63). In addition, the

cell growth rate of donors over 50 years old was significantly

lower than that of young donors. Furthermore, Choudhery et

al (64) demonstrated that the

BMSC markers do not change with age, but that the number of cells

per gram, colony-forming units and the number of cells doubled per

unit time decreases with the increase of the age of mesenchymal

stem cells and donors. Fosset et al (65) also suggested that there is no

age-related change in the expression of cell surface markers,

however, Stolzing et al (66) reported that the expression levels of

the MSC cell surface markers CD90, CD105 and stro1 decrease and

CD44 increase, and that the differentiation potential is also

different with age. In addition, Aksoy et al (67) suggested that various surface markers

of MSCs are expressed at different ages, but compared with older

donor cells, MSCs isolated from younger human donors have a higher

cell metabolic activity and proliferation rate. Therefore,

including cells from a single age group should minimize the

variability due to age, however, some interindividual variability

might remain.

Limits in image resolution and difficulties in

accurately determining tissue regions may present a potential

limitation of the present study. The applicability and clinical

safety of the present study remain to be assessed in future

studies, including more appropriate controls and intravital

microscopy. Finally, the systemic concentrations of simvastatin

were not determined, and it is unknown whether simvastatin can be

released into the peripheral circulation and whether it could exert

systemic effects that could influence bone regeneration, either

directly or indirectly. This will have to be addressed in future

studies.

In conclusion, a novel multi-layered

PCL-Gt/PCL-simvastatin membrane was successfully established by

coaxial electrospinning. This membrane is suitable for use in GBR.

The membrane was able to deliver simvastatin continuously and

promoted new bone formation without overt cytotoxic effects. This

new coaxial electrospinning method might provide new means for

fabricating membranes with both multi-layered structure and

osteoinductive ability.

Acknowledgements

We are grateful to Dr. Zhengjian Chen at the

Department of Polymer Science and Engineering, Zhejiang University

and Prof. Jindan Wu at the MOE Key Laboratory of Advanced Textile

Materials & Manufacturing Technology, Zhejiang Sci-Tech

University for their help with the synthesis of the membranes used

in this study.

Funding

Funding: The present study was funded by grants from the Medical

and Health Major Science and Technology Plan of Zhejiang Province,

China (grant no. wsk2014-2-008), the National Natural Science

Foundation of China (grant no. 31570989), the Natural Science

Foundation of Zhejiang Province of China (grant no. LY15H140002),

the Young Talents Project of Zhejiang Provincial Health Department,

China (grant no. 2019RC151) and Zhejiang Province Welfare

Technology Research Project, China (grant no. LGF20H140007).

Availability of data and materials

The datasets used and/or analyzed during the current

study are available from the corresponding author on reasonable

request.

Authors' contributions

DY and CH characterized the morphology of the

nanofibers and their release of simvastatin, assessed their

biological function in vitro, analyzed and interpreted the

data and was a major contributor to writing the manuscript. CH and

HZ performed the histological examination in vivo. CJ and DY

analyzed and interpreted the data. HZ was responsible for

conceptualization, project administration, article review and

quality control. DY, CH, CJ and HZ confirmed the authenticity of

all raw data. All authors read and approved the final

manuscript.

Ethics approval and consent to

participate

The Animal Experimental Ethical Committee of the

First Affiliated Hospital, College of Medicine, Zhejiang University

(Reference no. 2013-273) approved the protocols for animal

experiments. Informed consent was obtained and signed by the BMMSC

donors and the human cell study was approved by the Research Ethics

Committee of the First Affiliated Hospital, College of Medicine,

Zhejiang University (Hangzhou, China; Reference number

2013-273).

Patient consent for publication

Not applicable.

Competing interests

The authors declare that they have no competing

interests.

References

|

1

|

Rezvani Z, Venugopal JR, Urbanska AM,

Mills DK, Ramakrishna S and Mozafari M: A bird's eye view on the

use of electrospun nanofibrous scaffolds for bone tissue

engineering: Current state-of-the-art, emerging directions and

future trends. Nanomedicine. 12:2181–2200. 2016.PubMed/NCBI View Article : Google Scholar

|

|

2

|

Yang G, Li X, He Y, Ma J, Ni G and Zhou S:

From nano to micro to macro: Electrospun hierarchically structured

polymeric fibers for biomedical applications. Prog Polymer Sci.

81:80–113. 2018.

|

|

3

|

Jang JH, Castano O and Kim HW: Electrospun

materials as potential platforms for bone tissue engineering. Adv

Drug Deliv Rev. 61:1065–1083. 2009.PubMed/NCBI View Article : Google Scholar

|

|

4

|

Holzwarth JM and Ma PX: Biomimetic

nanofibrous scaffolds for bone tissue engineering. Biomaterials.

32:9622–9629. 2011.PubMed/NCBI View Article : Google Scholar

|

|

5

|

Mata A, Geng Y, Henrikson KJ, Aparicio C,

Stock SR, Satcher RL and Stupp SI: Bone regeneration mediated by

biomimetic mineralization of a nanofiber matrix. Biomaterials.

31:6004–6012. 2010.PubMed/NCBI View Article : Google Scholar

|

|

6

|

Li C, Vepari C, Jin HJ, Kim HJ and Kaplan

DL: Electrospun silk-BMP-2 scaffolds for bone tissue engineering.

Biomaterials. 27:3115–3124. 2006.PubMed/NCBI View Article : Google Scholar

|

|

7

|

Sharifi F, Atyabi SM, Irani S and Bakhshi

H: Bone morphogenic protein-2 immobilization by cold atmospheric

plasma to enhance the osteoinductivity of carboxymethyl

chitosan-based nanofibers. Carbohydr Polym.

231(115681)2020.PubMed/NCBI View Article : Google Scholar

|

|

8

|

Kostopoulos L and Karring T: Augmentation

of the rat mandible using guided tissue regeneration. Clin Oral

Implants Res. 5:75–82. 1994.PubMed/NCBI View Article : Google Scholar

|

|

9

|

Sedghi R, Shaabani A and Sayyari N:

Electrospun triazole-based chitosan nanofibers as a novel scaffolds

for bone tissue repair and regeneration. Carbohydr Polym.

230(115707)2020.PubMed/NCBI View Article : Google Scholar

|

|

10

|

Elgali I, Turri A, Xia W, Norlindh B,

Johansson A, Dahlin C, Thomsen P and Omar O: Guided bone

regeneration using resorbable membrane and different bone

substitutes: Early histological and molecular events. Acta

Biomater. 29:409–423. 2016.PubMed/NCBI View Article : Google Scholar

|

|

11

|

Samavedi S, Olsen Horton C, Guelcher SA,

Goldstein AS and Whittington AR: Fabrication of a model

continuously graded co-electrospun mesh for regeneration of the

ligament-bone interface. Acta Biomater. 7:4131–4138.

2011.PubMed/NCBI View Article : Google Scholar

|

|

12

|

Dalgic AD, Atila D, Karatas A, Tezcaner A

and Keskin D: Diatom shell incorporated PHBV/PCL-pullulan

co-electrospun scaffold for bone tissue engineering. Mater Sci Eng

C Mater Biol Appl. 100:735–746. 2019.PubMed/NCBI View Article : Google Scholar

|

|

13

|

Wang Y, Cui W, Zhao X, Wen S, Sun Y, Han J

and Zhang H: Bone remodeling-inspired dual delivery electrospun

nanofibers for promoting bone regeneration. Nanoscale. 11:60–71.

2018.PubMed/NCBI View Article : Google Scholar

|

|

14

|

Liu S, Dong C, Lu G, Lu Q, Li Z, Kaplan DL

and Zhu H: Bilayered vascular grafts based on silk proteins. Acta

Biomater. 9:8991–9003. 2013.PubMed/NCBI View Article : Google Scholar

|

|

15

|

Wu T, Zhang J, Wang Y, Li D, Sun B,

El-Hamshary H, Yin M and Mo X: Fabrication and preliminary study of

a biomimetic tri-layer tubular graft based on fibers and fiber

yarns for vascular tissue engineering. Mater Sci Eng C Mater Biol

Appl. 82:121–129. 2018.PubMed/NCBI View Article : Google Scholar

|

|

16

|

Han F, Jia X, Dai D, Yang X, Zhao J, Zhao

Y, Fan Y and Yuan X: Performance of a multilayered small-diameter

vascular scaffold dual-loaded with VEGF and PDGF. Biomaterials.

34:7302–7313. 2013.PubMed/NCBI View Article : Google Scholar

|

|

17

|

de Valence S, Tille JC, Giliberto JP,

Mrowczynski W, Gurny R, Walpoth BH and Möller M: Advantages of

bilayered vascular grafts for surgical applicability and tissue

regeneration. Acta Biomater. 8:3914–3920. 2012.PubMed/NCBI View Article : Google Scholar

|

|

18

|

Attalla R, Puersten E, Jain N and

Selvaganapathy PR: 3D bioprinting of heterogeneous bi- and

tri-layered hollow channels within gel scaffolds using scalable

multi-axial microfluidic extrusion nozzle. Biofabrication.

11(015012)2018.PubMed/NCBI View Article : Google Scholar

|

|

19

|

Blakeney BA, Tambralli A, Anderson JM,

Andukuri A, Lim DJ, Dean DR and Jun HW: Cell infiltration and

growth in a low density, uncompressed three-dimensional electrospun

nanofibrous scaffold. Biomaterials. 32:1583–1590. 2011.PubMed/NCBI View Article : Google Scholar

|

|

20

|

Wu T, Huang C, Li D, Yin A, Liu W, Wang J,

Chen J, Ei-Hamshary H, Al-Deyab SS and Mo X: A multi-layered

vascular scaffold with symmetrical structure by bi-directional

gradient electrospinning. Colloids Surf B Biointerfaces.

133:179–188. 2015.PubMed/NCBI View Article : Google Scholar

|

|

21

|

Garrett IR, Gutierrez G and Mundy GR:

Statins and bone formation. Curr Pharm Des. 7:715–736.

2001.PubMed/NCBI View Article : Google Scholar

|

|

22

|

Mundy G, Garrett R, Harris S, Chan J, Chen

D, Rossini G, Boyce B, Zhao M and Gutierrez G: Stimulation of bone

formation in vitro and in rodents by statins. Science.

286:1946–1949. 1999.PubMed/NCBI View Article : Google Scholar

|

|

23

|

Thylin MR, McConnell JC, Schmid MJ,

Reckling RR, Ojha J, Bhattacharyya I, Marx DB and Reinhardt RA:

Effects of simvastatin gels on murine calvarial bone. J

Periodontol. 73:1141–1148. 2002.PubMed/NCBI View Article : Google Scholar

|

|

24

|

Jiang H, Hu Y, Li Y, Zhao P, Zhu K and

Chen W: A facile technique to prepare biodegradable coaxial

electrospun nanofibers for controlled release of bioactive agents.

J Control Release. 108:237–243. 2005.PubMed/NCBI View Article : Google Scholar

|

|

25

|

Zhu H, Yu D, Zhou Y, Wang C, Gao M, Jiang

H and Wang H: Biological activity of a nanofibrous barrier membrane

containing bone morphogenetic protein formed by core-shell

electrospinning as a sustained delivery vehicle. J Biomed Mater Res

B Appl Biomater. 101:541–552. 2013.PubMed/NCBI View Article : Google Scholar

|

|

26

|

Chen H, Malheiro A, van Blitterswijk C,

Mota C, Wieringa PA and Moroni L: Direct writing electrospinning of

scaffolds with multidimensional fiber architecture for hierarchical

tissue engineering. ACS Appl Mater Interfaces. 9:38187–38200.

2017.PubMed/NCBI View Article : Google Scholar

|

|

27

|

Zhang X, Aubin JE and Inman RD: Molecular

and cellular biology of new bone formation: Insights into the

ankylosis of ankylosing spondylitis. Curr Opin Rheumatol.

15:387–393. 2003.PubMed/NCBI View Article : Google Scholar

|

|

28

|

Lee JS, Lee JM and Im GI:

Electroporation-mediated transfer of Runx2 and Osterix genes to

enhance osteogenesis of adipose stem cells. Biomaterials.

32:760–768. 2011.PubMed/NCBI View Article : Google Scholar

|

|

29

|

Wrobel E, Leszczynska J and Brzoska E: The

characteristics of human bone-derived cells (HBDCS) during

osteogenesis in vitro. Cell Mol Biol Lett. 21(26)2016.PubMed/NCBI View Article : Google Scholar

|

|

30

|

Termine JD, Kleinman HK, Whitson SW, Conn

KM, McGarvey ML and Martin GR: Osteonectin, a bone-specific protein

linking mineral to collagen. Cell. 26:99–105. 1981.PubMed/NCBI View Article : Google Scholar

|

|

31

|

Graneli C, Thorfve A, Ruetschi U, Brisby

H, Thomsen P, Lindahl A and Karlsson C: Novel markers of osteogenic

and adipogenic differentiation of human bone marrow stromal cells

identified using a quantitative proteomics approach. Stem Cell Res.

12:153–165. 2014.PubMed/NCBI View Article : Google Scholar

|

|

32

|

Pfaffl MW: A new mathematical model for

relative quantification in real-time RT-PCR. Nucleic Acids Res.

29(e45)2001.PubMed/NCBI View Article : Google Scholar

|

|

33

|

Bacevic M, Brkovic B, Lambert F, Djukic L,

Petrovic N and Roganovic J: Leukocyte- and platelet-rich fibrin as

graft material improves microRNA-21 expression and decreases

oxidative stress in the calvarial defects of diabetic rabbits. Arch

Oral Biol. 102:231–237. 2019.PubMed/NCBI View Article : Google Scholar

|

|

34

|

Chen P and Liu B: Study on repair of

critical calvarial defects with

nano-hydroxyapatite/collagen/polylactic acid material compounded

recombinant human bone morphogenetic protein 2 in rabbits. Zhongguo

Xiu Fu Chong Jian Wai Ke Za Zhi. 21:1191–1195. 2007.PubMed/NCBI(In Chinese).

|

|

35

|

Durmus E, Celik I, Aydin MF, Yildirim G

and Sur E: Evaluation of the biocompatibility and osteoproductive

activity of ostrich eggshell powder in experimentally induced

calvarial defects in rabbits. J Biomed Mater Res B Appl Biomater.

86:82–89. 2008.PubMed/NCBI View Article : Google Scholar

|

|

36

|

Li G, Wang X, Cao J, Ju Z, Ma D, Liu Y and

Zhang J: Coculture of peripheral blood CD34+ cell and mesenchymal

stem cell sheets increase the formation of bone in calvarial

critical-size defects in rabbits. Br J Oral Maxillofac Surg.

52:134–139. 2014.PubMed/NCBI View Article : Google Scholar

|

|

37

|

Swain LD, Cornet DA, Manwaring ME, Collins

B, Singh VK, Beniker D and Carnes DL: Negative pressure therapy

stimulates healing of critical-size calvarial defects in rabbits.

Bonekey Rep. 2(299)2013.PubMed/NCBI View Article : Google Scholar

|

|

38

|

Tuusa SM, Peltola MJ, Tirri T, Puska MA,

Roytta M, Aho H, Sandholm J, Lassila LVJ and Vallittu PK:

Reconstruction of critical size calvarial bone defects in rabbits

with glass-fiber-reinforced composite with bioactive glass granule

coating. J Biomed Mater Res B Appl Biomater. 84:510–519.

2008.PubMed/NCBI View Article : Google Scholar

|

|

39

|

Wang Z, Han L, Sun T, Wang W, Li X and Wu

B: Osteogenic and angiogenic lineage differentiated adipose-derived

stem cells for bone regeneration of calvarial defects in rabbits. J

Biomed Mater Res A. 109:538–550. 2021.PubMed/NCBI View Article : Google Scholar

|

|

40

|

Wang Z, Hu H, Li Z, Weng Y, Dai T, Zong C,

Liu Y and Liu B: Sheet of osteoblastic cells combined with

platelet-rich fibrin improves the formation of bone in

critical-size calvarial defects in rabbits. Br J Oral Maxillofac

Surg. 54:316–321. 2016.PubMed/NCBI View Article : Google Scholar

|

|

41

|

Kammerer PW, Lehnert M, Al-Nawas B, Kumar

VV, Hagmann S, Alshihri A, Frerich B and Veith M: Osseoconductivity

of a specific streptavidin-biotin-fibronectin surface coating of

biotinylated titanium implants-a rabbit animal study. Clin Implant

Dent Relat Res. 17 (Suppl 2):e601–e612. 2015.PubMed/NCBI View Article : Google Scholar

|

|

42

|

Chen Z, Wang L and Jiang H: The effect of

procyanidine crosslinking on the properties of the electrospun

gelatin membranes. Biofabrication. 4(035007)2012.PubMed/NCBI View Article : Google Scholar

|

|

43

|

Chen Z, Cao L, Wang L, Zhu H and Jiang H:

Effect of fiber structure on the properties of the electrospun

hybrid membranes composed of poly(ε-caprolactone) and gelatin. J

Appl Polymer Sci. 127:4225–4232. 2013.

|

|

44

|

McHugh J: Promising drug delivery system.

Nat Rev Rheumatol. 15(64)2019.PubMed/NCBI View Article : Google Scholar

|

|

45

|

Amschler K, Erpenbeck L, Kruss S and Schon

MP: Nanoscale integrin ligand patterns determine melanoma cell

behavior. ACS Nano. 8:9113–9125. 2014.PubMed/NCBI View Article : Google Scholar

|

|

46

|

Qian C, Zhu C, Yu W, Jiang X and Zhang F:

High-Fat diet/low-dose streptozotocin-induced type 2 diabetes in

rats impacts osteogenesis and wnt signaling in bone marrow stromal

cells. PLoS One. 10(e0136390)2015.PubMed/NCBI View Article : Google Scholar

|

|

47

|

Seif S, Planz V and Windbergs M: Delivery

of therapeutic proteins using electrospun fibers-recent

developments and current challenges. Arch Pharm (Weinheim).

350(1700077)2017.PubMed/NCBI View Article : Google Scholar

|

|

48

|

Yin L, Wang K, Lv X, Sun R, Yang S, Yang

Y, Liu Y, Liu J, Zhou J and Yu Z: The fabrication of an ICA-SF/PLCL

nanofibrous membrane by coaxial electrospinning and its effect on

bone regeneration in vitro and in vivo. Sci Rep.

7(8616)2017.PubMed/NCBI View Article : Google Scholar

|

|

49

|

Bigi A, Cojazzi G, Panzavolta S, Rubini K

and Roveri N: Mechanical and thermal properties of gelatin films at

different degrees of glutaraldehyde crosslinking. Biomaterials.

22:763–768. 2001.PubMed/NCBI View Article : Google Scholar

|

|

50

|

Yi H, Ur Rehman F, Zhao C, Liu B and He N:

Recent advances in nano scaffolds for bone repair. Bone Res.

4(16050)2016.PubMed/NCBI View Article : Google Scholar

|

|

51

|

Gilbert TW, Stewart-Akers AM and Badylak

SF: A quantitative method for evaluating the degradation of

biologic scaffold materials. Biomaterials. 28:147–150.

2007.PubMed/NCBI View Article : Google Scholar

|

|

52

|

Sung HJ, Meredith C, Johnson C and Galis

ZS: The effect of scaffold degradation rate on three-dimensional

cell growth and angiogenesis. Biomaterials. 25:5735–5742.

2004.PubMed/NCBI View Article : Google Scholar

|

|

53

|

Alsberg E, Kong HJ, Hirano Y, Smith MK,

Albeiruti A and Mooney DJ: Regulating bone formation via controlled

scaffold degradation. J Dent Res. 82:903–908. 2003.PubMed/NCBI View Article : Google Scholar

|

|

54

|

Zhang B, Zhang PB, Wang ZL, Lyu ZW and Wu

H: Tissue-engineered composite scaffold of

poly(lactide-co-glycolide) and hydroxyapatite nanoparticles seeded

with autologous mesenchymal stem cells for bone regeneration. J

Zhejiang Univ Sci B. 18:963–976. 2017.PubMed/NCBI View Article : Google Scholar

|

|

55

|

Gong YY, Xue JX, Zhang WJ, Zhou GD, Liu W

and Cao Y: A sandwich model for engineering cartilage with

acellular cartilage sheets and chondrocytes. Biomaterials.

32:2265–2273. 2011.PubMed/NCBI View Article : Google Scholar

|

|

56

|

Yin L, Yang S, He M, Chang Y, Wang K, Zhu

Y, Liu Y, Chang Y and Yu Z: Physicochemical and biological

characteristics of BMP-2/IGF-1-loaded three-dimensional coaxial

electrospun fibrous membranes for bone defect repair. J Mater Sci

Mater Med. 28(94)2017.PubMed/NCBI View Article : Google Scholar

|

|

57

|

Mi R, Liu Y, Chen X and Shao Z: Structure

and properties of various hybrids fabricated by silk nanofibrils

and nanohydroxyapatite. Nanoscale. 8:20096–20102. 2016.PubMed/NCBI View Article : Google Scholar

|

|

58

|

Teo BK, Wong ST, Lim CK, Kung TY, Yap CH,

Ramagopal Y, Romer LH and Yim EKF: Nanotopography modulates

mechanotransduction of stem cells and induces differentiation

through focal adhesion kinase. ACS Nano. 7:4785–4798.

2013.PubMed/NCBI View Article : Google Scholar

|

|

59

|

Stein D, Lee Y, Schmid MJ, Killpack B,

Genrich MA, Narayana N, Marx DB, Cullen DM and Reinhardt RA: Local

simvastatin effects on mandibular bone growth and inflammation. J

Periodontol. 76:1861–1870. 2005.PubMed/NCBI View Article : Google Scholar

|

|

60

|

Khan H, Mafi P, Mafi R and Khan W: The

effects of ageing on differentiation and characterisation of human

mesenchymal stem cells. Curr Stem Cell Res Ther. 13:378–383.

2018.PubMed/NCBI View Article : Google Scholar

|

|

61

|

Prall WC, Saller MM, Scheumaier A,

Tucholski T, Taha S, Bocker W and Polzer H: Proliferative and

osteogenic differentiation capacity of mesenchymal stromal cells:

Influence of harvesting site and donor age. Injury. 49:1504–1512.

2018.PubMed/NCBI View Article : Google Scholar

|

|

62

|

Mendes SC, Tibbe JM, Veenhof M, Bakker K,

Both S, Platenburg PP, Oner FC, de Bruijn JD and van Blitterswijk

CA: Bone tissue-engineered implants using human bone marrow stromal

cells: Effect of culture conditions and donor age. Tissue Eng.

8:911–920. 2002.PubMed/NCBI View Article : Google Scholar

|

|

63

|

Hu ML: Osteogenic differentiation ability

and related gene profiles of bone marrow mesenchymal stem cells

derived from different ages (unpublished PhD thesis). Tianjin

Medical University, 2019.

|

|

64

|

Choudhery MS, Khan M, Mahmood R, Mehmood

A, Khan SN and Riazuddin S: Bone marrow derived mesenchymal stem

cells from aged mice have reduced wound healing, angiogenesis,

proliferation and anti-apoptosis capabilities. Cell Biol Int.

36:747–753. 2012.PubMed/NCBI View Article : Google Scholar

|

|

65

|

Fossett E, Khan WS, Pastides P and Adesida

AB: The effects of ageing on proliferation potential,

differentiation potential and cell surface characterisation of

human mesenchymal stem cells. Curr Stem Cell Res Ther. 7:282–286.

2012.PubMed/NCBI View Article : Google Scholar

|

|

66

|

Stolzing A, Jones E, McGonagle D and Scutt

A: Age-related changes in human bone marrow-derived mesenchymal

stem cells: Consequences for cell therapies. Mech Ageing Dev.

129:163–173. 2008.PubMed/NCBI View Article : Google Scholar

|

|

67

|

Aksoy C, Kaya FA, Kuskonmaz BB, Uckan D

and Severcan F: Structural investigation of donor age effect on

human bone marrow mesenchymal stem cells: FTIR spectroscopy and

imaging. Age (Dordr). 36(9691)2014.PubMed/NCBI View Article : Google Scholar

|