Introduction

Autograft and allograft transplantations are the

primary treatments for large bone defects caused by trauma, tumor

resection and infection; however, the problems of limited bone

sources and immune rejection or infection persist. By contrast,

metallic biomedical materials are playing an increasingly important

role in the treatment of bone defects. However, since these metals

and their alloys do not exhibit the same elastic modulus as bone,

stress shielding occurs, resulting in relative displacement of

metal implants and friction along the metal-bone interface

(1,2). This friction generates debris,

inducing a macrophage response, which causes deterioration or

absorption of the bone tissue and ultimately leads to loosening of

the implant or fracture of the host bone (3–5).

Therefore, further research is required to enhance the in

vivo longevity of metallic biomedical materials.

To date, research in this area has focused primarily

on porous titanium and its alloys. However, the clinical

application of porous metal materials has remained limited due to

their low porosity, small surface friction coefficient and concerns

regarding their elastic modulus (6–8).

Porous tantalum has been reported as a promising material for use

in bone tissue engineering. However, only Zimmer Corporation

(Warsaw, IN, USA) has produced porous tantalum material with high

porosity (75–80%), good tissue compatibility, a large surface

friction coefficient and the proper elastic modulus that closely

matches that of human bone. As a result, porous tantalum has been

widely applied in arthroplasty, spinal fusion surgery and the

treatment of femoral head necrosis (9–12).

However, the widespread use of porous tantalum in China is limited

by the high price. Cooperating with numerous domestic research

institutions, Chongqing Runze Pharmaceutical Co., Ltd. (Chongqing,

China) have successfully developed porous tantalum materials, which

were prepared by slip-casting powder through teeming technology.

The porous tantalum selected was −250 mesh pure tantalum powder

with a certain amount of additives and added sponge carrier to

control the pore diameter of porous materials, porosity and pore

distribution, and approved by slip-casting forming and through

1,500–2,100°C high temperature sintered and post-treatment

technology of necessary preparation (preparation method has been

submitted for patenting). The biomechanical indexes showed that

Chinese porous tantalum possessed high porosity, an appropriate

pore diameter size and exhibited biomechanical performance

characteristics that were comparable to human bone, suggesting that

tantalum may be an ideal bone graft material (Table I).

| Table IMaterial physical and chemical

performance indicators. |

Table I

Material physical and chemical

performance indicators.

| Indicators | Range |

|---|

| Density

(g/cm3) | 3.5–7 |

| Porosity (%) | 65–80 |

| Pore diameter

(μm) | 400–600 |

| Elasticity modulus

(GPa) | 2.0–4.6 |

| Ultimate strength

(MPa) | 110–210 |

| Yield strength

(MPa) | 75–120 |

| Compressive strength

(MPa) | 100–170 |

| Tensile strength

(MPa) | 80–120 |

| Bending strength

(MPa) | 80–150 |

The present study investigated the physical

properties and cytotoxicity of Chinese porous tantalum and examined

osteogenesis at the tantalum-host bone interface following

implantation in the lateral epicondyle of a rabbit femora. The aim

of the study was to assess the possibility of the wider application

of Chinese porous tantalum material.

Materials and methods

Materials

Eight fetal New Zealand rabbits and 24 adult male

rabbits (weight, 2.5–3 kg) were provided by the Experimental Animal

Center of Hebei United University (Tangshan, China). Porous

tantalum was obtained from Chongqing Runze Pharmaceutical Co., Ltd.

The porous tantalum selected was −250 mesh pure tantalum powder

with a certain amount of additives and added sponge carrier to

control the pore diameter of porous materials, porosity and pore

distribution, and approved by slip-casting forming and through

1,500–2,100°C high temperature sintered and post-treatment

technology of necessary preparation (preparation method has been

submitted for patenting). Low-glucose Dulbecco’s modified Eagle’s

medium (DMEM) was purchased from Gibco Life Technologies (Carlsbad,

CA, USA), 3-(4,5-dimethylthiazol-2-yl)-2,5-diphenyltetrazolium

bromide (MTT) reagent was purchased from Sigma-Aldrich (St. Louis,

MO, USA) and an inverted phase contrast microscope was obtained

from Nikon Corporation (Tokyo, Japan). In addition, a scanning

electron microscope (JSM-6030LV; JEOL, Tokyo, Japan), a Leica

SP1600 hard tissue slicer (Leica Microsystems GmbH, Wetzlar,

Germany), a laser scanning confocal microscope (Olympus

Corporation, Tokyo, Japan) and a Bio-Rad 680 microplate reader

(Bio-Rad Laboratories, Hercules, CA, USA) were employed. This study

was approved by the Institutional Animal Care and Use Committee of

Hebei United University. Postoperative care was professionally

managed by trained personnel and supervised by veterinarians.

Osteoblast cultivation

The periosteum and soft tissue surrounding the

crania of the fetal New Zealand rabbits were removed and cut into

1xl mm pieces prior to digestion in a solution of 0.25% trypsin and

0.1% type II collagenase. Following centrifugation at 2,012 × g for

10 min at 37°C, the supernatant was discarded and DMEM containing

10% fetal bovine serum (Gibco Life Technologies) was added to the

white precipitate, which was pipetted into a cell suspension for

counting the total number of cells and then seeded into cell

culture dishes. The cells were cultured with DMEM supplemented with

10% fetal bovine serum in a humidified incubator containing 5%

CO2 at 37°C. Primary osteoblasts were passaged after

reaching 80–90% confluence. Osteoblasts were identified by alkaline

phosphatase (ALP) staining, collagen type I immunocytochemical

staining and calcium nodule staining.

Cytotoxicity evaluation

Porous tantalum extract was prepared according to

ISO 10993-5, 2009 for high pressure disinfection of porous tantalum

extract preparation (13).

Extracts were prepared based on the principle of ‘material

weight/extraction transmitter = 0.2 g/ml’, which represented 100%

concentration of the extract. Extraction conditions were 37°C in 5%

CO2 for 72 h, and metal ions were precipitated. Once the

extraction was completed, sterilization was achieved by passing the

extract through a 0.22-μm filter.

An MTT assay was conducted to determine the effects

of porous tantalum on osteoblast viability, growth and

proliferation (14). Third passage

osteoblasts were suspended and seeded in a 96-well plate at

2×104 cells per well. Porous tantalum extract

(experimental group) or complete medium (control group) was added

to the wells until the volume in each well was 200 μl. Next, 20 μl

MTT (5 mg/ml) solution was added to each well (pH 7.4) and the

plate was incubated for 4 h in the CO2 incubator.

Dimethyl sulfoxide was added and low-speed oscillation was applied.

A Bio-Rad enzyme-linked immunometric meter (measurement wavelength,

490 nm; reference wavelength, 650 nm) was used to detect the

optical density (OD) value of the solution in each well, from which

a cell growth curve was prepared.

Osteoblast culture on porous tantalum to

evaluate cytocompatibility

Pancreatin was used to digest a proportion of the

osteoblasts in order to adjust the cell concentration to

1×106 cells/ml. Subsequently, a 30-μl cell suspension

was seeded onto each presterilized porous tantalum sample in the

culture plates. The porous tantalum was turned over and the cells

were seeded onto the other side. DMEM containing 10% fetal bovine

serum was added, and samples were cultured at 37°C in 5%

CO2 and saturated humidity. Cell growth and adhesion to

the tantalum samples was observed on an inverted phase contrast

microscope every day.

Sterilized tantalum samples and those on which cells

were seeded were collected on days 3, 5, 7 and 10. The samples were

washed with phosphate-buffered saline, fixed in 2.5%

glutaraldehyde, dehydrated in 30–100% t-butyl alcohol solutions,

dried in a 37°C electric thermostatic drier (JEOL JFC-1600) for 24

h and underwent ion sputter metal spraying for scanning electron

microscopy (SEM) observation of cell adherence and growth on the

material.

Preparation of rabbits for porous

tantalum implantation

A total of 24 male adult New Zealand white rabbits

(weight, 2.5–3.0 kg) were selected. The model of porous tantalum

implantation in the femoral condyle was established using improved

surgical methods, as reported in a previous study (15). Briefly, 20% urethane (3–4 ml/kg)

was injected into the ear vein for anesthesia. The vastus lateralis

muscle was cut from the outside part of the lower femur, along the

femoral shaft, to expose the femoral condyle. A 3-mm Kirschner

skeletal wire [Association for Osteosynthesis(AO)/Association for

the Study of Internal Fixation (ASIF), Davos, Switzerland]was used

to drill into the femoral lateral condyle, which was ~1 cm from the

knee, perpendicular to the femoral shaft. The drilling resulted in

a cylindrical bone tunnel with a diameter of ~3 mm and a depth of 5

mm. A porous tantalum rod (diameter, 3 mm; height, 5 mm) was

implanted in the bone along the tunnel, with the tantalum rod

contacting as closely as possible with the tunnel wall of the host

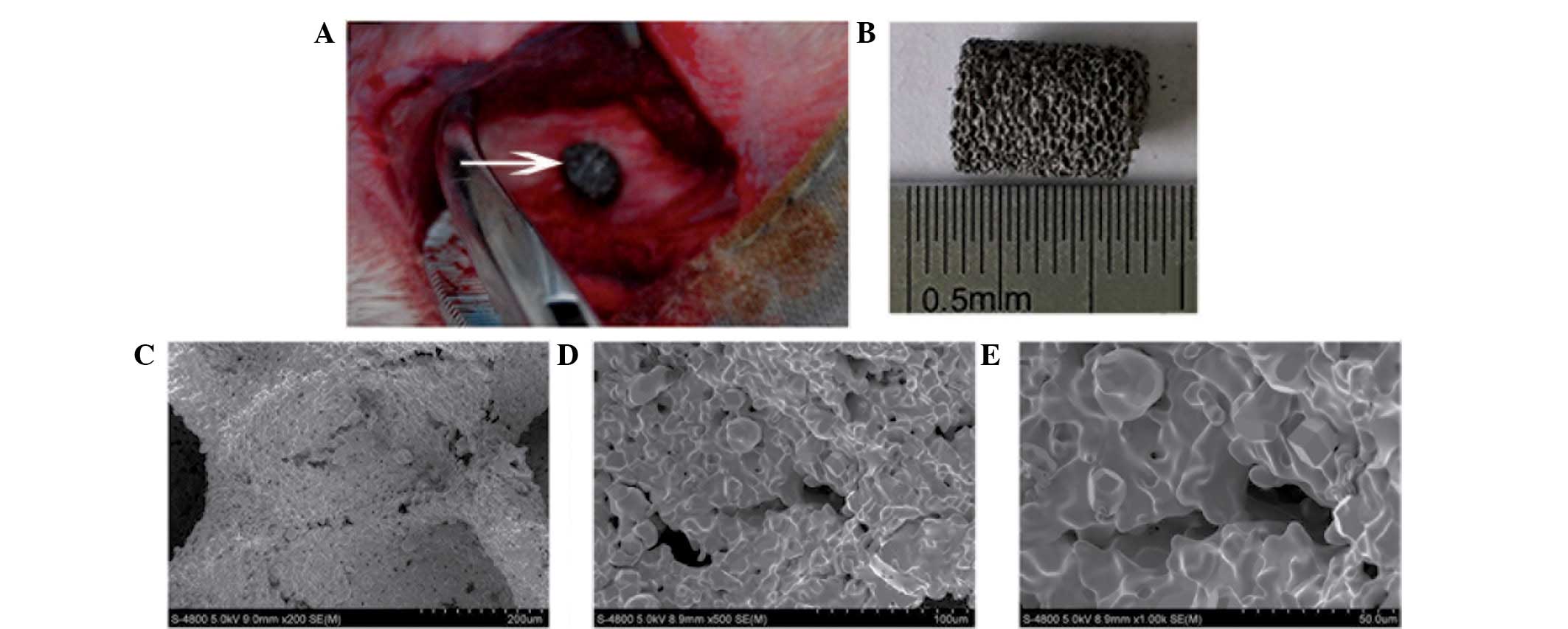

bone (Fig. 1A). The wound was

sutured and marked with adequate hemostasis. Three days after

surgery, the wound was disinfected and penicillin was injected

intramuscularly. Four animals were injected with luciferin calcein

solution (10 mg/kg) in the gluteus maximus on day 5 after surgery.

Fluorescein alizarin red solution (40 mg/kg) was injected in the

same manner on day 19 after surgery, in order to observe

osteogenesis. The animals were separated into cages, without

limitation of movement, and euthanized at week ten after

surgery.

Porous tantalum-bone hard tissue slicing

and staining

In total, 20 rabbits were euthanized by air embolism

at weeks 2, 4, 8 and 12 after surgery (five at each time point).

The bone tissue in the femoral condyle was removed along with the

porous tantalum rod, and then washed, trimmed and fixed in 10%

formaldehyde. Following dehydration, infiltration, embedding (20 g

benzoyl peroxide in 800 ml methacrylic acid methyl ester, phthalic

acid and 200 ml dibutyl) and polymerization, a metal slicer was

used to slice the material along the direction parallel to the

longitudinal axis of the porous tantalum rod, fully exposing its

plane. The plane was polished and 90-μm slices were prepared, which

were ground down to 20 μm, dried and exposed to glycol ether ester

to remove any plastic. Sections were stained with methylene blue

and osteogenesis was observed under a light microscope. The

materials acquired at week 10 after the surgery were processed into

porous tantalum-bone hard tissue slices using the same method and

were used to evaluate osteogenesis at the porous tantalum-bone

interface via laser scanning confocal microscopy with a 488-nm

laser (calcein excitation wavelength) and a 543 nm laser (alizarin

red excitation wavelength).

Statistical analysis

Data were analyzed using SPSS 20.0 statistical

software (IBM, Armonk, NY, USA). Experimental data are expressed as

the mean ± standard deviation. In the cytotoxicity and cell growth

experiments, comparisons between the experimental and control

groups were analyzed using the Student’s t-test. P<0.05 was

considered to indicate a statistically significant difference.

Results

Surface characteristics of porous

tantalum

Under microscopic observation, the appearance of the

porous tantalum scaffolds was gray and smooth, with pinpoint-sized

pores distributed evenly in a honeycomb pattern on the surface and

fracture surface (Fig. 1B).

SEM revealed that the material surface and

cross-section had an interconnected pore distribution, with a pore

diameter size of 400–600 μm. The trabecular pillars had a

microporous structure, where the diameter of the micropores was

~100 μm. Pore distribution was uniform and the pores were

interconnected. The microporous structure with interconnected pores

had a diameter of 200–400 μm, the particle diameter was 20–50 μm

and there were 50–200 μm interstices between the particles

(Fig. 1C–E).

Cultivation of isolated fetal rabbit

osteoblasts

Primary osteoblasts were observed as translucent

spheres under an inverted phase contrast microscope. The cells grew

adherently after 24 h, presenting a variety of forms, which were

primarily short fusiform and triangular with the cytoplasm

extending outward to form protrusions. The cell volume was enlarged

by day 3, with cells connecting and increasing in number. By day 7,

the cell groups fused to form a monolayer covering the bottom of

the plate, and the cell morphology became polygonal or irregular.

The cells were passaged when they reached 80–90% confluence. The

majority of the cells exhibited triangular or long fusiform shapes,

with the cell volumes and growth rate increasing. The third passage

cells exhibited a long fusiform morphology. The results of ALP

staining, collagen type I immunocytochemical staining and calcium

nodule staining were positive, confirming that the cells were

osteoblasts.

Effects of porous tantalum extract on

osteoblast viability and growth

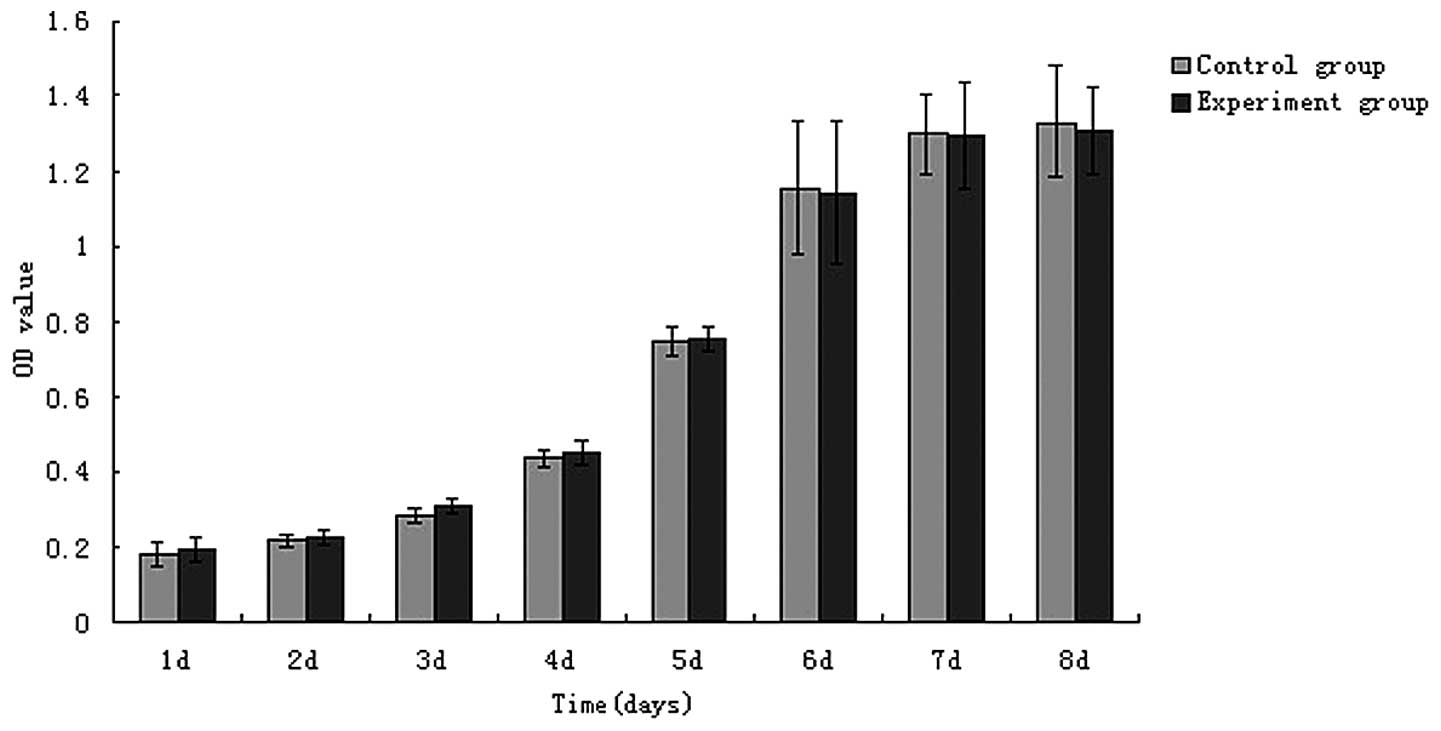

Absorbance values in the MTT assay showed that

between days 1 and 8 of osteoblast culture, osteoblast growth

changed from slow to rapid, and then to slow again, ultimately

entering a stable phase. Absorbance values for the control cells

and those exposed to porous tantalum extract at the same time

points were analyzed using an independent sample t-test, and the

results showed that the cell proliferation did not statistically

differ between the groups with extended cultivation time

(P>0.05). A cell growth curve was constructed based on the OD

values (Fig. 2). The results

demonstrated that tantalum metal ions were not cytotoxic to

osteoblasts, achieving the basic requirement of implant

materials.

Osteoblast culture on porous tantalum

samples for evaluation of cytocompatibility

Observation by inverted phase contrast microscopy

showed that in osteoblasts cultured on porous tantalum for one day,

a small number of cells began to adhere to the edge of the

material. In addition, cells of different sizes were dispersed on

the bottom of the culture plates, with cell processes exhibiting

fusiform or polygonal shapes. The number of cells adhering to the

edge increased and the cells proliferated rapidly between days 3

and 5, aggregating and fusing into flakes. Monolayers of cells were

formed in the bottom of the wells after seven days.

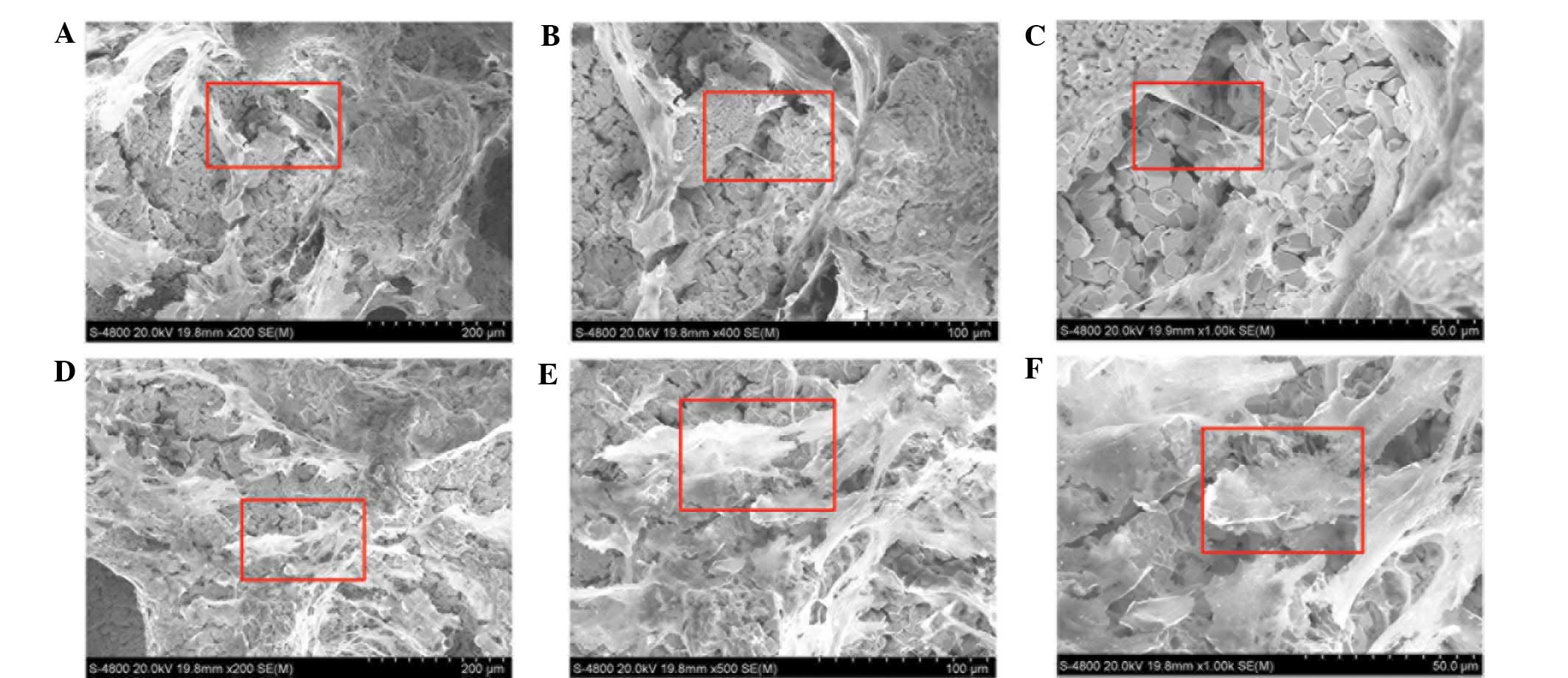

SEM revealed that the porous tantalum had numerous

pores. A small number of cells with varying morphologies were

sparsely arranged on the tantalum samples. By day 3, a few

protrusions grew adherently on the surface of the scaffolds and

within the scaffold pores. The cells stretched, lengthened and

extended pseudopodia gradually over time. By day 5, the processes

of adjacent cells connected with each other across the pores,

creating a flake with burr-like processes extending into the

surroundings. On day 10, cells on the surface and in the pores grew

into multiple layers, secreting matrix and covering the surface

completely (Fig. 3).

Morphological observations of the porous

tantalum implanted in the rabbit femoral condyle

Animals were conscious 30 min after the surgery and

exhibited recovery of knee movement. The incisions exhibited no

swelling, bleeding or oozing, and the wounds healed well. Loosening

of implantation materials was not observed. Implanted porous

tantalum rods were closely combined with the host bone at each time

point. No gap between the host bone and the tantalum implant was

visible by the naked eye and no adverse reactions, such as

infection, occurred.

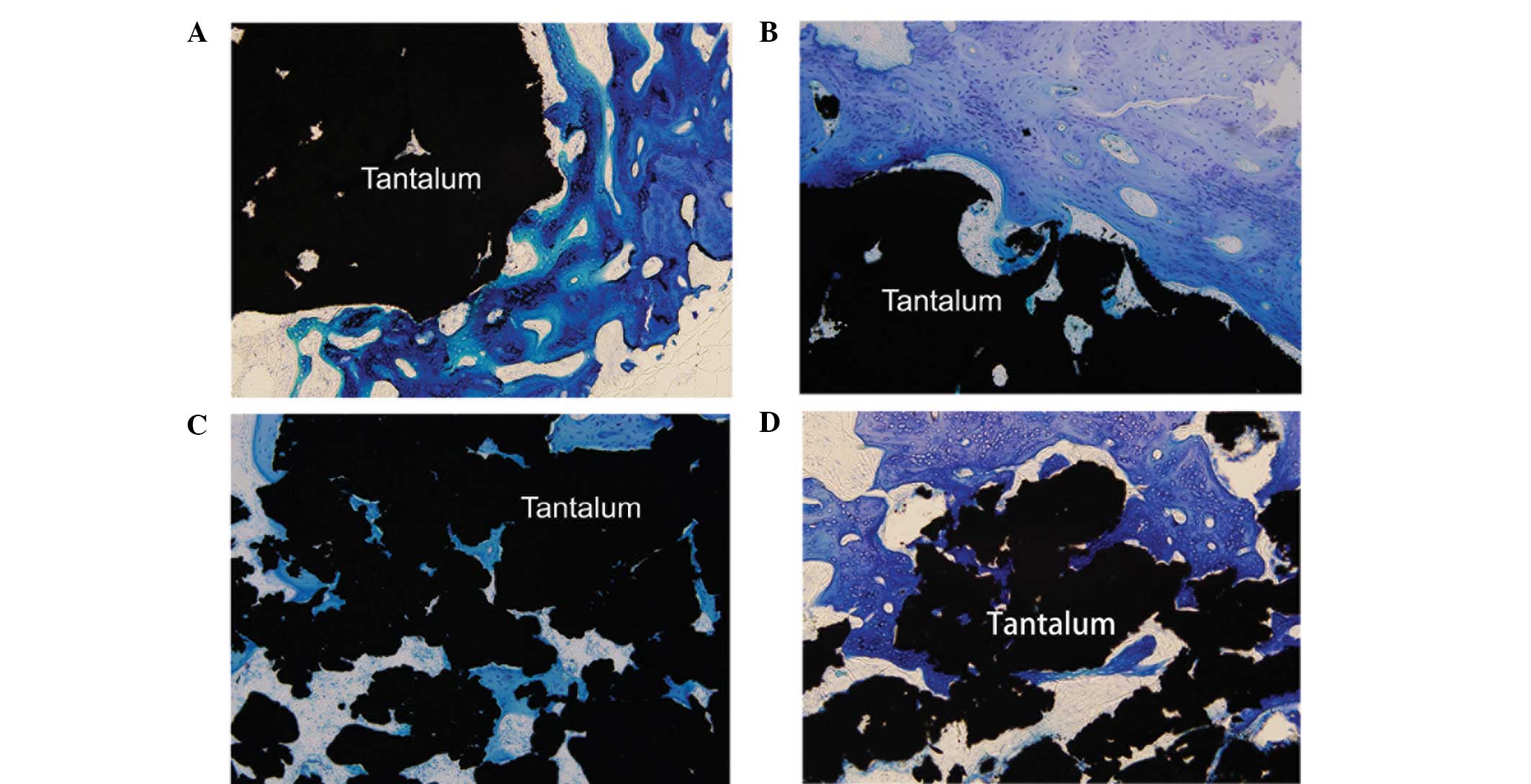

Observation of osteogenesis at the tantalum-host

bone interface in the hard tissue slices revealed that the porous

tantalum was in close contact with the bone tissue, as shown by

methylene blue staining.

During week 2, new bone tissue grew at the interface

of the tantalum and the host bone, on the surface of the material

and in the pores, with small blood vessels also growing in certain

areas. By week 4, the number of new bone cells at the interface

increased, and the cells connected with the host bone as flakes.

Bone collagen and the lacuna increased around the new trabecula, in

which bone cells were clearly observed. Between weeks 8 and 12, the

tantalum surface and pores were fully covered with new bone tissue.

New trabecula had matured and contacted the material directly,

presenting an interwoven, parallel arrangement, which covered the

surface and filled the pores. The tantalum and bone formed a solid

tantalum-bone direct bond, with no soft tissue layer at the

interface (Fig. 4).

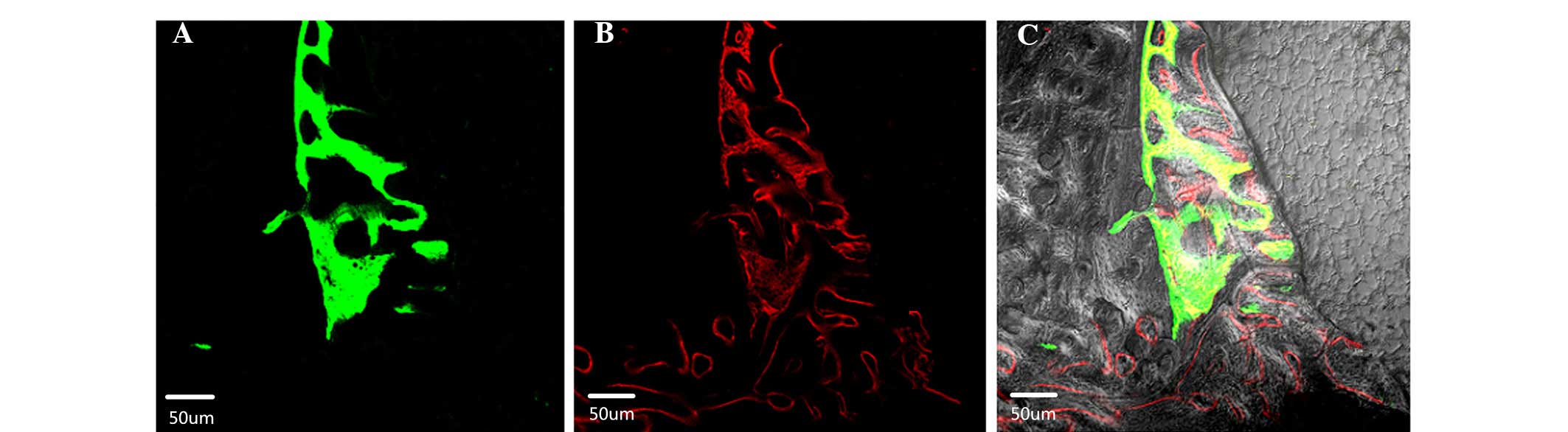

Observation by laser scanning confocal microscopy at

week 10 after the porous tantalum implantation revealed new bone

tissue, which was visible by green fluorescence (calcein) and red

fluorescence (alizarin red) at the tantalum-host bone interface and

within the pores. The red fluorescence band surrounded the green

band. The green and red fluorescent bands were discontinuous in the

early stage, but integrated by the late stage (Fig. 5).

Discussion

The porous tantalum used in the present study was

developed by Chongqing Runze Medical Devices Co. Ltd. The

appearance of the material is gray, bright and clean. Under SEM,

the material exhibits a three-dimensional spatial structure. Under

×500 magnification, pores with a diameter of 200–400 μm are visible

on the material surface, which are evenly distributed and

interconnected. The trabecula between the pores is rough,

presenting a micropore structure with a diameter of 100 μm. The

micropore structure is clearly visible under ×1,000 magnification,

with a diameter ranging between 50 and 200 μm. Since porous

tantalum has a three-dimensional geometric scaffold structure and

interconnected honeycomb pores, it offers a large internal surface

area, a three-dimensional structure and a good material-cell

interface on which osteoblasts are able to adhere, grow and develop

(16–18).

The roughness of the porous tantalum increases the

cell contact area, improving the adhesive strength of the

osteoblasts on the material surface. Tantalum surfaces ground by

grit and etched by acid have been shown to promote osteogenesis

(19,20). A study by Sagomonyants et al

(21) indicated that tantalum has

useful physical, chemical, mechanical and biological properties,

including a fully interconnected porous structure. This nanopore

structure has a large impact on osteoblast proliferation, and its

rough surface may absorb more large molecules, promoting cell

adhesion, proliferation and osteogenic capability. Tantalum also

facilitates the expression of osteoblast ALP and collagen type I.

In addition, bone tissue ingrowth and pore size are closely

associated. The microcolumn structure on the tantalum surface

promotes the overall osteogenic response. The high density per

volume of the column with a small diameter affords stronger

mechanical properties, resulting in more complete ingrowth of bone

tissue and better integration with the host tissue following

implantation. Thus, tantalum is particularly suitable for clinical

application as it cannot be degraded and supports bone function for

a long time (8).

In the present study, osteoblasts cultured in

vitro were seeded onto porous tantalum samples. Observation by

SEM showed that the cells adhered to the tantalum surface and pore

walls by day 3 of the culture, presenting various morphologies. The

cells proliferated further and numerous cells had merged into

flakes by day 7, while a number of cells secreted matrix, covering

the surface of the material. By day 10, the cells covering the

surface had secreted large amounts of matrix, which almost

completely covered the material. This result demonstrated that the

three-dimensional porous structure of the tantalum material

provided not only an ideal space for adhesion and proliferation,

but also promoted secretion and infiltration of nutrients and

metabolites, which demonstrates that Chinese porous tantalum offers

good biocompatibility.

The interaction between osteoblasts and implants is

an important focus of research into the compatibility of bone graft

materials. The basis of this interaction is the adhesion of cells

to the implant material. Cells must interact with the surface of

the scaffold, including adhering, extending, migrating,

differentiating and proliferating. Adhesion to a material,

including metal, can affect the proliferation and differentiation

of cells. The interaction between osteoblasts and the metallic

material depends largely on the surface properties of the material,

which include the geometric structure, porosity and chemistry. The

Chinese tantalum implantation material has a three-dimensional

structure and interconnected pores of sufficient size, which is

beneficial for bone cell adhesion and migration, and thus,

appropriate for osteogenesis. Therefore, this material may be used

as a bone graft substitute material.

The cytotoxicity test is one of the most important

detection indexes prior to the clinical application of biological

materials or medical devices, and is also the first test in

biological safety evaluation. Currently, there are two methods for

detecting cytotoxicity. The first is morphological observation,

which involves observing morphological changes and growth to

determine whether the material is toxic. The second method is to

evaluate viability with an MTT assay, which involves calculating

the relative cell proliferation rate based on light absorption

indirectly, in order to determine the level of cytotoxicity. Higher

cell proliferation rate was associated with lower toxicity of the

tantulum material (22). In the

present study, detection based on cytotoxicity test standards

outside the body from an international biological evaluation system

of medical devices showed that osteoblast proliferation increased

slowly in the early stage, increased rapidly in the middle stage

(days 4–7) and then increased slowly again. In the experimental and

control groups, osteoblasts maintained good morphology, with no

statistically significant difference observed in the OD values

between the groups (P>0.05). Therefore, the results indicated

that tantalum ions are not toxic to osteoblast cells. This result

was consistent with international standards; thus, Chinese porous

tantalum may be safe to implant in animals.

Requirements for bone graft materials include

excellent mechanical properties, a porous structure and the

capacity to support ingrowth of the host tissue. Compared with

other metallic materials, porous tantalum is stable and has a

higher porosity, larger pore size and a low elastic modulus

(7). Therefore, it is used in hip

and knee joint reconstruction surgery and in the production of

prostheses (23). In the present

study, hard tissue slicing technology combined with specific

pathological staining was applied. Light microscopy was used to

observe osteogenesis on the surface of the material at the

tantalum-bone interface. The results showed that the porous

tantalum-bone interface was the most active area of osteogenesis

during the early stages of culture. The morphological

characteristics of the new bone indicated that the osteoblasts were

able to adhere, grow and proliferate in the pores of the material

following the implantation of porous tantalum in the host bone, and

was accompanied by the ingrowth of small blood vessels. Bone

lacunae were observed in the new trabecula, in which new bone cells

were clearly visible. By week 12 after implantation, the surface

and the pores of the porous tantalum rods were fully covered with

new bone tissue, presenting an interwoven arrangement. Similarly to

common paraffin slices, hard tissue slices reflect only the local

osteogenic state at a particular point and are unable reveal the

complete osteogenic process. In the present study, rabbit hips were

injected intramuscularly with fluorescein calcein and alizarin red

on days 5 and 19 after implantation, respectively. New bone tissue

at the tantalum-bone interface and in the pores was observed in the

hard tissue slices using laser scanning confocal microscopy at

laser wavelengths of 488 nm (calcein) and 543 nm (alizarin red);

thus, the osteogenesis process was observed dynamically. On day 5,

the green fluorescent band of the immature bone cells marked by

calcein was observed, and a red fluorescent band of new bone tissue

marked by alizarin red was observed on day 19. The bands were in

direct contact with the surface of the tantalum and grew into the

pores. These results showed that osteogenesis occurred on the

surface of the host bone in the early stage after implantation and

that bone formation was time-dependent, which suggests that new

bone tissue at the tantalum-host bone interface matures over time,

with calcium deposition occurring later. The new bone and host bone

integrate and become difficult to distinguish. This form of

osteogenesis may explain the existence of a solid combination of

porous tantalum and bone, as well as bone conduction to a certain

extent.

When the pore diameter of a porous material is 15–40

μm, fibrous tissue has been reported to grow into the interior of

the material (24,25). When the diameter reaches 40–100 μm,

ingrowth of non-calcified bone-like tissue occurs. When the

diameter exceeds 150 μm, the pore structure of the scaffold may

fill completely with bone tissue, potentially facilitating an

improved osseointegrative effect. Chinese porous tantalum has a

high porosity (65–80%) and is able to induce the development of

fibrous tissue with rich blood vessels and bone tissue growth

inside its pores. Implanted tantalum and host bone may produce a

stable connection and integration. These results also further

confirm that porous tantalum offers good tissue compatibility and

promotes the adhesion, proliferation and differentiation of

osteoblasts. Therefore, Chinese porous tantalum is a suitable bone

graft substitute material for the construction of three-dimensional

structures for bone defect repair. In the present study, porous

tantalum was only observed in the animals for three months;

therefore, a longer observation period may be tested in future

studies. Furthermore, various metal implant materials were not

compared in the present study, such as porous titanium material,

which may be studied in future research.

References

|

1

|

Cardaropoli F, Alfieri V, Caiazzo F and

Sergi V: Manufacturing of porous biomaterials for dental implant

applications through selective laser melting. Adv Mat Res.

535–537:1222–1229. 2012. View Article : Google Scholar

|

|

2

|

Balla VK, Bodhak S, Bose S and

Bandyopadhyay A: Porous tamalum structures for bone implants:

fabrication, mechanical and in vitro biological properties. Acta

Biomater. 6:3349–3359. 2010. View Article : Google Scholar : PubMed/NCBI

|

|

3

|

Bobyn JD, Poggie RE, Krygier JJ, Lewallen

DG, Hanssen AD, Lewis RJ, Unger AS, O’Keefe TJ, Christie MJ, Nasser

S, Wood JE, Stulberg SD and Tanzer M: Clinical validation of a

structural porous tantalum biomaterial for adult reconstruction. J

Bone Joint Surg Am. 86-A(Suppl 2): 123–129. 2004.

|

|

4

|

Zhang HY, Luo JB, Zhou M, Zhang Y and

Huang YL: Biotribological properties at the stem-cement interface

lubricated with different media. J Mech Behav Biomed Mater.

20:209–216. 2013. View Article : Google Scholar : PubMed/NCBI

|

|

5

|

Zhang HY, Zhang SH, Luo JB, Liu YH, Qian

SH, Liang FH and Huang YL: Investigation of protein adsorption

mechanism and biotribological properties at simulated stem-cement

interface. J Tribol. 135:0323012013. View Article : Google Scholar

|

|

6

|

Pohler OE: Unalloyed titanium for implants

in bone surgery. Injury. 31(Suppl 4): 7–13. 2000. View Article : Google Scholar

|

|

7

|

Matsuno H, Yokoyama A, Watari F, Uo M and

Kawasaki T: Biocompatibility and osteogenesis of refractory metal

implants, titanium, hafnium, niobium, tantalum and rhenium.

Biomaterials. 22:1253–1262. 2001. View Article : Google Scholar : PubMed/NCBI

|

|

8

|

Stiehler M, Lind M, Mygind T, Baatrup A,

Dolatshahi-Pirouz A, Li H, Foss M, Besenbacher F, Kassem M and

Bünger C: Morphology, proliferation, and osteogenic differentiation

of mesenchymal stem cells cultured on titanium, tantalum, and

chromium surfaces. J Biomed Mater Res A. 86:448–458. 2008.

View Article : Google Scholar

|

|

9

|

Cohen R: A porous tantalum trabecular

metal: basic science. Am J Orthop (Belle Mead NJ). 31:216–217.

2002.

|

|

10

|

Bobyn JD, Stackpool GJ, Hacking SA, Tanzer

M and Krygier JJ: Characteristics of bone ingrowth and interface

mechanics of a new porous tantalum biomaterial. J Bone Joint Surg

Br. 81:907–914. 1999. View Article : Google Scholar : PubMed/NCBI

|

|

11

|

Zardiackas LD, Parsell DE, Dillon LD,

Mitchell DW, Nunnery LA and Poggie R: Structure, metallurgy, and

mechanical properties of a porous tantalum foam. J Biomed Mater

Res. 58:180–187. 2001. View Article : Google Scholar : PubMed/NCBI

|

|

12

|

Wang JC, Yu WD, Sandhu HS, Tam V and

Delamarter RB: A comparison of magnetic resonance and computed

tomographic image quality after the implantation of tantalum and

titanium spinal instrumentation. Spine (Phila Pa 1976).

23:1684–1688. 1998. View Article : Google Scholar

|

|

13

|

International Organization for

Standardization (ISO). Biological evaluation of medical devices -

Part 5: Tests for in vitro cytotoxicity. 3rd edition. ISO 10993-5.

2009

|

|

14

|

Wang N, Li H, Wang J, Chen S, Chen S, Ma Y

and Zhang Z: Study on the anticorrosion, biocompatibility, and

osteoinductivity of tantalum decorated with tantalum oxide nanotube

array films. ACS Appl Mater Interfaces. 4:4516–4523. 2012.

View Article : Google Scholar : PubMed/NCBI

|

|

15

|

Mrosek EH, Schagemann JC, Chung HW,

Fitzsimmons JS, Yaszemski MJ, Mardones RM, O’Driscoll SW and

Reinholz GG: Porous tantalum and poly-epsilon-caprolactone

biocomposites for osteochondral defect repair: preliminary studies

in rabbits. J Orthop Res. 28:141–148. 2010.

|

|

16

|

Li Y, Wei SB, Cheng XQ, Zhang T and Cheng

G: Corrosion behavior and surface characterization of tantalum

implanted TiNi alloy. Surf Coat Technol. 202:3017–3022. 2008.

View Article : Google Scholar

|

|

17

|

Christie MJ: Clinical applications of

trabecular metal. Am J Orthop (Belle Mead NJ). 31:219–220.

2002.

|

|

18

|

Jonitz A, Lochner K, Lindner T, Hansmann

D, Marrot A and Bader R: Oxygen consumption, acidification and

migration capacity of human primary osteoblasts within a

three-dimensional tantalum scaffold. J Mater Sci Mater Med.

22:2089–2095. 2011. View Article : Google Scholar : PubMed/NCBI

|

|

19

|

Hacking SA, Bobyn JD, Tanzer M and Krygier

JJ: The osseous response to corundum blasted implant surfaces in a

canine hip model. Clin Orthop Relat Res. 364:240–253. 1999.

View Article : Google Scholar : PubMed/NCBI

|

|

20

|

Tang Z, Xie Y, Yang F, et al: Porous

tantalum coatings prepared by vacuum plasma spraying enhance bmscs

osteogenic differentiation and bone regeneration in vitro and in

vivo. PLoS One. 8:e662632013. View Article : Google Scholar : PubMed/NCBI

|

|

21

|

Sagomonyants KB, Hakim-Zargar M, Jhaveri

A, Aronow MS and Gronowicz G: Porous tantalum stimulates the

proliferation and osteogenesis of osteoblasts from elderly female

patients. J Orthop Res. 29:609–616. 2011. View Article : Google Scholar

|

|

22

|

Shimko DA, Shimko VF, Sander EA, Dickson

KF and Nauman EA: Effect of porosity on the fluid flow

characteristics and mechanical properties of tantalum scaffolds. J

Biomed Mater Res B Appl Biomater. 73:315–324. 2005. View Article : Google Scholar : PubMed/NCBI

|

|

23

|

Levine BR, Sporer S, Poggie RA, Della

Valle CJ and Jacobs JJ: Experimental and clinical performance of

porous tantalum in orthopedic surgery. Biomaterials. 27:4671–4681.

2006. View Article : Google Scholar : PubMed/NCBI

|

|

24

|

Barrère F, van der Valk CM, Meijer G,

Dalmeijer RA, de Groot K and Layrolle P: Osteointegration of

biomimetic apatite coating applied onto dense and porous metal

implants in femurs of goats. J Biomed Mater Res B Appl Biomater.

67:655–665. 2003. View Article : Google Scholar : PubMed/NCBI

|

|

25

|

Wigfield C, Robertson J, Gill S and Nelson

R: Clinical experience with porous tantalum cervical interbody

implants in a prospective randomized controlled trial. Br J

Neurosurg. 17:418–425. 2003. View Article : Google Scholar : PubMed/NCBI

|