Introduction

Anterior cruciate ligament (ACL) ruptures are

frequently encountered in clinical practice, and can lead to the

dysfunction of injured joints, increased risk of subsequent injury

of the meniscus and cartilage and even increased risk of early

osteoarthritis (1–4). Due to the lack of blood supply, ACL

ruptures cannot heal independently, and therefore surgical

reconstruction or replacement is necessary (5,6).

Autologous grafts, including quadricep, patellar and hamstring

tendon grafts and iliotibial bands or tracts, are commonly used in

intra-articular replacements of ACL (2,7–9).

However, certain well-recognized drawbacks, including delayed

recovery of the intra-articular donor site, pain in the anterior

part of the knee, reduced strength of the tendon at the harvesting

site, and lengthy surgery required for harvesting the grafts,

restrict the application of autografts (10,11).

Allografts are usually used in lower-demand patients or patients

who are undergoing revision ACL surgery if an ACL reconstruction

fails (12). However, these grafts

are of poor strength and carry a significant risk of disease

transmission (13,14).

In order to overcome such drawbacks, artificial

ligaments have been widely studied over the past 50 years and have

become a potential choice for reconstructing torn ACLs (15–17).

Various materials, including carbon fibers, nylon,

polytetrafluoroethylene (PTFE) and polyethylene terephthalate

(PET), have been employed and have contributed greatly to the

diffusion of artificial ligaments (15,18–20).

Among these materials, PET fibers are considered to be especially

adapted to fabricate artificial ligaments, due to their plasticity,

flexibility and high mechanical resistance to rupturing (21). However, due to the lack of

hydrophilicity, artificial ligaments made of PET fibers appear to

have lower biocompatibility, and therefore cannot integrate into

the surrounding host bone tissue, which can eventually lead to

rupturing of the artificial ligaments and reconstruction failure in

the long-term (21,22).

In this study, in order to improve the

biocompatibility of PET fibers, we modified them by using a

hydrophilic molecule, dimethylolpropionic acid (DMPA), which

contains 2 types of functional groups, 2 primary hydroxyl and 1

tertiary carboxyl group, which make polyesters particularly water

soluble. We postulated that the introduction of DMPA would increase

the biocompatibility of the PET fibers without comprising their

other characteristics, particularly the high mechanical strength.

In order to test this hypothesis, scanning electron microscopy

(SEM), Fourier transform infrared spectroscopy (FTIR), differential

scanning calorimetry (DSC), X-ray diffraction (XRD), mechanical

testing and cell culture were applied to investigate these

fibers.

Materials and methods

Modification of PET by DMPA

Briefly, the original PET fibers (Taiji Co., Ltd.,

Wuxi, China), 5 cm long × 22 μm in diameter, were immersed in a

solution of 2.5 mol/l sodium hydroxide (Sigma-Aldrich, Shanghai,

China) at a ratio of 1:10 (w/w) for 3 h at 50°C. The PET fibers

were then placed into a 75% (w/v) tolylene-2,4-diisocyanate (TDI;

Sigma-Aldrich)/acetone solution, which contained 0.25% (v/v)

dibutyltin dilaurate (DBTDL; Sigma-Aldrich), at a ratio of 1:10

(w/w) for 3 h at 50°C. The PET fibers were then transferred into a

36.5% (w/v) DMPA/acetone solution (Sigma-Aldrich), which contained

0.07% (v/v) fluorite boron (Zibo Shuanglian Petroleum and Chemical

Co., Ltd., Shandong, China) as an activator for 2 h at 20°C.

Finally, the DMPA-modified PET (DMPA-PET) fibers were washed with

distilled water, air-dried and sterilized by γ radiation at 15 kGy

for 6 h. The original PET fibers were also sterilized and used as

the control.

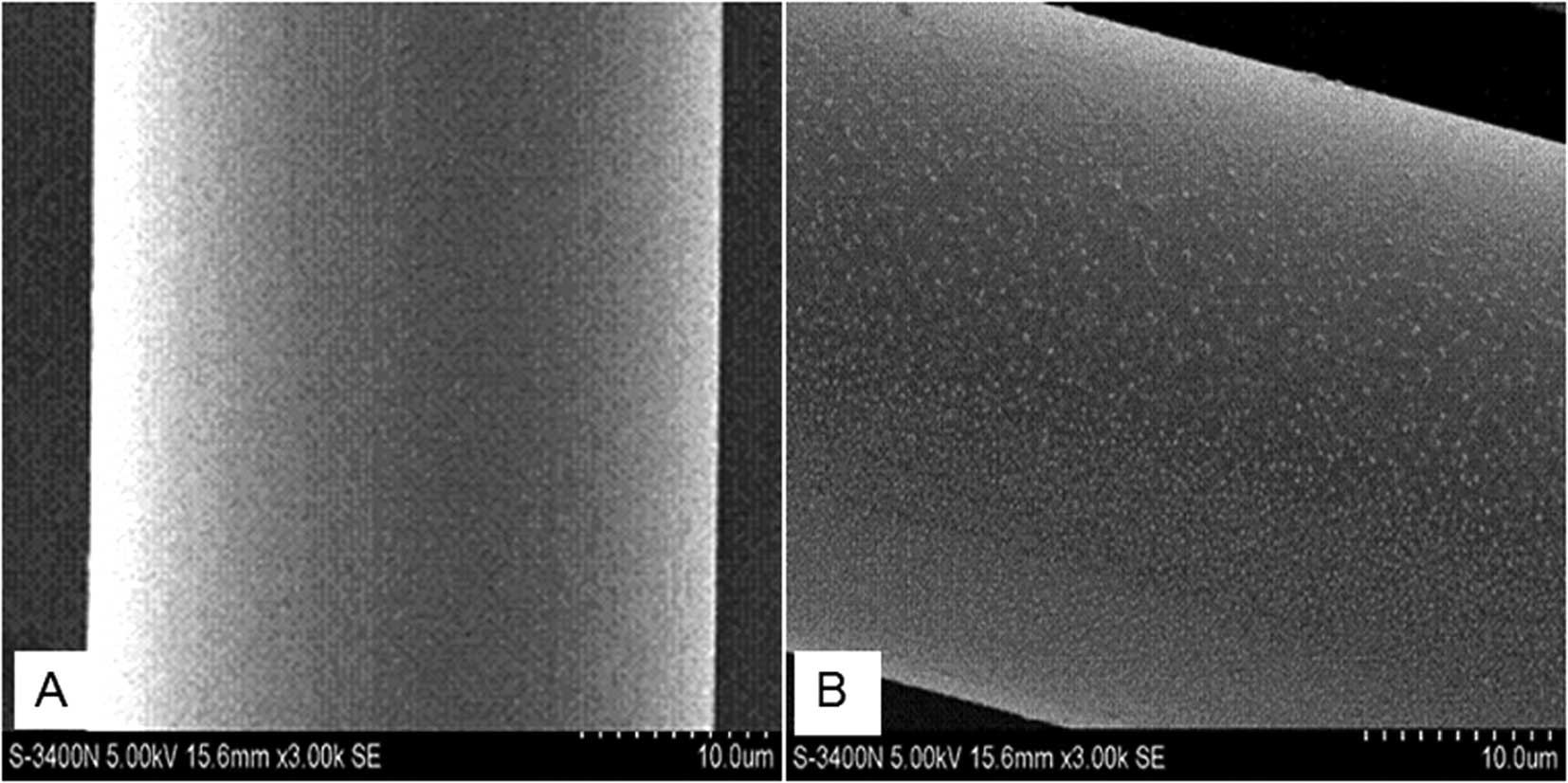

SEM observation

A total of 10 samples from the DMPA-PET and the PET

groups were fixed on stubs with carbon tape and sputter-coated with

gold in an ion coater. The surface characteristics of the samples

were studied under a vacuum using SEM (S-3400N, Hitachi, Osaka,

Japan) to analyze changes in the surface morphology.

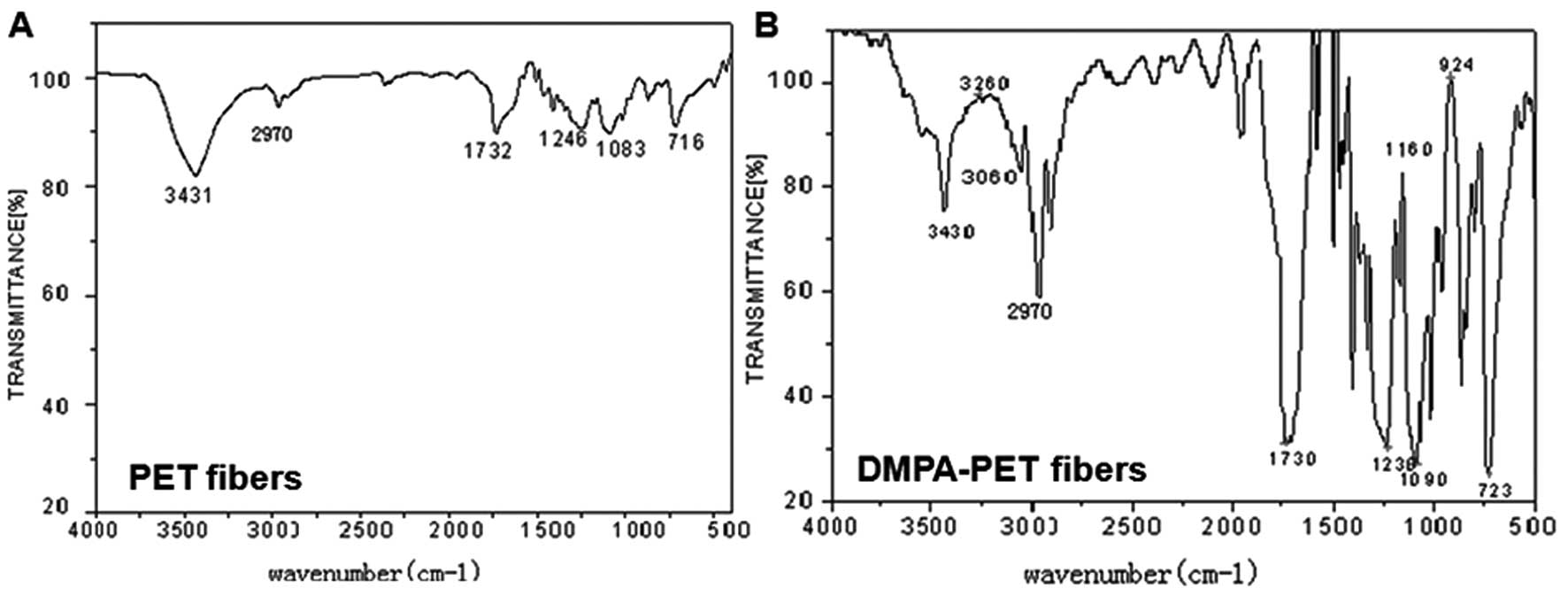

FTIR evaluation

A Fourier transform infrared spectrometer (IR-200

Thermo-Nicolet 2.2, Thermo-Nicolet corporation, Madison, WI, USA)

was used to detect the changes in the functional groups of the

DMPA-PET and PET fibers as previously described (23). Briefly, following appropriate

background subtraction, 2 mg of freeze-dried samples of each group

were mixed with dried potassium bromide, and the samples were

scanned from 4,000 to 400 cm−1 by the spectrometer. Each

spectrum reported is the average of at least three spectra measured

in different areas of the samples (n=10).

DSC evaluation

The thermal properties of DMPA-PET and PET were

analyzed by a differential scanning calorimeter (DSC-2041F;

Netzsch, Selb, Germany), which was equipped with an intra-cooler

and a refrigerated cooling system. Indium standard was used to

calibrate the DSC temperature and enthalpy scale. Nitrogen was used

to purge gas through the DSC cell at the flow rate of 50 ml/min

through the cooling unit. A total of 5 μg of samples from the 2

groups were hermetically sealed in an aluminium pan at a heating

rate of 20 K/min (n=10) (24).

Each examination was replicated three times.

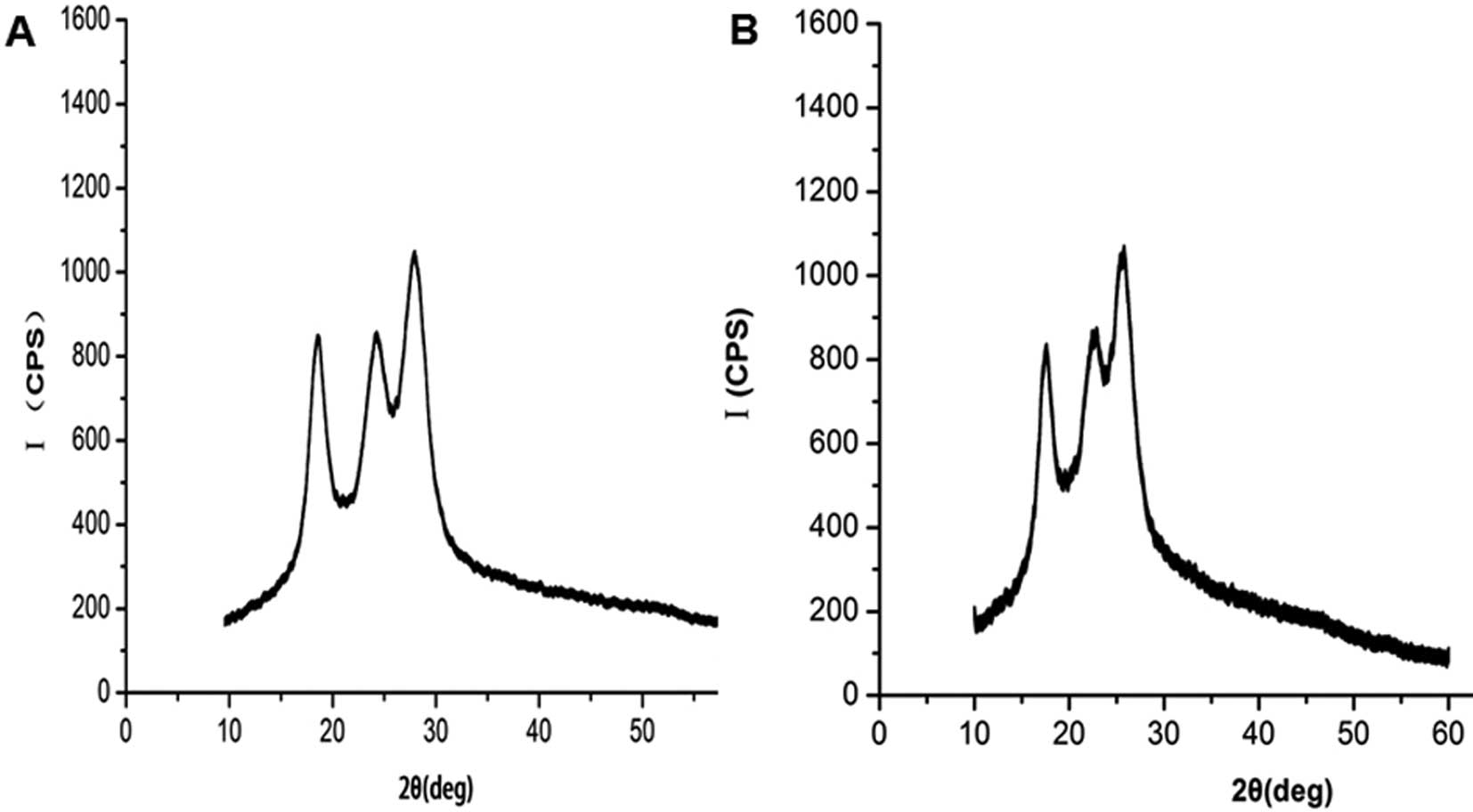

XRD evaluation

An X-ray diffractometer (XRD-6000, Shimazu, Japan)

was used to determine the crystalline phases of DMPA-PET and PET.

The generator working parameters were set at 40 kV and 30 mA to

create copper CuKα radiation (λ=1.542 Å). The scanning scope of 2θ

was 100-60° and the scanning rate was 2° per min. To obtain the

maximum diffraction intensity, the DMPA-PET and PET fibers were

prepared in a number of layers to obtain thick samples (total

thickness, 2 mm). This measurement was performed on at least ten

samples (24).

Mechanical testing

The tensile testing was performed by a materials

testing machine (Instron 5565; Instron, Norwood, MA, USA) with a

performance temperature of 20±2°C, a relative humidity of 65±5% and

a humidity controlling time of 4 h. The samples were fixed with a

nominal gauge length of 20 mm and a static pre-tension of 0.15±0.03

cN. The tensile testing was performed at a speed of 20 mm/min until

the testing fibers failed (n=10). The ultimate tensile strength,

tensile stress, elongation percentage at breakage and initial

modulus were determined as previously described (25).

Cytocompatibility evaluation

To determine the cytocompatibility of the 2 PET

fibers, bone marrow stromal cells (BMSCs) transfected with green

fluorescent protein (GFP) (Provided by Dr Lu from the Cell

Laboratory of the Affiliated Dental Hospital at the Fourth Military

Medical University, Xi'an, China) were seeded onto the 2 fibers at

a concentration of 2×10−6 cell/cm2 in

Dulbecco's modified Eagle's medium (DMEM, Sigma, St. Louis, MO,

USA) containing 10% fetal bovine serum (FBS; HyClone, Logan, UT,

USA) at 37°C. The adhesion and growth of the BMSCs on the fibers

were observed under an inverted phase-contrast fluorescence

microscope after 3 and 7 days. A PicoGreen double-stranded DNA

(dsDNA) Quantification kit (Molecular Probes, Eugene, OR, USA) was

used to determine the proliferation of the cells cultured in the

DMEM (10% FBS) with 20% leaching liquor of each type of fiber from

day 1 to 7. The total dsDNA was extracted through enzymatic

digestion and assayed following the manufacturer's instructions.

The proliferation of the cells in the scaffold was interpreted by

changes in the quantity of the dsDNA. The leaching liquors of the

fibers were prepared as previously described (26). Cells cultured in DMEM (10% FBS)

without any leaching liquor were used as the blank control

(n=10).

Statistical analysis

Statistical analyses were performed using SPSS

software version 14.0 (SPSS Inc., Chicago, IL, USA). The data are

presented as the means ± SD, and were compared using the

non-parametric Mann-Whitney U test or the Student's t-test.

P<0.05 was considered to indicate a statistically significant

difference.

Results

SEM observation

The SEM images demonstrate that the surface of the

original PET fibers was smooth without any deposits (Fig. 1A). By contrast, following

modification the surface of the DMPA-PET fibers became uneven, and

a number of granules, 300 to 500 nm in diameter, were found to be

deposited on the surface (Fig.

1B).

FTIR evaluation

The different infrared spectra of the PET and

DMPA-PET fibers were demonstrated by FTIR evaluation. The

characteristic peaks of PET appeared at 3,431 and 2,970, 1,732,

1,246, 1,083 and 716 cm−1, corresponding to the hydroxyl

(-OH), methyl (-CH3), carbonyl (C=O), and methanediyl

(-CH2-) groups, and ethers (C-O-C), respectively. By

contrast, a number of newly-formed absorption bands were found in

the spectrum of DMPA-PET at 3,400–3,500, 2,852–3,000 and

1,700–1,730 cm−1, which represented the newly-formed

peptide bonds (N-H), -OH and carboxy (-COOH) groups, respectively.

Furthermore, the greater absorption band at the 3,200

cm−1 area in the DMPA-PET group also confirmed the

increase in the hydrophilic -OH and -COOH groups (Fig. 2B).

DSC evaluation

DSC was used to characterize the thermophysical

properties of the fibers. In the PET group, the first sharp

endothermic peak was formed at 259.8±1.1°C, with a fusion enthalpy

of 39.5±0.5 J/g and a crystallinity of 28.2±1.5%. The second peak

formed at 254.1±1.2°C, with a fusion enthalpy of 28.0±0.5 J/g and a

crystallinity of 20.0±1.7%. Similarly, the first endothermic peak

of the DMPA-PET group was demonstrated at 258.1±1.2°C, with a

fusion enthalpy of 40.8±0.7 J/g and a crystallinity of 29.2±1.6%.

The second peak of DMPA-PET was formed at 253.0±1.4°C, with a

fusion enthalpy of 28.8±0.6 J/g and a crystallinity of 20.6±1.9%.

There were no significant differences in the endothermic peaks,

fusion enthalpies and crystallinity indices between the 2 groups

(P>0.05, n=10; Table I).

| Table IThermophysical properties of the PET

and DMPA-PET fibers (n=10). |

Table I

Thermophysical properties of the PET

and DMPA-PET fibers (n=10).

| Endothermic peak

(°C) | Fusion enthalpy

(J/g) | Crystallinity

(%) |

|---|

|

|

|

|

|---|

| Groups | 1st heating | 2nd heating | 1st heating | 2nd heating | 1st heating | 2nd heating |

|---|

| PET | 259.8±1.1 | 254.1±1.2 | 39.5±0.5 | 28.0±0.5 | 28.2±1.5 | 20.0±1.7 |

| DMPA-PET | 258.1±1.2 | 253.0±1.4 | 40.8±0.7 | 28.8±0.6 | 29.2±1.6 | 20.6±1.9 |

XRD evaluation

The XRD spectra recorded for the PET and the

DMPA-PET groups are shown in Fig.

3. The XRD pattern of the PET fibers demonstrated that the

original PET was mostly amorphous in nature with less

crystallinity. The tip of the amorphous halo of the original PET

was observed at 2θ=27.42±0.02° in the diffraction pattern as

demonstrated in the diffractogram (Fig. 3A). Only a small change was observed

in the the XRD pattern of the DMPA-PET samples compared with the

original one. The amorphous peak tip of the DMPA-PET samples was

found to be shifted slightly towards a lower angle (26.23±0.01°),

but the change was not significant (n=10, P<0.05; Fig. 3B).

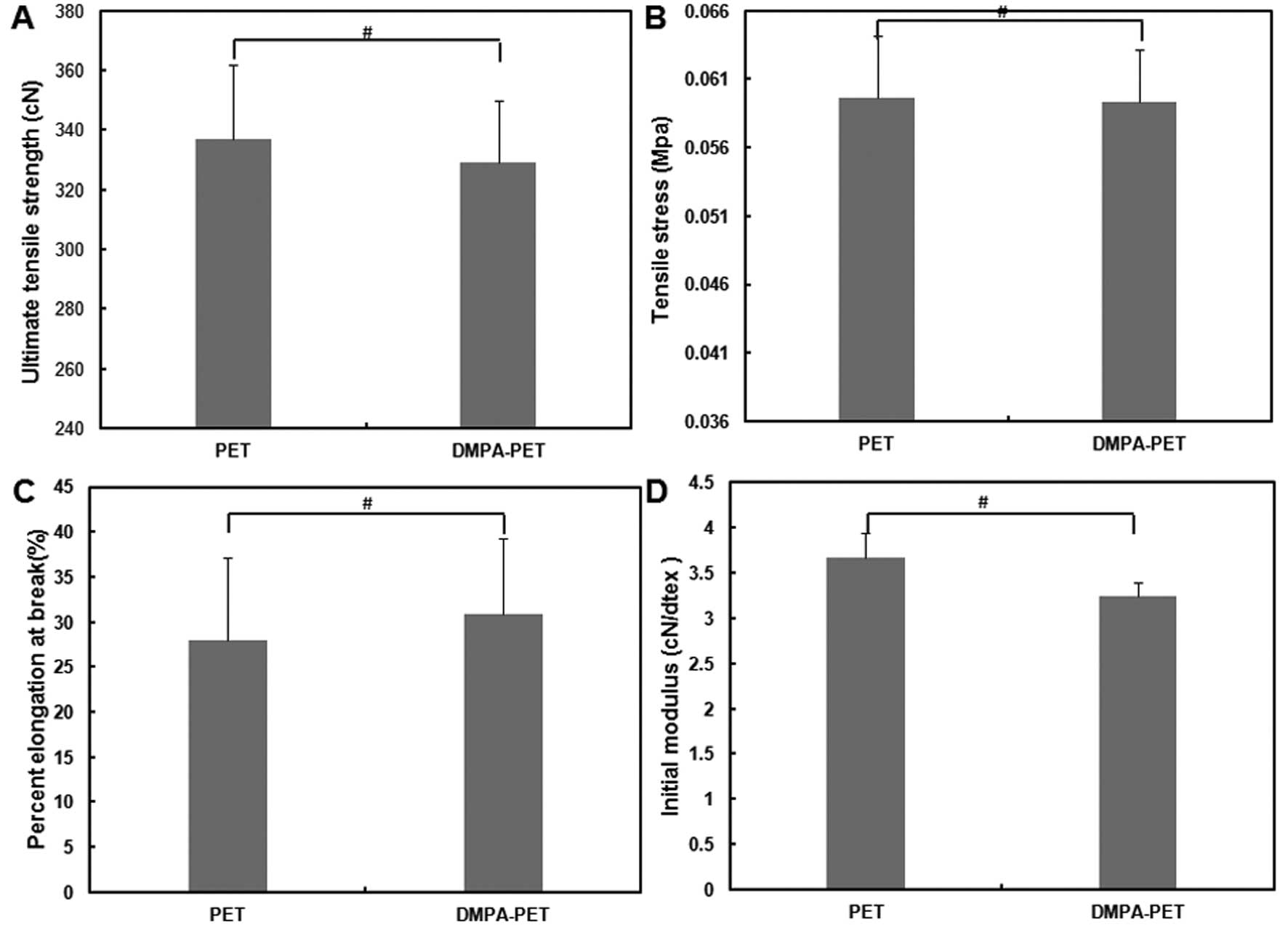

Mechanical testing

As shown in Fig. 4,

the ultimate tensile strength and tensile stress of the samples

from the DMPA-PET group were 329.2±20.62 cN and 0.05934±0.0038 MPa,

respectively, which were similar to those from the PET group

(336.8±25.15 cN and 0.05966±0.00445 MPa, respectively; n=10,

P>0.05; Fig. 4A and B).

Although the elongation percentage at breakage of the samples from

the DMPA-PET group (30.9±8.4%) was slightly higher than that from

the PET group (27.9±9.2%), there was no significant difference

between them (n=10, P>0.05; Fig.

4C). The initial modulus of the DMPA-PET group (3.234±0.1530

cN/dtex) was a little lower than that of the PET group

(3.661±0.2734 cN/dtex), but the difference was not significant

(n=10, P>0.05; Fig. 4D).

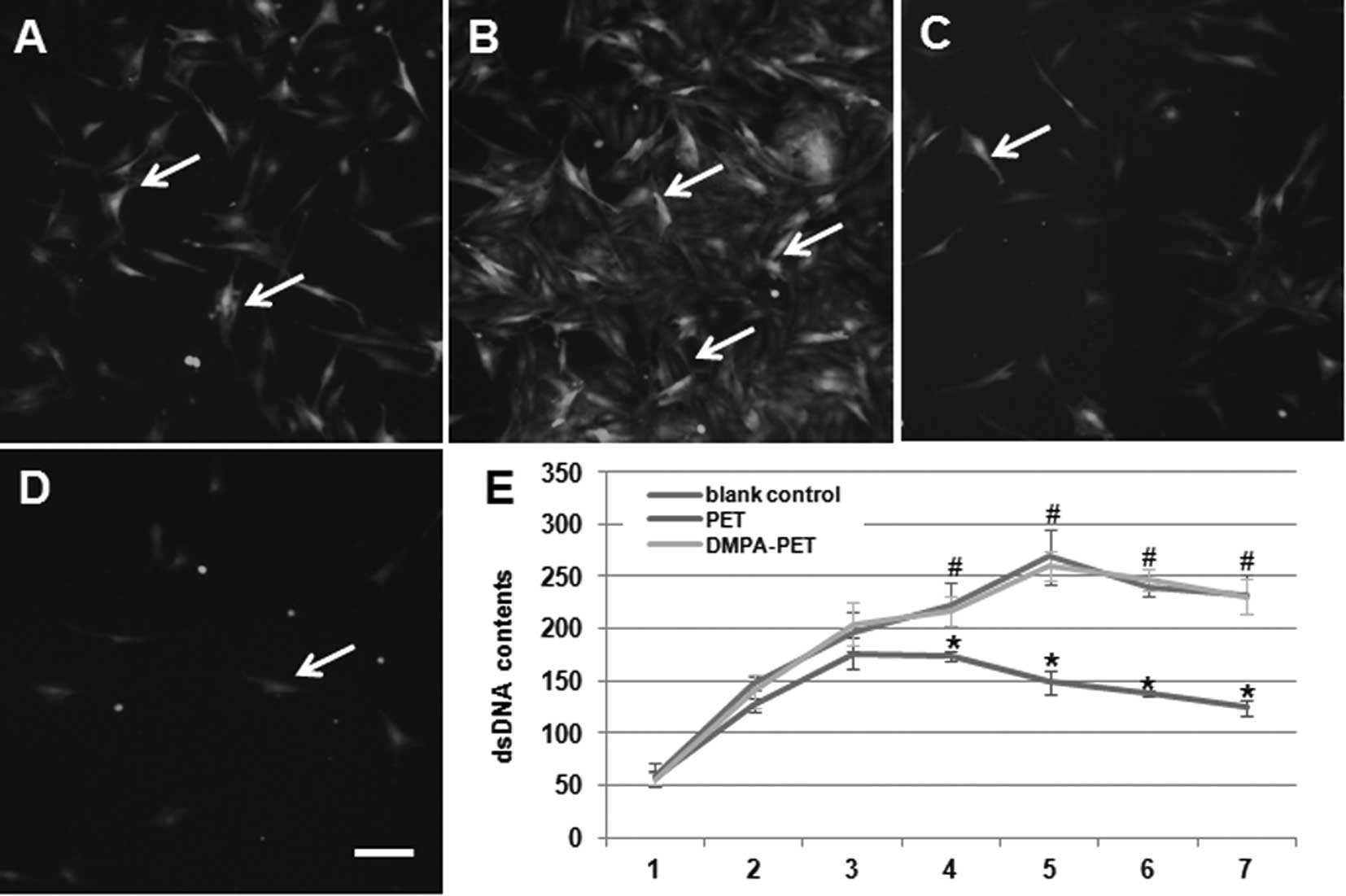

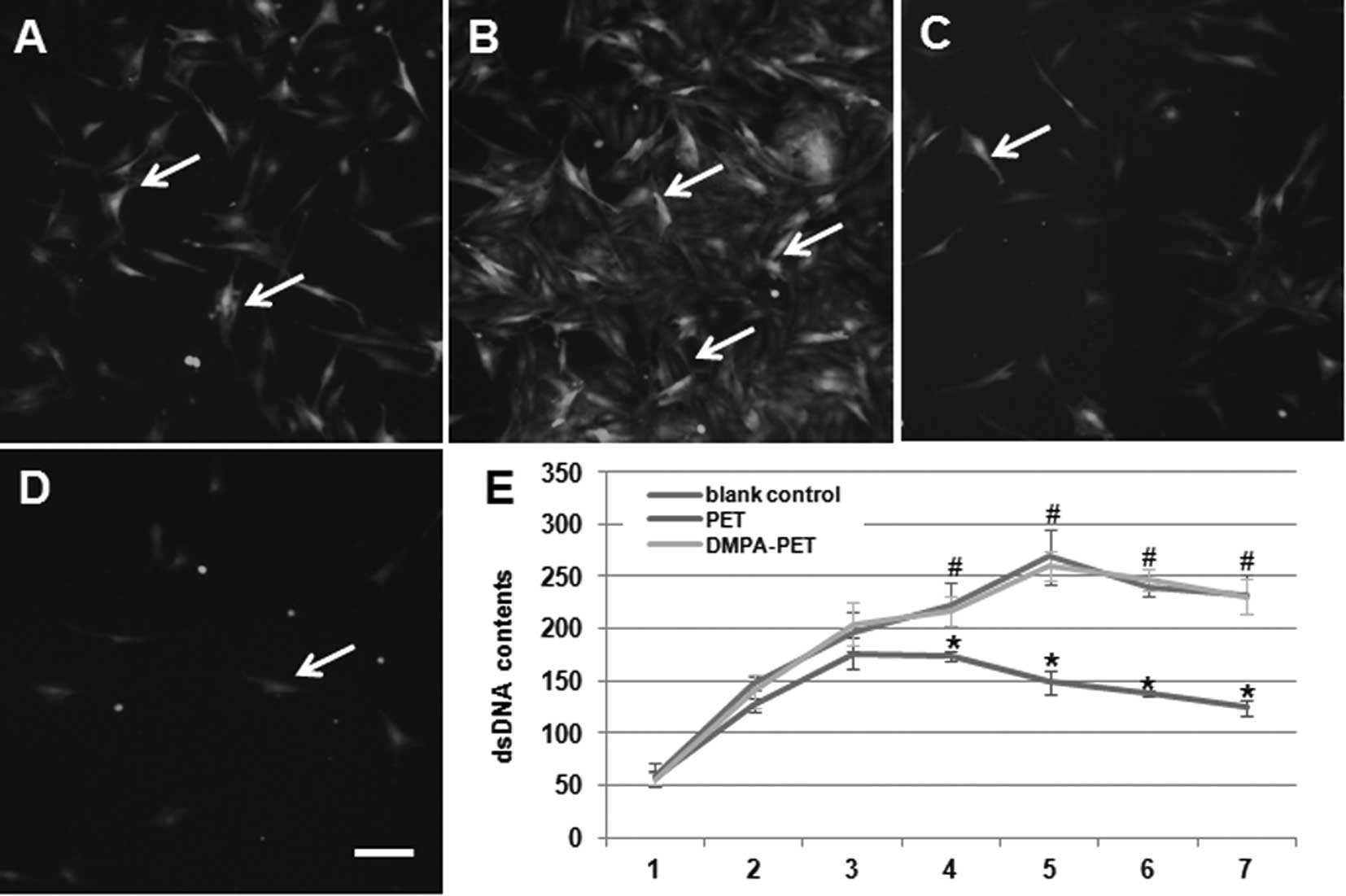

Cytocompatibility evaluation

Using inverted phase-contrast fluorescence

microscopy, we found that the BMSCs seeded onto the DMPA-PET fibers

appeared flattened, polygonal, spindle-shaped and evenly

distributed after 3 days of culture (Fig. 5A). On the 7th day, a number of

cells were spread and colonized patches appeared on the surface of

DMPA-PET (Fig. 5B). By contrast,

the number of cells that had adhered to the surface of the PET

fibers on the 3rd day had decreased (Fig. 5C). On the 7th day, only a few cells

were found on the surface of PET (Fig.

5D). The dsDNA content of the DMPA-PET group gradually

increased from days 1 to 5, with a slight decline from days 5 to 7

after confluence. There were no differences in the dsDNA content

between the DMPA-PET group and the blank control group (n=10,

P>0.05; Fig. 5E). On the

contrary, the dsDNA content of the PET group increased very slowly,

and began to decrease from the 4th day. The dsDNA content of the

PET group was much lower than that of the DMPA-PET group and the

blank control group after day 4 (n=10, P<0.05; Fig. 5E).

| Figure 5Fluorescence images of the BMSCs on

the different fibers: (A) DMPA-PET after 3 days, (B) DMPA-PET after

7 days, (C) PET after 3 days, (D) PET after 7 days (arrows, cells;

bar, 50μm). (E) DsDNA contents of the different groups

(*P<0.05, #P>0.05, n=10). BMSCs; bone

marrow stromal cells; PET, polyethylene terephthalate; DMPA-PET,

dimethylolpropionic acid-polyethylene terephthalate; dsDNA,

double-stranded DNA. |

Discussion

PET is commercially one of the most significant and

successful engineered polymers, and is widely used in the form of

fibers, films and molded articles (27). Due to its high plasticity,

flexibility and mechanical resistance to rupturing, PET fibers are

considered to be especially adapted to fabricate artificial

ligaments (22). The Ligament

Advanced Reinforcement System (LARS) ligament, which is made of

PET, has become one of the graft choices for ligament rupture

management, along with autografts and allografts, in a number of

countries (15). However, as PET

fibers are hydrophobic, certain clinical studies have proven that

LARS ligaments integrate poorly into the surrounding host tissue

resulting in failed ligament reconstruction after long-term

follow-up (28). Thus, a number of

studies have focused on modifying the surface of PET by grafting

functional chemical groups, including carboxylic, amide, sulfonate

and hydroxyapatite (21,29). However, since PET is

semi-crystalline in nature and does not contain chemically reactive

groups, it is resistant to straight chemical modification (27).

In order to improve the biocompatibility of PET, we

developed a novel modification method involving 3 steps. Firstly,

we treated PET fibers with sodium hydroxide to hydrolyze certain

esters on the surface of the fibers. Secondly, the hydrolyzed PET

fibers were reacted with TDI in acetone solution with DBTDL as the

activator. Finally, the fibers were reacted with a hydrophilic

molecule, DMPA, with fluorate boron as the activator. The excess

base was removed by repeated washing with distilled water until the

pH of the solution returned to a physiological range (7.0–7.4). The

SEM images demonstrated that plenty of granules were deposited on

the surface of the fibers after DMPA modification (Fig. 1B). This observed difference was

attributed to the fragmentation of polymer chains caused by surface

etching, and the deposition of grafted components (DMPA) on the

filament surface. This is a general behavior which has been

observed in other systems (30).

This rough surface was considered to be increasingly suitable for

the adhesion of cells (31). The

FTIR data further confirmed that a number of hydrophilic groups,

including hydroxyl and carboxyl, were formed on the surface of the

DMPA-PET fibers (Fig. 2B).

Furthermore, from the co-culture with the BMSCs, we proved that the

DMPA-PET fibers demonstrated excellent cytocompatibility compared

to the original PET fibers (Fig.

5).

DMPA is a unique, trifunctional molecule, which

incorporates a hindered, tertiary carboxylic acid group and 2

reactive primary hydroxyls. As a crystalline monomer, DMPA has been

proven to be odorless and considered to provide superior

advantages, including easy control, non-toxicity and high

hydrophilicity in the formulation and processing of water soluble

resins (32–35). It can be used as a modifier for

urethane, polyester/alkyd, phenolic, amino and epoxy systems

(33). The hindered carboxyl of

DMPA makes the introduction of free acid groups easy and convenient

(34). In this study, we succeeded

in improving the hydrophilicity and cytocompatibility of PET fibers

by modifying the surface of DMPA.

In order to investigate the effects of DMPA

modification on the changes in the thermophysical and crystal

properties of the PET fibers, DSC and XRD were employed in this

study. Notably, the DSC data demonstrated that there were no

significant changes in the endothermic peaks, fusion enthalpy and

crystalline indices between the DMPA-PET and the PET fibers, which

indicated that the original thermophysical and crystal properties

of PET remained in the DMPA-modified PET fibers (Table I). These results were further

confirmed by the XRD patterns (Fig.

3B). We considered that the main reason behind these results

was that the introduction of DMPA had no effect on the crystalline

structure of the PET fibers. In line with our study, DMPA was found

to be easily built into the polymer chain without side reactions

during the process, and to not influence the natural thermophysical

and crystal properties of the final product (34).

In order to observe the effects of DMPA modification

on the mechanical strength of PET, the tensile test was applied in

this study. The ultimate tensile strength and tensile stress of one

single fiber from the DMPA-PET group were similar to those from the

PET group. Although the elongation percentage at breakage of the

DMPA-PET group was slightly higher than that of the PET group,

there was no significant difference between the 2 groups.

Similarly, the difference in the initial modulus between the 2

groups was also not significant (Fig.

4). The PET fiber is regarded as an ideal material for the

preparation of artificial ligaments, due to its high strength and

stiffness, combined with reduced strain-to-failure (25). However, certain modified methods

have been found to cause a decrease in the mechanical properties,

including tensile strength, elongation at breakage or the elastic

modulus of PET during the processing of the modification (28–30).

In this study, we proved that our 3-step DMPA-modification method

can significantly increase the hydrophilicity of the PET fibers

without changing their mechanical strength.

In this study, we modified PET fibers by using DMPA.

The characteristics of the modified fibers were observed and

compared with those of the original PET. Based on our results, we

found that the introduction of DMPA can significantly increase the

hydrophilic group on the surface of the PET fibers, which results

in an improvement of the biocompatibility without comprising the

mechanical strength. These results demonstrate that DMPA-modified

PET fibers have significant potential as a material for the

development of artificial ligaments.

Acknowledgements

This study was supported by the National Science

Foundation of China (No. 81071457).

References

|

1

|

Söderman K, Pietilä T, Alfredson H, et al:

Anterior cruciate ligament injuries in young females playing soccer

at senior levels. Scand J Med Sci Sports. 12:65–68. 2002.PubMed/NCBI

|

|

2

|

Keene G: Arthroscopic reconstruction of

the anterior cruciate ligament. A comparison of patellar tendon

autograft and four-strand hamstring tendon autograft. Am J Sports

Med. 28:4382000.PubMed/NCBI

|

|

3

|

Mihelic R, Jurdana H, Jotanovic Z, et al:

Long-term results of anterior cruciate ligament reconstruction: a

comparison with non-operative treatment with a follow-up of 17–20

years. Int Orthop. 35:1093–1097. 2011.PubMed/NCBI

|

|

4

|

Price JS, Till SH, Bickerstaff DR, et al:

Degradation of cartilage type II collagen precedes the onset of

osteoarthritis following anterior cruciate ligament rupture.

Arthritis Rheum. 42:2390–2398. 1999. View Article : Google Scholar : PubMed/NCBI

|

|

5

|

Montgomery A: Can many anterior cruciate

ligament (ACL) ruptures heal without surgery? N Z Med J.

124:1042011.PubMed/NCBI

|

|

6

|

Vavken P and Murray MM: The potential for

primary repair of the ACL. Sports Med Arthrosc. 19:44–49. 2011.

View Article : Google Scholar : PubMed/NCBI

|

|

7

|

Bryant AL, Creaby MW, Newton RU and Steele

JR: Hamstring antagonist torque generated in vivo following ACL

rupture and ACL reconstruction. Knee. 17:287–290. 2010. View Article : Google Scholar : PubMed/NCBI

|

|

8

|

Mauch C, Arnold MP, Wirries A, et al:

Anterior cruciate ligament reconstruction using quadriceps tendon

autograft for adolescents with open physes- a technical note.

Sports Med Arthrosc Rehabil Ther Technol. 3:72011. View Article : Google Scholar : PubMed/NCBI

|

|

9

|

Bak K, Jørgensen U, Ekstrand J and

Scavenius M: Reconstruction of anterior cruciate ligament deficient

knees in soccer players with an iliotibial band autograft. A

prospective study of 132 reconstructed knees followed for 4 (2–7)

years. Scand J Med Sci Sports. 11:16–22. 2001.PubMed/NCBI

|

|

10

|

Burks RT, Crim J, Fink BP, et al: The

effects of semitendinosus and gracilis harvest in anterior cruciate

ligament reconstruction. Arthroscopy. 21:1177–1185. 2005.

View Article : Google Scholar : PubMed/NCBI

|

|

11

|

Lee S, Seong SC, Jo H, et al: Outcome of

anterior cruciate ligament reconstruction using quadriceps tendon

autograft. Arthroscopy. 20:795–802. 2004. View Article : Google Scholar : PubMed/NCBI

|

|

12

|

Miller SL and Gladstone JN: Graft

selection in anterior cruciate ligament reconstruction. Orthop Clin

North Am. 33:675–683. 2002. View Article : Google Scholar : PubMed/NCBI

|

|

13

|

Akhtar MA, Bhattacharya R, Ohly N, et al:

Revision ACL reconstruction-causes of failure and graft choices. Br

J Sports Med. 45:A15–A16. 2011. View Article : Google Scholar

|

|

14

|

Díaz-de-Rada P, Barriga A, Barroso JL, et

al: Positive culture in allograft ACL-reconstruction: what to do?

Knee Surg Sports Traumatol Arthrosc. 11:219–222. 2003.PubMed/NCBI

|

|

15

|

Legnani C, Ventura A, Terzaghi C, et al:

Anterior cruciate ligament reconstruction with synthetic grafts. A

review of literature. Int Orthop. 34:465–471. 2010. View Article : Google Scholar : PubMed/NCBI

|

|

16

|

Matsumoto H and Fujikawa K: Leeds-Keio

artificial ligament: a new concept for the anterior cruciate

ligament reconstruction of the knee. Keio J Med. 50:161–166. 2001.

View Article : Google Scholar : PubMed/NCBI

|

|

17

|

Bernardino S: ACL prosthesis: any promise

for the future? Knee Surg Sports Traumatol Arthrosc. 18:797–804.

2010. View Article : Google Scholar : PubMed/NCBI

|

|

18

|

Pavon-Djavid G, Gamble LJ, Ciobanu M, et

al: Bioactive poly (ethylene terephthalate) fibers and fabrics:

grafting, chemical characterization, and biological assessment.

Biomacromolecules. 8:3317–3325. 2007. View Article : Google Scholar : PubMed/NCBI

|

|

19

|

Bolton CW and Bruchman B: Mechanical and

biological properties of the GORE-TEX expanded

polytetrafluoroethylene (PTFE) prosthetic ligament. Aktuel Probl

Chir Orthop. 26:40–51. 1983.PubMed/NCBI

|

|

20

|

Lavoie P, Fletcher J and Duval N: Patient

satisfaction needs as related to knee stability and objective

findings after ACL reconstruction using the LARS artificial

ligament. Knee. 7:157–163. 2000. View Article : Google Scholar : PubMed/NCBI

|

|

21

|

Zhou J, Ciobanu M, Pavon-Djavid G, et al:

Morphology and adhesion of human fibroblast cells cultured on

bioactive polymer grafted ligament prosthesis. Conf Proc IEEE Eng

Med Biol So. 5115–5118. 2007.PubMed/NCBI

|

|

22

|

Ventura A, Terzaghi C, Legnani C, et al:

Synthetic grafts for anterior cruciate ligament rupture: 19-year

outcome study. Knee. 17:108–113. 2010.PubMed/NCBI

|

|

23

|

Carson L, Kelly-Brown C, Stewart M, et al:

Synthesis and characterization of chitosan-carbon nanotube

composites. Mater Lett. 63:617–620. 2009. View Article : Google Scholar : PubMed/NCBI

|

|

24

|

Hadjizadeh A, Ajji A and Bureau MN:

Nano/micro electro-spun polyethylene terephthalate fibrous mat

preparation and characterization. J Mech Behav Biomed Mater.

4:340–351. 2011. View Article : Google Scholar : PubMed/NCBI

|

|

25

|

Lechat C, Bunsell A, Davies P and Piant A:

Mechanical behaviour of polyethylene terephthalate and polyethylene

naphthalate fibres under cyclic loading. J Mater Sci. 41:1745–1756.

2006. View Article : Google Scholar

|

|

26

|

Peng CH, Bai BS and Chen YF: Study on the

preparation of Mn-Zn soft magnetic ferrite powders from waste Zn-Mn

dry batteries. Waste Manag. 28:326–332. 2008. View Article : Google Scholar : PubMed/NCBI

|

|

27

|

Abdolahifard M, Hajir Bahrami S and Malek

R: Surface modification of PET fabric by graft copolymerization

with acrylic acid and its antibacterial properties. ISRN Organic

Chemistry. Article ID 2654152011.PubMed/NCBI

|

|

28

|

Guidoin MF, Marois Y, Bejui J, et al:

Analysis of retrieved polymer fiber based replacements for the ACL.

Biomaterials. 21:2461–2474. 2000. View Article : Google Scholar : PubMed/NCBI

|

|

29

|

Li H, Ge Y, Wu Y, et al: Hydroxyapatite

coating enhances polyethylene terephthalate artificial ligament

graft osseointegration in the bone tunnel. Int Orthop.

35:1561–1567. 2011. View Article : Google Scholar

|

|

30

|

Gupta B, Revagade N, Atthoff B, et al:

Radiation-induced graft modification of knitted poly(ethylene

terephthalate) fabric for collagen immobilization. Polym Adv

Technol. 18:281–285. 2007. View

Article : Google Scholar

|

|

31

|

Pezzatini S, Morbidelli L, Gristina R, et

al: A nanoscale fluorocarbon coating on PET surfaces improves the

adhesion and growth of cultured coronary endothelial cells.

Nanotechnology. 19:2751012008. View Article : Google Scholar : PubMed/NCBI

|

|

32

|

Zia KM, Zuber M, Barikani M, et al:

Surface characteristics of chitin-based shape memory polyurethane

elastomers. Colloids Surf B Biointerfaces. 72:248–252. 2009.

View Article : Google Scholar : PubMed/NCBI

|

|

33

|

Narayan R, Chattopadhyay DK, Sreedhar B,

et al: Synthesis and characterization of crosslinked polyurethane

dispersions based on hydroxylated polyesters. J Appl Polym Sci.

99:368–380. 2006. View Article : Google Scholar

|

|

34

|

Rahman MM, Kim EY and Lee WK: Effect of

DMPA-clay-POSS content on thermal and mechanical properties of

nanostructured ionomeric polyurethanes. J Nanosci Nanotechnol.

10:6981–6985. 2010. View Article : Google Scholar : PubMed/NCBI

|

|

35

|

Ren Z, Ma D, Wang Y and Zhao G: Molecular

structure and hydrogen bonds in solid dimethylol propionic acid

(DMPA). Spectrochim Acta A Mol Biomol Spectrosc. 59:2713–2722.

2003. View Article : Google Scholar : PubMed/NCBI

|