Introduction

Researchers proposed the concept of osseointegration

in the 1960s, which laid the theoretical foundation for prostheses

implantation (1). Osseointegration

is the close connection between implant and bone in the body

without soft tissue interval, and is a prerequisite for prosthesis

stability, secure fixation and for the prosthesis to bear certain

pressure (2). There are numerous

factors that affect osseointegration, including biocompatibility,

shape design, material characteristics, patient bone conditions,

the application of bioactive molecules and surgical techniques

(2). Among these, material shape

design and characterization are the key factors that impact

bone-implant binding capacity and strength (2).

Currently, the surfaces of artificial joint

prostheses are usually treated with rough surfaces and

hydroxyapatite coating in order to provide good integration of the

bone and implant (3,4). However, this treatment limits the depth

and scope on the combination of bone and implants (5–7). A

porous implant design is speculated to an effective way to improve

bone ingrowth into prostheses and enhance the combination of the

range between bone and prosthetic surface so that aseptic loosening

may be prevented and long-term stability of artificial joints can

be obtained (8).

However, at present although several porous

materials have been used, they exhibit a range of disadvantages.

Titanium (Ti) has been extensively used for its excellent physical

properties and biocompatibility (9).

Though Ti has a porosity of 70%, which exhibited a plateau stress

of 53 MPa and an elastic modulus of 3.4 GPa (10), its compressive strength is still

lower compared with cortical bone. Certain other elements, such as

aluminum, nickel, iron, vanadium and chromidium, can generate

adverse biological effects due to the release of metal ions

(11). By contrast, Ti, niobium (Nb)

and tantalum (Ta) are believed to be nontoxic metals with good

biocompatibility (12). Compared

with Ta, Ti and Nb are lightweight and inexpensive (13). There is limited prior research on

porous Ti-Nb binary alloys. In our previous studies, we have

investigated the biocompatibility of porous Ti-25Nb in vitro

(13). This study aims to

investigate the characteristics of porous Ti-25Nb in vivo

and observe the binding capacity and strength of bone-implant

interface, thus providing further theoretical basis for the

clinical application of porous Ti-25Nb alloy.

Materials and methods

Ethical approval

All animal experiments were performed according to

protocols approved by the Institutional Animal Care and Use

Committee of Central South University (Changsha, China).

Design of the implanted prosthesis

sample for the rabbit model

A New Zealand white rabbit, provided by the

Experimental Animal Center of the Third Xiangya Hospital of Central

South University, weighing ~2.4 kg was euthanized, a full-length

femur was exposed after careful dissection, and then the

anteroposterior and lateral X-rays were obtained. The femur was cut

in the sagittal plane and coronal plane, respectively, so as to

observe the morphology of the medullary cavity. The prosthesis

specimen was designed accordingly.

Preparation of porous Ti-25Nb

prosthesis samples

Samples with different porosities were prepared

using powder metallurgy. The details of the process were described

in our previous study (9).

In vivo experiment

A total of 36 healthy New Zealand rabbits (age, 4–6

months; weight, 2.2–2.6 kg) were divided into three groups (n=12

per group). Dense specimens (<2% porosity), specimens with 40%

porosity and specimens with 70% porosity were tested in each of the

three groups, respectively.

Surgical procedures

After the rabbits were anesthetized using

pentobarbital (1 ml/kg; Sigma-Aldrich, St. Louis, MO, USA), skin

preparation and sterilization were performed on the lateral sides

of the left hips. A 3-cm straight incision was made on the skin of

the greater trochanter; the subcutaneous tissues and deep fascia

were cut layer by layer. Then, the gluteus maximus and the greater

trochanter were exposed. Parts of muscles attached to the great

trochanter were stripped, and the bone of the greater trochanter

and the top of the femoral neck were broken away. The medial part

of the femoral neck were carefully protected. Reamed into the

medullary cavity, gradually enlarged it, and drilled into 2 cm

depth using a drill 4–6 mm in diameter. The medullary cavity was

cleaned using normal saline and specimens were implanted into the

cavities along the longitudinal axis of the femur. The wound was

flushed with hydrogen peroxide and saline and sutured layer by

layer. Postoperatively, intramuscular injection of penicillin was

performed to prevent infection, for three days.

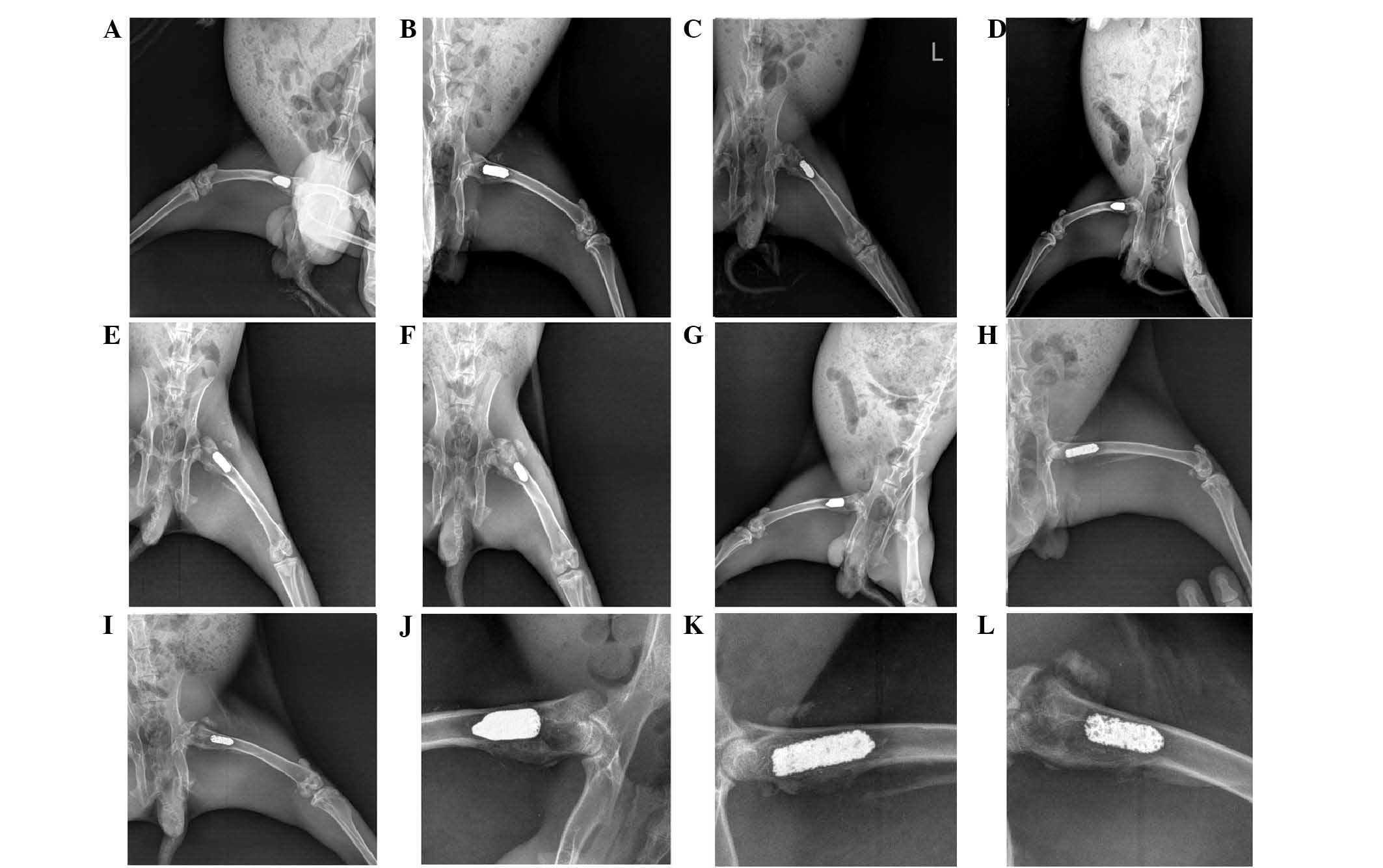

Postoperative X-rays

Rabbits underwent anteroposterior and lateral X-rays

at two, four, and eight-week time points postoperatively.

Sample extraction and preparation for

tests

Three rabbits in each group were sacrificed using 3%

pentobarbital overdose (4 ml/kg) at two, four and eight-week time

points postoperatively. The bilateral femurs and soft tissue on

them were all removed. Then they were immersed in formalin solution

as saved backup. Two of the specimens in each group underwent

scanning electron microscope (SEM) and energy dispersive X-ray

spectroscopy (EDS) analysis, with the rest for pulling-out

test.

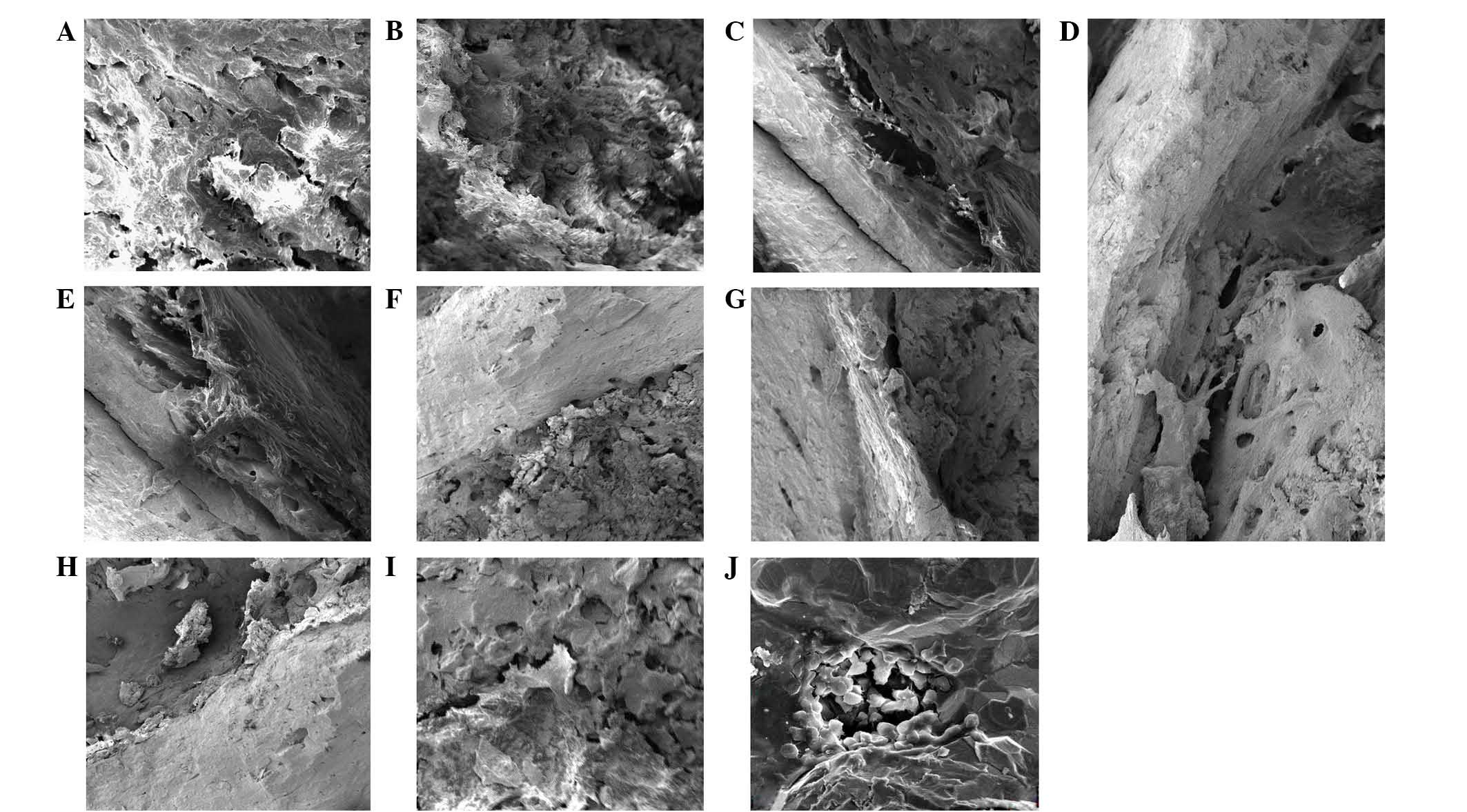

SEM of bone-implant interface and EDS

analysis

The anterior and posterior femoral cortical bones

were cut along the sagittal plane longitudinally, exposing the

bone-implant interface. The specimens, which were to be observed by

SEM and EDS analysis, were dried. EDS elemental analysis was

performed to characterize the calcium (Ca), Ti, Nb and phosphorus

(P) content of the samples.

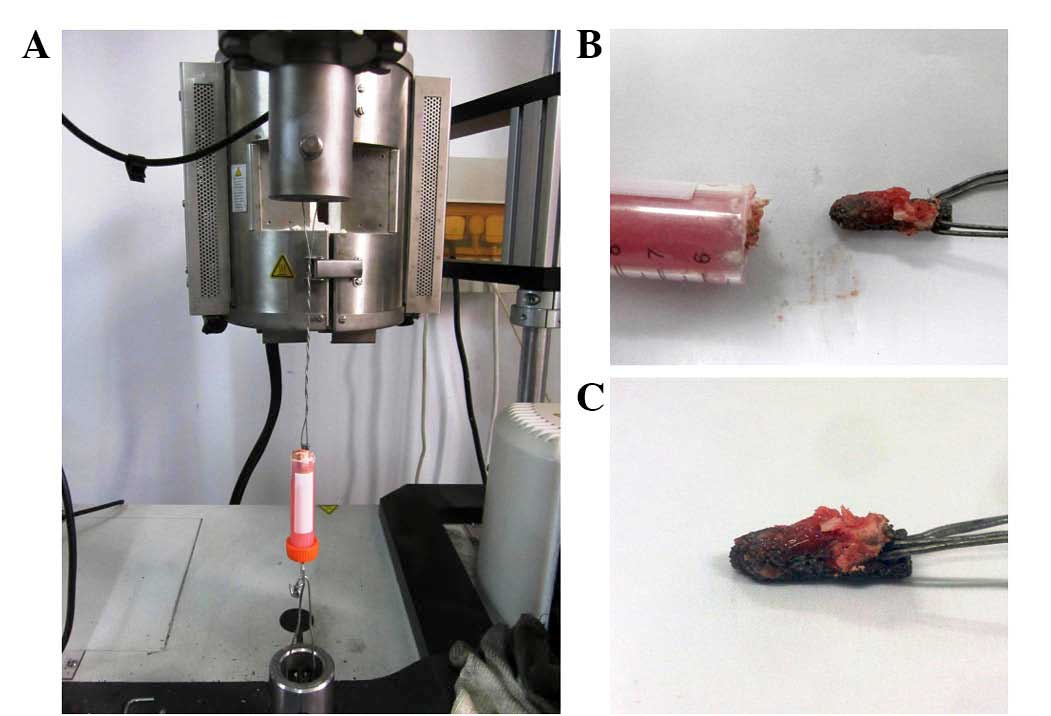

Pulling-out test

The samples that contained femurs with porous

Ti-25Nb specimens implanted were fixed into the mixture by mixing

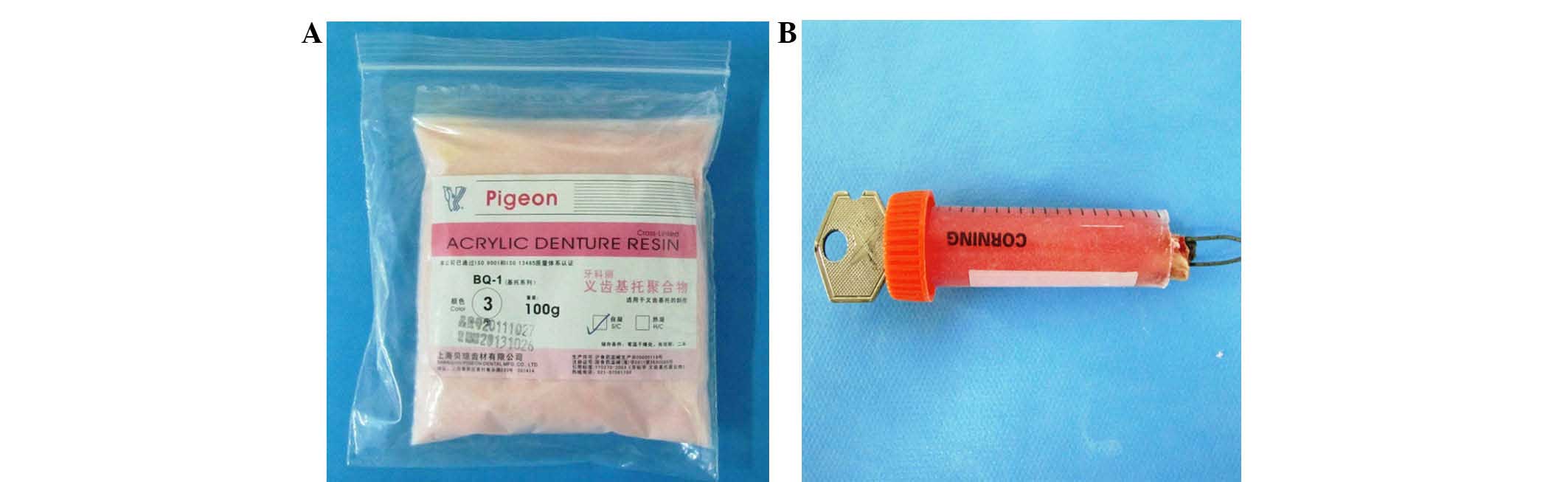

the denture powder (Fig. 1A)

(denture base polymer; Shanghai Beiqiong Tooth Material Co., Ltd.,

Shanghai, China) with self-curing denture water (methyl

methacrylate) in the mold. Care was taken to avoid the denture

powder infiltrating into the interface of exposed prosthesis and

bone, which may increase the pulling-out strength and affect the

accuracy of the observed data. A steel wire was crossed into a hole

pre-prepared on the prosthesis for pulling out (Fig. 1B), and it was fixed into the clamp of

the mechanical testing machine (3369 Dual-Column Universal Testing

System; Instron, Norwood, MA, USA). The distal ends of the

specimens were also fixed. The machine's continual displacement of

was set to 2 mm/min and underwent pretension for this test. The

pulling strength and displacement were recorded automatically using

a computer.

Statistical analysis

Statistical analyses were performed by SPSS version

20.0 (IBM SPSS, Amronk, NY, USA). Variance analysis was used to

compare the differences between groups at the same time point.

Values of P<0.05 were considered significant.

Results

Design of the implanted

prosthesis

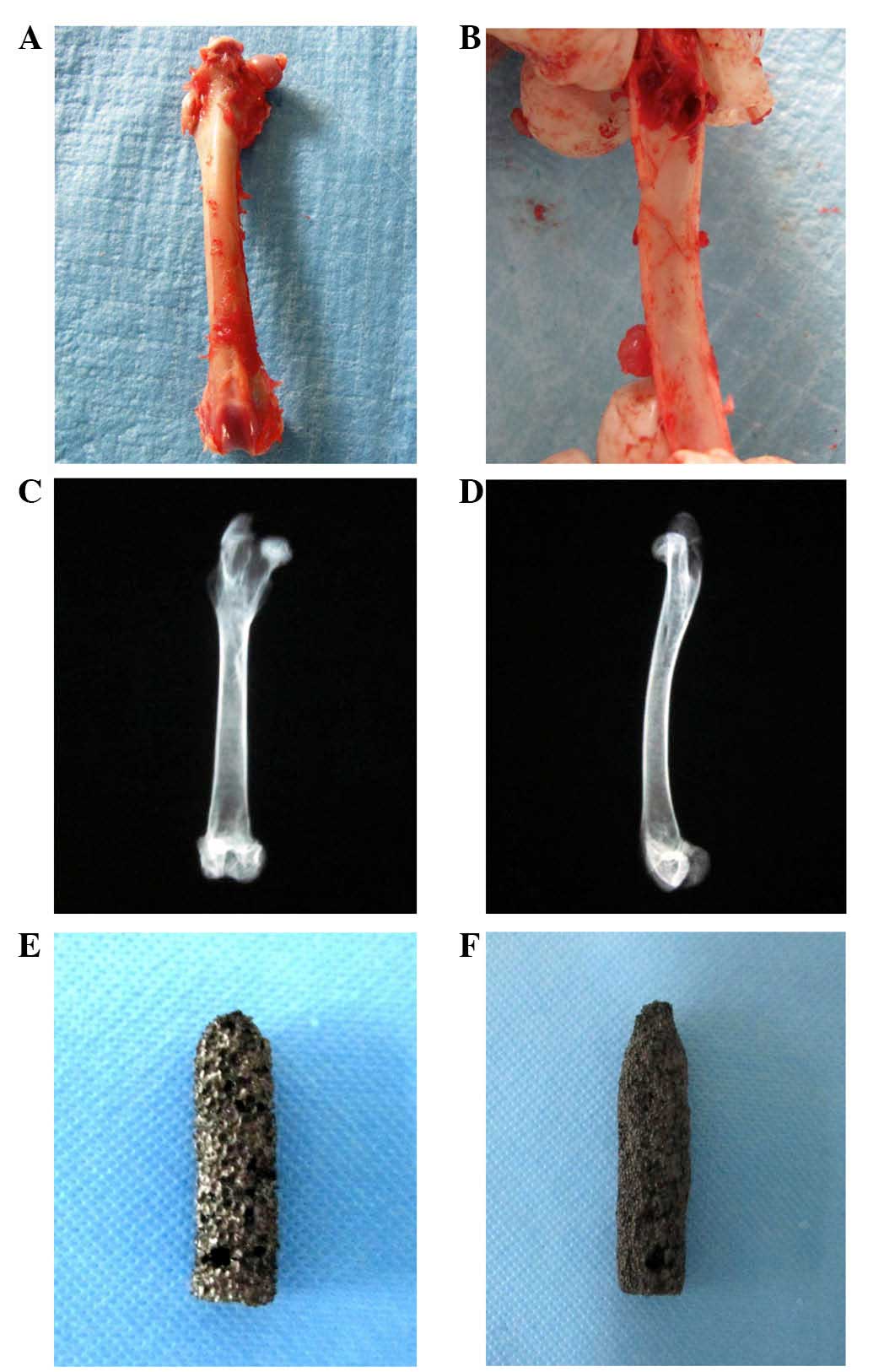

After dissecting the tissues around the femur, the

morphology and the inner diameter of the medullary cavity were

observed (Fig. 2A and B). The X-ray

was obtained for the whole-length femur (Fig. 2C and D). It showed that the cortex of

the lower femoral neck was thick, while the cortex in the femur

shaft was loose. According to these characteristics, the prosthesis

was designed for a cylindrical shape, with a diameter of 7 mm and a

height of 25 mm. Its distal end turns out to be cone-shaped

(Fig. 2E and F). A hole with a

diameter of 1.5 mm was designed on the top part of the specimen so

as to be prepared for the pulling-out test (Fig. 2E and F).

Observations for surgical procedures

and postoperative conditions

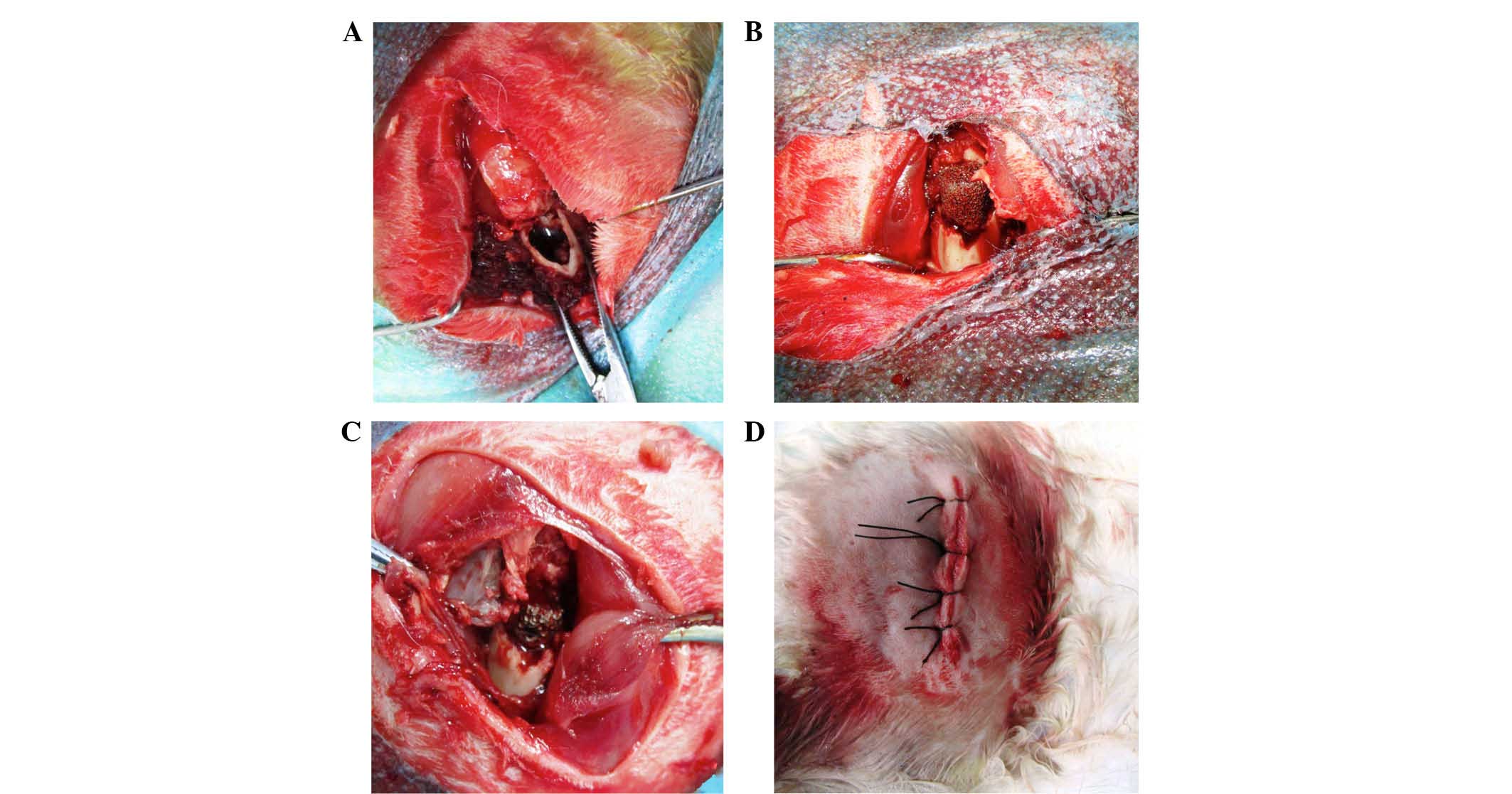

The process of the surgical procedure of the

specimen implantation was observed (Fig.

3). No fractures and side effects were observed during the

operations and for seven days postoperatively.

Observations for gross specimens and

HE staining

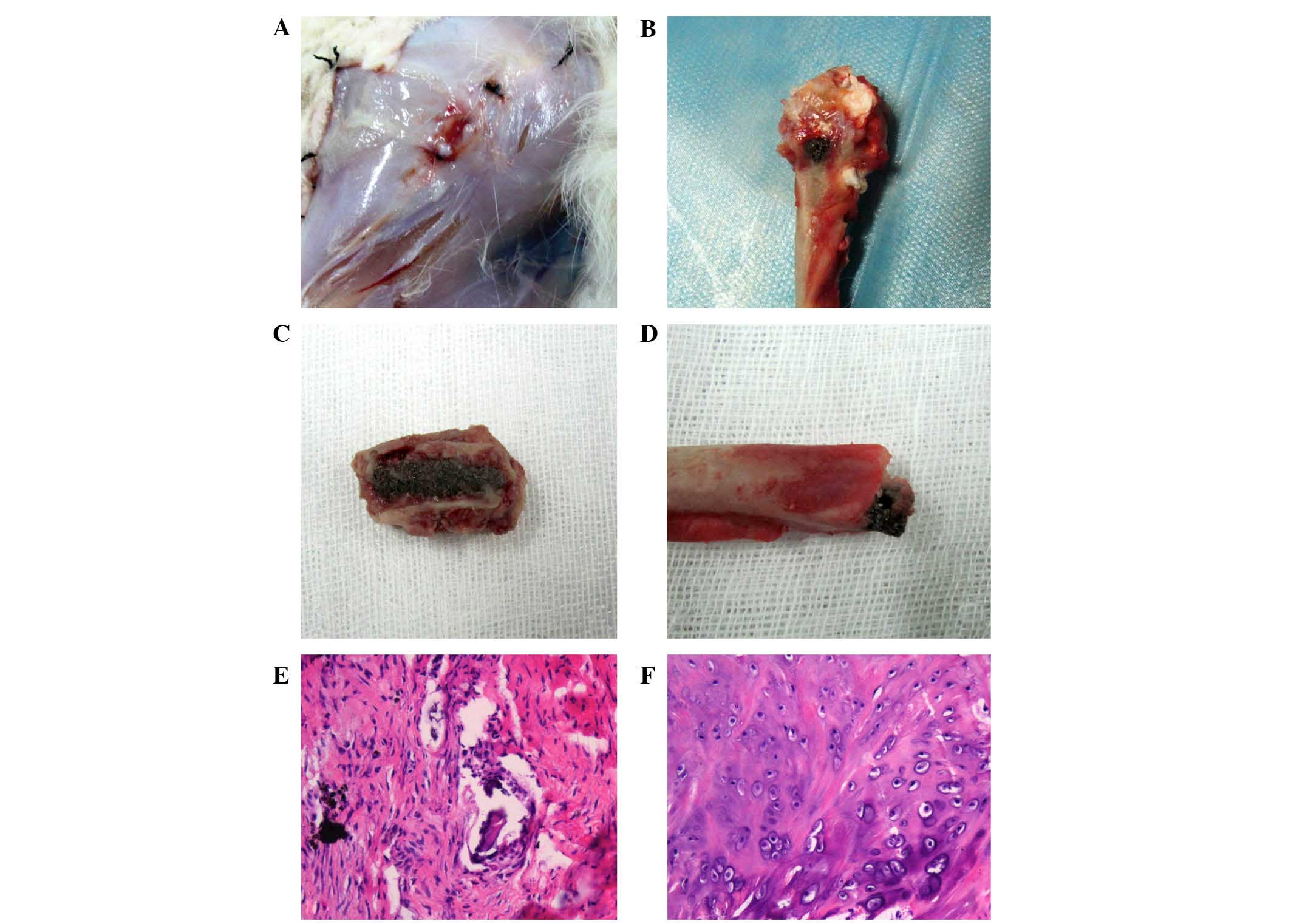

After the rabbits were euthanized, we dissected the

tissues around to expose the implants. The results revealed no

atrophy or noticeable secretions around the femurs (Fig. 4A). No loosening was observed in all

the specimens (Fig. 4B-D). While the

top part of the implant was exposed, a close bonding combination

was seen between the bone and implant (Fig. 4D). The soft tissue around the top

part of the implant was sliced for HE staining observation, and Ca

was observed in the soft tissues around, and no obvious

inflammation was seen (Fig. 4F).

X-ray examination

All specimens in each group showed a close

connection with bone tissues. No low-density shadow of bone

absorption was observed in bone tissues (Fig. 5A-K). By eight weeks, more cancellous

bone was observed around the implants.

SEM observation

SEM showed Ca deposits on the surface of the

materials (Fig. 6A and B). With

regard to the bonding condition on the interface of bone and

implant, gaps remained between them by two weeks (Fig. 6C and D). A close bonding was

observed, with tissue ingrowth of the pores at the time point of

four weeks (Fig. 6E and F). While it

showed Ca deposits on the surface of the specimens, and more inside

the pores by eight weeks, the interface between had no obvious

boundaries (Fig. 6G and H). The

sectional SEM showed osseointegration between bone and implant;

bone ingrowth could be seen deeply inside the pores (Fig. 6I and J).

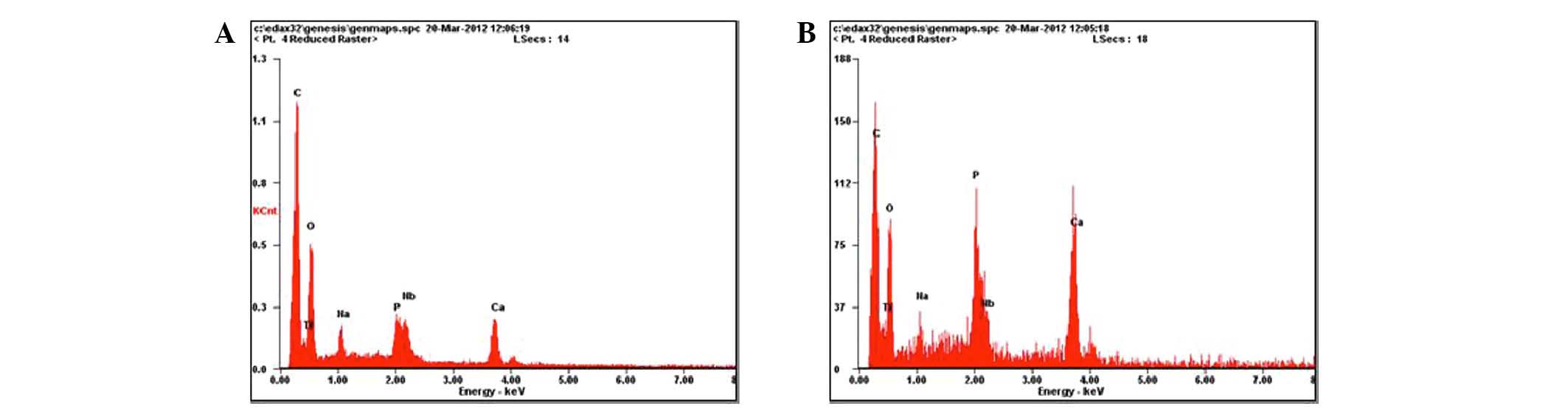

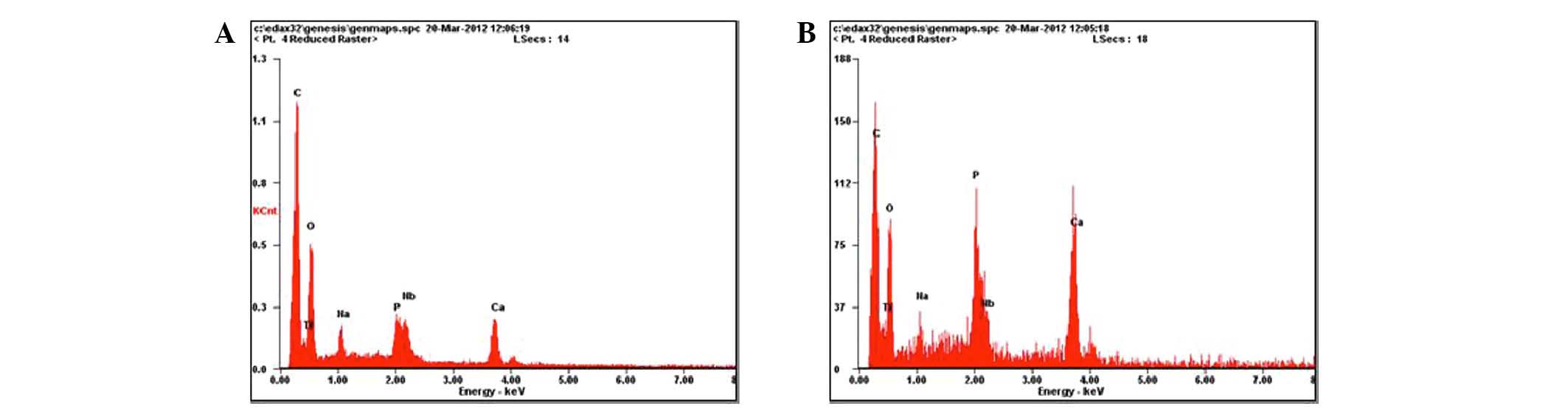

EDS analysis

By eight weeks, semiquantitative EDS analysis on the

interface of a specimen and bone showed that Ca, Ti and Nb were

3.24, 23.26 and 3.53% (Fig. 7A),

respectively, while inside the pores, 9.12% for Ca, 21.90% for Ti,

3.83% for Nb, and 4.37% for P was detected (Fig. 7B).

| Figure 7.Energy dispersive X-ray spectroscopy

(EDS) analysis. (A) By eight weeks, semiquantitative EDS analysis

on the interface of a specimen and bone showed that calcium,

titanium and niobium were 3.24, 23.26 and 3.53%, respectively. (B)

Inside the pores, the values for calcium, titanium, niobium and

phosphorus were 9.12, 21.90, 3.83 and 4.37%, respectively. |

Analysis of pulling-out test

A pulling-out test was conducted using a mechanical

testing machine (Instron) (Fig. 8A).

The upper and distal ends of the specimens were fixed in one

vertical axis so as to avoid shearing force. The data were

collected automatically by the machine, linked to the computer. All

tests were accomplished without any rupture of the prostheses;

however, certain prostheses were well pulled out with part of the

bone adhered (Fig. 8B and C). The

data of the different groups are listed in Table I. At two, four and eight weeks, the

maximum pulling-out force of the dense group was smaller compared

with the other two groups, and the difference was statistically

significant (P<0.05). The pulling-out force in the 70% porosity

group was significantly higher than the 40% porosity group by four

and eight weeks (P<0.05), while there was no significant

difference between the two groups at two weeks (P>0.05). By

eight weeks, the maximum pulling-out force of the 40% and 70%

porosity groups increased significantly compared with at two and

four weeks (P<0.05), while the force between two and four weeks

had no significant difference (P>0.05).

| Table I.Comparison of pull-out strength in the

three groups. |

Table I.

Comparison of pull-out strength in the

three groups.

|

| Maximal pull-out

force (N) |

|---|

|

|

|

|---|

| Group | 2 weeks | 4 weeks | 8 weeks |

|---|

| Dense |

76.0±11.1 |

80.2±16.0 |

113.8±11.5 |

| 40% porosity |

225.9±19.5 |

260.0±22.8 |

334.6±25.7 |

| 70% porosity |

229.5±25.5 |

280.3±20.8 |

376.1±27.4 |

Discussion

Osseointegration is a phenomenon by which a

prosthesis may make contact with the bone tissue directly and that

is able to withstand the stress of use (1). It is a combinative reaction of bone and

implant, which can be affected by a variety of factors, including

biocompatibility of the implant, morphology design of the implant,

surface structural properties and internal morphology of the

implant, the partial mechanical environment and biological

environment, systematic factors of the body, surgical techniques

and the load supported (2). The

bone-implant interface provides safe and reliable mechanical

transmission between implants and bone tissue, and the situation of

interface formation has a great influence on the long-term

stability. A stable tightly combined interface is not only

conducive to prevent migration of wear particles but also provides

a good foundation for the long-term stability of the prosthesis

(14). With the rate of the

bone-implant interface osseointegration improved, the mechanical

strength of the interface is also substantially improved and the

early osseointegration has a greater impact on bone-implant

interface strength (14).

The majority of the currently available Ti and Ti

alloy implants in clinical application are dense (15,16).

Although certain methods, such as surface treatment, can be applied

to increase the contact area, these methods produce certain effects

on bone integration between implants and bone. However, the bone

tissue can only extend to the implant surface field and not the

interior of implants (16).

Biological fixation is not achieved when long-term stability is not

guaranteed (16). Given the

difference in mechanical properties, the dense-type alloy causes

stress shelter after implantation in the body, which eventually

leads to bone resorption. Numerous studies have indicated that

excess bone loss influences the long-term effect of implants and

leads to implant displacement, aseptic loosening, fracture around

the prosthesis and increase in the difficulty of revision surgery

(14–17). To improve the binding capacity

between interface of bone and implant, the concept of

microtechnology was gradually introduced in recent years (18). Although several porous alloys are now

available in the medical field, porous Ti-Nb alloy is a relatively

cost-effective, which is also nontoxic and has good machinability

and mechanical strength compared with other porous alloys (13,18). The

porous Ti-Nb alloy used in the present study has a high strength

with the elastic modulus body close to human cortical bone, which

has been verified in our previous study in vitro (13). The degree of bone ingrowth of porous

materials depends on several factors, including the porosity, the

extent of micromotion and stability between implant and bone, and

whether cortical or cancellous bone is contacted with the implant

and the size of the gap between the implant and bone (19,20).

Furthermore, the porosity, pore size and

bone-implant contact situation have effects on bone ingrowth, in

addition to the spatial structure of the material key factor

affecting bone conduction. Studies have shown that porous implants

must have interconnected voids in order to provide space for the

ingrowth of blood vessels and promote further bone tissue ingrowth

(16,21). Another point is that the porous

communication of the material is conductive to fluid transfer

within the body, which can accelerate its tissue growth in order to

increase the fixing strength (22).

The presently investigated porous Ti-Nb alloys, which have a pore

diameter of 200–500 µm, present with three-dimensional

connectivity, thus can provide more space for ingrowth. The EDS

analysis results in this study showed that Ca and P presented

increased deposits in the 70% porosity specimens, which had more

three-dimensional communication.

The increased surface area and roughness of the

materials could improve the mechanical interlocking of the bone,

thus enhancing the stability of the bone and implant. This

mechanical interlock condition increased the strength of the

pulling-out, while this condition could not be found in dense Ti-Nb

alloys. Bonding strength depends on a combination area of

bone-implant contacting, materials with higher porosity, and pore

size that has a larger surface area; therefore, the capacity to

resist pulling-out is increased (23–25). The

pulling-out test showed that the strength was higher in the 70% and

40% porosity groups compared with the dense group after being

implanted for four weeks. The strength for the 70% porosity group

was significantly higher compared with the 40% porosity and dense

groups after being implanted for eight weeks. This result indicates

that high porosity provided more space for the ingrowth of the bone

tissue and enhanced the mechanical interlock. De Vasconcellos et

al (26) developed a porous Ti

alloy using powder metallurgy technology, which can control the

porosity, pore size, and pore connectivity. The in vivo

experiment of his research also showed that high porosity,

appropriate pore size and connectivity of porous material is good

for bone tissue ingrowth and increase of pull-out strength.

SEM examination of the specimens after being

implanted for four and eight weeks showed that the bone tissue grew

into the inner pores. This was attributed to the properties of the

trabecular bone that grows along the mechanical direction (27), which indicated that pores began

bearing the mechanical load after they were implanted. This

indirectly confirms the young modulus of this material, which is

close to the bone around, so that it can avoid the shielding effect

of stress. A study by Ryan et al (28) that the compressive strength and young

modulus of the porous materials were more matched to bone rather

than dense materials. The mismatch of the mechanical properties

between bone and materials can cause stress shielding, leading to

local bone resorption and low bone regeneration, thus affecting the

growth of bone tissue. Studies have shown that the mechanical

stability of the implants depends on the quantity of bone tissue

present (28,29). The present experimental results

showed that the pull-out force increased with the extension of the

time after implantation. This may be associated with the increase

of mature bone tissue around implants, which is consistent with the

findings of Chen et al (30).

As mentioned earlier, we altered the mechanical properties of the

implant by adding the element of Nb into the Ti alloy, so as to

more closely replicate the mechanical properties of bone. In

addition, the porous Ti-Nb alloy not only improved the contact area

of bone-implant and enhanced bonding strength, but also reduced the

difference in elastic modulus between the bone and the implant.

In conclusion, a porous Ti-25Nb alloy implants

presents good biocompatibility as well as providing a biological

fixation between the bone and implant. A porosity of 70% is more

advantageous to the newborn bone ingrowth, combined with achieving

a more solid bone-implant interface.

Acknowledgements

The present study was supported by the Scientific

Research Project of the First Affiliated Hospital of Hunan Normal

University (grant no. RS201305).

References

|

1

|

Brånemark PI, Adell R, Breine U, Hansson

BO, Lindström J and Ohlsson A: Intra-osseous anchorage of dental

prostheses. I. Experimental studies. Scand J Plast Reconstr Surg.

3:81–100. 1969. View Article : Google Scholar : PubMed/NCBI

|

|

2

|

Zarb GA and Schmitt A: Implant

prosthodontic treatment options for the edentulous patient. J Oral

Rehabil. 22:661–671. 1995. View Article : Google Scholar : PubMed/NCBI

|

|

3

|

Faghihi S, Zhilyaev AP, Szpunar JA, Azari

F, Vali H and Tabrizian M: Nanostructuring of a titanium material

by high-pressure torsion improves pre-osteoblast attachment. Adv

Mater. 19:1069–1073. 2007. View Article : Google Scholar

|

|

4

|

Rupp F, Scheideler L, Olshanska N, de Wild

M, Wieland M and Geis-Gerstorfer J: Enhancing surface free energy

and hydrophilicity through chemical modifi cation of

microstructured titanium implant surfaces. J Biomed Mater Res A.

76:323–334. 2006. View Article : Google Scholar : PubMed/NCBI

|

|

5

|

Vora A, Kudrna JC, Harder VS and Mazahery

B: Early failure of a proximally cemented, distally uncemented

total hip arthroplasty. J Arthroplasty. 18:889–896. 2003.

View Article : Google Scholar : PubMed/NCBI

|

|

6

|

Song Y, Beaupre G and Goodman SB:

Osseointegration of total hip arthroplasties: Studies in humans and

animals. J Long Term Eff Med Implants. 9:77–112. 1999.PubMed/NCBI

|

|

7

|

LaPorte DM, Mont MA and Hungerford DS:

Proximally porous-coated ingrowth prostheses: Limits of use.

Orthopedics. 22:1154–1160. 1999.PubMed/NCBI

|

|

8

|

Kujala S, Ryhanen J, Danilov A and

Tuukkanen J: Effect of porosity on the osteointegration and bone

ingrowth of a weight-bearing nickel-titanium bone graft substitute.

Biomaterials. 24:4691–4697. 2003. View Article : Google Scholar : PubMed/NCBI

|

|

9

|

Li XK, Yuan CF, Wang JL, Zhang YQ, Zhang

ZY and Guo Z: The treatment effect of porous titanium alloy rod on

the early stage talar osteonecrosis of sheep. PLoS One.

8:e584592013. View Article : Google Scholar : PubMed/NCBI

|

|

10

|

Wen CE, Yamada Y, Shimojima K, Hosokawa H

and Mabuchi M: Novel titanium foam for bone tissue engineering. J

Mater Res. 17:2633–2639. 2002. View Article : Google Scholar

|

|

11

|

Wapner KL: Implications of metallic

corrosion in total knee arthroplasty. Clin Orthop Relat Res.

271:12–20. 1991.PubMed/NCBI

|

|

12

|

Long M and Rack HJ: Titanium alloys in

total joint replacement-a materials science perspective.

Biomaterials. 19:1621–1639. 1998. View Article : Google Scholar : PubMed/NCBI

|

|

13

|

Xu J, Weng XJ, Wang X, Huang JZ, Zhang C,

Muhammad H, Ma X and Liao QD: Potential use of porous

titanium-niobium alloy in orthopedic implants: Preparation and

experimental study of its biocompatibility in vitro. PLoS One.

8:e792892013. View Article : Google Scholar : PubMed/NCBI

|

|

14

|

Good V, Ries M, Barrack RL, Widding K,

Hunter G and Heuer D: Reduced wear with oxidized zirconium femoral

heads. J Bone Joint Surg Am. 85:105–110. 2003.PubMed/NCBI

|

|

15

|

Ryan GE, Pandit AS and Apatsidis DP:

Porous titanium scaffolds fabricated using a rapid prototyping and

powder metallurgy technique. Biomaterials. 29:3625–3635. 2008.

View Article : Google Scholar : PubMed/NCBI

|

|

16

|

Li C and Zhu Z: Dynamic Young's modulus of

open-porosity titanium measured by the electromagnetic acoustic

resonance method. J Porous Mater. 13:21–26. 2006. View Article : Google Scholar

|

|

17

|

Kröger H, Venesmaa P, Jurvelin J,

Miettinen H, Suomalainen O and Alhava E: Bone density at the

proximal femur after total hip arthroplasty. Clin Orthop Relat Res.

66–74. 1998.

|

|

18

|

Wang X, Li Y, Hodgson PD and Wen C:

Biomimetic modification of porous TiNbZr alloy scaffold for bone

tissue engineering. Tissue Eng Part A. 16:309–316. 2010. View Article : Google Scholar : PubMed/NCBI

|

|

19

|

Cornell CN and Lane JM: Current

understanding of osteoconduction in bone regeneration. Clin Orthop

Relat Res. (355 Suppl): S267–S273. 1998. View Article : Google Scholar : PubMed/NCBI

|

|

20

|

Tisdel CL, Goldberg VM, Parr JA, Bensusan

JS, Staikoff LS and Stevenson S: The influence of a hydroxyapatite

and tricalcium-phosphate coating on bone growth into titanium

fiber-metal implants. J Bone Joint Surg Am. 76:159–171.

1994.PubMed/NCBI

|

|

21

|

van Eeden SP and Ripamonti U: Bone

differentiation in porous hydroxyapatite in baboons is regulated by

the geometry of the substratum: Implications for reconstructive

craniofacial surgery. Plast Reconstr Surg. 93:959–966. 1994.

View Article : Google Scholar : PubMed/NCBI

|

|

22

|

Nugroho AW, Leadbeater G and Davies IJ:

Processing of a porous titanium alloy from elemental powders using

a solid state isothermal foaming technique. J Mater Sci Mater Med.

21:3103–3107. 2010. View Article : Google Scholar : PubMed/NCBI

|

|

23

|

Baril E, Lefebvre LP and Hacking SA:

Direct visualization and quantification of bone growth into porous

titanium implants using micro computed tomography. J Mater Sci

Mater Med. 22:1321–1332. 2011. View Article : Google Scholar : PubMed/NCBI

|

|

24

|

Vasconcellos LM, Leite DO, Oliveira FN,

Carvalho YR and Cairo CA: Evaluation of bone ingrowth into porous

titanium implant: Histomorphometric analysis in rabbits. Braz Oral

Res. 24:399–405. 2010. View Article : Google Scholar : PubMed/NCBI

|

|

25

|

Faria PE, Carvalho AL, Felipucci DN, Wen

C, Sennerby L and Salata LA: Bone formation following implantation

of titanium sponge rods into humeral osteotomies in dogs: A

histological and histometrical study. Clin Implant Dent Relat Res.

12:72–79. 2010. View Article : Google Scholar : PubMed/NCBI

|

|

26

|

de Vasconcellos LM, Oliveira FN, Leite Dde

O, de Vasconcellos LG, do Prado RF, Ramos CJ, Graça ML, Cairo CA

and Carvalho YR: Novel production method of porous surface Ti

samples for biomedical application. J Mater Sci Mater Med.

23:357–364. 2012. View Article : Google Scholar : PubMed/NCBI

|

|

27

|

Allori AC, Sailon AM, Pan JH and Warren

SM: Biological basis of bone formation, remodeling, and repair-part

III: Biomechanical forces. Tissue Eng Part B Rev. 14:285–293. 2008.

View Article : Google Scholar : PubMed/NCBI

|

|

28

|

Ryan G, Pandit A and Apatsidis DP:

Fabrication methods of porous metals for use in orthopaedic

applications. Biomaterials. 27:2651–2670. 2006. View Article : Google Scholar : PubMed/NCBI

|

|

29

|

Simank HG, Stuber M, Frahm R, Helbig L,

van Lenthe H and Müller R: The influence of surface coatings of

dicalcium phosphate (DCPD) and growth and differentiation factor-5

(GDF-5) on the stability of titanium implants in vivo.

Biomaterials. 27:3988–3994. 2006. View Article : Google Scholar : PubMed/NCBI

|

|

30

|

Chen D, Bertollo N, Lau A, Taki N, Nishino

T, Mishima H, Kawamura H and Walsh WR: Osseointegration of porous

titanium implants with and without electrochemically deposited DCPD

coating in an ovine model. J Orthop Surg Res. 6:562011. View Article : Google Scholar : PubMed/NCBI

|