Introduction

Bone is a highly specialized tissue comprising a

network of extracellular matrix components (1,2).

Bone exhibits a poor capacity for self-repair; therefore, even

small defects may require surgery (3). Tissue engineering approaches using

autologous cells and various scaffolds are becoming a promising

alternative to conventional surgery. A combinatorial approach for

treating large bone defects includes seeding cells, growth factors

and biomaterials used in bone tissue engineering, which can enhance

the success of cell therapy (4–7).

Several scaffolds fabricated from natural or synthetic biomaterials

have been suggested for use in bone tissue engineering. Selection

of an appropriate biomaterial is important, as the behaviors and

fates of cells are markedly affected by the structure and

components of the biomaterial (8).

Growth factors have been shown to be critical in the

induction and maintenance of osteoblast cell phenotype, and are

active in the regulation of cell proliferation and differentiation

in bone tissue engineering (9).

Transforming growth factor-β1 (TGF-β) is the most abundant cytokine

in bone and, due to its abundance (200 mg/kg), it may be central in

bone turnover (10). TGF-β1 is

critical in bone formation, mineral storage and hematopoietic cell

generation. Of the TGF-β superfamily, TGF-β1 exhibits the most

marked chemotactic effect towards human osteoblasts, and

application of this cytokine in a dog model was observed to enhance

mechanical fixation, bone ingrowth and gap bone formation in the

presence of unloaded implants surrounded by a gap (11); an effect, which was pronounced with

low concentrations of TGF-β1, but not with higher concentrations

(12). TGF-β1 has been widely used

to promote the osteogenesis of bone marrow stromal cells in a

variety of in vitro culture systems, by supplying it in the

medium continuously for >4 weeks (13–15).

Arious technologies have been engineered with the aim of local

delivery and controlled release of an appropriate concentration of

these growth factors in vitro (16–22).

Therefore, the controlled administration of TGF-β1 may represent an

emerging tissue engineering technology, which may modulate cellular

responses to encourage bone regeneration of skeletal defects

(23,24).

Osteoblasts are mononucleated cells, which are

responsible for bone formation. They arise from osteoblastic

precursors located in the deeper layer of periosteum and the bone

marrow, and produce a matrix of osteoid, which is composed

predominantly of type I collagen (25). TGF-β1 has a variety of widely

recognized roles in bone formation. For example, TGF-β1 enhances

osteoblast proliferation (26),

and it also enhances the production of extracellular bone matrix

protein by osteoblasts in the early stages of osteoblast

differentiation (27).

The silk fibroin-chitosan (SF-CS) scaffold has been

recognized as a suitable material for applications in orthopedics

and maxillofacial surgery due to it being biodegradable,

biocompatible and exhibiting osteoconductive properties (28–30).

In our previous study, SF and CS were combined into a three

dimensional (3D) scaffold to provide unique chemical, structural

and mechanical properties, for utilization in bone tissue

engineering and regenerative applications. The investigation found

that the most appropriate proportion of CS and SF was 5:5 for bone

tissue engineering (31).

In the present study, TGF-β1 was introduced into the

SF-CS scaffold to reconstruct a 3D scaffold for the first time, to

the best of our knowledge. The subsequent aim was to examine the

application and biocompatibility of the TGF-β1-SF-CS 3D scaffolds

in meeting the requirements of bone tissue engineering scaffolds.

The effect of the TGF-β1-SF-CS composite scaffolds on hFOB1.19

osteoblast cell morphology, differentiation and function remain to

be elucidated, and have not been investigated previously. TGF-β1

was used in the present study to evaluate the suitability of the

SF-CS scaffolds as matrices, using hFOB1.19 osteoblast cells. The

cellular activity, viability, and biochemistry were analyzed for

bone tissue engineering. The critical effects of the materials in

morphogenesis were analyzed from the in vitro response to

identify the clinical relevance of the SF-CS scaffold.

Materials and methods

Materials

Raw silk was purchased from Silk Co., Ltd.

(Nanchong, Sichuan, China). Chitosan was purchased from Tongxing

Company (Jiangsu, China). TGF-β1 (100 ng/bottle) was purchased from

ProSpec-Tany TechnoGene, Ltd. (Rehovot, Israel). hFOB1.19

osteoblast cells were purchased from BioHermes Co., Ltd. (Shanghai,

China). NaHCO3, CaCl2 and ethanol were

purchased from Nanjing Jiancheng Bioengineering Institute,

(Nanjing, China). All other chemicals and reagents were of

analytical grade, unless specified otherwise.

Preparation of the TGF-β1-SF-CS and SF-CS

scaffolds

The Bombyx mori silk fibers were treated

twice with 0.5% (w/w) NaHCO3 solution at 100°C for 30

min, and were then rinsed with 70°C distilled water to remove the

sericin for 30 min, followed by drying at 37°C. The degummed silk

was dissolved in a solvent mixture of CaCl2 (44.4

g)/CH3CH2OH (46 ml)/H2O (57.5 ml)

with a molar ratio of 1:2:8, at 70°C for 6 h, and was filtered to

obtain the SF solution. Following dialysis in cellulose dialysis

tubing (molecular weight cut-off; MWCO=50,000; Nanjing Jiancheng

Biotechnology Institute, Nanjing, China) against distilled water

for 3 days, with the water replaced every 12 h. The final

concentration of SF used was 8%.

The CS solutions were prepared by dissolving high

molecular-weight CS (82.7% deacetylation; Tongxing Company) at

3.66% (w/v) in 2% acetic acid (Nanjing Jiancheng Biotechnology

Institute). The final concentration of CS used was 2%.

TGF-β1 solution was prepared by dissolving 100 ng

TGF-β1 in 1 ml deionized sterile water (100 ng/ml).

The SF/CS blend solution (100 ml) with a SF/CS

weight ratio of 5:5, was prepared in the same solvent at 10 wt%

(combined weight of CS and SF). Following dialysis in cellulose

dialysis tubing (MWCO=50,000) against distilled water for 3 days,

with water replaced every 12 h, the CS and SF solution was

obtained. Subsequently,1 ml TGF-β1 solution was added and stirred

in a magnetic stirrer (JB-2A; Bante Instruments Limited, Shanghai,

China) for 50 min. The mixture of CS, SF and TGF-β1 was then added

into a 24-hole teflon culture plate. The CS, SF and TGF-β1 solution

was then lyophilized (VFD-2000; Boyikang Laboratory Instruments

Co., Ltd., Beijing, China) to obtain the TGF-β1-SF-CS scaffold. The

SF-CS scaffolds were prepared using the same method.

To improve water stability, the dry TGF-β1-SF-CS and

SF-CS scaffolds were treated in methanol solution (concentration

<10%) for 2 h to crystallize the SF content and neutralize the

CS content. The TGF-β1-SF-CS and SF-CS scaffolds were then

lyophilized to remove the excess methanol.

hFOB1.19 osteoblast cell culture

The hFOB1.19 osteoblast cells, supplied by

BioHermes, were cultured in DMEM/F12 medium supplemented with 10%

fetal bovine serum (ProSpec-Tany TechnoGene, Ltd.), 200 mM/l

glutamine, 2 mg/ml sodium bicarbonate and 100 mg/ml

penicillin/streptomycin (ProSpec-Tany TechnoGene, Ltd.). The cells

were cultured in 25 cm2 flasks at 37°C in a humidified

atmosphere of 5% CO2. Confluent monolayers were split by

treatment with phosphate-buffered saline (PBS) and 0.05%

trypsin/EDTA solution (Nanjing Jiancheng Biotechnology Institute),

and the culture medium was replaced every 2 days.

The samples were sterilized with 75% alcohol under

ultraviolet light overnight, and were then rinsed extensively three

times with sterile PBS. Prior to cell culture, the scaffolds were

pre-soaked by immersion in DMEM for 12 h in the 37°C incubator.

The hFOB1.19 osteoblast cells were cultured onto the

TGF-β1-SF-CS scaffolds, SF-CS scaffolds and 24-well tissue culture

plate wells as a control group (n=3; diameter 15 mm; height 13 mm)

for 3 and 6 days at 37°C under an atmosphere of 5% CO2

and 95% air, with an original cell culture density of 4,000

cells/well.

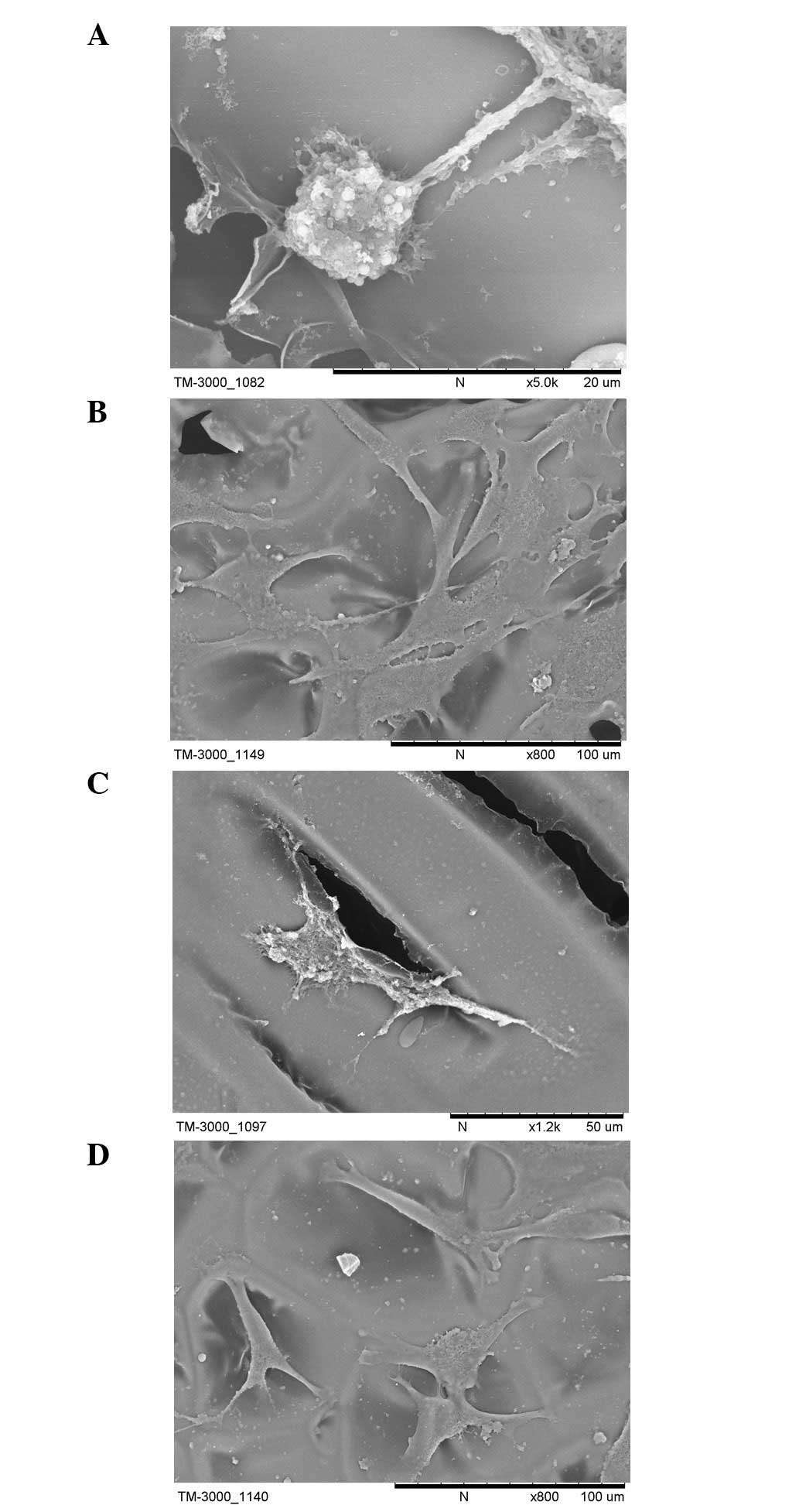

Cell morphology

The morphological features of the osteoblast cells

on the TGF-β1-SF-CS scaffold and SF-CS scaffold were observed on

days 1, 3 and 7 of culture using a scanning electron microscope

(SEM; TM3000; Hitachi, Ltd., Tokyo, Japan). The samples were washed

with PBS and fixed with 3.0% glutaraldehyde (Nanjing Jiancheng

Biotechnology Institute) at 4°C for 4 h. Subsequently, the samples

were dehydrated through a series of graded ethanol solutions (30,

50, 70, 80, 90, 95 and 100%), air-dried overnight, and sputtered

with gold for SEM observation. Adherent cell morphology, patterns

of cellular adherence with respect to structural features of the

TGF-β1-SF-CS scaffold and SF-CS scaffold, cell-cell interactions,

and adherent cell density were assessed.

Adhesion of cells

The cells, which had adhered to the TGF-β1-SF-CS

scaffold, SF-CS scaffold and control group were harvested, and the

concentration was adjusted to 1×104/ml. The cells were

placed in cell culture plates, which were pre-coated with the

TGF-β1-SF-CS scaffold and SF-CS scaffold (1 ml per well). Cells

cultured in culture plates with no scaffold served as controls. A

total of six parallel wells were used for each group. The cells

were cultured in an incubator at 37°C with 5% CO2. The

numbers of non-adhered cells were quantified at 1, 2, 4, 8 and 24

h.

The cell adhesion rate was calculated according to

the following formula: Adhesion rate (%) = (number of seeded cells

- non-adhered cells) / number of seeded cells × 100.

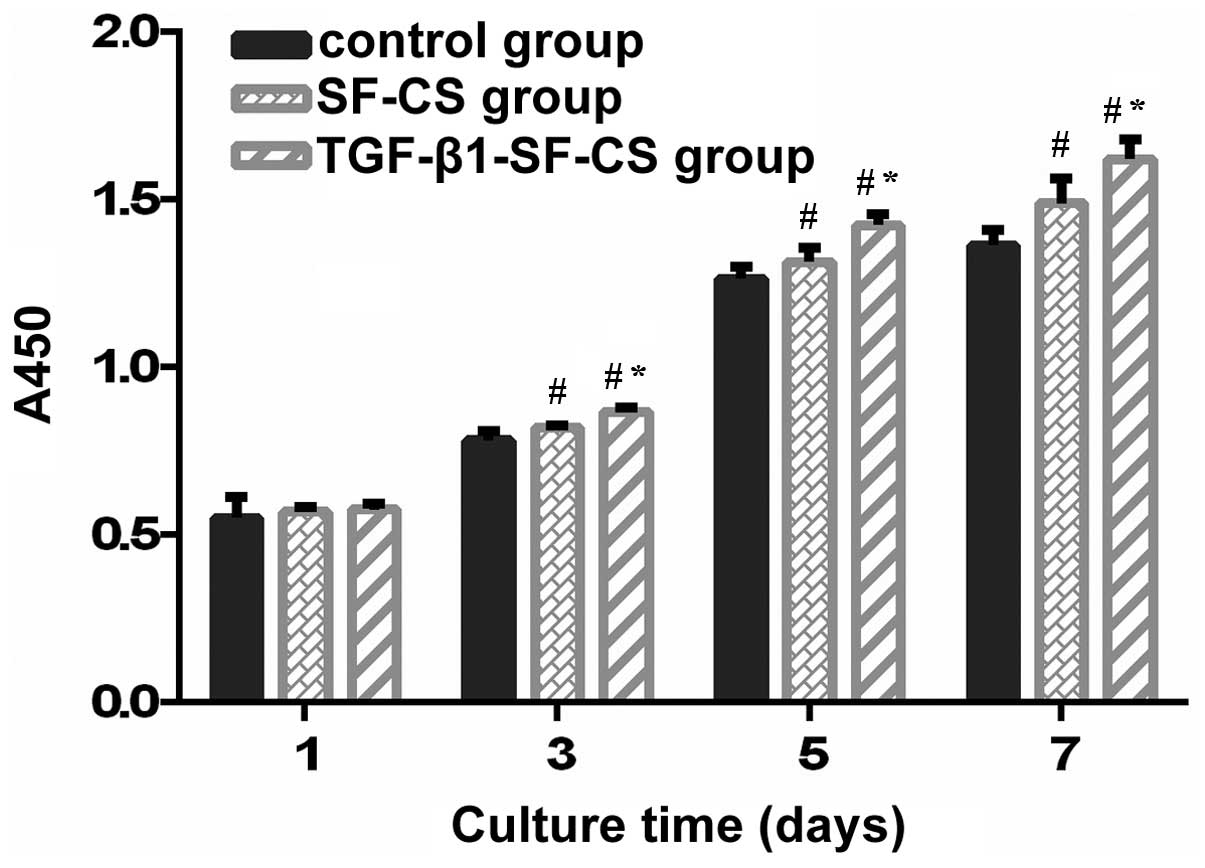

Cell Counting Kit-8 (CCK-8) assay

In order to examine the survival of the grafted

cells, the cell viability and proliferation rates were determined

using a CCK-8 assay (Nanjing Jiancheng Biotechnology Institute).

Briefly, following culture of the samples for 1, 3, 5 and 7 days,

the culture medium was replaced with serum-free culture medium

containing CCK-8 (0.5 mg/ml). Following culture for 4 h, the

samples were transferred onto a 96-well plate. The absorbance was

measured at 450 nm using an ELISA reader (Bio-Rad 550 Bio-Rad

Laboratories, Inc., Hercules, CA, USA).

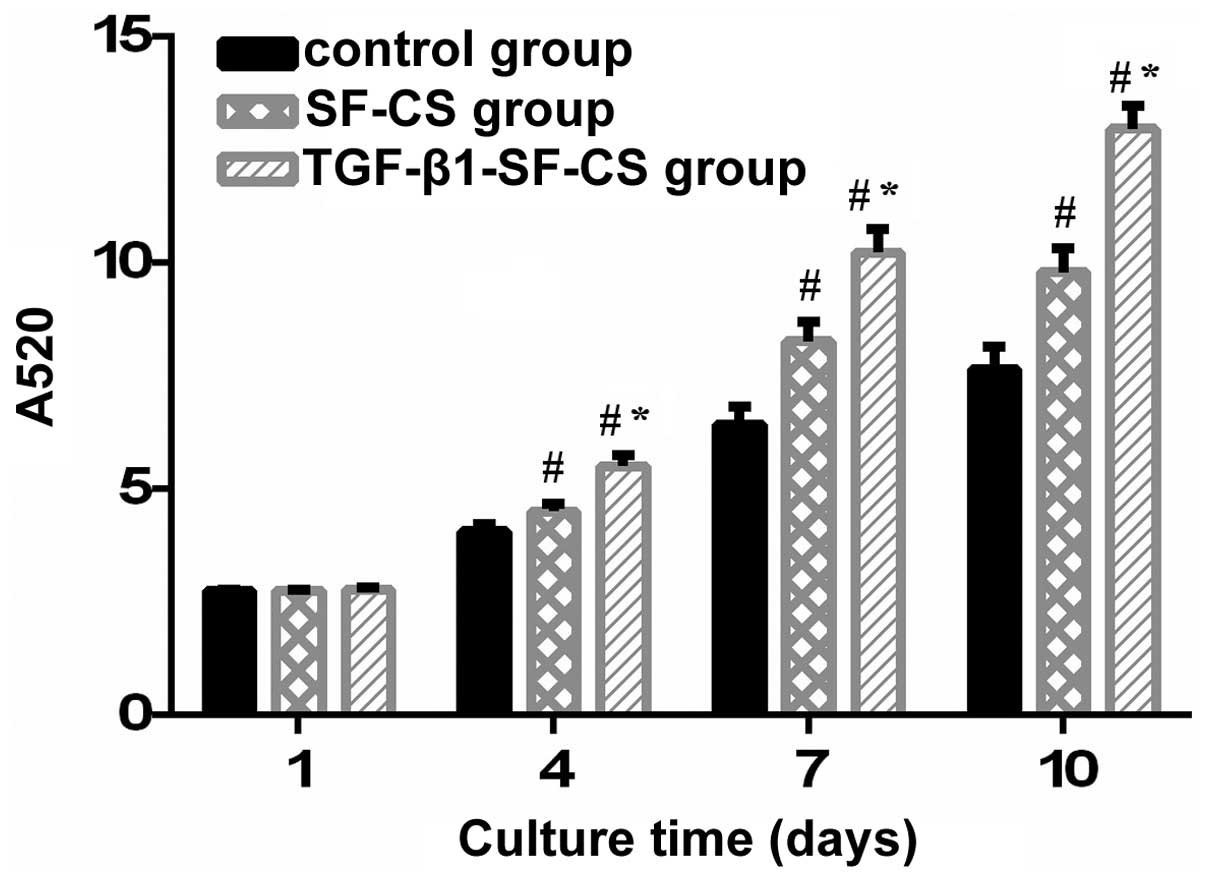

Alkaline phosphatase (ALP) activity

The activities of intracellular ALP in the scaffolds

and control group were measured using an ALP assay kit (Nanjing

Jiancheng Bioengineering Institute). Briefly, the samples were

cultured 1, 4, 7 and 10 days, and then washed with PBS three times.

The cells in the samples and control were then immersed in 500

µl of cell lysis solution containing 0.1% Triton X-100

(Nanjing Jiancheng Biotechnology Institute) and 5 mM

MgCl2 (Nanjing Jiancheng Biotechnology Institute) at

room temperature overnight. The whole solution was transferred into

a tube and centrifuged at 28,340 × g for 10 min at 4°C. ALP

activity was measured by mixing 50 µl of supernatant with 50

µl p-nitrophenyl phosphate (5 mM) in 150 mM

2-amino-2-methyl-1-propanol buffer solution at room temperature for

30 min in the dark. Following the incubation period, the reaction

was terminated by adding 50 µl of 0.2 N NaOH to denature the

ALP. The optical density (OD) was then measured at 520 nm using an

ELISA reader (Bio-Rad Model 550; Bio-Rad Laboratories, Inc.).

Statistical analysis

All quantitative data are expressed as the mean ±

standard deviation. Statistical analyses were performed using the

statistical program, SPSS 17 (SPSS, Inc., Chicago, IL, USA). The

results were analyzed using one-way analysis of variance (ANOVA)

with Student's t-test. P<0.05 were considered to indicate

a statistically significant difference. Prior to results being

analyzed using one-way ANOVA, all quantitative data were confirmed

as normally distributed.

Results

Cell morphology

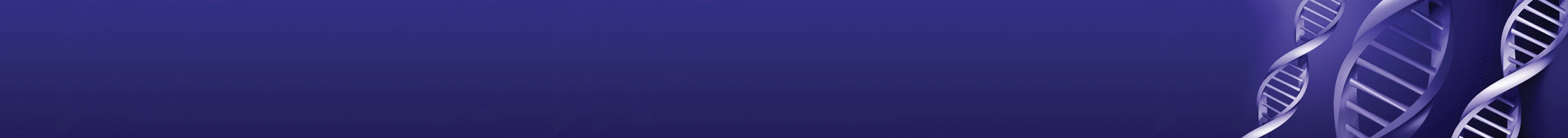

Cell morphology was examined using a light-inverted

microscope (CKX41; Olympus Corporation, Tokyo, Japan) (Fig. 1), in which the hFOB1.19 osteoblast

cells demonstrated a high rate of survival and rapid

proliferation.

In the primary cells, the hFOB1.19 osteoblast cells

exhibited a round morphology. After 12 h, the hFOB1.19 cells were

sparsely attached to the culture flasks, and exhibited a

fibroblast-like, spindle-shaped morphology. As the cell number

increased and the cells continued to grow, a substantial number of

cells on day 3 had adhered to the surface of the culture flask, and

the majority of the cells had become large and flattened, with a

polygonal or triangular shape. After 6 days of culture, the cells

showed adequate growth and exhibited active proliferation. A higher

density was observed in the primary and transformed cells, which

did not change throughout the different passages. The osteoblast

cells had become well-formed mineral nodules at day 18 (Fig. 1).

Adhesion rate of the hFOB1.19 osteoblast

cells is not altered by TGF-β1

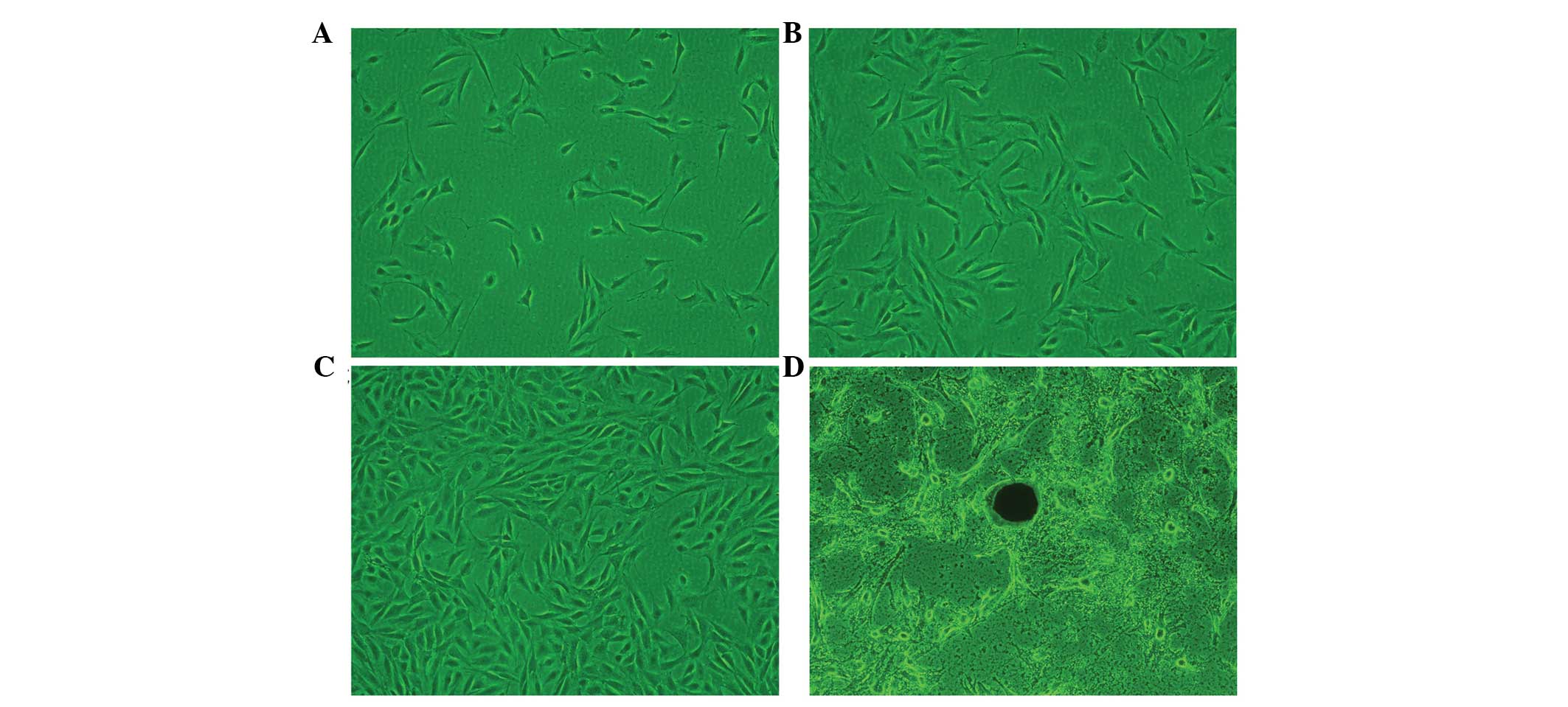

Following culture for 1, 3 and 6 h, cell adhesion

rate increased with increasing duration in the three groups. The

adhesion rates in the TGF-β1-SF-CS group and SF-CS group were

higher, compared with that in the control group (P<0.01;

Fig. 2). After 1 h, the adhesion

rate of the major populations of cells in the SF-CS scaffolds were

almost the same as those in the TGF-β1-SF-CS scaffolds, with no

significant differences between the scaffold groups (P>0.05).

The rapid time-course of osteoblast cell adhesion to the SF-CS and

TGF-β1-SF-CS scaffolds was significant, exhibiting 29% adhesion by

60 min post-seeding. After 3 and 6 h, there were significant

increases in the numbers of adherent cells, compared with the

numbers after 1 h (Fig. 2). The

adhesion rates in the TGF-β1-SF-CS scaffold and SF-CS scaffold

groups were significantly higher, compared with that in the control

group (P<0.01), however, there remained no significant

differences between the two scaffold groups (P>0.05). These

results confirmed that the SF-CS scaffold increased the adhesion of

the osteoblasts cells. The results also revealed that TGF-β1 did

not promote hFOB1.19 osteoblast cell adhesion in the SF-CS

scaffolds.

SEM images of hFOB1.19 cells cultured

with the TGF-β-SF-CS scaffolds indicate biocompaitibilty

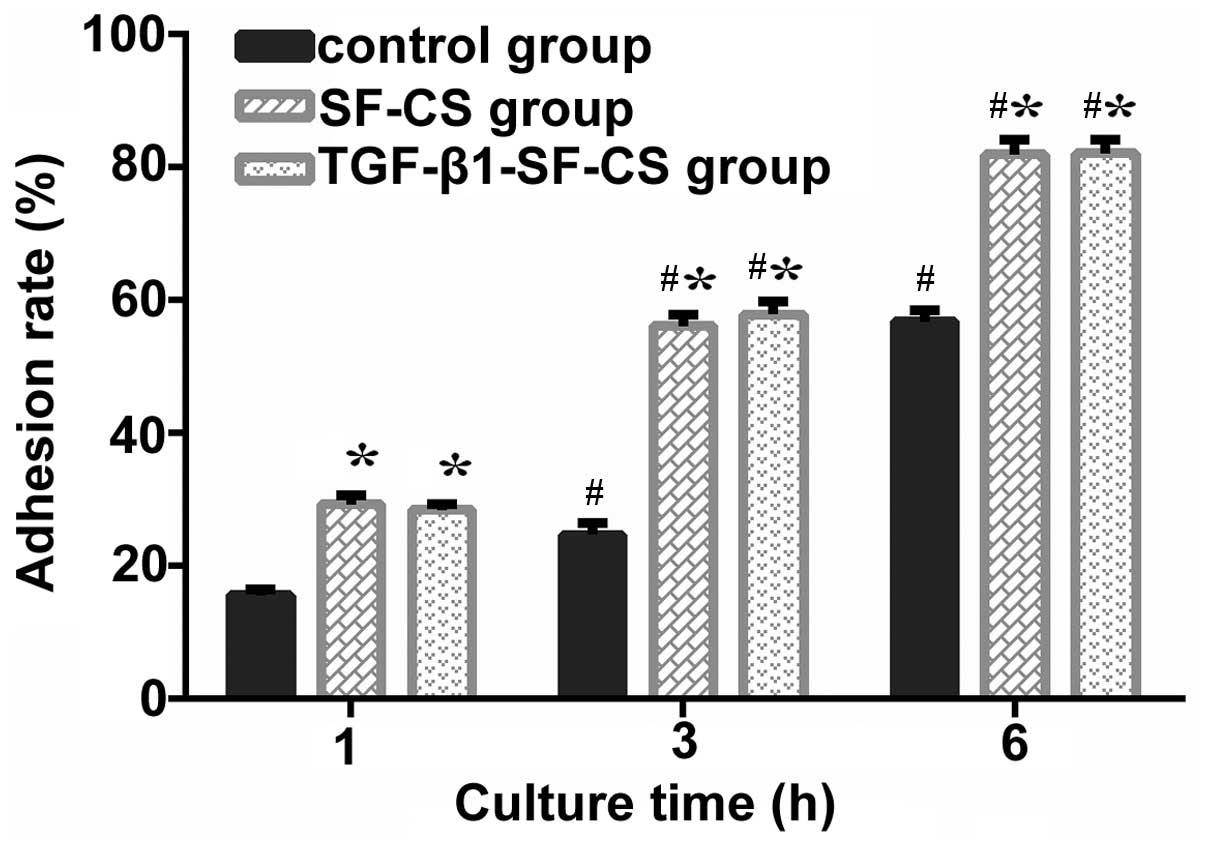

The SEM images showed randomly distributed cells on

the surface and inside the TGF-β1-SF-CS scaffold and SF-CS

scaffold.

On examining the growth of cells on the scaffold at

1 day, scattered round cells had adhered to the scaffold and a

large number of particles were observed on the cell surface. Cell

microfilaments were connected with the scaffold material (Fig. 3A).

| Figure 3Scanning electron microscopy images of

the hFOB1.19 cells cultured with the transforming growth

factor-β1-silk fibroin-chitosan scaffold for (A) 1 day, scattered

round cells had adhered to the scaffold and a large number of

particles were observed on the cell surface, cell microfilaments

were connected with the scaffold material; (B) 3 days, single round

cells had become polygonal or triangular in shape, granular and

filiform substances were observed around the cells and cell

microfilaments and pseudopodia were tightly connected to the

scaffold; and (C) 7 days, the cells exhibited a typical osteoblast

cell morphology, and adhered tightly on the scaffold surface or

inside via the formation of lamellipodia and filopodia, indicative

of cell spreading. A number of cells present were observed to

extend towards other cells in the culture. (D) hFOB1.19 cells

cultured with the SF-CS scaffold at 7 days, fewer and more sparse

attachment of cells was observed compared with the TGF-β1-SF-CS

scaffolds. TGF-β1, transforming growth factor-β1; SF, silk fibroin;

CS, chitosan. |

After 3 days, a large number of the cells had

adhered to the surface and pores of the scaffold. The cell

aggregates had become enlarged and actively proliferating. The SEM

results showed that the single round cells had become polygonal or

triangular in shape. Granular and filiform substances were observed

around the cells, and cell microfilaments and pseudopodia were

tightly connected to the scaffold (Fig. 3B).

After 7 days, an increased number of cells had

adhered to the surface and pores of the scaffold, compared with the

number at 3 days, and the cells had grown and proliferated well.

The cells exhibited a typical osteoblast cell morphology, and

adhered tightly on the scaffold surface or inside via the formation

of lamellipodia and filopodia, indicative of cell spreading. A

number of cells present were observe to extend towards other cells

in the culture. The cells were well attached to the TGF-β1-SF-CS

scaffolds and appeared to have spread. The majority of the cells

had collected together to form cellular aggregations, which is

crucial for the viability and function of hFOB1.19 cells in

vitro. The SF-CS scaffolds showed fewer or more sparse

attachment of cells, compared with the TGF-β1-SF-CS scaffolds

(Fig. 3C).

TGF-β1 promotes the proliferation of

hFOB1.19 cells

The proliferation rats of the hFOB1.19 cells on the

VEGF-SF-CS scaffolds, SF-CS scaffolds and control group cultured

for 1, 3, 5 and 7 days were compared using a CCK-8 assay. The

absorbance values for the TGF-β1-SF-CS scaffolds and SF-CS

scaffolds gradually increased, indicating significant cell growth

within the two scaffolds (Fig. 4).

The hFOB1.19 cells cultured without scaffolds showed similar

results. The number of cells increased with culture duration in all

three groups. hFOB1.19 cell proliferation was observed in the

TGF-β1-SF-CS scaffolds and SF-CS scaffolds, and there were no

significant differences between these groups and the cells cultured

in the control group after 1 day (P>0.05). However, after 3

days, the numbers of hFOB1.19 cells cultured in the TGF-β1-SF-CS

scaffolds were higher than thoses cultured in the SF-CS scaffolds,

and the numbers of hFOB1.19 cells cultured in the two scaffold

groups were significantly higher, compared with the number of cells

cultured without scaffolds (P<0.05).

TGF-β1 promotes the activity of ALP in

hFOB1.19 cells

The ALP activity of the hFOB1.19 cells cultured in

the TGF-β1-SF-CS scaffolds, SF-CS scaffolds and control group are

shown in Fig. 5. In the

measurements of total ALP activity during the culture period

between days 1 and 4, no significant difference in OD values were

identified between the TGF-β1-SF-CS, SF-CS and control groups

(P>0.05). However, between days 4 and 10, significant

differences in the OD values were found between the scaffold groups

and the control group (P<0.01). The OD values in the

TGF-β1-SF-CS groups were the highest. This suggested that TGF-β1

had an effect on the activity of the hFOB1.19 cells. As the

duration of culture increased between days 4 and 10, the growth

trend of the OD values in three groups increased rapidly, and the

OD values peaked after 10 days.

Discussion

The development of biomimetic scaffolds to enhance

bone-formation has largely focused on altering the chemical

composition of scaffolds. Therefore, the present study combined

SF-CS scaffolds with the TGF-β1 growth factor, in order to promote

bone-formation. The results of the present study demonstrated that

the SF-CS scaffolds provided a suitable environment for osteoblast

cell proliferation and differentiation in the presence of TGF-β1

in vitro.

The response of cells to TGF-β1 varies depending on

the dose, length of exposure and target tissue (32). A prolonged exposure and high dose

of TGF-β1 may result in pathological conditions, including

extensive fibrosis, hypertrophic scarring and the formation of

osteophytes (32,33). An engineered system capable of

inducing cell-mediated TGF-β1 activation can begin to address these

problems through bone tissue engineering. The novel strategy

investigated in the present study aimed to incorporate TGF-β1 onto

an SF-CS scaffold and allow osteoblast cells to sense and activate

TGF-β1, as required.

When fabricating the TGF-β1-SF-CS scaffold for bone

tissue engineering, it is critical to maintain the bioactivity of

TGF-β1 as, during the course of manufacture, TGF-β1 bioactivity is

most likely to be destroyed in lyophilization and methanol

crosslinking. In lyophilization, the use of a cryoprotector may

reduce or even prevent the effects of stress on the activity of the

protein (34). Silk protein and

chitosan can be used as cryoprotectors to maintain the activity of

TGF-β1 (35,36). Klibanov (37) reported that the conformation of

proteins treated with low concentration methanol remain unchanged,

and the covalent structure of the protein molecule is not

destroyed. In the present study, the following measures were taking

in constructing the TGF-β1-SF-CS scaffold to prevent the TGF-β1

bioactivity from being destroyed: (i) Lyophilization temperature

was set at −40°C, and silk and chitosan were used as cryoprotectors

to further maintain TGF-β1 activity; (ii) methanol concentration

was <10%. Through ALP and CCK-8 assays, it was evident that no

significant degradation of TGF-β1 bioactivity had occurred.

In the present study, the SF-CS scaffold was

manufactured in aqueous solution to incorporate the active TGF-β1

molecule without damaging TGF-β1 activity. Mandal and Kundu

(38) utilized lyophilization to

prepare a 3D silk fibroin scaffold in bovine serum albumin, and

then examined its in vitro release and performance. The

results of the ALP and CCK-8 assays in the present study result

revealed that, in the TGF-β1-SF-CS scaffold, TGF-β1 was evenly and

continuously released within a certain period.

In the present study, osteoblast cell morphology was

investigated using SEM to further evaluate the biocompatibility of

the SF-CS and TGF-β1-SF-CS scaffolds. The seeding of hFOB1.19 on

TGF-β1-SF-CS scaffolds up to 7 days resulted in polygonal or

triangular cell morphologies, similar to what is typically observed

in standard cell culture flasks. These observations confirmed cell

survival and proliferation on the TGF-β1-SF-CS scaffolds, assuring

its biocompatibility. The evidence of cell-cell interactions and

cell spreading are considered to be signs of healthy cells and

indicative of a non-cytotoxic response of the cells on TGF-β1-SF-CS

scaffolds (39,40).

The time course of the adhesion of osteoblast cells

to the SF-CS and TGF-β1-SF-CS scaffolds clearly demonstrated that

adhesion of the hFOB1.19 to the SF-CS and TGF-β1-SF-CS scaffolds

occurred within minutes. The rapid time-course of osteoblast cell

adhesion to the SF-CS and TGF-β1-SF-CS scaffolds was significant,

exhibiting 29% adhesion by 60 min post-seeding. The adhesion rate

of the hFOB1.19 cells in the TGF-β1-SF-CS group and SF-CS group

significantly exceeded those in the control group (P<0.05),

although no statistically significant differences (P>0.05) were

observed between the SF-CS and TGF-β1-SF-CS scaffold groups.

Previous studies have indicated that SF-CS scaffolds increase the

adhesion and growth of osteoblast cells. The observations in the

present study achieved the primary objective in determining whether

SF-CS scaffolds have the potential to establish an adhesive

interface with osteoblast cells in vitro. The results also

confirmed that TGF-β1 was unable to promote the adhesion of

hFOB1.19 osteoblast cells to the SF-CS scaffolds.

The levels of cell growth and proliferation on the

scaffolds and control group were assessed in the present study

using CCK-8 and ALP assays in vitro. It was observed that

the absor-bance index of the assessed groups increased with the

increase in culture duration. After 1 day, no statistically

significant differences (P>0.05) were observed in cell activity

among the three groups. The activities of the hFOB1.19 cells

cultured on the TGF-β1-SF-CS and SF-CS scaffolds were higher than

that of the cells cultured in the control group after 3 days in

culture, which suggested that the scaffolds were beneficial to cell

development. The number of osteoblast cells on the TGF-β1-SF-CS

scaffolds were significantly higher, compared with those on the

SF-CS scaffolds. These results indicated that TGF-β1 significantly

promoted the attachment and proliferation of the osteoblast cells.

The results of the present study also support evidence from in

vitro experiments that TGF-β1 may regulate bone formation

through a direct effect on osteoblasts. It has been reported that

human TGF-β1 binds to osteoblasts in culture, and is capable of

inducing migration and alkaline phosphatase activity (41). The results of the present study

indicated differences in the activities of the osteoblast cells in

the different scaffold groups. The reason for the differences in

the production of extracellular matrices in the different scaffolds

may be due to the differences in the chemical compositions of the

matrices.

The enhancement of osteoblast cell proliferation and

activity by TGF-β1 was time-dependent. TGF-β1 did not significantly

promote the activity or proliferation of osteoblast cells during

the first 3 days of culture, however, it had a marked effect when

cultured between days 3 and 10, demonstrating that the effect of

TGF-β1, which promotes the activity and proliferation of osteoblast

cells, was time-dependent. These results indicated that the TGF-β1

delivery strategies have a marked affect on osteogenic

differentiation and require consideration when designing such a

delivery system.

Previous results have indicated that this 3D

environment, coupled with growth factor application, may be key in

recreating an in vitro tissue-specific microenvironment for

improving bone repair strategies. The results of the present study

support the suggested that TGF-β1 is important for promoting

hFOB1.19 osteoblast cell extracellular matrix production. Based on

the observations in the present study following 10 days of culture,

future bone tissue engineering investigations can be performed to

focus on how TGF-β1 combines with the SF-CS scaffold, whether the

sustained release of TGF-β1 is maintained and enhanced over longer

durations, and whether the culture of different type of cells on

the SF-CS-SF-CS scaffolds yield similar outcomes.

In conclusion, the results of the present study

confirmed that the direct effects of TGF-β1 on osteoblast cells

were an increase in the proliferation, migration, differentiation

and survival of the cells. The TGF-β1-SF-CS scaffolds were

biocompatible and had no negative effects on the hFOB1.19

osteoblast cells in vitro. The SF-CS composite material may

offer potential as an ideal scaffold material for bone tissue

engineering.

Acknowledgments

The current study was supported by the Science and

Technology Plan Project of Liaoning Province (grant. no. 20

12-B-00002012225082).

References

|

1

|

Vacanti JP and Langer R: Tissue

engineering: The design and fabrication of living replacement

devices for surgical reconstruction and transplantation. Lancet.

354(Supp 1): SI32–SI34. 1999. View Article : Google Scholar : PubMed/NCBI

|

|

2

|

Scheller EL, Krebsbach PH and Kohn DH:

Tissue engineering: State of the art in oral rehabilitation. J Oral

Rehabil. 36:368–389. 2009. View Article : Google Scholar : PubMed/NCBI

|

|

3

|

Hankenson KD, Dishowitz M, Gray C and

Schenker M: Angiogenesis in bone regeneration. Injury. 42:556–561.

2011. View Article : Google Scholar : PubMed/NCBI

|

|

4

|

Marsell R and Einhorn TA: The biology of

fracture healing. Injury. 42:551–555. 2011. View Article : Google Scholar : PubMed/NCBI

|

|

5

|

Muschler GF, Nakamoto C and Griffith LG:

Engineering principles of clinical cell-based tissue engineering. J

Bone Joint Surg Am. 86-A:1541–1558. 2004.PubMed/NCBI

|

|

6

|

Grayson WL, Chao PH, Marolt D, Kaplan DL

and Vunjak-Novakovic G: Engineering custom-designed osteochondral

tissue grafts. Trends Biotechnol. 26:181–189. 2008. View Article : Google Scholar : PubMed/NCBI

|

|

7

|

Vunjak-Novakovic G, Meinel L, Altman G and

Kaplan D: Bioreactor cultivation of osteochondral grafts. Orthod

Craniofac Res. 8:209–218. 2005. View Article : Google Scholar : PubMed/NCBI

|

|

8

|

Adams JC and Watt FM: Regulation of

development and differentiation by the extracellular matrix.

Development. 117:1183–1198. 1993.PubMed/NCBI

|

|

9

|

Zhang LH and Zhang QQ: Study on the

osteoblast and the growth factors of bone tissue engineering.

Zhongguo Yi Xue Ke Xue Yuan Xue Bao. 23:631–637. 2001.In

Chinese.

|

|

10

|

Bonewald LF and Dallas SL: Role of active

and latent transforming growth factor beta in bone formation. J

Cell Biochem. 55:350–357. 1994. View Article : Google Scholar : PubMed/NCBI

|

|

11

|

Saitta B, Passarini J, Sareen D, Ornelas

L, Sahabian A, Argade S, Krakow D, Cohn DH, Svendsen CN and Rimoin

DL: Patient-derived skeletal dysplasia induced pluripotent stem

cells display abnormal chondrogenic marker expression and

regulation by BMP2 and TGF-β1. Stem Cells Dev. 23:1464–1478. 2014.

View Article : Google Scholar : PubMed/NCBI

|

|

12

|

Lind M: Growth factor stimulation of bone

healing. Effects on osteoblasts, osteomies and implants fixation.

Acta Orthop Scand Suppl. 283:2–37. 1998.PubMed/NCBI

|

|

13

|

Connelly JT, Wilson CG and Levenston ME:

Characterization of proteoglycan production and processing by

chondrocytes and BMSCs in tissue engineered constructs.

Osteoarthritis Cartilage. 16:1092–1100. 2008. View Article : Google Scholar : PubMed/NCBI

|

|

14

|

Mouw JK, Connelly JT, Wilson CG, Michael

KE and Levenston ME: Dynamic compression regulates the expression

and synthesis of chondrocyte-specific matrix molecules in bone

marrow stromal cells. Stem Cells. 25:655–663. 2007. View Article : Google Scholar

|

|

15

|

Johnstone B, Hering TM, Caplan AI,

Goldberg VM and Yoo JU: In vitro chondrogenesis of bone

marrow-derived mesenchymal progenitor cells. Exp Cell Res.

238:265–272. 1998. View Article : Google Scholar : PubMed/NCBI

|

|

16

|

Vehof JW, Haus MT, de Ruijter AE, Spauwen

PH and Jansen JA: Bone formation in transforming growth factor

beta-I-loaded titanium fiber mesh implants. Clin Oral Implants Res.

13:94–102. 2002. View Article : Google Scholar : PubMed/NCBI

|

|

17

|

Holland TA, Tessmar JK, Tabata Y and Mikos

AG: Transforming growth factor-beta 1 release from oligo

(poly(ethylene glycol) fumarate) hydrogels in conditions that model

the cartilage wound healing environment. J Control Release.

94:101–104. 2004. View Article : Google Scholar

|

|

18

|

Motoyama M, Deie M, Kanaya A, Nishimori M,

Miyamoto A, Yanada S, Adachi N and Ochi M: In vitro cartilage

formation using TGF-beta-immobilized magnetic beads and mesenchymal

stem cell-magnetic bead complexes under magnetic field conditions.

J Biomed Mater Res A. 92:196–204. 2010. View Article : Google Scholar

|

|

19

|

Park H, Temenoff JS, Tabata Y, Caplan AI,

Raphael RM, Jansen JA and Mikos AG: Effect of dual growth factor

delivery on chondrogenic differentiation of rabbit marrow

mesenchymal stem cells encapsulated in injectable hydrogel

composites. J Biomed Mater Res A. 88:889–897. 2009. View Article : Google Scholar

|

|

20

|

Fischer U, Hempel U, Becker D, Bierbaum S,

Scharnweber D, Worch H and Wenzel KW: Transforming growth factor

beta1 immobilized adsorptively on Ti6Al4V and collagen type I

coated Ti6Al4 V maintains its biological activity. Biomaterials.

24:2631–2641. 2003. View Article : Google Scholar : PubMed/NCBI

|

|

21

|

Dickhut A, Dexheimer V, Martin K, Lauinger

R, Heisel C and Richter W: Chondrogenesis of human mesenchymal stem

cells by local TGF-beta delivery in a biphasic resorbable carrier.

Tissue Eng Part A. 16:453–464. 2010. View Article : Google Scholar

|

|

22

|

Park JS, Yang HJ, Woo DG, Yang HN, Na K

and Park KH: Chondrogenic differentiation of mesenchymal stem cells

embedded in a scaffold by long-term release of TGF-beta3 complexed

with chondroitin sulfate. J Biomed Mater Res A. 92:806–816.

2010.

|

|

23

|

Murphy CM, O'Brien FJ, Little DG and

Schindeler A: Cell-scaffold interactions in the bone tissue

engineering triad. Eur Cell Mater. 26:120–132. 2013.PubMed/NCBI

|

|

24

|

Roberts AB and Sporn MB: Physiological

actions and clinical applications of transforming growth

factor-beta (TGF-beta). Growth Factors. 8:1–9. 1993. View Article : Google Scholar : PubMed/NCBI

|

|

25

|

D'Ippolito G, Schiller PC, Ricordi C, Roos

BA and Howard GA: Age-related osteogenic potential of mesenchymal

stromal stem cells from human vertebral bone marrow. J Bone Miner

Res. 14:1115–1122. 1999. View Article : Google Scholar : PubMed/NCBI

|

|

26

|

Kassem M, Kveiborg M and Eriksen EF:

Production and action of transforming growth factor-beta in human

osteoblast cultures: Dependence on cell differentiation and

modulation by calcitriol. Eur J Clin Invest. 30:429–437. 2000.

View Article : Google Scholar : PubMed/NCBI

|

|

27

|

Alliston T, Choy L, Ducy P, Karsenty G and

Derynck R: TGF-beta-induced repression of CBFA1 by Smad3 decreases

cbfa1 and osteocalcin expression and inhibits osteoblast

differentiation. EMBO J. 20:2254–2272. 2001. View Article : Google Scholar : PubMed/NCBI

|

|

28

|

Park SJ, Lee KY, Ha WS and Park SY:

Structural changes and their effect on mechanical properties of

silk fibroin/chitosan blends. Journal of Applied Polymer Science.

74:2571–2575. 1999. View Article : Google Scholar

|

|

29

|

El Sayed K, Marzahn U, John T, Hoyer M,

Zreiqat H, Witthuhn A, Kohl B, Haisch A and Schulze-Tanzil G:

PGA-associated heterotopic chondrocyte cocultures: Implications of

nasoseptal and auricular chondrocytes in articular cartilage

repair. J Tissue Eng Regen Med. 7:61–72. 2013. View Article : Google Scholar

|

|

30

|

De Santis R, Gloria A, Russo T, et al: A

basic approach toward the development of nanocomposite magnetic

scaffolds for advanced bone tissue engineering. Journal of Applied

Polymer Science. 122:3599–3605. 2011. View Article : Google Scholar

|

|

31

|

Gobin AS, Froude VE and Mathur AB:

Structural and mechanical characteristics of silk fibroin and

chitosan blend scaffolds for tissue regeneration. J Biomed Mater

Res A. 74:465–473. 2005. View Article : Google Scholar : PubMed/NCBI

|

|

32

|

Saharinen J, Hyytiäinen M, Taipale J and

Keski-Oja J: Latent transforming growth factor-beta binding

proteins (LTBPs)-structural extracellular matrix proteins for

targeting TGF-beta action. Cytokine Growth Factor Rev. 10:99–117.

1999. View Article : Google Scholar

|

|

33

|

Mierisch CM, Cohen SB, Jordan LC,

Robertson PG, Balian G and Diduch DR: Transforming growth

factor-beta in calcium alginate beads for the treatment of

articular cartilage defects in the rabbit. Arthroscopy. 18:892–900.

2002. View Article : Google Scholar : PubMed/NCBI

|

|

34

|

Haines AH: Non-equivalence of D- and

L-trehalose in stabilising alkaline phosphatase against

freeze-drying and thermal stress. Is chiral recognition involved?

Org Biomol Chem. 4:702–706. 2006. View

Article : Google Scholar : PubMed/NCBI

|

|

35

|

Kreilgaard L, Jones LS, Randolph TW,

Frokjaer S, Flink JM, Manning MC and Carpenter JF: Effect of Tween

20 on freeze-thawing- and agitation-induced aggregation of

recombinant human factor XIII. J Pharm Sci. 87:1597–1603. 1998.

|

|

36

|

Pikal-Cleland KA and Carpenter JF:

Lyophilization-induced protein denaturation in phosphate buffer

systems: Monomeric and tetrameric beta-galactosidase. J Pharm Sci.

90:1255–1268. 2001. View

Article : Google Scholar : PubMed/NCBI

|

|

37

|

Klibanov AM: Enzymatic catalysis in

anhydrous organic solvents. Trends Biochem Sci. 14:141–144. 1989.

View Article : Google Scholar : PubMed/NCBI

|

|

38

|

Mandal BB and Kundu SC: Calcium alginate

beads embedded in silk fibroin as 3D dual drug releasing scaffolds.

Biomaterials. 30:5170–5177. 2009. View Article : Google Scholar : PubMed/NCBI

|

|

39

|

Nwe N, Furuike T and Tamura H: The

mechanical and biological properties of chitosan scaffolds for

tissue regeneration templates are significantly enhanced by

chitosan from gongronella butleri. Materials. 2:374–398. 2009.

View Article : Google Scholar

|

|

40

|

Neamnark A, Sanchavanakit N, Pavasant P,

Bunaprasert T, Supaphol P and Rujiravanit R: In vitro

biocompatibility evaluations of hexanoyl chitosan film.

Carbohydrate Polymers. 68:166–172. 2007. View Article : Google Scholar

|

|

41

|

Bonewald LF and Mundy GR: Role of

transforming growth factor beta in bone remodeling: A review.

Connect Tissue Res. 23:201–208. 1989. View Article : Google Scholar : PubMed/NCBI

|