1. Introduction

The increasing global population is facing

challenges with respect to environmental aspects, healthcare

issues, optimal food supply and safety. Resolving these issues

necessitates the use of innovative technologies and scientific

achievements, and with the feasibility of technologies,

nanotechnology is a promising field (1). Food products produced must fulfil the

satisfaction of the consumers, as the awareness of consumers about

food quality and safety is increasing. Worldwide, this urges

scientists to develop the strategies with which to boost food

quality with health benefits and nutraceutical values. The

conventional method of the food chain involves food production,

fortification, processing, food preservation, analysis and

packaging (2). Of note, 60% of the

current world human population is accounted for by Asia, where the

current global populationis4 billion. There is a surplus of food in

developed countries; however, as a result of environmental impacts,

the majority of the population of developing countries faces daily

food shortages. Nanotechnology can be applied to various stages of

the food sector, initially from agro-practice, post-harvest

practice and food processing (3).

In the agricultural sector, nanotechnology plays a key role with

the use of nanodevices, facilitating the prediction of the

functions of pesticides and fertilizers in the growth and yield of

crops. Post-harvest aspects include the storage and aggregation of

agricultural products, while raw food processing deals with

obtaining grains, fruits, vegetables and several other ingredients

into consumable processed food. The food processing techniques

include all the aspects of the food industry, which begins with the

transfer of food from the farm land to the market (1).

2. Nanotechnology

Nanotechnology unites several disciplines of

sciences, such as biotechnology, physics, chemistry and

engineering; nanotechnology is generally defined as the use of

nanomaterials whose nanoscale structures range from 1 to 100 nm.

The use of nanotechnology has extended to the food sector, which

mainly includesthe incorporation of specific types of nanomaterials

to respective food products to achieve the desired properties

(4). As an integral part of

research and development, nanotechnology involves the large-scale

manufacturing of agricultural feeds and food products, processed

foods, as well as high-quality food packaging materials to ensure

food safety worldwide (5). Several

researchers working in the field of nanotechnology have assured

consumers about the successful improvisation of the efficiency of

using nanomaterials in food safety by enhancing the efficacy of

food packaging, shelf-life and the nutritional value of the food,

without altering the original taste and physical characteristics of

foods. The main aim of nano-techniques is to produce innovative

food formulations and novel nanofoods which are non-toxic for human

consumption; however, the implementation of cost-effective methods

composed in nanotechnology is a main drawback of this technology.

Hence, there is an urgent need to create alarming concerns

pertaining to the development of safe, non-toxic, biocompatible

nanostructures from food grade ingredients using biological means,

and cost-effective and simple strategies. The field of

nanotechnology may pave the way to the development of innovative,

quality food products, hence possessing a major application in the

food industry (6).

3. Food processing

In general, food processing was defined as the

culture of developing, manufacturing, handling and preserving food

by making use of traditional, innovative methods and technologies

to convert unstapled food to an edible form. The field of food

processing technology must include key aspects, such as

multi-technological industries, which are well-enriched with an

immense diversity of raw materials, well-regulated technological

processes and high biosafety needs (3). The conventional methods of food

processing techniques in practice include ohmic heating,

irradiation and high hydrostatic pressure. In order to meet the

consumer's requirements with approved food safety standards, a

number of challenges have to be resolved; mainly the management of

chemical toxins, and microbial hazards by disease-causing

microorganisms should always be noted. Since the beginning of the

century, the production of nano foods has become a part of food

processing with its main objectives being the advancement of food

safety, enhancing flavor and nutrition, and reducing costs, in

order for these foods to be accessible to all classes of the

population. Food processing requires nanotechnology in the

manufacturing of metal coatings of the machines used for

processing, food preservatives, additives, as well as in the

production of nanoencapsulated products to deliver food (7).

Nanofood processing actually begins from farming and

food preservation techniques and the process is completed in the

food packaging stage. In agricultural farming, nanoparticles are

used as fertilizers and pesticides, which alters the growth rate of

plants and positively affects the yield of crops. During the

post-harvest stage, the food storage and preservation techniques

involving nanomaterials have revolutionized the food industry, and

the final step in the food processing is food packaging; active

packaging using nanocarriers is the currently used packaging system

(8).

4. Nanomaterials used in food

processing

According to the EU Commission (Recommendation

2011/696/EU) ‘Nanomaterial means a natural, incidental or

manufactured material containing particles, in an unbound state or

as an aggregate or as an agglomerate and where, for 50% or more of

the particles in number size distribution, one or more external

dimensions is in the size range 1-100 nm’. WHO has reported that

material which has one or more dimensions in the nanoscale range is

termed as a nanomaterial, whereas if all the three dimensions are

in the nanoscale, it is then termed a nanoparticle. Different

nanoparticles exhibit different properties, such as surface, small

size, quantum size and quantum tunneling effects; these lead to the

different functions of nanoparticles (9).

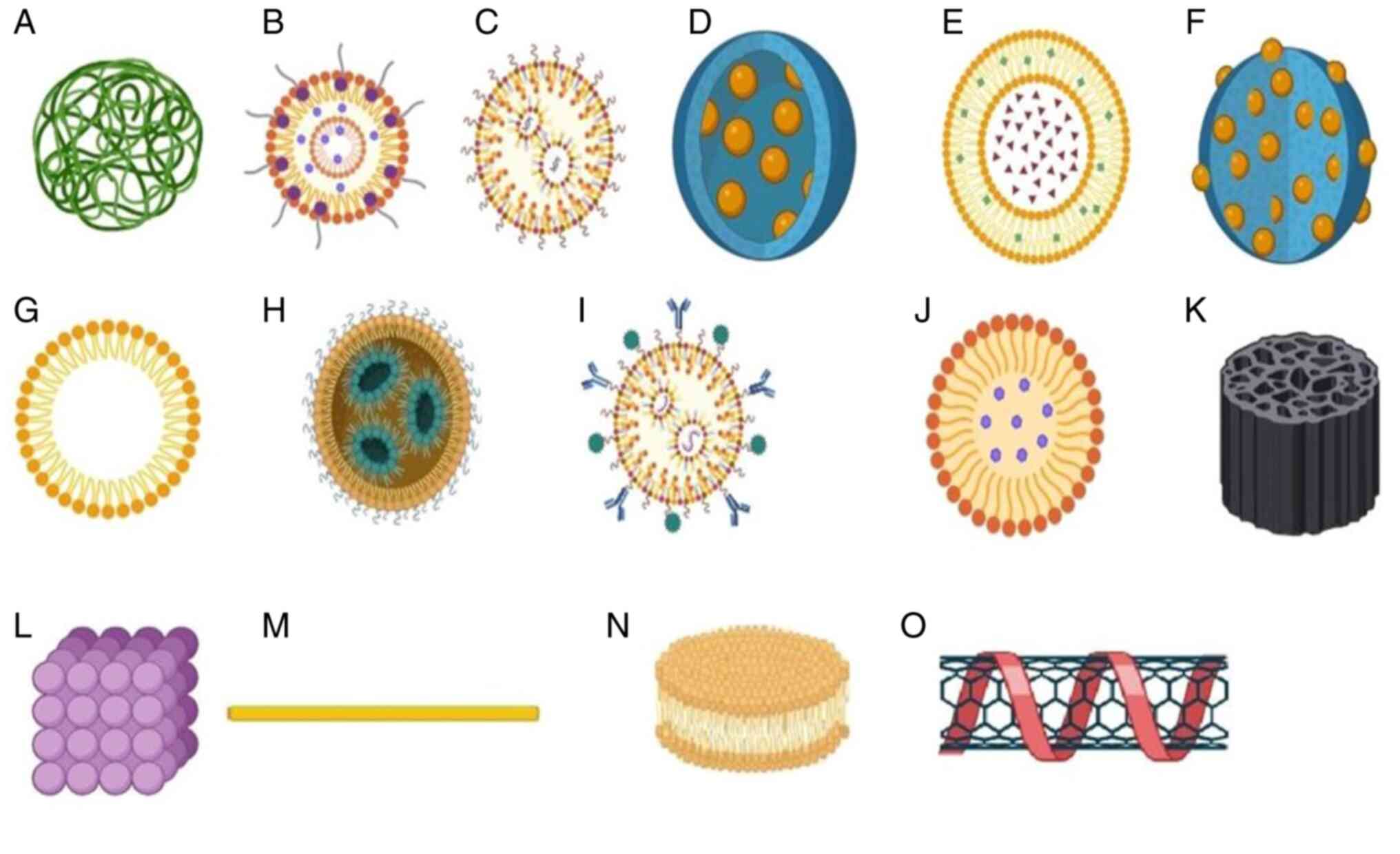

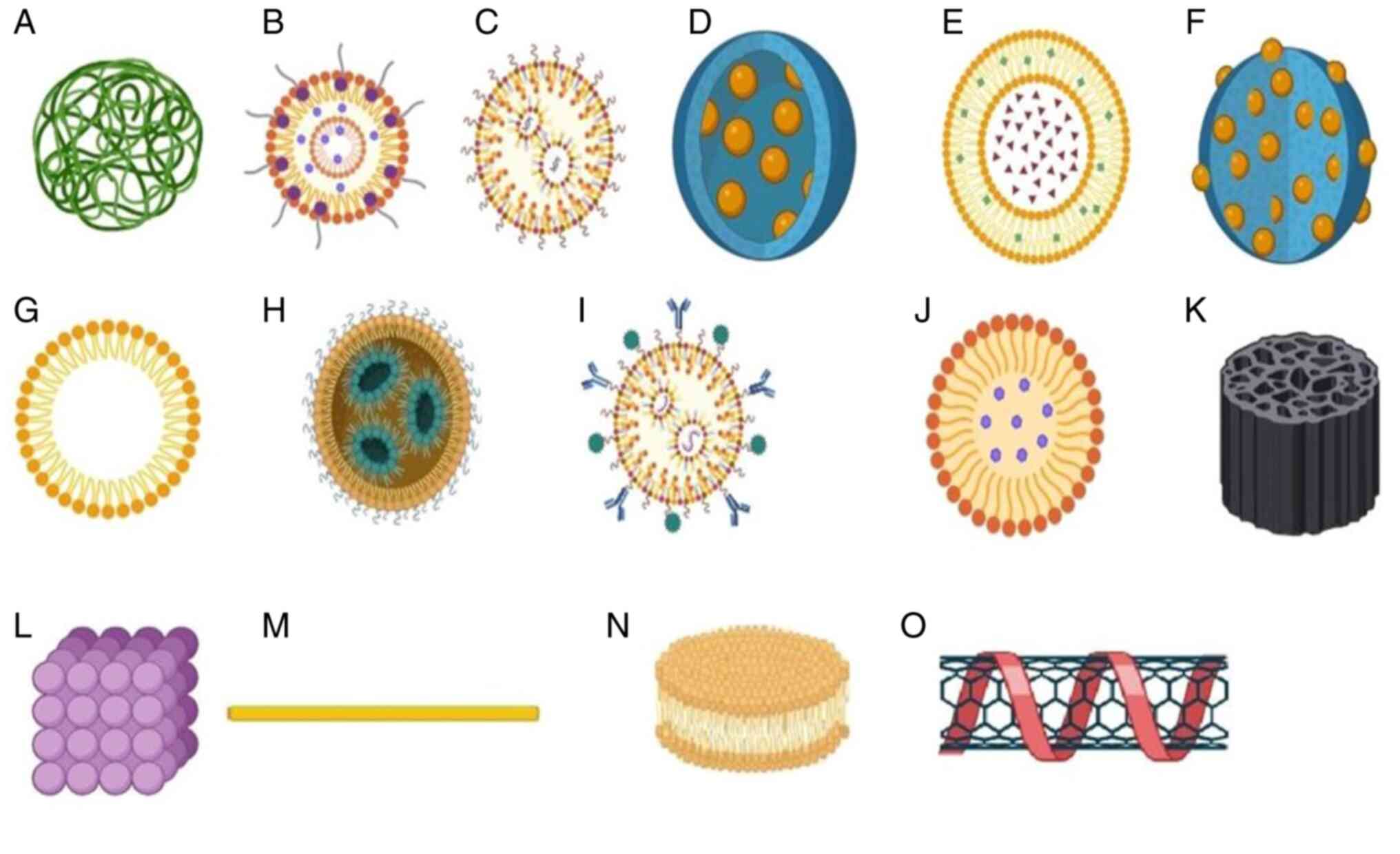

In order for nanoscaled substances to be used n the

food industry, they should have good encapsulation capacity and an

enhanced level of desired particles released to the target region.

Some routinely used nanoparticles include metallic nanoparticles,

polymeric micelles, liposomes nanoparticles, polymeric

nanoparticles, solid-core mesoporous nanoparticles, branched gold

nanoparticles, mesoporous nanoparticles, surface functionalized

nanoparticles, nanorods, porous silica nanoparticles, dendrimer and

carbon nanotubes (5); these are

illustrated in Fig. 1. On an

industrial scale, numerous technologies use nanoparticles to

increase the diversity of food-related applications, such as the

use of silver nanoparticles as antimicrobial agents in food

packaging, chopping boards and refrigerators. Zinc and zinc oxide

are used in food preservation as a nutritional enhancers and

antimicrobial agents. Silicon dioxide and carbon nanoparticles are

used as food additives (10).

Platinum and gold nanowires are used as biosensors to improve food

analysis. The nanoscaled ingredients used in the manufacturing of

food products share different properties to improve texture,

consistency and taste (11).

| Figure 1Nanoparticles used in food processing:

(A) Polymeric nanoparticle, (B) core shell-type hollow

lipid-polymer-lipid hybrid nanoparticle, (C) solid lipid

nanoparticle, (D) nanocapsulewith drug, (E) liposome with active

compound, (F) nanosphere, (G) liposome, (H) lipid nanoparticle, (I)

ligand-targeted lipid nanoparticle, (J) nanoemulsion, (K) porous

silicon nanoparticle, (L) nanocrystal, (M) gold nanowire, (N)

nanodiscand (O) carbon nanotube. |

The major applications of nanotechnology in food

engineering include nanosensing and designing nanostructured

ingredients. The developed nanosensing technology increases food

quality and safety evaluation, and nanostructured ingredients help

improve food processing (12). The

application of food processing techniques mainly involves the

appropriate delivery of nutrients, bio-separation of proteins, and

the rapid sampling of biological and chemical toxins (12).

The expansion of nanostructured food constituents in

the delivery of nutrients and supplements is the prime area of

interest in current nanotechnology discipline. This eminent

standard has become noticeable in the food processing industry,

which is promoting the development of a number of nanomicelles,

nanoemulsions, liposomes, biopolymeric nanoparticles and cubosome

nanoparticles to achieve successful food safety assurance (13). Nanocomposites in the form of novel

food, food or feed additives, biocides, pesticides and food contact

materials have a bright future in the field of food processing

(12).

5. Stages of food processing

The general methods of the food processing

technology include physical, chemical and biological methods.

Physical processing involves thermal processing the high

temperature short time (HTST) or long holding temperature (LHT)

concept, retorting, cold treatment and or drying) and non-thermal

processing (such as the use of radiation, specifically UV

radiation). Chemical and biological processing includes the use of

chemical preservatives or food additives and pH controlling and

fermentation (14). Upon

processing, food undergoes a variety of post-harvest and

processing-induced modifications that would affect the biological

and biochemical consistency of food. In this context,

nanotechnology developments in the fields of biology and

biochemistry could eventually take great stride in the food

industry to retain its molecular integrity. Often, the nanometer

length range could affect certain aspects from food safety to

molecular synthesis (15).

In general, nanofoods refer to food products that

use nanotechnological tools during their production and harvesting,

processing and packaging. Nanoparticles employed in food processing

industry are commonly distinguished as two forms of nanofoods based

on its route of application: i) Food additives (nanoinside); and

ii) food packaging (nano outside). Nanoscale food additive

substances are used to influence product shelf life, texture,

flavor and nutrient composition, or even detect food pathogens and

provide functions as food quality indicators. An incremental

nanotechnology involves the ability to use nanoscience to improve

the quality of materials by understanding and refining their

nanoscale structures, which improves food quality during its

processing (15).

In food processing, nanoparticle formation can

result in homogenization techniques at a high pressure or

ultrasonic emulsification, which are used in the production of

salad dressings, chocolate syrup, sweeteners, flavored oils and

numerous other foods (16).

However, there are certain ethical issues associated with the

acceptance of nanotechnology in the food system; for example,

various areas in Europe have questioned the incorporation of

traceable nano-chips in livestock (17).

6. Green synthesized nanoparticles in food

processing

Green synthesis is an eco-friendly, cost-effective

harmless approach, and these methods are more efficient than

physical and chemical means. Biological synthesis is still

considered as a more acceptable, cost-effective method of

synthesizing nanoparticles. Various parts of plants, such as roots,

fruits, stem, seeds and leaves and other parts, in addition to the

use of microorganisms (such as bacteria, yeasts, fungi and

actinomycetes) are used to synthesize nanoparticles. Green

synthesis is the most skillful, flexible, biologically apt and

feasible strategy for the synthesis of nanoparticles (16). Organic acids, proteins, vitamins

and secondary metabolites viz alkaloids, flavonoids, terpenoids,

polysaccharides are the key biomolecules for the formation of

divergent varieties of nanoparticles (18).

Some of the green synthesized nanoparticles used in

food processing, using the leaves of Protium serratum,

silver nanoparticles (AgNPs), have been synthesized, and have

exhibited distinct antibacterial activity against food borne

pathogens such as Pseudomonas aeruginosa, Escherichia

coli and Bacillus subtilis (19). Plant origin AgNPs have been used in

a number of consumables, food contact surfaces and food packaging.

They are antimicrobial, anti-odorant and health supplements.

Similarly, nano-iron also acts as a health supplement, and can be

used in the treatment of contaminated water (to break down organic

pollutants) and isknown to inactivate microbial pathogens (17).

The use of microbiologically produced metal oxide

nanoparticles, such as silicon dioxide (SiO2), magnesium

oxide (MgO) and titanium dioxide (TiO2) are permitted by

the US FDA as anti-caking agents, flavor carriers and food color

additives (20).

It is evident that green synthesized nanoparticles

play a vital role in the food processing industry compared with

physical and chemical based nanoparticles, as the biosynthesized

nanomaterials present certain advantages, such as: i) A decrease in

the use of hazardous materials, as employed in biological systems

such as capping, reducing and stabilizing agents; ii) the reduction

of energy resources and chemicals, as biosynthesis reactions

usually occur at a neutral pH, room temperature and pressure; iii)

the biocompatibility and low toxicity of the majority of

synthesized materials, due to surface functionalization (20).

7. Nanotechnology in food processing

The recent advent of nanotechnological approaches in

food processing has led to numerous advantages. For example, the

delivery of colors/additives/flavors using nanoemulsions in the

production of functional and adjunct foods. In addition, the

controlled release of food through nanoencapsulation and

nanodiagnostics (21). A schematic

representation of food processing using the nanotechnological

approach is presented in Fig.

2.

8. Implementation of nanotechnology in food

processing

The implementation of nanotechnology in food

processing involves various aspects, such as: i) Carrier materials

used in the manufacturing of coatings for food processing machines;

ii) nanostructures and nanocarriers applied in the nanodelivery of

food additives, preservatives, flavors, colors, taste enhancers and

antimicrobials.; iii) the nano-preservation of food; and iv)

nano-food packaging. Details of nanomaterials or nanocomposites

used in food processing are presented in Table I (20).

| Table INanotechnologies and nanomaterials

commonly used in food processing and their uses. |

Table I

Nanotechnologies and nanomaterials

commonly used in food processing and their uses.

| No. | Nanotechniques |

Nanomaterials/nanocomposites | Uses | (Refs.) |

|---|

| 1 |

Nanoencapsulation | Nanocapsules | Enhance the taste,

stability and bioavailability of food. Protect the food against

oxidation. Controlled release of food ingredients under pH and

moisture effect. | (13) |

| | | Nanoliposomes | Nanoliposomes have

been widely used in food industries for nutrient enrichment and

supplements. Deliver food additives, flavors, vitamins and enzymes.

Entrap unwanted components and odour of food. | (14) |

| | | Colloidosomes | For the easy

delivery of vitamins and minerals. | (15) |

| | | Nanocochleates | Protect the

antioxidants from degradation throughout the processing and storage

stages. | (16) |

| | | Archaeosome | Protect food from

particles from oxidation, enzymatic and chemical degradation. | (17) |

| | | Nanoceuticals | Improve the variety

and protection of food products. | (18) |

| 2 | Nanoemulsion | Nanoemulsions | Produce food

products for flavored oils, salads and sweeteners. | (19) |

| | | Carbohydrates and

proteins | Xanthan and guar

gum are used to help improve the texture of ice creams. | (20) |

| | | Brominated

vegetable oil, dammar gum, ester gum, sucrose-acetate,

isobutyrate | Used as a whitening

agent, reduces cream formation, also helps in dispersion and

availability of nutrients in food. | (20) |

9. Nanocarriers used in the delivery

system

Certain criteria should be followed for the proper

delivery of food, which include: i) The nanocomposite/nanomaterials

to be used in the delivery actions must have the ability to

accompany the desired material specifically to the target position

in the food system; ii) at a definite rate and definite time, the

nanomaterials must be available to reach the target food particle;

and iii) most notably, it is critical to maintain the compounds in

an active state at appropriate levels for extended phases of time

storage. The major nanodelivery systems used in practice are

nanoencapsulation and nanoemulsion (22).

10. Nanoencapsulation

The nanoencapsulation technique involves the

incorporation of food ingredients, antioxidants, vitamins, slimming

agents and enzymes with nanomeric size diameters. The

nanoencapsulates increase the bioavailability cargo and also

disguise unwanted tastes, colors and odors (23). Over the past few decades,

applications in the area of food have focused towards the safe and

controlled delivery of the nanoencapsulates. As regards the human

digestive system, for example, the aim is to provide protection for

encapsulated materials/nutraceuticals/probiotics against the

gastric environment of the colon. The nanoencapsulated materials

must satisfy the following criteria, where these materials have to

be sustained and retained in the human gastrointestinal tract (GIT)

and gradually release the desired products to the target. The

systemic understanding of the digestion process and physiological

conditions of the GIT are required for the designing of

nanoencapsulates. As this nanocarrier faces a turbulent environment

in the GIT, a smart design is crucial for the successful delivery

of encapsulate materials, which should consider the digestive

parameters, such as bile salt composition, electrolyte balance,

temperature, pH and mechanical stress to be counteracted in order

to achieve the controlled release of nanoencapsulated compounds in

the digestive tract (23).

Nanoencapsulation is the process of packing or

encapsulating the substances with several coating materials at

atomic, molecular and supramolecular level range from 1 to 100 nm.

The nanoencapsulated products provides functionality that includes

controlled and effective release of the healthy functional

bioactive ingredients in to the body cells. Different

nanotechnologies are implemented for the encapsulation of food

components, which protect from the rigors of food processing and

damaging environmental factors (24).

The nanoencapsulation technique enhances the

bioavailability of nutrients by shielding them during digestion and

are released gently into the body during the digestion process; it

also improves the solubility of poorly water-soluble compounds

(25).

For the production of mayonnaise, milk, sauces and

salad dressings, nanoemulsions are used. The texture of the

nanoemulsions allow them to present as a viscous cream at very low

concentrations and are used in low-fat foods. The nanoemulsion

technique is mostly centered on improving the bioavailability of

bioactive compounds, such as curcumin, and polyphenolic compounds

with anticancer, anti-inflammatory and antioxidant properties. The

use of nano-emulsions has been studied using liposomes, which

encapsulate lactoferrin to increase the shelf life of dairy

products and vitamin C. It has been observed that encapsulated

lactoferrin is active in liposomes for 50 days of refrigeration,

without losing vitamin activity in 19 days (26).

11. Materials used in nanoencapsulation

Nanoliposomes

Liposomes are minute sacs of phospholipids generally

used as nano-based carrier in the nanoencapsulation technique.

Nanoliposomes are well known to deliver essential compounds, such

as nutrients, nutraceuticals, vitamins, enzymes, additives and

antimicrobials (26). The

utilization of digestible lipids in nanodelivery systems enhances

the absorption rate of nutrients, since these lipids increase the

amount of mixed micelles to be dissolved and also transport

hydrophobic materials across the body (25).

Colloidosomes

Colloidosomes are hollow capsule-like structures

usually measuring in size <1/4th of a normal human cell. They

have been proven to function as efficient carriers of food

supplements within biological systems (27).

Nanocochleates

Nanocochleates stabilize and improve the quality of

processed food by wrapping the micronutrients to form nanocoils.

They are composed of soy-based phospholipids, which can be either

phosphatidylserine, phosphatidic acid or

di-oleoyl-phosphatidylglycerol etc. (3). Nanocochleatesincrease the efficiency

of cross-membrane diffusion for charged and impermeable molecules,

thus having numerous applications in nanoencapsulation. They also

possess resistance to degradation by gastrointestinal fluids, which

render them suitable for oral delivery (28).

Tocosomes

Colloidal bioactive phosphate-group-bearing alpha

tocopherols are known as tocosomes, which can also accommodate

sterols, proteins and polymers in their structure, such as

nanoliposomes (29). The main

purpose of using tocosomes in nanoemulsion is to enhance the

antioxidant activities of foods via the synergistic delivery of

tocopherols and ascorbic acid into the body, as well as to

stabilize minerals, such as calcium and iron, in milk and other

drinks (26).

12. Production technique of

encapsulation

In order to develop novel food products, it is

common to find strategies to supplement the functionality of the

desired food products. Naturally available compounds with high

biological activities are used to enrich the food products; these

nanofoods have to be non-hazardous to human health, this is the

most common strategy incorporated to achieve consumer's attention

towards food quality and safety. In this context, several types of

nanoencapsulation methods and nanocarrier systems have been devised

(14). These involve both

colloidal and non-colloidal systems.

Coacervation

The coacervation technique follows the deposition

and formation of the coacervation phase around the active food

substances by separating a single or poly electrolyte mixture

contained in the solution. This hydrocolloid shell may be

cross-linked using an appropriate chemical or enzymatic

cross-linker, such as glutaraldehyde or transglutaminase, with the

main intention of speeding up the process. According to the number

and types of polymers used in the process of coacervation, this can

be termed as either simple or complex coacervation. Due to the very

high payloads achievable (up to 99%) and the possibilities of

controlled release based on mechanical stress, temperature, or

sustained release,coacervation has its own notable application in

the field of nanotechnology (14).

Inclusion complexation

Inclusion complexation is a type of

nanoencapsulation, which is associated with the encapsulation of a

supramolecular association of a ligand into a cavity containing

shell-like substrate formed through hydrogen bonding and least

vander Waals forces of attraction. The encapsulation of highly

volatile organic molecules, such as essential oils and vitamins

follows the inclusion of complexation process; it often also helps

to conceal odors and flavors and preserve good aromas. Compared

with other techniques, this has the highest encapsulation

efficiency with higher stability of the core component; however,

the drawback of this technique is that it only encapsulates a few

particular molecular compounds, such as ß-cyclodextrin and

ß-lactoglobulin (30).

Nanoprecipitation

The nanoprecipitation method is also known as

solvent displacement. It is based on the spontaneous emulsification

of the organic internal phase containing the dissolved polymer,

drug and organic solvent into the aqueous external phase. The

nanoprecipitation technique involves the precipitation of a polymer

from an organic solution and the diffusion of the organic solvent

in the aqueous medium. The solvent displacement forms both

nanocapsules and nanospheres. Biodegradable polymers are commonly

used, particularly polycaprolactone, polylactide and poly

(lactide-co-glicolide), eudragit and polyalkylcyanoacrylate

(31).

Extrusion techniques

The extrusion technique involves a combination of

several major operational units, including the mixing, cooking,

kneading, shearing, shaping and forming of food, which finally

mixes the polymer and bioactive substances into the gelling

solution using a dripping tool. After a particular set of time, the

gelling solutions become hardened and are collected in the form of

beads (32). The types of

extrusion technique include the following: i) Spinning disk

atomization; ii) jet-cutting; iii) vibrating jet/nozzle extrusion;

iv) electrostatic extrusion; and v) coaxial air-flow extrusion

(33).

Molecular inclusion

The molecular inclusion technique employs

cyclodextrin molecules as a bioactive coating material (34). Among the numerous advantages of the

molecular inclusion technique by employing cyclodextrins, the most

notable are that it enhances the solubility of poorly water-soluble

molecules and also increases their bioavailability.

13. Nanoencapsulated food additives

Conventional methods of food preservation techniques

employ hazardous chemical substances that, upon degradation,

undergo cross reactions and certain biochemical changes, resulting

in sulfite allergies, nitrate toxicity and neurological damage. In

addition, uncontrollable processes are initiated inside the food

matrix following the addition of conventional preservatives

(35). In such problematic

situations, the replacement of such toxic preservatives with new

advent nanoencapsulated food additives prevents such undesirable

changes occurring in food material. The nanocarriers protect the

food from thermal degradation and also disguise the flavors of

peculiar food additives. Lycopene, citric acid, ascorbic acid,

benzoic acid, omega-3 and omega-6 fatty acids, fat-soluble vitamins

A and E, iso flavones, lutein, and β-carotene are the commercially

available nanoencapsulated food additives listed (36).

14. Nanoemulsion

Nanoemulsions are one of the most notable delivery

systems, with a vast number of applications and advantages in the

food industry (37,38). Nanoemulsions are the emulsions

formed of very small sized particles with an increased surface

area. These emulsions are least sensitive to physical and chemical

changes, and are thermodynamically unstable due to its positive

interfacial tension between oil and water phases (39); all these qualities render them

ideal formulas for use in the food industry. Among the basic

emulsion compositions, food grade nanoemulsions are widely used in

the market commercially due to their highly improved digestibility,

efficient encapsulation, increased bioavailability and proper

delivery of targeted food ingredients. The aforementioned

advantages of nanoemulsions over conventional emulsions have

increased the utility of this process in the food industry

(37). In order to enhance the

delivery of vitamins, fragile micronutrients and medicines,

currently, small edible capsules coated with nanoparticles are used

in daily foods to provide beneficial health effects (39).

15. Applications of nanoparticles in food

processing technology

In the recent past, nanotechnological applications

have gained tremendous scope, particularly for improving the

properties of packaging/container capacity, the barrier against the

flow of gasses and light. Thus, the use of smart sensors has been

found to be beneficial to consumers and leads to the rapid

identification, producer distribution, and authentication of food

products (40).

Due to nano-adhesive properties, nanoparticles can

bind to harmful matters in the gastrointestinal GIT and remove them

effectively. Pure silver colloid liquid, reduced to a size of 1 nm

with atomic particles, has been found to be highly bactericidal and

can inactivate 99.9% of 650 species of microorganisms within 6 min,

when compared to antibiotics which can be effective against only

five to sixspecies (15). This new

technology platform has provided food quality assurance by

detecting Escherichia coli in food samples by measuring and

detecting light scattering by the cells. This sensor functions

based on the principle that a protein of a known and characterized

bacterium set on a silicon chip can bind with specific bacteria

present in the food sample. The binding process will result in a

nano-sized light scattering, which is detectable by the analysis of

digital images (18).

Nanotechnology is widely used in the production of

healthier foods, which lack or contain low levels of fat, sugar and

salt to avoid food-borne diseases, out of which the nanoparticles,

SiO2 and TiO2, have been reported to be used

as food additives in bulk quantities. Biodegradable

poly-D,L-lactide is a quercetin used for bioencapsulation in order

to increase the life of tomatoes, and this approach should perhaps

extend the shelf life of other fruits and vegetables as well. Other

commercialized nanotechnology-based products in the market are

nanogreen tea, Neosino capsules as dietary supplements, canola

active oil, Aquanova Used as micelles to enhance the solubility of

vitamins (A, C, D, E and K), β-carotene, omega fatty acids and

nutralease as fortifying nanocarriers to carry nutraceuticals and

drugs (41). In line with this, in

the USA, Australia, China and Japan the widely sold nano-processed

foods in the market are fortified fruit juices, oat nutritional

drinks, nanoteas, nanocapsules containing tuna fish oil in breads

and nanoceuticals slim shakes (41).

16. Role of nanotechnology in food safety

and security

Worldwide, a number of food manufacturing industries

are searching for various methodologies which can be used to

improve the quality, safety, competence and nutritional properties

of food (42). The application of

nanotechnology in food safety follows the use of nanoparticles in

order to develop nanosensors. The nanosensors are formed to detect

spoilage-causing microorganisms and other food contaminants in the

food system. Durán and Marcato (43) reported that biosensors have been

designed to detect most common food pathogens, such as Listeria

monocytogenes, Escherichia coli and Salmonella

sp. as well as mycotoxins in food. Magnetic nanogoldimmune sensor,

is the nanosensor designed to detect the most common type of

mycotoxin termed aflatoxin produced by Aspergillus flavus

and Aspergillus parasiticus, which contaminate numerous

foods (44).

17. Nanotechnology-associated health hazards

in food processing

The nanoemulsion technique has achieved worldwide

application due to various advantages; however, it also has certain

drawbacks, such as instances where consumers have to pay the cost

for physical ailments, such as the presence of toxic compounds.

Several nano-compounds are known to cause cellular damage to

biological systems by binding to the receptors of immune cells and

confounding them (45). The

potential risks associated with meat processing, require the use of

a number of tests to be detected, such as skin toxicity, oral

toxicity, oxidative stress, genotoxicity, cytotoxicity and other

acute and chronic issues. The nanoscale materials used in food

processing also meet production costs, and are complicated

methodologies used in synthesis and stability (46). One can reduce the burden of health

hazard risks in nanomaterial-assisted food processing by

disinfecting equipment and production rooms by using an alkaline

solution of 1.5% sodium hydroxide, by using surface biocides for

surface sterilization, by wearing protective clothing and by

incorporating high-efficiency water and air filters (47).

18. Conclusion and future perspectives

Nanotechnology is one of the most notable

technologies involved in manufacturing. Nanomaterials are minute

particles ranging from 1 to 100 nm in size, and are used for

various purposes; they play a primary role in food and agriculture

sectors, particularly in crop development, food quality enhancement

and safety, and thus promote human health through novel and

innovative approaches. Nanotechnology with its applications in

advanced processing, packaging and long-term storage, provides vast

growth opportunities to the food industry through the enhancement

of food quality by improving its flavor and texture. Nanomaterials

incorporated in nanosensors help consumers by providing the inner

status of food and its nutritional status with enhanced security,

in addition to pathogen detection. The majority of foods that are

bioactive against various diseases are hydrophobic in nature, with

the least bioavailability and stability; hence,

nanotechnology-based delivery systems provide the enhanced

bioavailability and targeted delivery of food bioactive

compounds.

Nanotechnology-based foods are associated with

significant challenges to both governments and industries, ensuring

gaining consumer confidence and acceptance and, thus, availability

in the market. Furthermore, the effective application of

nanocolloidal particles in various sectors in the food industry,

such as food quality, safety, nutrition, processing and packaging

has been widely reported in recent days.

Nanoparticles are produced worldwide; however, only

a limited number of countries have the standard regulatory rules

and regulation policies for the implementation of nanotechnology in

food products. The lack of sufficient scientific information about

nanosystems and nanotechnology creates hurdles in arriving at any

conclusions regarding their efficacy. Appropriate labeling and

regulations are required for the marketing of nanofoods, which can

help to increase consumer acceptability. In this context, the

utilization of these nanotechnologies, particularly green

nanotechnological approaches, if managed and regulated efficiently,

can play a crucial role in improving food processing and product

quality; this may benefit human health and the well-being of

humans, animals and an ecosystem for a better tomorrow.

Acknowledgements

Not applicable.

Funding

Funding: No funding was received.

Availability of data and materials

Not applicable.

Authors'contributions

DG conceived the study and was also involved in the

editing, reviewing and revising of the manuscript, and also

communicated the manuscript to the journal. RS and CSP drafted the

manuscript, obtained the data acquired for the review and processed

the figures. All three authors have read and approved the final

manuscript. Data authentication is not applicable.

Ethics approval and consent to

participate

Not applicable.

Patient consent for publication

Not applicable.

Competing interests

The authors declare that they have no competing

interests.

References

|

1

|

Krishnakumar TS, Sheeba A, Mahesh V and

Prakash MJ: Heat transfer studies on ethylene glycol/water

nanofluid containing TiO2 nanoparticles. Int J Refrig. 102:55–61.

2019.

|

|

2

|

Khorasani S, Danaei M and Mozafari MR:

Nanoliposome technology for the food and nutraceutical industries.

Trends Food Sci Technol. 79:106–115. 2018.

|

|

3

|

Kadam DM and Kaur A: Novel approaches of

nanotechnology in agro and food processing. In: Handbook of

Nanomaterials for Industrial Applications. Hussain CM (ed). 1st

edition. Elsevier, pp271-291, 2018. eBook ISBN: 9780128133521.

|

|

4

|

Abeer Mohammed AB, Al-Saman MA and Tayel

AA: Antibacterial activity of fusion from biosynthesized

acidocin/silver nanoparticles and its application for eggshell

decontamination. J Basic Microbiol. 57:744–751. 2017.PubMed/NCBI View Article : Google Scholar

|

|

5

|

Shafiq M, Anjum S, Hano C, Anjum I and

Abbasi BH: An overview of the applications of nanomaterials and

nanodevices in the food industry. Foods. 9(148)2020.PubMed/NCBI View Article : Google Scholar

|

|

6

|

Ozimek L, Pospiech E and Narine S:

Nanotechnologies in food and meat processing. Acta Sci Pol Technol

Aliment. 4:401–412. 2010.

|

|

7

|

Kumar LY: Role and adverse effects of

nanomaterials in food technology. J Toxicol Health. 2(2)2015.

|

|

8

|

Sekhon BS: Nanotechnology in agri-food

production: An overview. Nanotechnol Sci Appl. 7:31–53.

2014.PubMed/NCBI View Article : Google Scholar

|

|

9

|

Catauro M, Bollino F, Papale F, Gallicchio

M and Pacifico S: Influence of the polymer amount on bioactivity

and biocompatibility of SiO2/PEG hybrid materials synthesized by

sol-gel technique. Mater Sci Eng C Mater Biol Appl. 48:548–555.

2015.PubMed/NCBI View Article : Google Scholar

|

|

10

|

Abdelmonem AM: Application of carbon-based

nanomaterials in food preservation area. In Carbon Nanomaterials

for Agri-Food and Environmental Applications. Elsevier, pp583-593,

2019.

|

|

11

|

Jafarzadeh S, Salehabadi A and Jafari SM:

Metal nanoparticles as antimicrobial agents in food packaging. In:

Handbook of Food Nanotechnology. Elsevier, Netherlands, pp379-415,

2020.

|

|

12

|

Kumar H, Bhardwaj K, Nepovimova E, Kuča K,

Dhanjal DS, Bhardwaj S, Bhatia SK, Verma R and Kumar D: Antioxidant

functionalized nanoparticles: A combat against oxidative stress.

Nanomaterials (Basel). 10(1334)2020.PubMed/NCBI View Article : Google Scholar

|

|

13

|

Kalpana VN and Rajeswari VD: Biosynthesis

of metal and metal oxide nanoparticles for food packaging and

preservation: A green expertise. In: Food Biosynthesis. Academic

Press, pp293-316, 2017.

|

|

14

|

Amit SK, Uddin MM, Rahman R, Islam SR and

Khan MS: A review on mechanisms and commercial aspects of food

preservation and processing. Agric Food Secur. 6(51)2017.

|

|

15

|

Ravichandran R: Nanotechnology

applications in food and food processing: Innovative green

approaches, opportunities and uncertainties for global market. Int

J Green Nanotechnol: Phys Chem. 1:72–96. 2010.

|

|

16

|

Jassal PS, Kaur D, Prasad R and Singh J:

Green synthesis of titanium dioxide nanoparticles: Development and

applications. J Agric Food Res. 10(100361)2022.

|

|

17

|

Kumar P, Mahajan P, Kaur R and Gautam S:

Nanotechnology and its challenges in the food sector: A review.

Mater Today Chem. 17(100332)2020.PubMed/NCBI View Article : Google Scholar

|

|

18

|

Carrillo-Inungaray ML, Trejo-Ramirez JA,

Reyes-Munguia A and Carranza-Alvarez C: Use of nanoparticles in the

food industry: Advances and perspectives. Impact of nanoscience in

the food industry. Academic Press; Cambridge, MA, USA, pp419-444,

2018.

|

|

19

|

Prakash J, Vignesh K, Anusuya T, Kalaivani

T, Ramachandran C, Sudha RR, Momna R, Imran K, Fazle E, Deog-Hwan O

and Devanand Venkatasubbu G: Application of nanoparticles in food

preservation and food processing. J Food Hyg Saf. 34:317–324.

2019.

|

|

20

|

Ingle AP, Philippini R, Martiniano SE,

Antunes FAF, Rocha TM and da Silva SS: Application of

microbial-synthesized nanoparticles in food industries. Microbial

Nanobiotechnology: Principles and Applications. Springer Singapore,

pp399-424, 2021.

|

|

21

|

Li G, Zhang Z, Liu H and Hu L:

Nanoemulsion-based delivery approaches for nutraceuticals:

Fabrication, application, characterization, biological fate,

potential toxicity and future trends. Food Funct. 12:1933–1953.

2021.PubMed/NCBI View Article : Google Scholar

|

|

22

|

Zambrano-Zaragoza ML, Quintanar-Guerrero D

and González-Reza RM: Nanocontainers in food preservation:

Techniques and uses. Smart Nanocontainers. Elsevier, pp137-155,

2020.

|

|

23

|

Jafari SM: An overview of

nanoencapsulation techniques and their classification. In: Jafari

SM (ed). Nanoencapsulation technologies for the food and

nutraceutical industries. Academic Press, Cambridge, pp1-34,

2017.

|

|

24

|

Awuchi CG, Morya S, Dendegh TA, Okpala COR

and Korzeniowska M: Nanoencapsulation of food bioactive

constituents and its associated processes: A revisit. Bioresour

Technol Rep. 19(101088)2022.

|

|

25

|

Zarrabi A, Alipoor Amro Abadi M, Khorasani

S, Mohammadabadi MR, Jamshidi A, Torkaman S, Taghavi E, Mozafari MR

and Rasti B: Nanoliposomes and Tocosomes as multifunctional

nanocarriers for the encapsulation of nutraceutical and dietary

molecules. Molecules. 25(638)2020.PubMed/NCBI View Article : Google Scholar

|

|

26

|

Hussain I, Singh NB, Singh A, Singh H and

Singh SC: Green synthesis of nanoparticles and its potential

application. Biotechnol Lett. 38:545–560. 2016.PubMed/NCBI View Article : Google Scholar

|

|

27

|

Thompson KL, Williams M and Armes SP:

Colloidosomes: Synthesis, properties and applications. J Colloid

Interface Sci. 447:217–228. 2015.PubMed/NCBI View Article : Google Scholar

|

|

28

|

Lasekan O, Ng S, Teoh L, Azeez S and Gie

ML: Current trends in nano encapsulation of flavours and aromas. J

Food Bioeng Nanoprocessing. 1:1–3. 2016.

|

|

29

|

Shahgholian N: Encapsulation and delivery

of nutraceuticals and bioactive compounds by nanoliposomes and

tocosomes as promising nanocarriers. Handbook of Natural Products:

Biological, Medicinal, and Nutritional Properties and Applications.

Vol. 1. Wiley: Hoboken, NJ, pp403-439, 2022.

|

|

30

|

Cid-Samamed A, Rakmai J, Mejuto JC,

Simal-Gandara J and Astray G: Cyclodextrins inclusion complex:

Preparation methods, analytical techniques and food industry

applications. Food Chem. 384(132467)2022.PubMed/NCBI View Article : Google Scholar

|

|

31

|

Hitanga J, Sharma N, Chopra H and Kumar S:

Nanoprecipitation technique employed for the development of

nano-suspension: A review. WJPPS. 4:2127–2136. 2015.

|

|

32

|

Roos YH and Livney YD (eds): Engineering

foods for bioactives stability and delivery. New York, USA:

Springer, pp1-423, 2017.

|

|

33

|

Zuidam NJ and Shimoni E: Overview of

microencapsulates for use in food products or processes and methods

to make them. In: Zuidam N, Nedovic V (eds). Encapsulation

Technologies for Active Food Ingredients and Food Processing.

Springer, New York, NY, pp3-29, 2010.

|

|

34

|

dos Santos C, Buera P and Mazzobre F:

Novel trends in cyclodextrins encapsulation. Applications in food

science. Curr Opin Food Sci. 16:106–113. 2017.

|

|

35

|

Anand SP and Sati N: Artificial

preservatives and their harmful effects looking toward nature for

safer alternatives. Int J Pharm Sci Res. 4:2496–2501. 2013.

|

|

36

|

Zanetti M, Carniel TK, Dalcanton F, dos

Anjos RS, Gracher Riella H, de Araújo PHH, de Oliveira D and

Antônio Fiori M: Use of encapsulated natural compounds as

antimicrobial additives in food packaging: A brief review. Trends

Food Sci Technol. 81:51–60. 2018.

|

|

37

|

Salem MA and Ezzat SM: Nanoemulsions in

food industry. Some New Aspects Colloid Syst Foods. 2:238–267.

2019.

|

|

38

|

Borthakur P, Boruah PK, Sharma B and Das

MR: Nanoemulsion: Preparation and its application in food industry.

In: Emulsions. Academic Press, pp153-191, 2016.

|

|

39

|

Prakash A, Baskaran R, Paramasivam N and

Vadivel V: Essential oil based nanoemulsions to improve the

microbial quality of minimally processed fruits and vegetables: A

review. Food Res Int. 111:509–523. 2018.PubMed/NCBI View Article : Google Scholar

|

|

40

|

Luo Z, Xu Y and Ye Q: Effect of

nano-SiO2-LDPE packaging on biochemical, sensory, and

microbiological quality of Pacific white shrimp Penaeus vannamei

during chilled storag. Fish Sci. 81:983–993. 2015.

|

|

41

|

Nile SH, Baskar V, Selvaraj D, Nile A,

Xiao J and Kai G: Nanotechnologies in food science: Applications,

recent trends, and future perspectives. Nanomicro Lett.

12(45)2020.PubMed/NCBI View Article : Google Scholar

|

|

42

|

Neme K, Nafady A, Uddin S and Tola YB:

Application of nanotechnology in agriculture, postharvest loss

reduction and food processing: Food security implication and

challenges. Heliyon. 7(e08539)2021.PubMed/NCBI View Article : Google Scholar

|

|

43

|

Durán N and Marcato PD: Nanobiotechnology

perspectives. Role of nanotechnology in the food industry: A

review. Int J Food Sci Technol. 48:1127–1134. 2013.

|

|

44

|

Berekaa MM: Nanotechnology in food

industry; advances in food processing, packaging and food safety.

Int J Curr Microbiol App Sci. 4:345–357. 2015.

|

|

45

|

Pradhan N, Singh S, Ojha N, Shrivastava A,

Barla A, Rai V and Bose S: Facets of nanotechnology as seen in food

processing, packaging, and preservation industry. Biomed Res Int.

2015(365672)2015.PubMed/NCBI View Article : Google Scholar

|

|

46

|

Ramachandraiah K, Han SG and Chin KB:

Nanotechnology in meat processing and packaging: Potential

applications-a review. Asian-Australas J Anim Sci. 28:290–302.

2015.PubMed/NCBI View Article : Google Scholar

|

|

47

|

King T, Osmond-McLeod MJ and Duffy LL:

Nanotechnology in the food sector and potential applications for

the poultry industry. Trends Food Sci Technol. 72:62–73. 2018.

|