Introduction

Cardiovascular disease is a major disease that

threatens human health, with the main pathological feature being

atherosclerosis (AS). The identification of methods for suppressing

intimal hyperplasia and delaying the progress of AS remains a

worldwide challenge (1). There is

currently no effective preventive measure for diseases with intimal

plaque hyperplasia as the main pathological feature; in particular,

there is no drug that directly targets the molecular components of

blood-intimal atherosclerotic plaques.

Rapamycin and its derivatives can inhibit the

proliferation of vascular smooth muscles (2). In certain research, rapamycin

exhibited significant effects against restenosis occurring

post-coronary intervention when used as a drug-coated stent

(3). While a drug-coated stent is

effective in the focal vessel, it is not able to act at non-stent

covered sites or in other systemic diseases, such as AS, which

cannot be treated with a stent (4). Moreover, rapamycin is a drug with

poor solubility that is unstable in stomach acid, and has an oral

bioavailability of only 14%. Therefore, it cannot play a systemic

role through oral or intravenous administration methods (5).

In the present study, rapamycin was encapsulated

into liposomes. In the future, these may be modified with an

antibody or receptor, so that the liposomes are actively targeted

via antigen-antibody or substrate-receptor combination towards the

molecular components of atherosclerotic plaques, thus developing a

receptor- or antibody-mediated active targeting administration

system towards atherosclerotic plaques. Such a system could greatly

increase the concentration of drug at the focal site, and provide a

new prevention method with active targeting towards a variety of

diseases involving AS.

In this study, the ethanol injection method was used

to prepare a liposomal rapamycin-delivery system, and the

formulation was optimized. Reverse dialysis was used to investigate

the in vitro release characteristics of the

rapamycin-containing liposomes, with the aim of exploring the

mechanism, method and characteristics of in vitro release.

The findings should lay a foundation for the further development of

a liposomal delivery system for rapamycin, actively targeted

towards the cellular components of atherosclerotic plaques.

Materials and methods

Preparation of rapamycin-containing

liposomes

Various amounts of phospholipids (Shanghai Taiwei

Pharmaceutical Co., Ltd., Shanghai, China), cholesterol (Tianjin

Bodi Chemical Co., Ltd., Tianjin, China) and rapamycin (purity,

99.2%; Shanghai Qi Ao Chemical Science Co., Ltd., Shanghai, China)

were dissolved in various amounts of absolute ethanol. Then, under

stirring, the above mixture was slowly and uniformly injected into

phosphate buffer (Tianjin Bodi Chemical Co., Ltd.), and the

resulting mixture was stirred at 60°C. The ethanol was then removed

by reduced-pressure evaporation, and the obtained crude liposome

solution was then sequentially filtered through 0.8-, 0.45-, 0.22-

and 0.1-μm membranes, five times each, for particle preparation.

Finally, rapamycin-containing liposomes were obtained.

Establishment of the method for the

determination of rapamycin content

This was conducted using a Diamonsil C18 column

(150×4.6 mm, 5 μm; Dikma Technologies Inc., Lake Forest, CA, USA)

with Hitachi Pump L-2130 and UV Detector L-2400 (Hitachi, Tokyo,

Japan). The mobile phase was methanol (chromatographic grade;

Jiangsu Hanbang Technology Co., Ltd., Huai’an, China) and water

(78:22), with a flow rate of 1.0 ml/min. The UV detection

wavelength was 278 nm, the column temperature was 50°C and the

injection volume was 20 μl

A 10.0 mg sample of rapamycin was precisely weighed

into a 100-ml volumetric flask, dissolved in acetonitrile

(chromatographic grade; Jiangsu Hanbang Technology Co., Ltd.) and

diluted to the 100 ml mark, which gave a stock solution of

rapamycin at the concentration of 100 mg/l. A precise amount of

this stock solution was diluted with acetonitrile to form solutions

with concentrations of 2.0, 5.0, 10.0, 20.0, 50.0 and 100.0 mg/l.

The samples were analyzed according to the chromatographic

conditions described above. Then, a linear regression plot was

prepared of mass concentration (C) to peak area (A). The standard

curve had the formula: A = 55307C − 9873.2 (r=1), indicating that

the linear relationship of rapamycin was good in the range of 2 to

100 mg/l.

Into a 10-ml flask was added 0.5 ml blank liposome,

followed by 0.5, 2.0 or 5.0 ml stock rapamycin solution. Methanol

was used to break the liposomes and for dilution. The process was

repeated three times, and sample solutions with concentrations of

5.0, 20.0 and 50.0 mg/l were obtained for injection and the

calculation of recovery. The recovery rates were 99.73, 100.5 and

98.02%, respectively, with relative standard deviations of 0.24,

1.70 and 1.74 %, respectively.

Determination of encapsulation efficiency

(EE)

Sephadex G-50 microcolumn-centrifuging

high-performance liquid chromatography (HPLC) was used to separate

the liposomes and free rapamycin for the determination of EE

(6,7). The specific steps were as follows:

Sephadex G-50 (Bio-Rad, Hercules, CA, USA), which was fully swelled

with distilled water, was placed into a 5-ml syringe, then

centrifuged at 600 × g for 3 min, dehydrated and used to establish

the Sephadex G-50 microcolumn. Following the addition of 0.5 ml

rapamycin-containing liposomes to the top of the microcolumn, the

column was centrifuged at 600 × g for 3 min and the separated

liquid was collected. Then, 0.5 ml pH 7.4 buffer was continuously

added and the column was centrifuged using the same method to elute

the liposomes. The above process was repeated twice, and the eluent

was collected. Methanol was used to break the liposomes and dilute

to a volume of 10 ml prior to sample determination to calculate the

concentration of rapamycin (C1) encapsulated inside the

liposomes. Another 0.5 ml liposomes were directly diluted with

methanol to the same extent, but were not subjected to microcolumn

centrifugation, and sample determination was conducted to calculate

the rapamycin concentration C2. EE was then calculated

using the formula: EE (%) = C1/C2 × 100.

Statistical methods

Experimental data were statistically processed using

SPSS 12.0 software (SPSS, Inc., Chicago, IL, USA) and were

expressed as mean ± standard deviation. The results of orthogonal

experiments were analyzed by multivariate analysis of variance

(MANOVA), while partial results were analyzed by ANOVA.

Results

Investigation of univariate factors of

the rapamycin-containing liposome formulation

The phospholipid-cholesterol mass ratio, the

drug-lipid ratio and the aqueous phase pH of the formulation were

fixed; only the concentrations of phospholipid was changed to

prepare liposomes with phospholipid concentrations of 1, 2, 3, 4

and 5%, with the aim of investigating the impact of phospholipid

concentrations on the EE. The results demonstrated that in these

experimental conditions, as the phospholipid concentration

increased, the EE increased. However, excessively high phospholipid

concentrations resulted in the aggregation of phospholipids, making

it difficult for the rapamycin to be released.

The phospholipid concentration, drug-lipid ratio and

the aqueous phase pH of the formulation were fixed; only the

quantity of cholesterol was changed to prepare liposomes with

phospholipid-cholesterol mass ratios of 15:1, 10:1, 8:1, 6:1, 4:1

and 3:1. The results indicated that the EE exhibited a trend of

increasing initially and then decreasing as the amount of

cholesterol incorporated into the liposomes increased. Cholesterol

played the role of a regulating agent towards liposome membrane

fluidity, and improved the drug EE and stability. However,

excessive amounts of cholesterol competed for position in the

phospholipid bilayer position with the liposoluble drug, namely

rapamycin, resulting in decreased EE.

The phospholipid concentration,

phospholipid-cholesterol mass ratio and the aqueous phase pH of the

formulation were fixed, and the drug-lipid ratio was established at

1:10, 1:15, 1:20, 1:30 and 1:40 to prepare the liposomes. The

results indicated that when the drug-lipid ratio was greater than

1:20, the EE was low.

The phospholipid concentration,

phospholipid-cholesterol mass ratio and drug-lipid ratio of the

formulation were fixed, and the ethanolic solution of the

formulation was injected into phosphate buffer with a pH of 5.8,

6.5, 7.0, 7.4 or 8.0 to prepare liposomes. The results demonstrated

that liposomes prepared at a pH of between 6.5 and 7.4 were stable

and the EE was high, while flocculation or aggregation occurred

under other pH conditions.

Optimization of the rapamycin-containing

liposome formulation by orthogonal design

Based on the investigation of single factors, the

four factors, namely phospholipid concentration (factor A),

phospholipid-cholesterol mass ratio (factor B), drug-lipid ratio

(factor C) and aqueous phase pH (factor D) were selected, and three

levels of each factor were designated for the orthogonal design,

with the EE as the investigating indicator to screen the

formulation. The orthogonal factors and levels are shown in

Table I.

| Table IFactors and levels. |

Table I

Factors and levels.

| Factors |

|---|

|

|

|---|

| Levels | A | B | C | D |

|---|

| Level 1 | 2 | 10:1 | 1:15 | 7.4 |

| Level 2 | 3 | 8:1 | 1:20 | 7.0 |

| Level 3 | 4 | 6:1 | 1:30 | 6.5 |

The L9 (34) orthogonal table

(8) was used and nine formulations

were obtained, according to the above designs. Rapamycin-containing

liposomes were prepared for EE determination. The orthogonal test

results are shown in Table II,

and the variance analysis is shown in Table III.

| Table IIResults of orthogonal testing. |

Table II

Results of orthogonal testing.

| No. | A | B | C | D | EE % |

|---|

| 1 | 1 | 1 | 1 | 1 | 71.75 |

| 2 | 1 | 2 | 2 | 2 | 74.64 |

| 3 | 1 | 3 | 3 | 3 | 72.80 |

| 4 | 2 | 1 | 2 | 3 | 75.61 |

| 5 | 2 | 2 | 3 | 1 | 81.16 |

| 6 | 2 | 3 | 1 | 2 | 70.49 |

| 7 | 3 | 1 | 3 | 2 | 85.64 |

| 8 | 3 | 2 | 1 | 3 | 77.39 |

| 9 | 3 | 3 | 2 | 1 | 84.28 |

| K1 | 219.19 | 233.00 | 219.63 | 237.19 | |

| K2 | 227.26 | 233.19 | 234.53 | 230.77 | |

| K3 | 247.31 | 227.57 | 239.60 | 225.80 | |

| K̄1 | 73.06 | 77.67 | 73.21 | 79.06 | |

| K̄2 | 75.75 | 77.73 | 78.18 | 76.92 | |

| K̄3 | 82.44 | 75.86 | 79.87 | 75.27 | |

| R | 9.38 | 1.87 | 6.66 | 3.79 | |

| Table IIIVariance analysis. |

Table III

Variance analysis.

| Source | S | f | MS | F-statistic | P-value |

|---|

| Factor A | 139.98 | 2 | 69.99 | 635.27 | <0.01 |

| Factor B | 6.78 | 2 | 3.39 | 30.82 | <0.05 |

| Factor C | 71.92 | 2 | 35.96 | 326.91 | <0.01 |

| Factor D | 21.67 | 2 | 10.84 | 98.55 | <0.01 |

| Error | 0.22 | 2 | 0.11 | | |

It can be determined by direct-viewing analysis of

the extremum values (R) in Table

II that the importance degrees of the factors were in the

order: A>C>D>B, and the optimized formulation composition

was A3B2C3D1, that is,

the phospholipid concentration was 4%, the phospholipid-cholesterol

ratio was 8:1, the drug-lipid ratio was 1:30 and the pH was

7.4.

The variance analysis indicates that factors A, C

and D had significant impacts on the experimental results, and

factor B was also significant. According to the F value, the

impacts of various factors towards the test results were

A>C>D>B, which is consistent with the results of

direct-viewing analysis.

The optimized formulation had a drug-lipid ratio of

1:30; however, considering the amount of liposomal drug loading, a

drug-lipid ratio of 1:20 was selected. As for factor C, the levels

2 and 3 were subjected to single-factor variance analysis, and the

result was F<F0.05 (1,4)=7.71, indicating that the levels 2 and

3 of factor C were not statistically significant towards the

experimental results. The final formulation was adjusted to

A3B2C2D1, that is, the

phospholipid concentration was 4%, the phospholipid-cholesterol

ratio was 8:1, the drug-lipid ratio was 1:20 and the pH value was

7.4. The preparation and analysis of the above optimal formulation

was repeated three times, and the EE of the rapamycin-containing

liposomes was measured as 82.11±2.13%.

Investigation of in vitro

release

A previously described reverse dialysis method

(9) was modified for the

determination of the in vitro release of rapamycin from the

liposomes.

In the reverse dialysis, 500 ml 20% ethanol was used

as the release medium; 10 ml release medium was drawn and placed

into a dialysis bag (diameter, 25 mm; trapping substances with a

relative molecular mass of 12,000–14,000; Beijing Huamei

Biotechnology Co., Ltd, Beijing, China). The dialysis bag was then

clamped and attached on the paddle of a dissolution apparatus; 5 ml

rapamycin-containing liposomes and 5 ml ethanol solution of

rapamycin with the same drug content as the liposomes, were

respectively dissolved in the dialysis vessel, with stirring at

37°C and 300 × g. Sampling of 100 μl liquid from the dialysis bag

was conducted at 1, 2, 4, 6, 8, 10, 12 and 24 h for sample

determination and calculation of the accumulative release rate. A

release curve was drawn using time (t) as the abscissa, and the

accumulative release rate (Q%) as the ordinate; the resulting curve

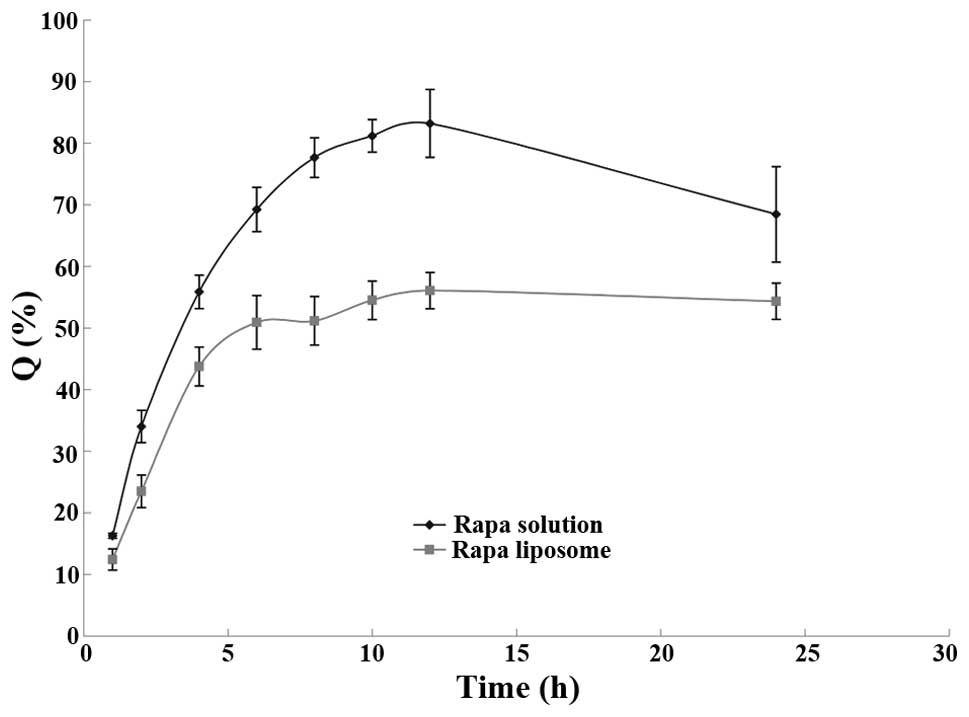

is shown in Fig. 1.

It was found from the experiment that after 12 h,

the amount of drug released gradually decreased with the extension

of release time. Theoretically, the accumulative release of the

drug should be maintained at a high level; however, at 37°C,

rapamycin was unstable in aqueous solution and the drug content was

reduced (10). Thus, it was

necessary to consider the degradation of rapamycin in the release

medium.

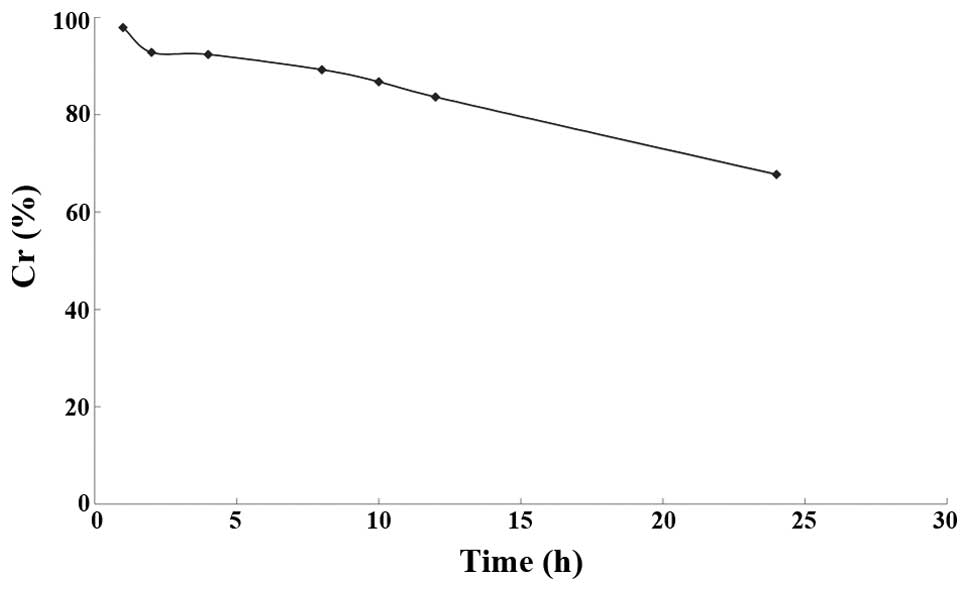

The 20% ethanolic solution of rapamycin was placed

in a 37°C water bath, and sampled at 0, 1, 2, 4, 8, 10, 12 and 24

h, respectively, for the determination of rapamycin concentration

(Ct) by HPLC at different time points. The ratio Ct/Co, where Co is

the rapamycin concentration at 0 h, was used to calculate the

residual percentage Cr, with the time t as the abscissa and Cr as

the ordinate. The resulting curve is shown in Fig. 2.

The results demonstrated that rapamycin was unstable

in the release medium; after 24 h, the drug content was 67.72% of

the initial content. Linear fitting plots for zero-, first- and

second-order models were drawn to study the degradation kinetics

(Table IV). The linear fitting

results revealed that the degradation kinetics of rapamycin fitted

the first-order model.

| Table IVDegradation curve-fitting equations

of rapamycin solution in release medium. |

Table IV

Degradation curve-fitting equations

of rapamycin solution in release medium.

| Model | Fitting

equation | Correlation

coefficient r |

|---|

| Zero-order

model | Cr = −0.0122 t +

0.9397 | 0.9786 |

| First order

model | lnCr = −0.0162 t +

0.0095 | 0.9931 |

| Second order

model | 1/Cr = 0.0202 t +

0.9711 | 0.9809 |

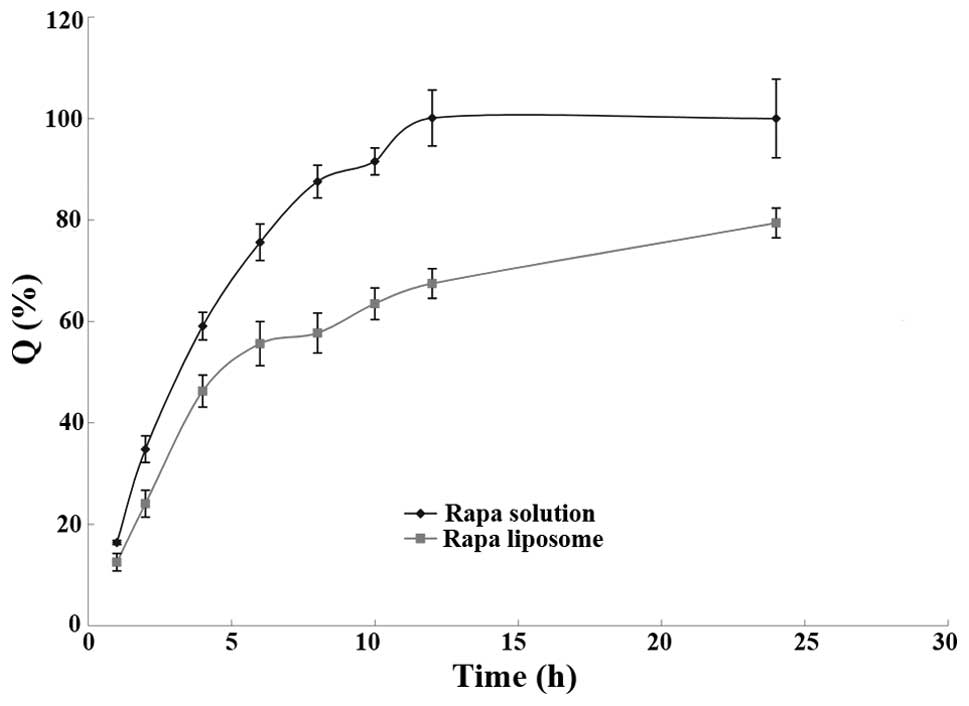

The amount of released drug at each time point was

entered into the fitted degradation kinetics equation to calculate

the amount of degraded drug; the accumulation of the released and

degraded drug was set as the ordinate and the time t was set as the

abscissa to fit the release profile of the rapamycin-containing

liposomes. The resulting curve is shown in Fig. 3.

As can be observed in Fig. 3, the liposomes had a

sustained-release effect for rapamycin; the 24 h total release dose

was 80%. The release process of rapamycin from the liposomes can be

divided into two phases: In the first 4 h, the release rate was

fast and ~50% of the total dose was released; this phase was the

rapid release phase. This may be due to the release of the

encapsulated free drug and the drug that was adsorbed on the

surface of the liposomes by a weak binding force. Four hours later,

the drug release became relatively slow, known as the slow release

phase. The rapamycin solution and rapamycin-containing liposomes

were fitted according to the release models including the Higuchi

(11) Ritger-Peppas (12) and Weibull (13) models; the results are shown in

Tables V and VI. The results indicated that the in

vitro release profile of rapamycin from the liposomes and

solution best fitted the first-order release model.

| Table VRelease curve-fitting equations of

rapamycin solution. |

Table V

Release curve-fitting equations of

rapamycin solution.

| Model | Fitting

equation | Correlation

coefficient r |

|---|

| Zero-order release

model | Q = 0.073 t +

0.2158 | 0.9181 |

| First-order release

model | ln(1-Q) = −0.2609 t

+ 0.1046 | 0.9959 |

| Higuchi model | Q = 0.3402

t1/2 − 0.1289 | 0.9802 |

| Ritger-Peppas

model | lnQ = 0.7144 lnt −

1.6521 | 0.9076 |

| Weibull model | ln(1/1-Q) = 0.9816

lnt − 0.1067 | 0.9003 |

| Table VIRelease curve-fitting equations of

rapamycin-containing liposomes. |

Table VI

Release curve-fitting equations of

rapamycin-containing liposomes.

| Model | Fitting

equation | Correlation

coefficient r |

|---|

| Zero-order release

model | Q = 0.0152 t +

0.4544 | 0.9101 |

| First-order release

model | ln(1-Q) = −0.046 t

− 0.5090 | 0.9770 |

| Higuchi model | Q = 0.1166

t1/2 + 0.2697 | 0.9673 |

| Ritger-Peppas

model | lnQ = 0.2965 lnt −

0.1067 | 0.9600 |

| Weibull model | ln(1/1-Q) = 0.5311

lnt − 0.1704 | 0.9710 |

Discussion

With the use of new technology and equipment, and

the development and application of excellent carrier materials and

accessories, targeted drug delivery (TDD) technology has been

developing rapidly in recent years, and has gradually extended to

the treatment fields of multiple diseases (14–17).

Although nanoparticles, nanocapsules, microspheres,

microcapsule, micelle multimers and monoclonal antibody coupling

may be considered as the ideal medicament carriers, liposomes

remain inexpensive, readily available and more studied drug

carriers (18–21).

Liposomes are extensively researched TDD carriers,

with a sustained-release, long-lasting effect, low systemic

toxicity and good biocompatibility, and are suitable for

administration by a variety of routes. However, traditional

liposomes only have a passive targeting role; if antibody or ligand

molecules, which are targeted towards proliferated intimal tissues,

are connected to the liposomal membrane and thus form targeting

liposomes, active targeting can be achieved, significantly

enhancing the concentration of liposomes in vascular tissues,

particularly in atherosclerotic plaques (22–26).

The liposomal bilayer is amenable to surface modification to

achieve TDD towards the cardiovascular system.

Rapamycin is a lipophilic substance, which is easily

compatible with the hydrophobic chains that are used in the

preparation of liposomes, and form a part of the bilayer. The

optimum mass ratio of phospholipids, cholesterol and rapamycin is

that at which liposomes with the highest EE are formed. In this

study, the ethanol injection method was used to prepare

rapamycin-containing liposomes, a microcolumn centrifugation HPLC

method was used to determine the EE, and the EE was used as the

evaluation indicator to inspect the impacts of phospholipid

concentration, phospholipid-cholesterol mass ratio, drug-lipid

ratio and aqueous phase pH on the liposomes. Based on these

evaluations, an orthogonal design experiment was performed to

optimize the formulation. The orthogonal test results revealed that

the best formulation had a phospholipid concentration of 4%,

phospholipid-cholesterol mass ratio of 8:1, drug-phospholipid mass

ratio of 1:20 and aqueous phase pH of 7.4. The encapsulation rate

of the resultant rapamycin-containing liposomes was high, reaching

82.11±2.13%, and the reproducibility was good. The higher EE also

indicated that the lipid bilayer was able to significantly

solubilize the hydrophobic drug rapamycin, enabling it to be

administered through the inner vessel, which would be an effective

means to resolve the low oral bioavailability of rapamycin.

The EE is an important indicator when evaluating a

liposomal delivery system, and there are numerous methods for

determining it. In this study, Sephadex column chromatography was

initially used, with online elution using a buffer of pH 7.4;

however, free rapamycin did not dissolve in the buffer and could

not be eluted quickly. Subsequently, a dialysis method was used to

isolate the liposomes and free the drug. As rapamycin is strongly

liposoluble, the unencapsulated drug was present in the external

aqueous phase in the form of small crystals, which would not pass

through the dialysis bag; therefore, the measured quantity of free

drug was likely to be inaccurate. Finally, with reference to the

literature, a microcolumn centrifugation HPLC method was

established to determine the EE; the method was simple and

reproducible.

For drugs with poor solubility, when performing a

release characteristics study, a surfactant or an organic solvent

is typically used to improve the drug solubility in the release

medium to meet sink conditions. In the present study, ethanol was

selected as a cosolvent to increase the solubility of rapamycin.

When the rapamycin-containing liposomes reached sink conditions,

drug release was not complete in 24 h, indicating that the

liposomes had sustained release effects.

Currently, the main method used in in vitro

release studies of liposomal preparations is the dialysis method

(27). In this method, liposomes

contact only a small amount of release medium in the dialysis bag;

when the drug diffuses from the liposomes and is released into the

release medium in the bag, it then diffuses through the dialysis

bag to a massive release medium. As the drug concentration gradient

inside and outside the dialysis bag is small, passive diffusion is

slow, so that the release rate is low. In the present study, the

reverse dialysis method was used to determine the in vitro

release of rapamycin from the liposomes (9); since the liposomes directly contacted

the release medium and were largely diluted, it better simulated

the state that the drug achieves following intravenous injection.

The experimental results indicated that the dialysis bag had almost

no adsorption of rapamycin, and the rapamycin recovery rate was

99.21±1.12% (n=3).

In order to investigate the release properties of

the rapamycin-containing liposomes, a release equation was used for

fitting, and the optimal equation was determined by means of the

correlation coefficient r. The results revealed that the release of

rapamycin from the solution and liposomes best fitted the

first-order release model, in which the in vitro release may

be described by a concentration-dependent permeation release model.

Since the in vitro release conditions were not the same as

the in vivo blood environment, the in vitro release

experiment did not truly reflect the situation of in vivo

release. Further studies of the correlation of in vivo

absorption and in vitro release of rapamycin from the

liposomal delivery system are required.

References

|

1

|

de Jager SC and Kuiper J: Vaccination

strategies in atherosclerosis. Thromb Haemost. 106:796–803. 2011.

View Article : Google Scholar : PubMed/NCBI

|

|

2

|

Sabers CJ, Martin MM, Brunn GJ, Williams

JM, Dumont FJ, Wiederrecht G and Abraham RT: Isolation of a protein

target of the FKBP12-rapamycin complex in mammalian cells. J Biol

Chem. 270:815–822. 1994. View Article : Google Scholar

|

|

3

|

Cheng-Lai A and Frishman WH:

Sirolimus-eluting coronary stents: novel devices for the management

of coronary artery disease. Am J Ther. 11:218–228. 2004. View Article : Google Scholar : PubMed/NCBI

|

|

4

|

Klugherz BD, Llanos G, Lieuallen W, et al:

Stent-based delivery of sirolimus for the prevention of resrenosis.

J Am Coll Cardiol. 35(Suppl 1): 58A2000.

|

|

5

|

Gallo R, Padurean A, et al: Inhibition of

intimal thickening after balloon angioplasty in porcine coronary

arteries by targeting regulators of the cell cycle. Circulation.

99:2164–2170. 1999. View Article : Google Scholar : PubMed/NCBI

|

|

6

|

Zhang JA, Anyarambhatla G, Ma L, Ugwu S,

Xuan T, Sardone T and Ahmad I: Development and characterization of

a novel Cremophor EL free liposome-based paclitaxel (LEP-ETU)

formulation. Eur J Pharm Biopharm. 59:177–187. 2005. View Article : Google Scholar

|

|

7

|

Li C and Deng Y: A novel method for the

preparation of liposomes: freeze drying of monophase solutions. J

Pharm Sci. 93:1403–1414. 2004. View Article : Google Scholar : PubMed/NCBI

|

|

8

|

Lu YP, Lasne C and Chouroulinkov I: Use of

an orthogonal design method to study two-stage chemical

carcinogenesis in BALB/3T3 cells. Carcinogenesis. 7:893–898. 1986.

View Article : Google Scholar : PubMed/NCBI

|

|

9

|

Levy MY and Benita S: Drug release from

submicronized O/W emulsion: a new in vitro kinetic evaluation

model. Int J Pharm. 66:291990. View Article : Google Scholar

|

|

10

|

Rouf MA, Bilensoy E, Vural I and Hıncal

AA: Determination of stability of sirolimus following exposure to

different conditions. Eur J Pharm Sci. 32(Suppl): S462007.

|

|

11

|

Higuchi WI, Tzeng CS, Chang SJ, Chiang HJ

and Liu CL: Estimation of cholesterol solubilization by a mixed

micelle binding model in aqueous

tauroursodeoxycholate:lecithin:cholesterol solutions. J Pharm Sci.

97:340–349. 2008. View Article : Google Scholar

|

|

12

|

Ravi PR, Ganga S and Saha RN: Design and

in vitro evaluation of zidovudine oral controlled release tablets

prepared using hydroxypropyl methylcellulose. Chem Pharm Bull

(Tokyo). 56:518–524. 2008. View Article : Google Scholar

|

|

13

|

Lionberger RA, Raw AS, Kim SH, Zhang X and

Yu LX: Use of partial AUC to demonstrate bioequivalence of Zolpidem

Tartrate Extended Release formulations. Pharm Res. 29:1110–1120.

2012. View Article : Google Scholar : PubMed/NCBI

|

|

14

|

Masaka T, Matsuda T, Li Y, et al:

Synthesis of VIP-lipopeptide using a new linker to modify

liposomes: Towards the development of a drug delivery system for

active targeting. Chem Pharm Bull (Tokyo). 61:1184–1187. 2013.

View Article : Google Scholar

|

|

15

|

Wang X, Lin Y, Zeng Y, Sun X, Gong T and

Zhang Z: Effects of mycophenolic acid-glucosamine conjugates on the

base of kidney targeted drug delivery. Int J Pharm. 456:223–234.

2013. View Article : Google Scholar : PubMed/NCBI

|

|

16

|

Pehlivan SB: Nanotechnology-based drug

delivery systems for targeting, imaging and diagnosis of

neurodegenerative diseases. Pharm Res. 30:2499–2511. 2013.

View Article : Google Scholar : PubMed/NCBI

|

|

17

|

Arias JL: Liposomes in drug delivery: a

patent review (2007 - present). Expert Opin Ther Pat. 23:1399–1414.

2013. View Article : Google Scholar : PubMed/NCBI

|

|

18

|

Murakami M, Cabral H, Matsumoto Y, et al:

Improving drug potency and efficacy by nanocarrier-mediated

subcellular targeting. Sci Transl Med. 3:64ra22011. View Article : Google Scholar : PubMed/NCBI

|

|

19

|

Musacchio T and Torchilin VP: Recent

developments in lipid-based pharmaceutical nanocarriers. Front

Biosci (Landmark Ed). 16:1388–1412. 2011. View Article : Google Scholar

|

|

20

|

Roger M, Clavreul A, Venier-Julienne MC,

Passirani C, Montero-Menei C and Menei P: The potential of

combinations of drug-loaded nanoparticle systems and adult stem

cells for glioma therapy. Biomaterials. 32:2106–2116. 2011.

View Article : Google Scholar

|

|

21

|

Suo X, Deng Y and Hao A: Determination of

lauroyl-indapamide in rat whole blood by high-performance liquid

chromatography. J Chromatogr B Analyt Technol Biomed Life Sci.

819:191–196. 2005. View Article : Google Scholar : PubMed/NCBI

|

|

22

|

Torchilin VP, Narula J, Halpern E and Khaw

BA: Poly(ethylene glycol)-coated anti-cardiac myosin

immunoliposomes: factors influencing targeted accumulation in the

infarcted myocardlium. Biochem Biophys Acta. 1279:75–83. 1996.

View Article : Google Scholar

|

|

23

|

Chen Y, Deng YJ and Hao YL: Surface

modification of liposomes for cardiomyocytes targeting in vitro.

Pharmazie. 60:238–240. 2005.PubMed/NCBI

|

|

24

|

Chen Y, Deng YJ, Hao YL, Hao AJ, Zhong HJ

and Wang XM: Uptake of liposomes by cultured cardiomyocytes.

Pharmazie. 60:844–848. 2005.PubMed/NCBI

|

|

25

|

Nag OK and Awasthi V: Surface engineering

of liposomes for stealth behavior. Pharmaceutics. 25:542–569. 2013.

View Article : Google Scholar

|

|

26

|

Paszko E and Senge MO: Immunoliposomes.

Curr Med Chem. 19:5239–5277. 2012. View Article : Google Scholar : PubMed/NCBI

|

|

27

|

Shen J and Burgess DJ: In vitro

dissolution testing strategies for nanoparticulate drug delivery

systems: recent developments and challenges. Drug Deliv Transl Res.

3:409–415. 2013. View Article : Google Scholar : PubMed/NCBI

|