Introduction

Inhalation drug products have been developed for the

treatment of respiratory diseases, such as asthma, chronic

obstructive pulmonary disease (COPD) and pulmonary infections.

Inhalation drug products are also used to treat systemic diseases,

including diabetes (1,2), and their application for pulmonary

vaccination (3) is expected. Three

types of inhalation drug products are currently on the market:

nebulizers, pressurized metered dose inhalers (pMDIs) and dry

powder inhalers (DPIs). In contrast to nebulizers and pMDIs, DPIs

deliver a powder formulation without synchronizing the timing of

nebulization and inhalation. Furthermore, a nebulizer and

propellant are not necessary for DPI and the device is small.

However, drug release from DPIs is affected by the inhalation

patterns of patients (4-7),

inhalation devices (5), inhalation

formulations (8) and the

physiology of the airways (9).

There are two types of DPIs, the multi- and single-unit-dose

inhalers (10-12).

A typical example of a single-unit-dose inhaler is capsule-based

DPIs, including Intal® Spinhaler®,

Spiriva® Handihaler®, Onbrez®,

Ultibro® and Seebri® Breezhaler®.

These inhalers are widely distributed as commercial inhalers. The

advantages of capsule-based DPIs are the accurate and uniform drug

delivery as well as the simplicity of use for patients (13). Patients can also visually confirm

whether a dose has been administered (14). Drug retention in capsules affects

inhalation performances and attenuates therapeutic efficacy for

pulmonary diseases (15,16). Therefore, the development of a

formulation with controlled drug release from capsules is needed

for capsule-based DPIs. To improve drug release from capsules,

previous studies focused on inhalation particles. For example, drug

release from capsules is improved by preparing drug-carrier

particles and drug-drug granulate particles or adding dispersive

agents, including L-leucine, L-phenylalanine, DPPC and DOTAP. These

inhalation particles preparation techniques attenuate drug-drug and

drug-capsule adhesive-cohesive forces (17-21).

The capsule body has also been previously investigated. Wauthoz

et al (22) and Saleem

et al (23) have reported

that inhalation characteristics depend on capsule compositions

[e.g., gelatin and hydroxypropyl methylcellulose (HPMC)], capsule

loss on drying, capsule piercing pattern, the manufacturing method

and the lubricant content. Most of these findings were related to

the capsule outer properties; however, there are few studies on the

effect of capsule inner properties. In addition, most of the

previous studies have been performed using a low resistance device

instead of a high resistance device.

The present study aimed to evaluate the effects of

capsule inner surface physical properties on drug release from

capsules and lung drug delivery using a high resistance device.

Materials and methods

Materials

As a model capsule-based DPIs, Spiriva®

Handihaler® was purchased from Boehringer Ingelheim

Japan Ltd. Spiriva® Handihaler® is a typical

capsule-based DPIs, used for the treatment of COPD and for reducing

COPD exacerbations. A dry powder in Spiriva® inhalation

capsules containing tiotropium bromide (TIO) as the main component

was used as a model drug. The capsule contained 5.5 mg of a powder

formulation consisting of 18 µg micronized tiotropium (as bromide

hydrate, 22.5 µg) with coarse lactose monohydrate (24). The Handihaler®

(Boehringer Ingelheim Japan Ltd.) was used as a model high

resistance device for capsule-based DPIs (device specific

resistance 3.03 Pa* min2/l2) (25). Size 3 capsules with different

compositions were supplied by Qualicaps, Co., Ltd. (G-Cap, gelatin

capsule; PEG/G-Cap, gelatin capsule containing 5% PEG4000 as

plasticizer; and HPMC-Cap, HPMC capsule). PEG/G-Cap is a gelatin

capsule that is resistant to cracking due to the presence of PEG.

HPMC-Cap is resistant to cracking under dry conditions and may be

filled with highly hygroscopic drugs. Each capsule was stored at

15-25˚C and under 40-50% relative humidity (RH) in a glass

desiccator. The characteristics of each capsule are presented in

Table I. All other reagents and

solvents were of analytical or HPLC grade.

| Table ICharacteristics of each capsule. |

Table I

Characteristics of each capsule.

| | G-Cap | PEG/G-Cap | HPMC-Cap |

|---|

| Main material | Gelatin | Gelatin,

PEG4000 | Hydroxypropyl

methyl cellulose |

|---|

| Length diameter,

mm | 12.7±1.53 | 13.9±0.79 | 14.1±0.56 |

| Width diameter,

mm | 4.37±0.53 | 4.67±0.14 | 4.52±0.27 |

| Surface area,

mm2 | 289±6.14 | 245±20.5 | 268±24.6 |

| Volume,

mm3 | 304±1.03 | 301±2.04 | 313±17.9 |

| Loss of drying,

% | 14.3 | 13.2 | 5.0 |

| Lubricant

content | NR | NR | NR |

Characterization of three type of

capsule with different compositions

Each capsule image was analyzed using the image

analysis software ImageJ, and the length diameter, width diameter,

surface area and volume were calculated (Table I). The loss on drying (LOD) and

lubricant content of each capsule are shown as stated in the

analysis certificate. The numbers shown in Table I correspond to the average of three

capsules of each capsule type except for LOD and lubricant content.

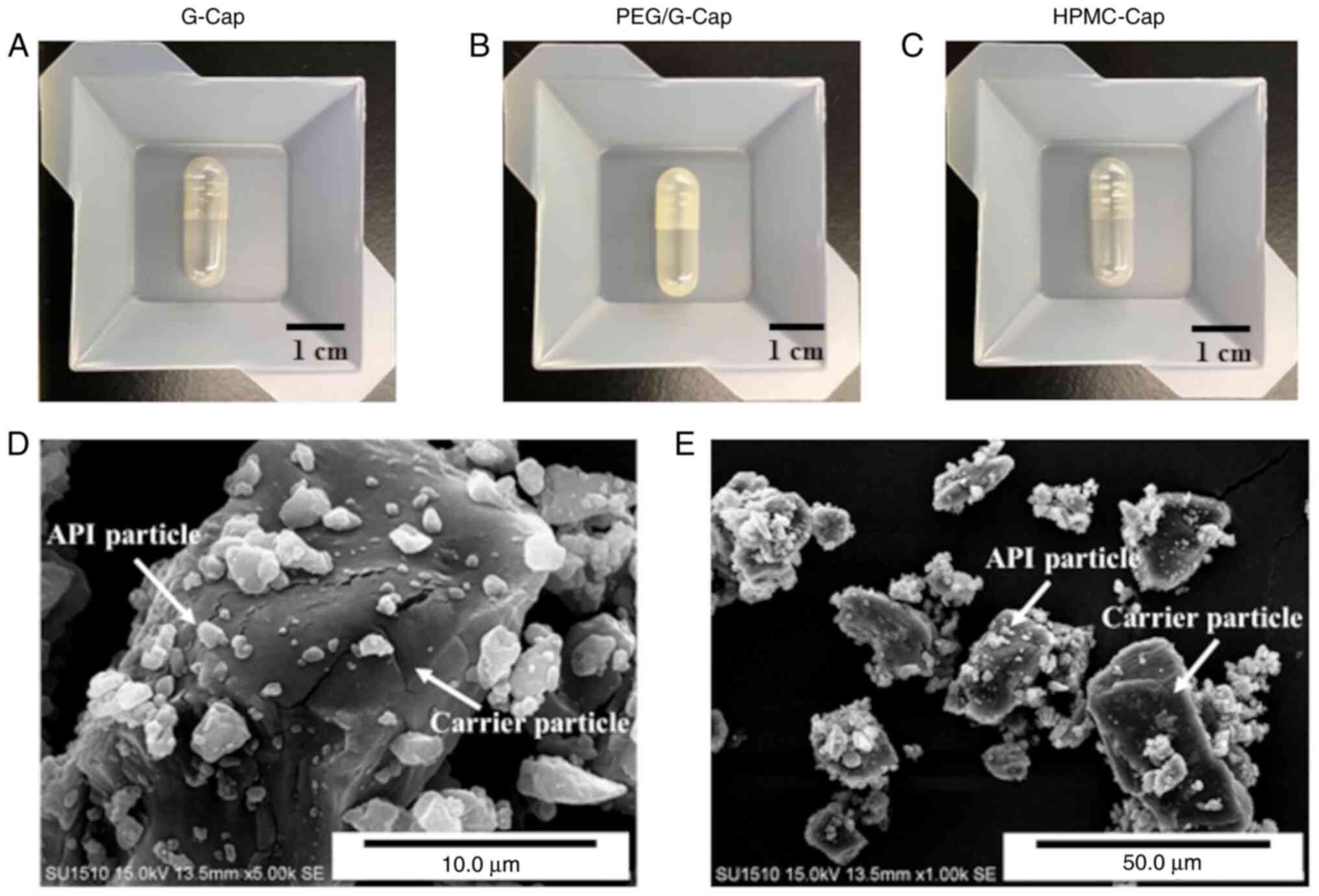

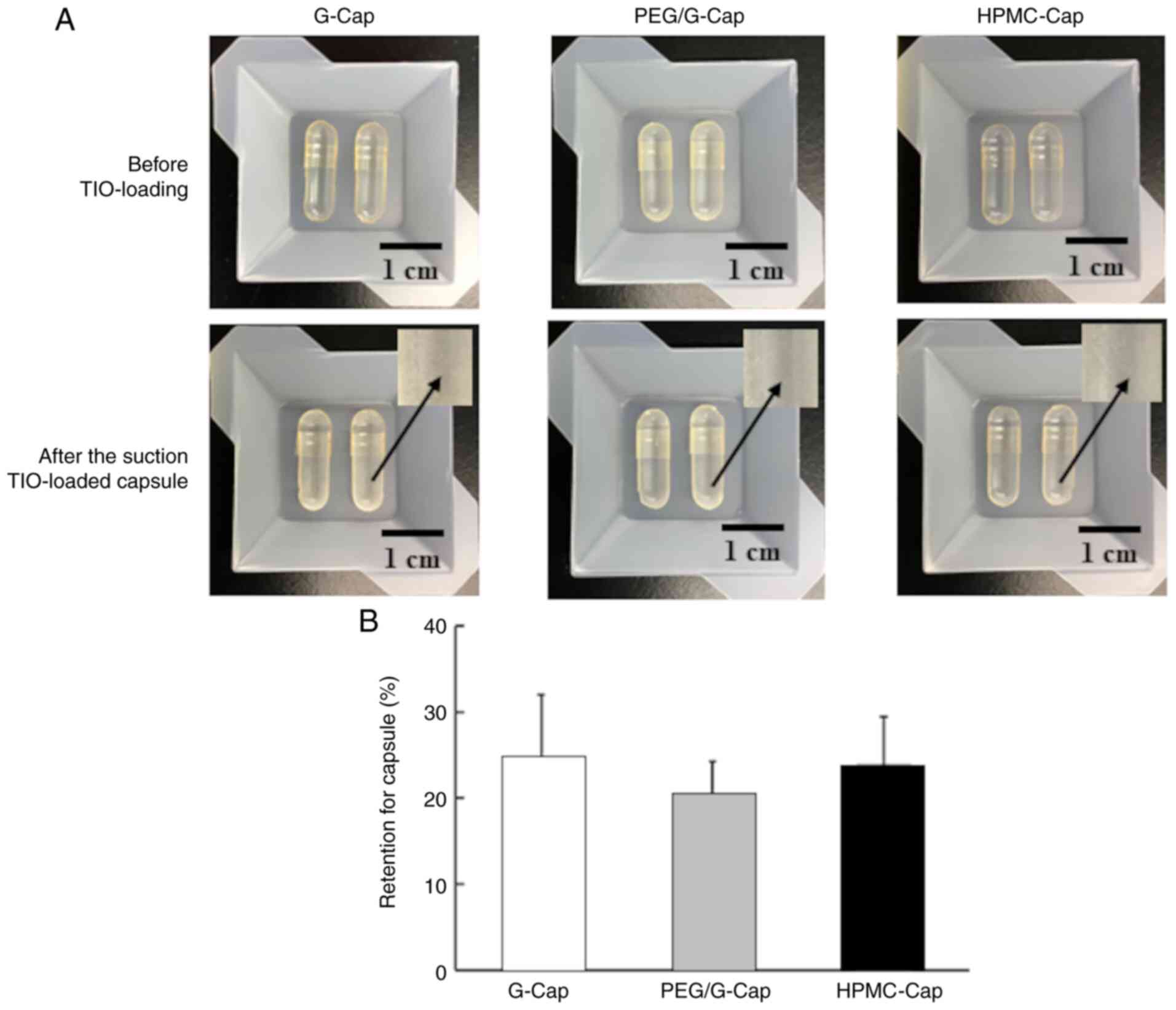

Fig. 1A-C display the appearance

of each capsule.

| Figure 1Images of the (A-C) three capsule

types and (D and E) SEM images of TIO. (A) G-Cap, (B) PEG/G-Cap,

and (C) HPMC-Cap. (D) High magnification, x5000 image of TIO. (E)

Low magnification, x1,000 image of TIO. G-Cap, gelatin capsule;

PEG/G-Cap, gelatin capsule containing 5% PEG4000 as plasticizer;

HPMC-Cap, hydroxypropyl methylcellulose capsule; API, active

pharmaceutical ingredient; TIO, tiotropium bromide. |

Morphological analysis of TIO by

scanning electron microscopy

The morphology of TIO was examined using scanning

electron microscopy (SEM; SU1510; Hitachi High-Technologies Corp.).

Prior to observations, free falling powders from a spatula were

manually dispersed on a specimen mount with double-side tape and

were then coated with platinum using an ion sputter coater (E-1013;

Hitachi High-Technologies Corp.).

Capsule hole examination after

piercing in Handihaler®

Ten capsules of each type were successively placed

in the Handihaler® to be pierced. Capsule hole images

were taken of the most representative hole type of each capsule. In

addition, each capsule hole image was analyzed using the image

analysis software ImageJ (version 1.8.0_172; National Institutes of

Health), and the hole diameter and hole area were calculated.

Topographical analysis of capsule

inner surface by AFM

AFM is widely used for micro- and nanoscale material

conditions to create a 3D image of a physical surface (26). In the present study, the AFM

topography of each capsule inner surface was obtained by scanning

probe microscopy (SPM-9700HT; Shimadzu Corp.). Prior to

observations, the capsule was cut off and placed on a specimen

mount with double-side tape. AFM topography was performed in air

using an EFM cantilever with a force constant 42 N/m in the phase

mode. All experiments were performed in triplicate with an area of

20.0x20.0 µm in each capsule. The obtained AFM images were

evaluated and quantified using ImageJ software. The capsule inner

surface of each capsule using AFM was characterized by calculating

the valley diameter, the valley area and the valley ratio. The

valley diameter corresponds to the average diameter of capsule

valleys in the total observed area. The valley area is the average

area of capsule valleys in the total observed area. The valley

ratio was expressed as the ratio of valley areas in the total

observed area. The valley diameter, valley area and valley ratio

were evaluated for 40 valleys in one observation area, and the

average value was calculated.

Measurement of capsule inner surface

potential distribution with the KFM mode

The potential distribution of each capsule inner

surface was obtained using the KFM mode from SPM-9700HT. The KFM

mode is a method used to measure the potential distribution of the

sample surface. This distribution is evaluated by detecting the

electrostatic force acting between the sample surface and the probe

tip by applying an alternating current signal to the electric

conductive cantilever. A KFM image is obtained in air using the EFM

cantilever with a force constant of 2.8 N/m in KFM mode. Prior to

observation, the capsule was cut off and placed on a specimen mount

with double-side tape. All experiments were performed in triplicate

with an area of 5.0x5.0 µm in each capsule. Image analysis was

performed on a representative image of each capsule. Images were

analyzed using SPM-9700HT manager software (Shimadzu Corp.).

In vitro inhalation performance

evaluation

Inhalation performance was evaluated using a

twin-stage liquid impinger (TSLI; European Pharmacopoeia Apparatus;

Copley Scientific Ltd.) equipped with a suction pump. Stages 1 and

2 in TSLI contained 7 and 30 ml of purified water and methanol

(75:25, volume ratio), respectively. Each capsule (G-Cap, PEG/G-Cap

and HPMC-Cap) was manually filled with 5.5±0.1 mg of TIO while the

weight was measured using sensitive digital balance (±0.1 mg;

Balance XS64; Mettler-Toledo GmbH). Once Handihaler® was

connected to the mouthpiece of TSLI, the TIO-loaded capsule was

placed in the holder of Handihaler® with a pin to pierce

it. The Handihaler® pierced one hole in the side wall of

the cap and the body. The suction pump was operated to disperse the

powder in the capsule at a flow rate 30 l/min. Since the lower

limit of peak inhalation flow rates for Handihaler® is

>20 l/min (25), the flow rate

of the suction pump was set to 30 l/min in the present study. Dry

powder remaining in the capsule and device at each stage after

dispersion by the suction pump was collected by rinsing with

purified water and methanol (75:25, volume ratio). The collected

samples were diluted into 50 ml purified water and methanol (75:25,

volume ratio), and the concentration of TIO in each sample was

measured by high performance liquid chromatography (HPLC). All

experiments were performed in triplicate. The inhalation

performance of TIO by TSLI was characterized using the following

parameters: i) Recovered dose (RD) is the mass of TIO recovered

from all parts of the apparatus (capsule, device and TSLI); ii)

mass balance (MB) is the ratio between RD to the amount of TIO to

be loaded into capsule; iii) drug retention for capsule is the

ratio of the amount of capsule drug deposition of the RD, while

Emitted dose (ED) is the amount of drug particles emitted from a

capsule to that from an inhalation device; iv) fine particle dose

(FPD) is the mass of drug particles from Stage 2 within the RD; and

v) fine particle fraction (FPF) is the ratio between FPD to RD.

Conditions for measuring TIO by

HPLC

The concentration of TIO in in vitro

inhalation characteristics samples was determined using Shimadzu

LC-20AT system (Shimadzu Corp.), which consists of a UV-vis

detector (SPD-20A), column oven (CTO-20A), degassing unite

(DGU-20A3R) and an auto sampler (SIL-10AF). The mobile

phase was composed of 100 mM potassium dihydrogenphosphate solution

(pH 4.0) and acetonitrile (80:20, volume ratio). The flow rate was

set to 0.25 ml/min. The column (Inertsil® ODS-3, 3.0 µm,

2.1x50 mm; GL Science Co., Inc.) was heated at 35˚C. The injection

volume was 100 µl. The UV absorbance of each sample was measured at

238 nm. Under these HPLC condition, the limit of detection for TIO

was 0.03 µg/ml, and a calibration curve was linear at a

concentration range of 0.1-20 µg/ml. The correlation coefficients

(R2) was 0.999 (y=326.12x+2684.8). All samples were

properly diluted to fit within this calibration range and peak area

was used for quantification of TIO.

Statistical analysis

All data were presented as the means ± standard

errors of measurements. The ‘BellCurve for Excel’ (Social Survey

Research Information Co., Ltd.) was used for statistical data

analysis. One-way ANOVA followed by Dunnett's post hoc test for

multiple comparison and an unpaired Student's t-test were used for

statistical analyses. P<0.05 was considered to indicate a

statistically significant difference.

Results

Capsule characterization

The characterization of the three type of capsules

(G-Cap, PEG/G-Cap and HPMC-Cap) are presented in Table I. The appearance of each capsule is

shown in Fig. 1A-C. G-Cap and

HPMC-Cap were clear capsule bodies, whereas PEG/G-Cap had a

translucent capsule body. No significant differences were observed

in the length diameter, width diameter, surface area and volume of

each capsule between G-Cap, PEG/G-Cap and HPMC-Cap [non-significant

(NS), ANOVA]. The LOD of HPMC-Cap was much lower than the LOD of

G-Cap and PEG/G-Cap, with no difference between G-Cap to PEG/G-Cap

(Table I).

Morphology of a model dry powder

In the present study, TIO was used as a dry powder

model for capsule-based DPIs. TIO consists of micronized tiotropium

particles and coarse lactose monohydrate particles as carriers. The

morphology of TIO is presented in Fig.

1D and E. The SEM images

clearly demonstrated that micronized tiotropium particles [active

pharmaceutical ingredient (API) particles] adhered to coarse

lactose monohydrate particles (carrier particles).

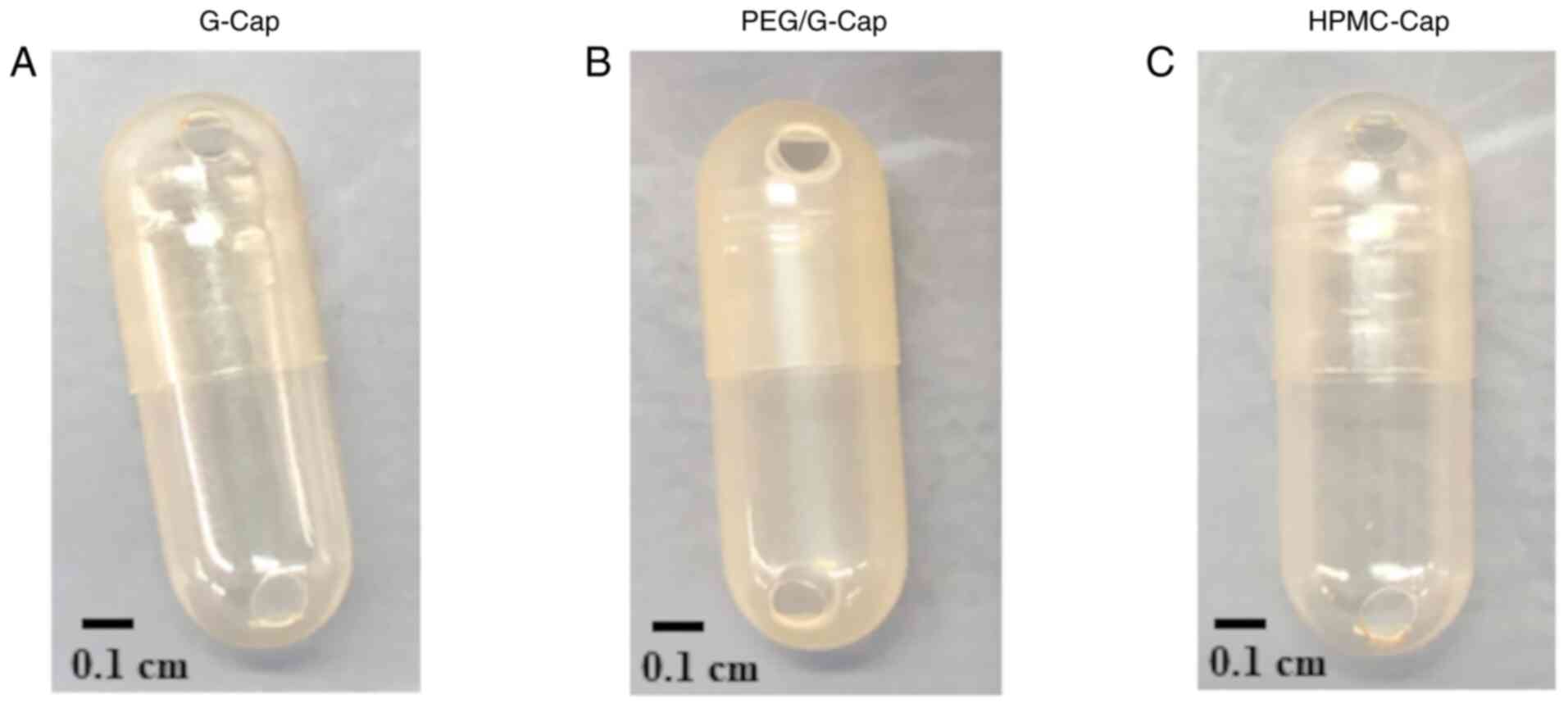

Pierced capsule hole

characterization

The image of capsule hole of each capsule is

presented in Fig. 2. The

characteristics of pierced capsule holes of each capsule are

presented in Table II. In terms

of capsule hole after piercing, no cracked holes between G-Cap,

PEG/G-Cap and HPMC-Cap were seen (Fig.

2). The capsule hole diameter and hole area of G-Cap tended to

be larger than that of PEG/G-Cap and HPMC-Cap (Table II; NS, ANOVA).

| Table IICharacteristics of pierced capsule

holes of each capsule. |

Table II

Characteristics of pierced capsule

holes of each capsule.

| | Hole diameter,

mm | Hole area,

mm2 |

|---|

| G-Cap | 1.28±0.02 | 1.56±0.08 |

| PEG/G-Cap | 1.14±0.98 | 1.26±0.06 |

| HPMC-Cap | 1.17±0.15 | 1.35±0.19 |

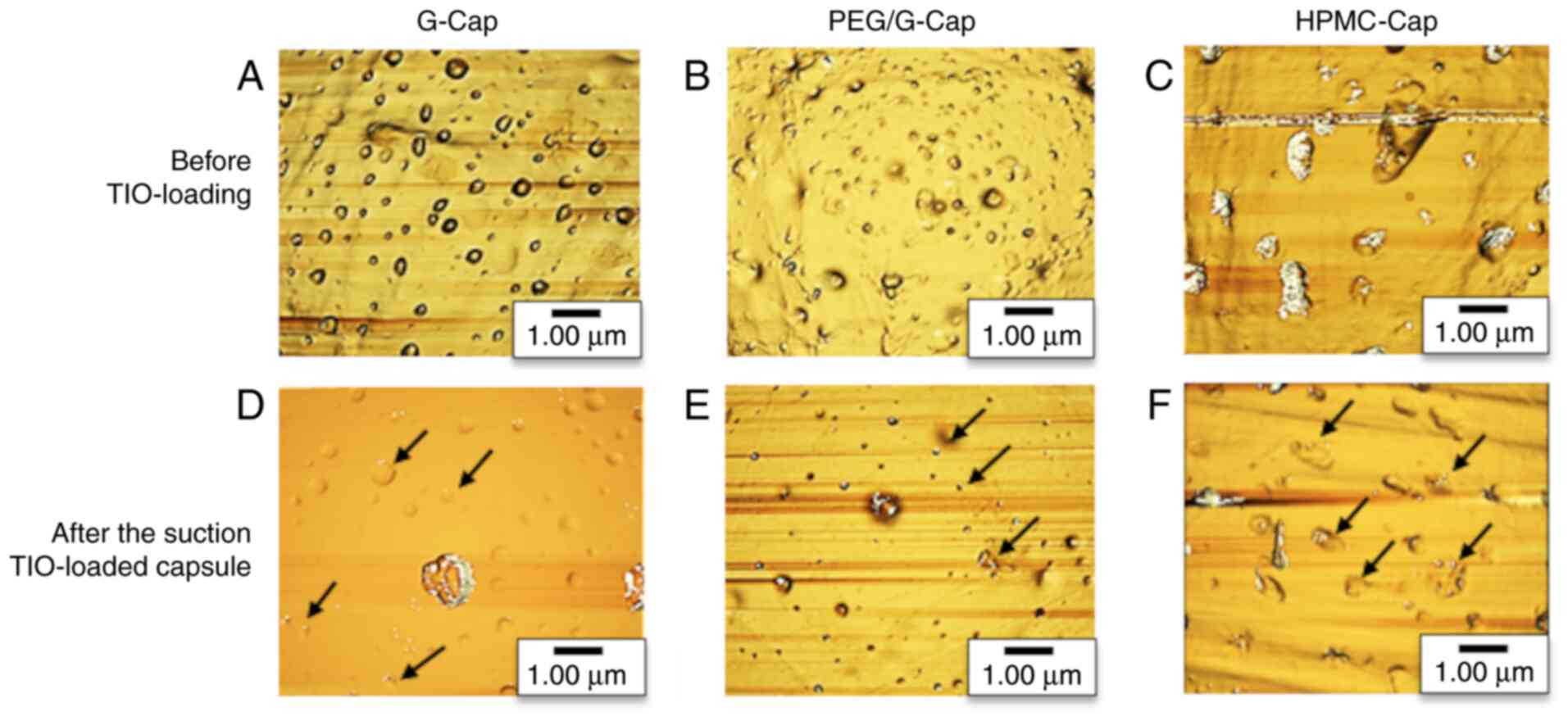

Comparison of inner surface structure

of each capsule

Fig. 3 presents the

inner surface structure of each capsule before TIO loading and

after suction of TIO-loaded capsules. The valley diameter, valley

area and valley ratio of capsule inner surface before TIO loading

and after the suction of TIO-loaded capsules are shown in Table III. In Fig. 3A-C, the areas darker than

background indicated the valleys while the lighter areas indicated

the mountains. Numerous valleys and mountains were observed on the

capsule inner surface regardless of the capsule composition. After

the suction of TIO-loaded capsules, TIO was observed in valleys on

the capsule inner surface (Fig.

3D-F). The black arrows in Fig.

3D-F indicated the area where particles were placed in the

valley. As presented in Table

III, the valley diameter, valley area and valley ratio were

decreased following suction, regardless of the type of capsule.

Furthermore, valley diameter, valley area and valley ratio of

HPMC-Cap were significantly difference before TIO loading and after

the suction of TIO-loaded capsules (P<0.05, unpaired Student's

t-test).

| Table IIIValley diameter, valley area and

valley ratio of each capsule type determined by atomic force

microscopy images analysis. |

Table III

Valley diameter, valley area and

valley ratio of each capsule type determined by atomic force

microscopy images analysis.

| | Valley diameter,

µm | Valley area,

µm2 | Valley ratio,

% |

|---|

| | Before | After | Before | After | Before | After |

|---|

| G-Cap | 0.59±0.26 | 0.54±0.28 | 0.28±0.22 | 0.24±0.16 | 4.60±0.75 | 3.68±0.09 |

| PEG/G-Cap | 0.68±0.39 | 0.64±0.36 | 0.64±0.58 | 0.46±0.32 | 5.24±3.65 | 4.51±0.54 |

| HPMC-Cap | 1.97±0.98 |

1.06±0.40a | 2.05±1.89 |

1.02±0.67a | 10.6±6.24 |

6.39±0.16a |

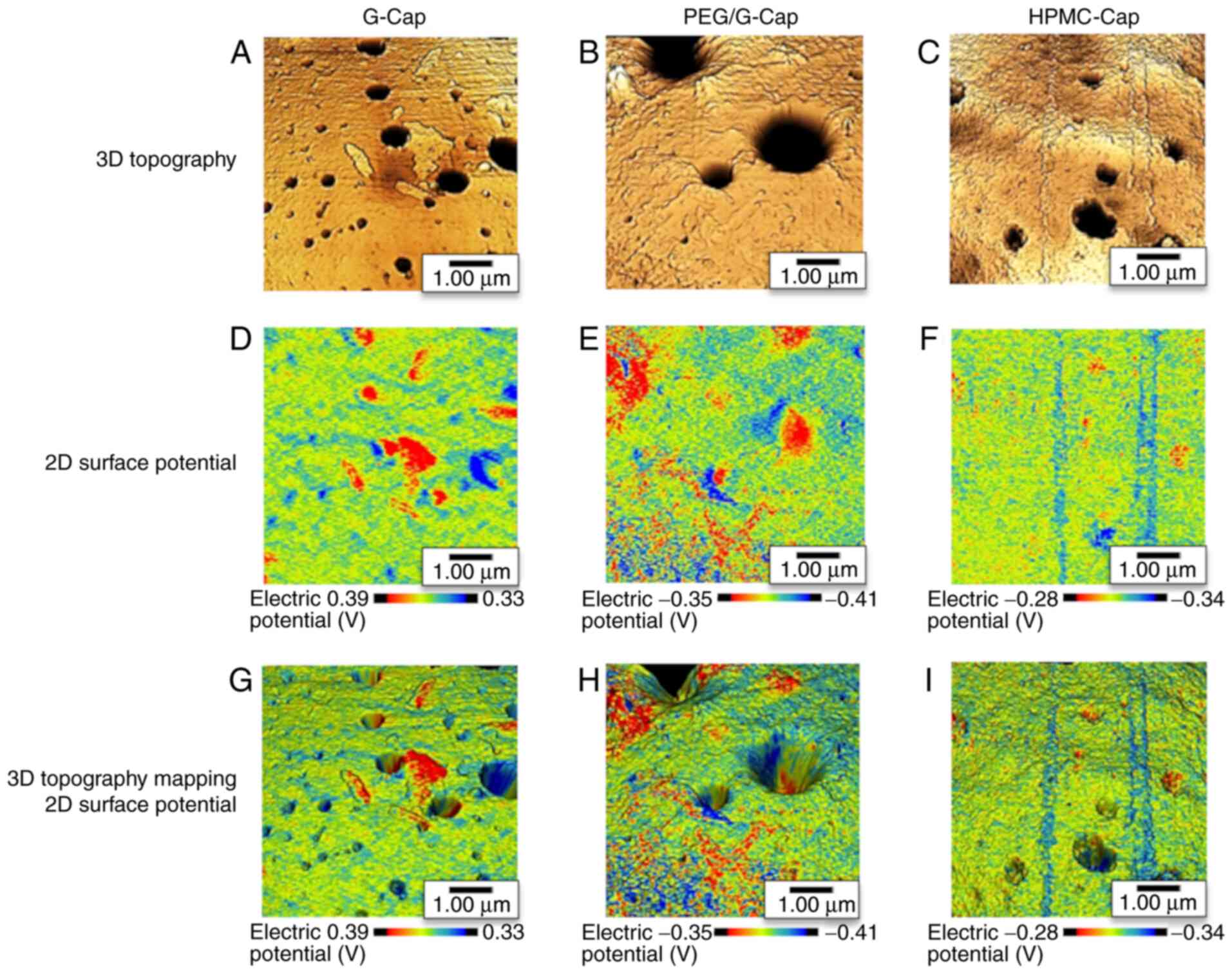

3D mapping analysis of the capsule

inner surface structure and surface potential distribution

The 3D topography of the capsule inner surface and

capsule inner surface potential distribution were evaluated using

SPM-9700HT. The 3D topographies of the three capsule inner surfaces

are presented in Fig. 4A-C. In

Fig. 4A-C, the areas darker than

background indicated the valleys, and the lighter areas indicated

the mountains. These topographies revealed the distribution of

valleys and mountains on the inner surface of each capsule. KFM

images of the three capsule inner surfaces are shown in Fig. 4D-F. In these images, the red

fraction indicates a higher potential and the blue fraction a lower

potential. KFM images showed mixed high and low potential fractions

in all three capsules. In addition, 3D topography and KFM image

mapping were performed to confirm the relationship between the

capsule inner surface structure and surface potential. The results

of image mapping demonstrated that the distribution of valleys and

mountains on the capsule inner surface corresponded to high and low

potential fractions, respectively (Fig. 4G-I).

Comparison of inhalation

performance

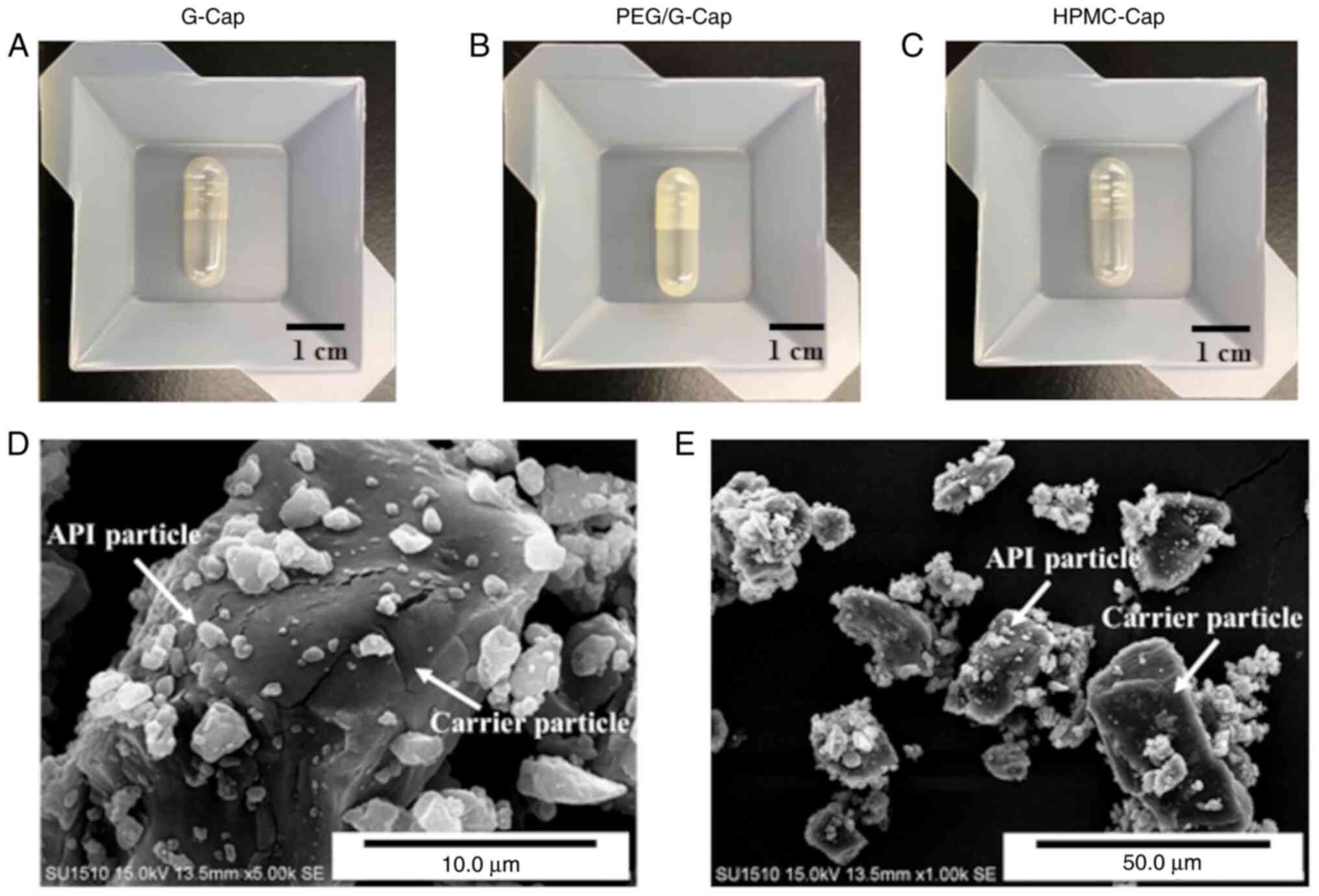

We evaluated drug release from capsule and lung drug

delivery with different compositions using TSLI. Fig. 5A shows an image of the inner

surface of each capsule before TIO loading and after the suction of

TIO-loaded capsules. Images of TIO-loaded capsules after the

suction demonstrated the adherence of TIO to the surface of capsule

regardless of the capsule type. The results for inhalation

performance parameters are presented in Fig. 5B and Table IV. The drug retention for capsule,

RD, MB, ED, FPD and FPF were not significantly different between

G-Cap, PEG/G-Cap and HPMC-Cap (NS, ANOVA).

| Table IVInhalation performance of tiotropium

bromide loaded in three capsules with different compositions using

twin-stage liquid impinger. |

Table IV

Inhalation performance of tiotropium

bromide loaded in three capsules with different compositions using

twin-stage liquid impinger.

| | G-Cap | PEG/G-Cap | HPMC-Cap |

|---|

| Recovery dose,

µg | 17.4±0.18 | 16.8±0.42 | 17.5±0.6 |

| Mass balance,

% | 96.9±0.98 | 93.2±2.36 | 97.5±3.54 |

| Emitted dose,

µg | 4.37±0.53 | 4.67±0.14 | 4.52±0.27 |

| Fine particle dose,

µg | 7.94±0.85 | 7.54±0.45 | 8.27±0.74 |

| Fine particle

fraction, % | 25.7±4.85 | 28.3±4.50 | 26.7±1.25 |

Discussion

The advantages of capsule-based DPIs over other DPIs

are as follows: Accurate and uniform drug delivery, ease to use for

patients and the visual confirmation of whether a dose has been

administered (13,14). The inhalation performance of

capsule-based DPIs is related to numerous factors, such as the

inhalation patterns of patients (4-7),

the inhalation devices (5) and the

inhalation formulations (8). The

inhalation performance of capsule-based DPIs was recently reported

to be affected by the capsule properties. In a previous study,

inhalation performance was evaluated by filling five capsules with

binary or ternary particles of different compositions and

manufacturing methods, and the findings demonstrated that

inhalation performance was affected by capsule compositions and

manufacturing methods (22).

However, few studies have investigated the effects of the physical

properties of the capsule inner surface on inhalation performance.

The present study aimed therefore to determine the capsule inner

surface structures and surface potential distributions using the 3D

mapping technologies, AFM topography and KFM imaging. Because the

previous studies of capsule-based DPIs mainly focused on low

resistance devices, not high resistance devices (22,23),

the present study investigated the effects of capsule physical

properties on inhalation performance using a high resistance device

of capsule-based DPIs.

To characterize the properties of the capsules, each

capsule was evaluated by image analysis using ImageJ software. No

significant difference was observed in the length diameter, width

diameter, surface area and volume of each capsule, while the LOD of

HPLC-Cap (5.0%) was much lower than of G-Cap (14.3%) and PEG/G-Cap

(13.2%; Table II). As the result

of pierced capsule hole characteristics, there were no cracked

holes in G-Cap, PEG/G-Cap and HPMC-Cap (Fig. 2). The capsule hole diameter and

hole area of G-Cap tended to be larger than that of PEG/G-Cap and

HPMC-Cap (Table II). The results

of a previous study reported that different capsule compositions

exhibit different levels of water content. The gelatin capsule and

HPMC capsule demonstrated 13-16% and 3-7% water content,

respectively (27). Under low RH

conditions, a decreased water content increases brittleness, with

gelatin capsules being more sensitive to this effect (27). The capsule shell may therefore

crack or fracture when the capsule is pierced, thereby affecting

inhalation performance (28). In

the present study, the capsule compositions were different, and it

was expected that the capsules would crack during capsule piercing

due to the difference in LOD. Although the hole diameter and hole

area in each capsule was slightly different, no cracks occurred

during capsule piercing. We considered that the capsule storage

condition (15-25˚C, 40-50% RH) and the piercing condition using two

needles in the Handihaler® had a role in the lack of

cracking.

To confirm the capsule inner surface structure, each

capsule was observed using SPM. The inner surface structure on the

center, top, bottom, left and right parts were observed in a

previous experiment, and the results confirmed that there was no

significant difference among these regions. The images from

Fig. 3 were obtained by SPM of the

central part of the capsule body. Numerous valleys and mountains

were observed on each capsule inner surface before TIO loading,

irrespective of the capsule composition (Fig. 3A-C). Following the suction

TIO-loaded capsules, the inner surface of the capsule became smooth

and TIO was placed in the valleys (Fig. 3D-F). To confirm whether the

smoothness of the capsule inner surface was due to the TIO in the

valleys, the valley diameter, valley area and valley ratio were

compared before TIO loading and after the suction of TIO-loaded

capsules (Table III). The valley

diameter, valley area and valley ratio were slightly decreased

after suction, regardless of the type of capsule. In particular,

the valley diameter, area and ratio of the HPMC-Cap following the

suction of TIO-loading were significantly different compared with

these characteristics prior to TIO loading. The results suggested

that, although the capsule had valley and mountain structure on the

inner surface regardless of the capsule composition, the

characteristics of valleys were affected by the capsule

composition. Furthermore, drug particles may be trapped in the

valleys on the capsule inner surface, which would affect the

inhalation performance.

Subsequently, to confirm the electric properties of

capsule inner surface, we evaluated the surface potential

distribution using the KFM mode of SPM. KFM images demonstrated

that regions with high and low potential fractions were mixed in

each capsule (Fig. 4D-F). The 3D

topography and KFM images mapping of capsules showed that the

distribution valleys and mountains on the capsule inner surface

corresponded to high and low potential fractions, respectively

(Fig. 4G-I). Therefore, a local

potential difference may have occurred due to the distribution of

valleys and mountains on the capsule inner surface. These results

suggested that the effect of the inner surface structure and the

surface potential difference between the drug particles and the

valleys may both contribute to the increase in TIO amount in the

valleys.

To clarify the effects of the physical properties of

the capsule inner surface on inhalation performance, the inhalation

performance of each capsule type were evaluated using TSLI. The

results of drug retention for capsule and lung drug delivery were

not significantly different between G-Cap, PEG/G-Cap and HPMC-Cap

(Fig. 5B and Table IV). These findings may be due to

the fact that no significant difference in hole diameter and hole

area between capsules was observed. In addition, drug particles

were present in the inner surface valleys of each capsule, although

their impact on drug retention for capsule and lung drug delivery

was expected to be minimal. In the present study, we evaluated the

inhalation performance using the high resistance device at an

appropriate flow rate of 30 l/min. The influence of inhalation

device and flow rate on the drug release from capsule was therefore

considered to be greater than that of the capsule compositions and

physical properties of the capsule inner surface. In other words,

at an appropriate flow rate using high resistance device, the

physical properties of the capsule inner surface due to the capsule

composition did not significantly affect the drug release from

capsule and lung drug delivery. In this study, we particularly

focused on the drug release from capsule, and inhalation

performance was evaluated using TSLI. The TSLI is a simple

inhalation characteristic apparatus that contains Throat, Stage 1

and Stage 2. The TSLI was set up so that drug particles reaching

Stage 2 at a flow rate of 60 l/min showed a cut-off of less than

6.4 µm. Unfortunately, in the present study, the TSLI was examined

at a flow rate of 30 l/min, and the exact cut-off diameter could

not be measured. Therefore, the stage grouping in the inhalation

performance evaluation could not be performed, and the mass median

aerodynamic diameter (MMAD) ± geometric standard deviation (GSD)

could not be calculated. To understand the exact aerodynamic

differences in inhalation characterization, representative stage

grouping data and MMAD ± GSD are therefore needed (29,30).

Future investigation will evaluate the inhalation performance by

calculating MMAD ± GSD using Andersen cascade impactor, Next

generation impactor and Multistage liquid impinger.

In summary, the present study investigated the

effects of the physical properties of the capsule inner surface on

drug release form capsules and lung drug delivery using AFM and a

high resistance device. The results demonstrated that the capsule

inner surface had many valleys and mountains regardless of the type

of capsule. In addition, the valley and mountain areas on the

capsule inner surface presented with potential fluctuations where

there were significant differences in the surface structure.

Following inhalation of capsule-based DPIs, the drug remained in

valleys on the capsule inner surface; however, no significant

difference was observed in drug retention for capsule and lung drug

delivery. Therefore, drug release from capsule and lung drug

delivery in capsule-based DPIs when a high resistance device, such

as Handihaler®, is used at an appropriately flow rate

may have not significantly been affected by the physical properties

of the capsule inner surface of the capsule due to capsule

composition. However, since the present study only evaluated one

DPI formulation and inhalation device, the effect of the physical

properties of capsule inner surface on drug release and lung drug

delivery remain currently unclear. Further studies using various

DPI formulations, including indacaterol, glycopyrronium and

andrographolide, and inhalation devices, such as

Breezhaler®, are needed to elucidate the relationship

between the physical properties of capsule inner surface and

inhalation performance.

Acknowledgements

We would like to thank Qualicaps, Co., Ltd., for

supplying G-Cap, PEG/G-Cap and HPMC-Cap, and Shimadzu Corp. for

providing AFM topography and KFM images of each capsule surface

using SPM-9700HT. This study was partly supported by the Hosokawa

Powder Technology Foundation.

Funding

The present study was supported partly by The Mochida Memorial

Foundation for Medical and Pharmaceutical Research (grant no.

14).

Availability of data and materials

All data generated or analyzed during this study are

included in this published article.

Author's contributions

HO and MM performed the experiments and were the

major contributors to writing the manuscript. MY, SA and KI

analyzed and interpreted the data. HO and NN made substantial

contributions to the conception and design of the study. NN

designed the experiments and gave final approval for the version of

the manuscript to be published. MM and MY confirm the authenticity

of all the raw data. All authors read and approved the final

manuscript.

Ethic approval and consent to

participate

Not applicable.

Patient consent for publication

Not applicable.

Competing interests

The authors declare that they have no competing

interests.

References

|

1

|

Claus S, Weiler C, Schiewe J and Friess W:

How can we bring high drug doses to the lung? J Pharm Biopharm.

86:1–6. 2014.PubMed/NCBI View Article : Google Scholar

|

|

2

|

Yang MY, Chan JG and Chan HK: Pulmonary

drug delivery by powder aerosols. J Control Rel. 193:228–240.

2014.PubMed/NCBI View Article : Google Scholar

|

|

3

|

Tonnis WF, Lexmond AJ, Frijlink HW, de

Bore AH and Hinrichs WL: Devices and formulations for pulmonary

vaccination. Expert Opin Drug Deliv. 10:1383–1397. 2013.PubMed/NCBI View Article : Google Scholar

|

|

4

|

Bouwmeester C, Kraft J and Bungay KM:

Optimizing inhaler use by pharmacist-provided education to

community-dwelling elderly. Respir Med. 109:1363–1368.

2015.PubMed/NCBI View Article : Google Scholar

|

|

5

|

Broeders ME, Vincken W, Corbetta L and

Group AW: The ADMIT series-Issues in inhalation therapy. 7. Ways to

improve pharmacological management of COPD: The importance of

inhaler choice and inhalation technique. Prime Care Respir J.

20:338–343. 2011.PubMed/NCBI View Article : Google Scholar

|

|

6

|

Cochrane MG, Bala MV, Downs KE, Mauskopf J

and Ben-Joseph RH: Inhaled corticosteroids for asthma therapy:

Patient compliance, devices, and inhalation technique. Chest.

117:542–550. 2000.PubMed/NCBI View Article : Google Scholar

|

|

7

|

Baily MM, Gorman EM, Munson EJ and

Berkland C: Pure insulin nanoparticle agglomerates for pulmonary

delivery. Lungmuir. 24:13614–13620. 2008.PubMed/NCBI View Article : Google Scholar

|

|

8

|

Weer JG and Miller DP: Formulation design

of dry powders for inhalation. J Pharm Sci. 104:3259–3288.

2015.PubMed/NCBI View Article : Google Scholar

|

|

9

|

Stocks J and Hislop AA: Structure and

function of the respiratory system: Developmental aspects and their

relevance to aerosol therapy. In: Drug Delivery to the Lung:

Clinical Aspects. Bisgaard H, O'Callaghan C, Smaldone CG (eds.)

Marcel Dekker, Inc., New York, NY pp47-104, 2002.

|

|

10

|

Lavorini F, Pistolesi M and Usmani OS:

Recent advances in capsule-based dry powder inhaler technology.

Multidiscip Respir Med. 12(11)2017.PubMed/NCBI View Article : Google Scholar

|

|

11

|

Berkenfeld K, Lamprecht A and McConville

JT: Devices for dry powder drug delivery to the lung. AAPS

PharmSciTech. 16:479–490. 2015.PubMed/NCBI View Article : Google Scholar

|

|

12

|

Faulhammer E, Flink M, Liusa M, Lawrence

SM, Biserni S, Calzolari V and Khinast JG: Low-dose capsule filling

of inhalation products: Critical material attributes and process

parameters. Int J Pharm. 473:617–626. 2014.PubMed/NCBI View Article : Google Scholar

|

|

13

|

Wauthoz N, Hennia I, Dejaeger B, Ecenarro

S and Amighi K: Proposed algorithm for healthcare professionals

based on product characteristics and in vitro performances in

different use conditions using formoterol-based marketed products

for inhalation. Int J Pharm. 530:415–429. 2017.PubMed/NCBI View Article : Google Scholar

|

|

14

|

Smith IJ, Bell J, Bowman N, Everard M,

Stein S and Weer JG: Inhaler devices: What remains to be done? J

Aerol Med Pulm Drug Deliv. (Suppl 2):S25–S37. 2010.PubMed/NCBI View Article : Google Scholar

|

|

15

|

Steckel H and Muller BW: In-vitro

evaluation of dry powder inhalers 1: Drug deposition of commonly

used devices. Int J Phar. 154:19–29. 1997.

|

|

16

|

Vidgren M, Kärkkäinen A, Karjalainen P,

Paronen P and Nuutinen J: Effect of powder inhaler design on drug

deposition in the respiratory tract. Int J Pharm. 42:211–216.

1988.

|

|

17

|

Chew NY, Shekunov BY, Tong HH, Chow AH,

Savage C, Wu J and Chan H: Effect of amino acids on the dispersion

of disodium cromoglycate powders. J Pharm Sci. 94:2289–2300.

2005.PubMed/NCBI View Article : Google Scholar

|

|

18

|

Otake H, Okuda T and Okamoto H:

Development of spray-freeze dried powders for inhalation with high

inhalation performance and antihygroscopic property. Chem Pharm

Bull (Tokyo). 64:239–245. 2016.PubMed/NCBI View Article : Google Scholar

|

|

19

|

Li HY, Seville PC, Williamson IJ and

Birchall JC: The use of amino acids to enhance the aerosolisation

of spray-dried powders for pulmonary gene therapy. J Gene Med.

7:343–353. 2005.PubMed/NCBI View

Article : Google Scholar

|

|

20

|

Ungaro F, Giovino C, Coletta C, Sorrentino

R, Miro A and Quaglia F: Engineering gas-foamed large porous

particles for efficient local delivery of macromolecules to the

lung. Eur J Pharm Sci. 41:60–70. 2010.PubMed/NCBI View Article : Google Scholar

|

|

21

|

Duan J, Vogt FG, Li X, Hayes Jr D and

Mansour HM: Design, characterization, and aerolization of organic

solution advanced spray-dried moxifloxacin and ofloxacin

dipalmitoylphosphatidylcholine (DPPC)

microparticulate/nanoparticulate powders for pulmonary inhalation

aerosol delivery. Int J Nanomedicine. 8:3489–3505. 2013.PubMed/NCBI View Article : Google Scholar

|

|

22

|

Wauthoz N, Hennia I, Ecenarro S and Amighi

K: Impact of capsule type on aerodynamic performance of inhalation

products: A case study using a formoterol-lactose binary or ternary

blend. Int J Pharm. 553:47–56. 2018.PubMed/NCBI View Article : Google Scholar

|

|

23

|

Saleem IY, Diez F, Jones BE and Polo L:

Investigation on the aerosol performance of dry powder inhalation

hypromellose capsules with different lubricant levels. Int J Pharm.

492:258–263. 2015.PubMed/NCBI View Article : Google Scholar

|

|

24

|

Horhota ST, van Noord JA, Verkleij CB,

Bour LJ, Sharma A, Trunk M and Cornelissen PJ: In vitro,

pharmacokinetic, pharmacodynamic, and safety comparisons of single

and combined administration of Tiotropium and Salmeterol in COPD

patients using different dry powder inhalers. AAPS J. 17:871–880.

2015.PubMed/NCBI View Article : Google Scholar

|

|

25

|

Hira D, Koide H, Nakamura S, Okada T,

Ishizeki K, Yamaguchi M, Koshiyama S, Oguma T, Ito K, Funayama S,

et al: Assessment of inhalation flow patterns of soft mist inhaler

co-prescribed with dry powder inhaler using inspiratory flow meter

for multi inhalation devices. PLoS One. 13(e0193082)2018.PubMed/NCBI View Article : Google Scholar

|

|

26

|

García R and Pérez R: Dynamic atomic force

microscopy methods. Surf Sci Rep. 47:197–301. 2002.

|

|

27

|

Nagata S: Gellulose capsules-an

alternative to gelatin. In: Biolodical Polymers and Polymer

Therapeutics. Chiellini E, Sunamoto J, Migliaresi C, Ottenbrite RM,

Cohn D (eds). Kluwer Academics/Plenum Publishers, New York, NY, pp

53-62, 2001.

|

|

28

|

Coate MS, Fletcher DF, Chan HK and Raper

JA: The role of capsule on the performance of a dry powder inhaler

using computational and experimental analysis. Pharm Res.

22:923–932. 2005.PubMed/NCBI View Article : Google Scholar

|

|

29

|

Mehta PP, Kadam SS and Pawar AP: Effect of

USP induction ports and modified glass sampling apparatus on

aerosolization performance of lactose carrier-based fluticasone

propionate dry powder inhaler. J Drug Deliv Sci Technol.

58(101794)2020.

|

|

30

|

Timsina MP, Martin GP, Marriott C,

Ganderton D and Yianneskis M: Drug delivery to the respiratory

tract using dry powder inhalers. Int J Pharm. 101:1–13. 1994.

|