Introduction

The study of tissue-engineered cartilage with the

basic goals of predetermined shaping and regeneration has provided

novel ideas and techniques for research into laryngeal cartilage

erosion (1–3); however, due to the special nature of

the morphology, location and function of laryngeal cartilage,

tissue engineering research has not, to date, exhibited its full

advantages in the reconstruction of laryngeal cartilage (4). This is not only due to the large

quantity of seed cells and biomaterials required for the

construction and shaping of the tissue-engineered laryngeal

cartilage, but also due to the difficulty of constructing the ideal

irregular, hollow, three-dimensional structure. Tissue-engineered

laryngeal cartilage with a hollow, semi-flared shape should show

good biocompatibility, biodegradability and structures of the pores

inside the biological materials, as well as sufficient mechanical

strength and flexibility (5). How

to ensure that the cartilage maintains its shape and structure and

how to develop the potential of cartilage reshaping applications

are two problems currently faced in the process of

tissue-engineered, hollow, semi-flared laryngeal cartilage

construction. The exploration of hollow structural biomaterials

that are more suitable for shaping and tissue-engineered cartilage

regeneration, as well as the practical application of the cartilage

tissue engineering regenerative technology, is the only way to

improve laryngeal cartilage repair and reconstruction. In the

present study, on the basis of previously published tissue

engineering findings (6,7), the new biomaterial

poly(3-hydroxybutyrate-co-3-hydroxyhexanoate) (PHBHH) was used in

the shaping of laryngeal tissue-engineered cartilage tissue into a

hollow, half-flared shape, and the compatibility of the PHBHH with

chondrocytes was investigated. The aim of the study was to

determine the feasibility of constructing laryngeal cartilage

tissue with a hollow, half-flared shape using the muscle wrapping

and filling method and using the fascia lining of a pedicled

myofascial flap, in order to provide an experimental basis for the

tissue engineering of laryngeal cartilage with a hollow,

half-flared shape through the transplantation of myofascial

tissue.

Materials and methods

Chondrocyte harvest

Costal and articular cartilages were obtained under

sterile conditions from young New Zealand rabbits of both genders,

aged between three and seven days, provided by the Center of

Laboratory Animals, Shenyang Military Area Command (Shenyang,

China). The cartilage was cleaned, washed twice with 0.1 mol/l

sterile phosphate-buffered saline (PBS) containing 200 U/ml

penicillin and streptomycin, respectively, and digested with 0.25%

trypsin (Sigma-Aldrich, St. Louis, MO, USA) for 2 min. Following

digestion, the cartilage was washed with PBS a further three times,

cut into pieces (1–2 mm3) and washed again with PBS. The

pieces were then placed in a small 50-ml beaker. Type II

collagenase (0.3%; Sigma-Aldrich) was added and stirred for

digestion at 37°C, and the cells were subsequently collected once

every 0.5 h, starting from 1 h, until all the solids had

disappeared. The cell suspension was obtained and centrifuged at

250 xg for 10 min, the supernatant was discarded and the

precipitate was washed with PBS two times. Dulbecco’s Modified

Eagle’s medium/Ham-F12 (1:1) mixed culture medium (Gibco-BRL;

Invitrogen Life Technologies, Carlsbad, CA, USA), containing 20%

fetal bovine serum (Zhejiang Evergreen Biologicals, Hangzhou,

China), was used to resuspend the cells, and trypan blue staining

was performed. The cells were counted using a cell counting board;

stained cells were considered to be non-viable cells while

unstained cells were considered to be viable). Cells were seeded in

100-ml culture flasks at a density of 2×105 cells/ml and

cultured in a humidified CO2 incubator (Thermo Fisher

Scientific Inc., Waltham, MA, USA). The medium was changed every 48

h, and the cells were passaged when the whole wall of the culture

flask was covered by adhered cells.

Mold preparation

Shaping was performed in reference to the full

morphology of adult laryngeal cartilage, and the plastic models

were prepared by 3:1 shrinking. Polytetrafluoroethylene was taken

as the mold material, and sculpted in the form of the corresponding

female die, which was comprised of an inner core and two outer

plates.

Poration and shaping of the biological

material

The biological materials exhibiting a laryngeal

cartilage-like hollow, semi-flared morphology were prepared by

solvent casting, compression molding and particulate filter

leaching methods (8). In brief,

quantitative PHBHH flocculent material (molecular weight, 600,000;

provided by the Department of Chemical Engineering, Tsinghua

University, Beijing, China) was placed inside a spherical,

heat-resistant glass container, and chloroform solvent (Sinopharm

Chemical Reagent Co., Ltd., Shanghai, China) was added (at a ratio

of 2:3). The mixture was then heated for reflux under sealed

conditions, stirred with a magnetic stirrer and rapidly poured into

a wide-neck flask containing sodium salt (Sinopharm Chemical

Reagent Co., Ltd.) (screening of 150–200 μm). Once the solution

formed a uniform thin paste, the bottle was sealed and placed at

room temperature overnight (making the material naturally penetrate

the salt layer). The mixture of the material and the salt was

firstly prepared into a sheet, then wrapped around the mold core

portion, closed around the outer mold and fixed by metal fixture;

the liquid was then compressed into the mold. The samples were

placed in the fume cupboard for ≥48 h for full evaporation of the

chloroform and subsequently placed in a vacuum pump suction filter

for 12 h to remove any possible residual chloroform. The obtained

samples were set within an inner metal mesh, suspended in glass

containers containing distilled water, magnetically stirred and

filtered for desalination. The triple-distilled water was replaced

at least three times. The desalinated samples were dried naturally

for porosimetry.

Determination of PHBHH porosity

The liquid displacement method (9) was used in the determination of PHBHH

porosity, Due to the lipophilic nature of the PHBHH, ethanol

(Sinopharm Chemical Reagent Co., Ltd.) was used instead of water.

This facilitated the penetration of the liquid into the material.

The ethanol was added with a volume scale (V1) into a sealable test

tube and the test sample (mass, M) was weighed and then also added

to the tube. The tubes were subsequently sealed, opened after 8 h

(to release the gas) and closed again. After 24 h, the ethanol

penetrated sufficiently into the pores within the sample, and the

volume was recorded as V2. Subsequent to removing the sample

saturated with ethanol, the volume of ethanol in the tube was

recorded as V3. The material density was calculated using the

following formula: ρ=M/(V2−V3). The porosity (%) was calculated

using the formula e=(V1−V3)/(V2−V3)×100.

Assistance for shaping and adhesion

The shaping of the hollow, semi-flared PHBHH objects

was aided by the inner surface of a steel wire with a diameter of

0.4 mm, which was uninterruptedly woven into the form of two

approximate rings and three longitudinal supports. Compared with

the PHBHH with the hollow semi-flared shape, the larger ring

fluctuated correspondingly up and down along the semiflared shape

of the corners and edges of the stent, mainly helped the shaping of

the edges and rear parts with less material of the PHBHH with

hollow semi-flared shape. The smaller ring was nearly round, which

assisted in the shaping of the small end of the hollow, semi-flared

PHBHH, and the three longitudinal wire supports were located in the

sides of the PHBHH shape and in the middle of the front. The steel

support frame was placed tightly inside the PHBHH model with no

special fixation. The hollow, semi-flared PHBHH constructions and

the steel wire support frame were disinfected by immersion into 75%

alcohol and then rinsed three times with PBS, prior to being dried

under sterile conditions. Adhesion was promoted by immersing the

PHBHH and the frame into sterile poly-L-lysine aid (relative

molecular mass, 1.89 million; Sigma-Aldrich) for 1 h, prior to

drying.

Compounding of chondrocytes with PHBHH

porous materials and culturing in vitro

Following the adjustment of the cell suspension to a

density of 5×107/ml, the chondrocytes were inoculated in

the pre-dried shaping materials by culture medium containing ~30%

wet culture medium, a small amount of cell suspension each time

when inoculated, was scattered and multicasted to make the cells

distribute as evenly as possible, the inoculated cells of the inner

surface of the shaping hollow material were pipetted using a bend

head. The cells were placed in a CO2 saturated humidity

incubator (Thermo Fisher Scientific, Inc.) at 37°C and 5%

CO2 for 0.5 h, and then removed and agitated. The cell

suspension around the bottom of the material was sucked out and

inoculation was performed from top to bottom twice, prior to

further incubation for 1 h. Fresh culture medium was then added

slowly along the sidewall so that the composite was infiltrated by

2–3 cm. The medium was changed once every 48 h. Cell growth and

adhesion in the composite edge were observed under an inverted

microscope (Huxing XSP-20CD; Shanghai Huxing Optical Instrument

Co., Shanghai, China). The shaped material loaded with chondrocytes

was used in the experimental group, while a control group was

established by shaping the PHBHH without the chondrocytes. All

other steps in the two groups were identical. Each 5×5-mm

sheet-like chondrocyte-PHBHH composite was fixed with 2.5%

glutaraldehyde, dehydrated progressively with alcohol, dried,

mounted and observed using light-emitting plasma spraying with

scanning electron microscopy (SEM) (S570; Hitachi, Tokyo,

Japan).

Surgical procedure

Experimental grouping

Twelve male New Zealand white rabbits (age, ~6

months; weight, 2.5±0.5 kg) were randomly divided into an

experimental (n=9) and a control (n=3) group. This study was

carried out in strict accordance with the recommendations in the

Guide for the Care and Use of Laboratory Animals of the National

Institutes of Health. The animal use protocol was reviewed and

approved by the Institutional Animal Care and Use Committee of the

General Hospital of Shenyang Military Area Command (Shenyang,

China; permit no. 20060828001).

Design of the pedicled myofascial

flap

Intravenous anesthesia was induced with 3%

barbiturate. The side of the back skin of the rabbit was

disinfected and shaved, and the middle portion of the sacral spine

muscle and fascia was isolated from the distal side of the rabbit’s

back to form the myofascial tissue flap with the pedicle for the

proximal and distal sides of the flap. The filled myofascial flap

with a conical hollow portion was designed according to the size of

the chondrocyte-PHBHH composite. The fascial layer of the

myofascial flap, similar to a conical shape, was then stabbed into

the form of a net with a scalpel blade for filling in the prepared

hollow part of the composite. During flap preparation, the sacral

spinal fascia in the sides of the depression was freed, simply

sutured, connected and placed in the recessed slots, and the fascia

in the depressed trench was subjected to poration for the in

situ implantation of the PHBHH-chondrocyte complex. Following

implantation, the remaining sacral spine muscle and fascia were

separated to enclose the chondrocyte-PHBHH complex. Autologous

fascia tissues were used for each implanted chondrocyte-PHBHH

composite.

Implantation in vivo

The chondrocyte-PHBHH composites were co-cultured

in vitro for 7–10 days, until abundant extracellular matrix

was observed using inverted microscopy. The composites were removed

subsequent to reaching a certain degree of support (hardness). The

in situ implantation was designed, filled and wrapped in the

body according to the design of myofascial tissue, and the distal

portion of the filled myofascial flap was fixed. The subcutaneous

skin was sutured. Each batch of surgical procedures was performed

by the same group of technicians, and the surgical procedures and

technology used were consistent. The rabbits were administered an

intramuscular injection of 800,000 units penicillin, and the

surgery was then repeated the next day for a total of four

times.

Experimental observation and

evaluation

Poration, shaping and cellular

compatibility of PHBHH

The PHBHH composites were observed and assessed for

shapes similar to the hollow, semi-flared laryngeal cartilage

morphology. The composite pore continuity and chondrocyte adhesion,

distribution and growth were observed using SEM.

Construction of tissue-engineered,

hollow, semi-flared laryngeal cartilage

The animals were anesthetized and the implants were

removed: Three rabbits from the experimental group and one from the

control group were selected at each time-point, six, 12 and 18

weeks after surgery, respectively. The gross morphology of the

tissue-engineered laryngeal cartilage was observed, and hematoxylin

and eosin (HE), Masson’s trichrome and Alcian blue/periodic acid

Schiff reaction (AB/PAS) staining were performed, as well as

collagen type II immunohistochemical detection for the evaluation

of cartilage formation.

Results

Fabrication of PHBHH porous models

The porous PHBHH composite was prepared by solvent

casting, compression molding and particulate filtering, and had a

hollow, semi-flared shape, which was substantially similar to

laryngeal cartilage morphology (Fig.

1). Following the filtering and demineralization, the whole

structure was porous and spongy. The porosity was measured using

the ethanol static volumetric measurement method (92±2%), and the

pore size and thickness were found to be 100–150 μm and ~1.5 mm,

respectively.

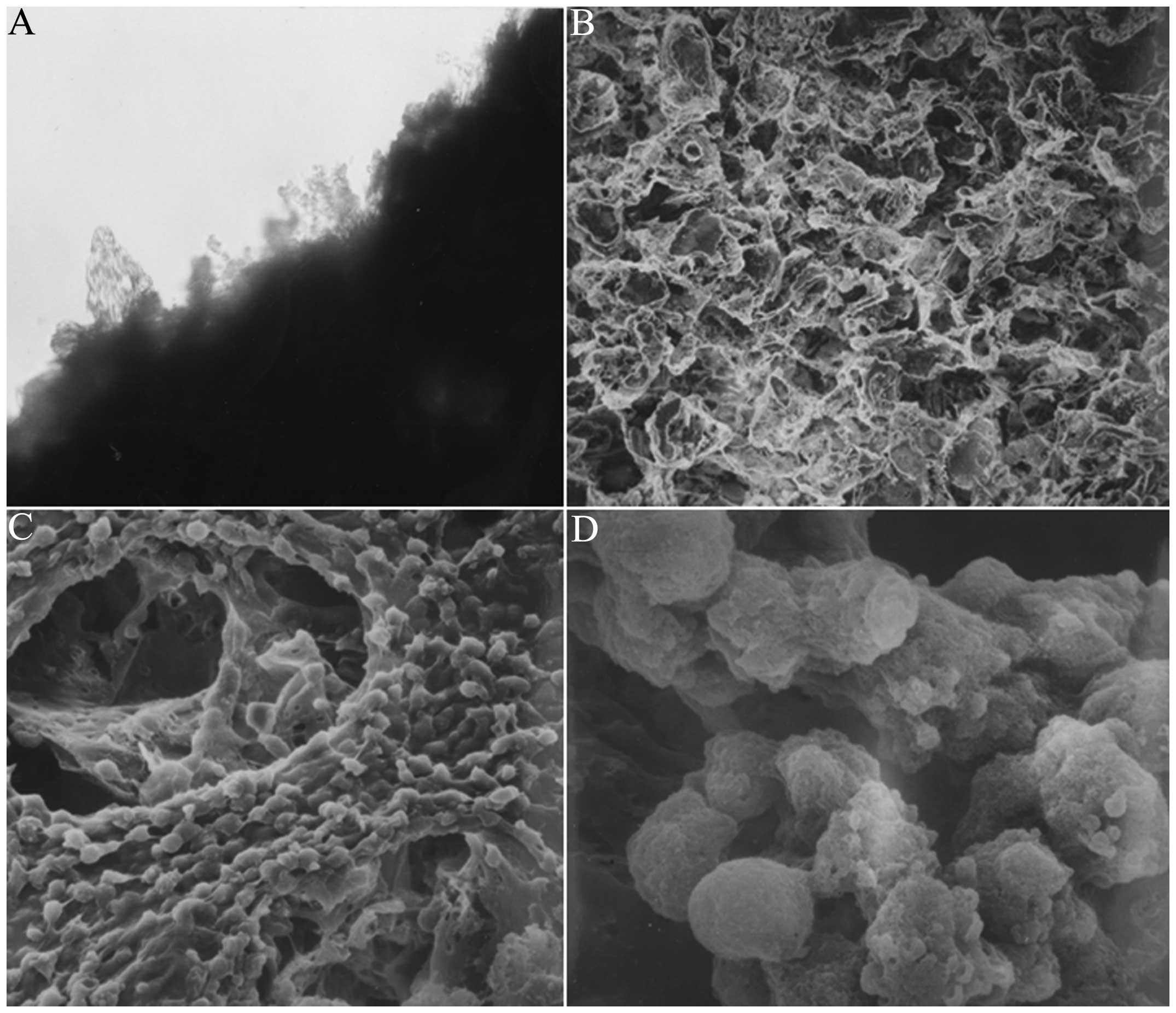

Experimental observation in vitro

At 24 h after the inoculation of chondrocytes into

the hollow, semi-flared PHBHH biomaterials, the chondrocytes were

observed to attach to the surface of the lower edge of the material

under an inverted microscope. Following co-culture of the

chondrocytes and PHBHH for one week, a jelly-like matrix, secreted

by the chondrocytes, was visible at edge of the material (Fig. 2A).

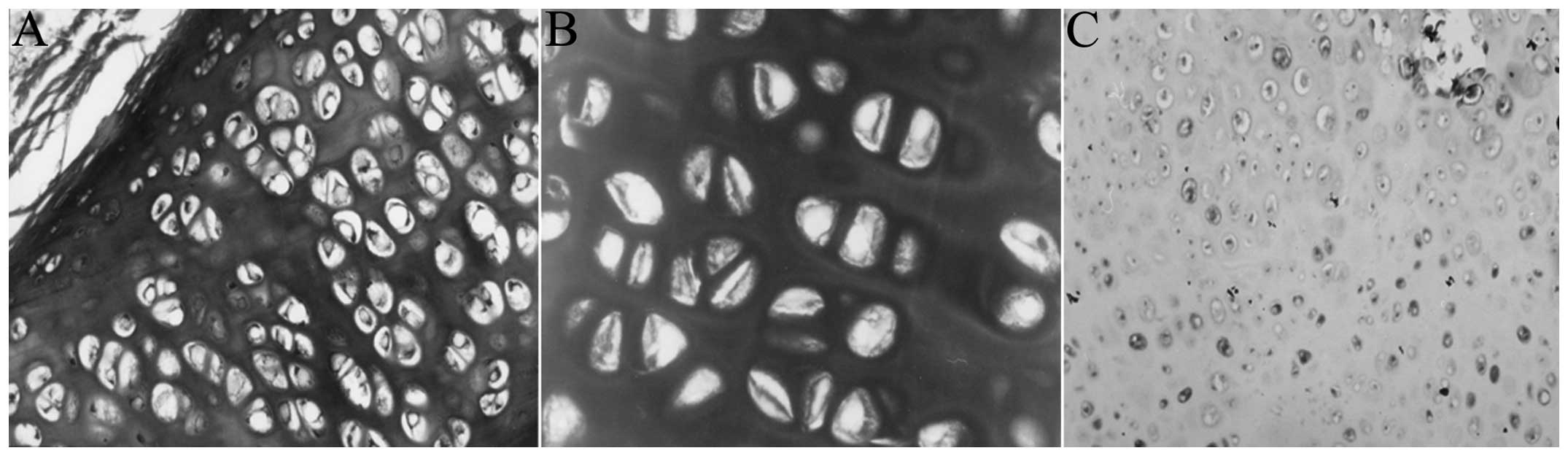

SEM

The simple PHBHH material was porous and spongy,

exhibiting a pore size of 100–150 μm (Fig. 2B). SEM showed that the cells

(single, string or cluster) were distributed at the surface and in

the cavernous, spongy hollow of the chondrocyte-PHBHH complex.

Mucus-like stromal substances around the cells exhibited

interlinking adhesions (Fig. 2C),

and numerous small projections were visible under

high-magnification microscopy, which may have been fused matrix

components secreted by the chondrocytes (Fig. 2D).

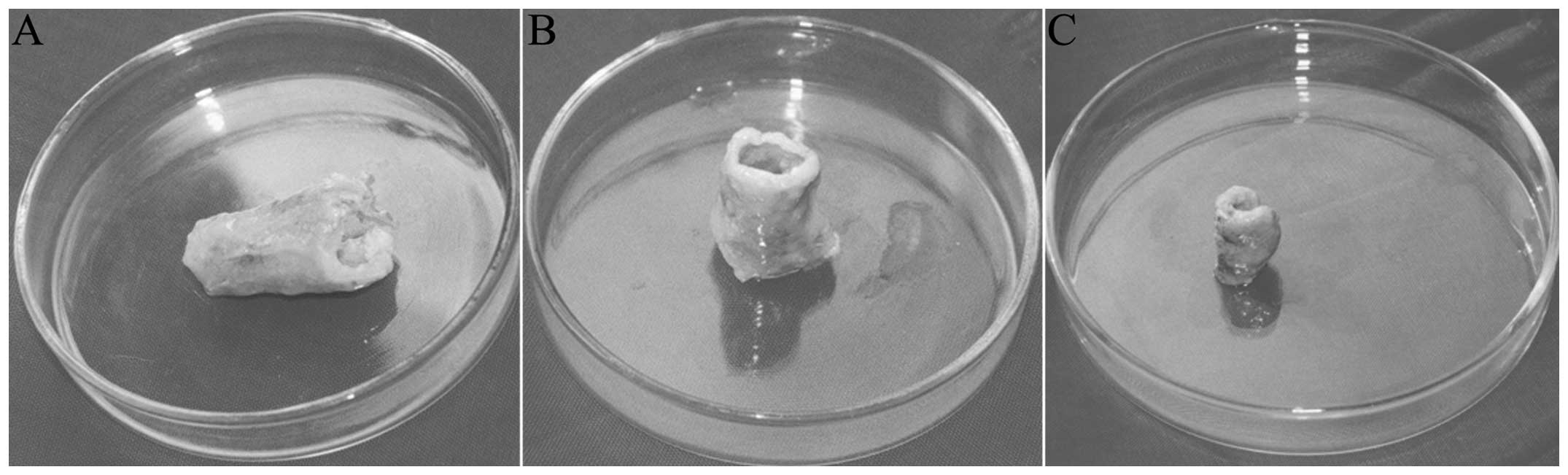

General morphology

The materials were harvested six weeks after

implantation, and the implants and connective tissue myofascial

adhesions were wrapped together. Dense, tiny blood vessels were

distributed on the connective tissue. Subsequent to stripping away

part of the wrapped organization it was observed that the filled

myofascial tissue was closely in contact with the implants. The

steel wire support frame, filled packages and fascia tissues were

removed, and it was found that the general form of the implants in

the two cases was consistent with the morphology prior to

implantation (Fig. 3A). The

specimens possessed a certain hardness with smooth inner and outer

surfaces. In one case the implant had collapsed, showing angular

release and a loss of the predetermined hollow, semi-flared shape

(Fig. 3B). At 12 weeks, only two

complete specimens of the three experimental group implants

remained for harvesting, as the third collapsed; the general form

showed a hollow, semi-flared, tissue-engineered laryngeal

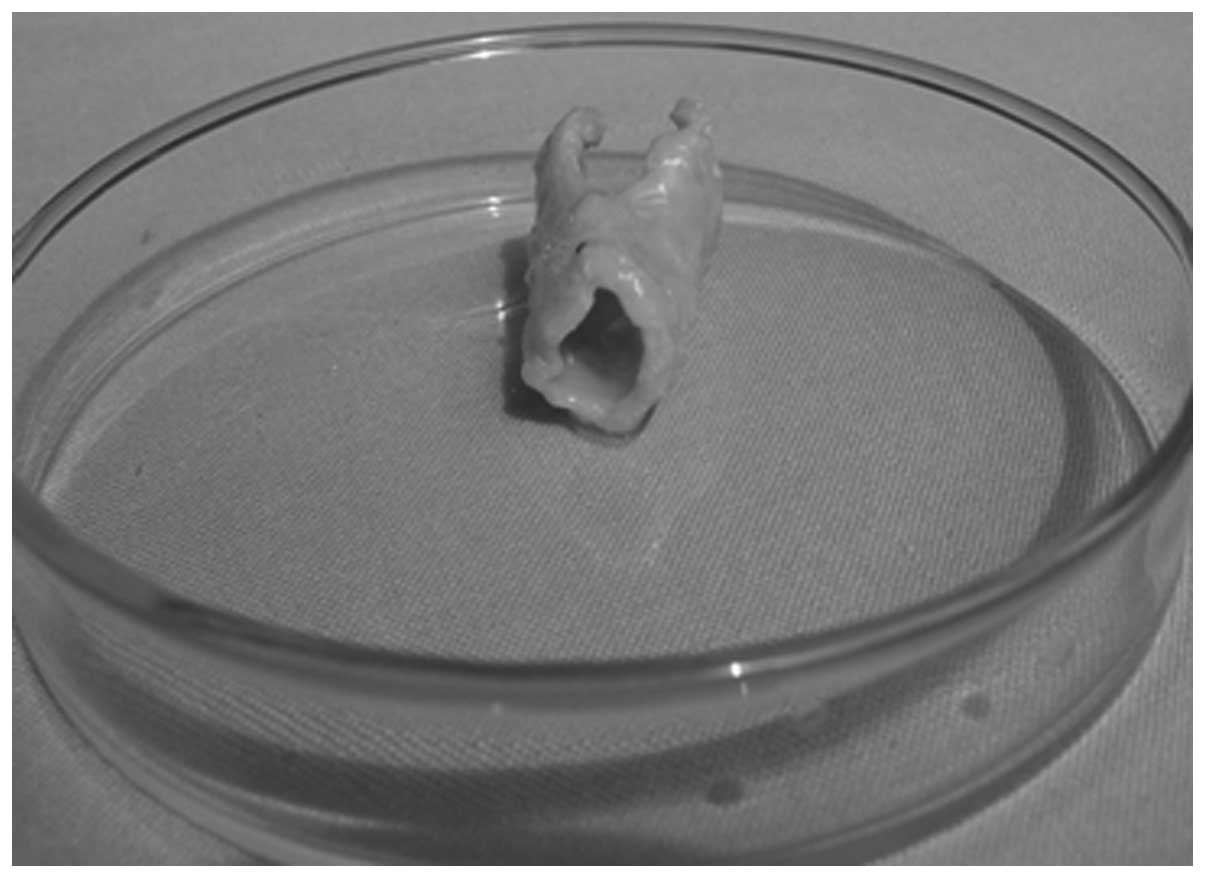

cartilage. When harvested at 18 weeks, the implant shape of the

three cases was consistent, and the milky white, hollow,

semi-flared, tissue-engineered laryngeal cartilage exhibited a

realistic shape (Fig. 4). In the

control group, one implant was removed at each corresponding

time-point. The retained hollow, semi-flared shape of the gross

specimens in the control group at six weeks (Fig. 3C) was significantly less than that

of the experimental group at the same time-point (Fig. 3A). At 12 and 18 weeks the gross

morphology of the implants in the control group had almost

disappeared; only the built-in medical steel support frame was

visible in the implant area.

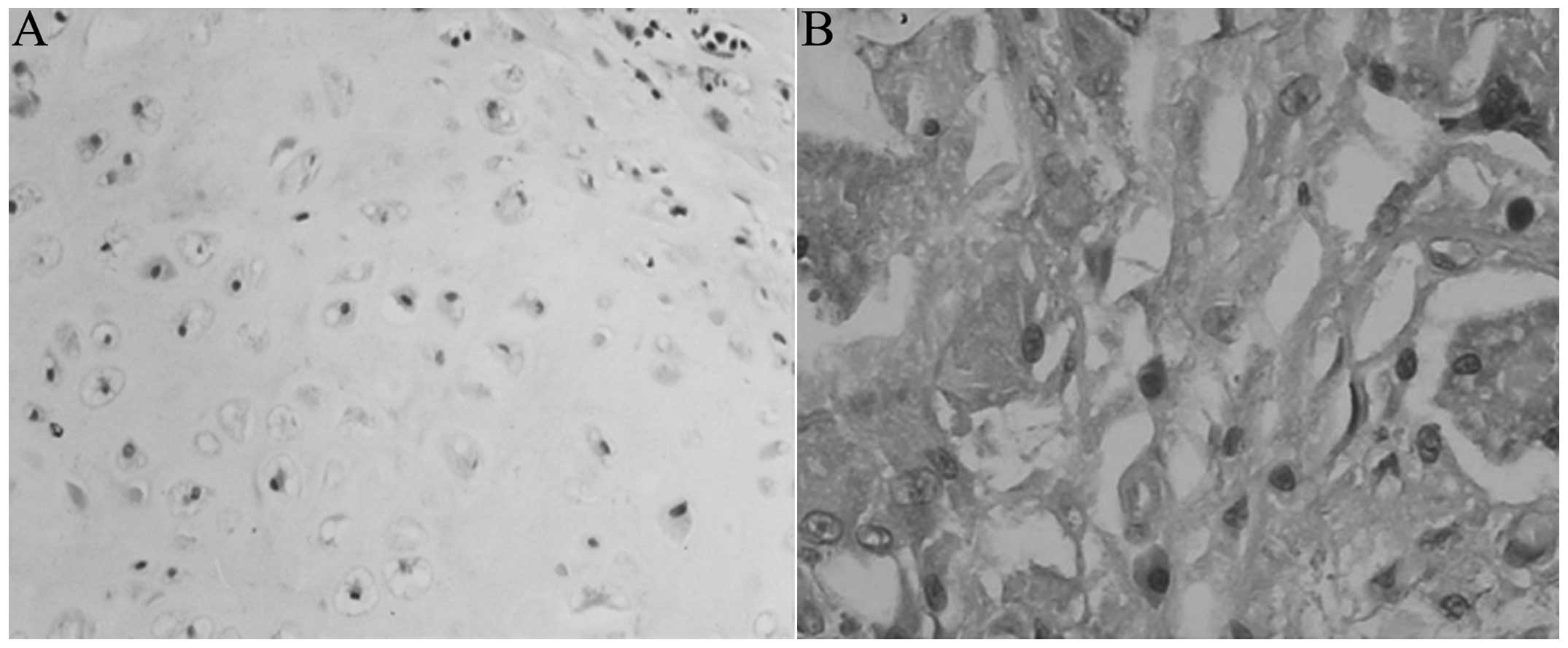

Histological observation

HE staining

At the six-week time-point the cells of the

experimental group exhibited a circular, oval or polygonal

morphology, and single cells were scattered. Incomplete degradation

‘impurities’, such as material around the PHBHH, were visible among

the cells, and inflammatory cell infiltration was present around

the cartilage (Fig. 5A). At 12

weeks, the majority of the cells exhibited an oval morphology; two

to three cells were commonly clustered together and showed a

uniform stromal staining. The morphology of the cells at 18 weeks

was similar to that at 12 weeks; the ‘impurities’ had disappeared,

but a small number of inflammatory cells remained in the

surroundings. Cartilage-like cells in the control group were

visible amongst the collapse of the pores and degradation of the

material at six weeks, and few other tissue cells were scattered on

the surface (Fig. 5B).

Masson’s trichrome staining

Pale green objects were observed in the chondrocytes

and cartilage matrix following cytoplasmic staining of the

experimental group at the sixth week, and the presence of the green

pollutants increased significantly at the 12th week, with deeper

staining (Fig. 6A). The cell

morphology, distribution and coloring at 18 weeks were not

different from the observations at 12 weeks.

AB/PAS

The matrix was purple at the six-, 12- and 18-week

time-points (Fig. 6B).

Immunohistochemistry for type II

collagen

At six weeks, immunohistochemistry for type II

collagen in the experimental group (Boster Biotechnology Co., Ltd.,

Wuhan, China) revealed weakly positive staining, which was mainly

distributed in the cytoplasm, with very small amounts in the

matrix. At 12 weeks, the positive staining in the cytoplasm was

significantly enhanced, and increased type II collagen-positive

staining was detected in the matrix (Fig. 6C). Similar results were observed at

18 weeks.

Discussion

Different from the regeneration of sheet cartilage

tissue by tissue engineering technology, the construction of

hollow, semi-flared, tissue-engineered laryngeal cartilage has a

higher demand for biocompatibility, biodegradability, pore

structure, mechanical strength and the shaping of extracellular

matrix materials (10).

Biomaterials that are currently used in cartilage tissue

engineering include natural biomaterials, such as collagen, fibrin

and chitosan; synthetic biomaterials, such as polyglycolic acid;

microbial biosynthetic material, such as types of biological

polyhydroxyalkanoates and copolymers; and composite materials, such

as polylactic acid-collagen and fibrin-polyurethane (11–14).

The biomaterials each have individual advantages and disadvantages

in terms of biocompatibility, degradation suitability, cell

adhesion, metabolic microenvironment, mechanical strength, shaping

and flexibility. Natural biological materials lack sufficient

mechanical strength, while artificial and compound biomaterials are

expensive and involve complex processing, but are easy to shape

(15–19).

Polyhydroxyalkanoate is a natural substance produced

by microorganisms and exhibits characteristics such as good

biocompatibility, no induction of inflammation, no degradation and

reduced rejection (20,21). As more types of polymers become

available, and as the compatibility among the polymers is enhanced,

tissue engineering scaffolds with improved strength, toughness,

biocompatibility and controlled degradation are likely to be able

to be obtained through the advantages resulting from the

combination of different polymers (6).

In the present study, the selected material PHBHH, a

copolymer of poly-3-hydroxybutyrate and poly-3-hydroxyhexanoate

ester, not only had the advantages common to biological materials

belonging to the polyhydroxyalkanoate class, but could also be

found at low prices and from abundant sources. PHBHH was made into

a hollow, semi-flared, tissue-engineered, larynx-shape model by

solvent casting and compression molding methods; the material

maintained a good shape subsequent to desalting by filtering and

exhibited considerable mechanical strength. The material was porous

and spongy under the electron microscope, the pore size was

consistent with the screening of the salt, the porosity was high,

which was in line with the basic requirements for a porous

structure, and the model showed a certain degree of mechanical

strength. Following the co-culture of the cartilage cells with the

PHBHH composite material in vitro, the model showed good

cell adhesion, distribution and vigorous growth; however, the

mechanical strength was still insufficient to maintain the

predetermined shape upon implantation, which highlighted the

necessity of the auxiliary, in-built support frame. The

implantation of simple PHBHH laryngeal cartilage scaffolds, without

cells, was taken as the control group; after six weeks an increased

loss of general shape was observed in the control group compared

with the experimental group, in which a chondrocyte-PHBHH composite

had been implanted. Under the microscope, no cartilage-like

structure was observed in the control group, and more incomplete

degradation impurities of PHBHH were apparent in the cartilage

tissue. The shape of the control group implants was lost at the

12th and 18th weeks, suggesting that implantation of the material

for six weeks resulted in significant, but not complete,

degradation and absorption. Implantation of PHBHH alone, without

seed cells, led to an ineffective generation of cartilage tissue.

By contrast, after 12 weeks of in vivo implantation in the

experimental group, mature, hollow, semi-flared, tissue-engineered

laryngeal cartilage could be obtained.

Although basic research in cartilage tissue

engineering has achieved encouraging results (22,23),

the functional repair and reconstruction of tissue-engineered

laryngeal cartilage has not yet been implemented in a practical

sense (24,25). The factors impeding this

implementation are the blood supply and mucosal and supportive

defects of the regenerated cartilage. The limitations in the

regeneration of cartilage could be overcome by combining the

advantages of tissue engineering technology and the

predetermination of cartilage morphology with the advantages of the

use of a tissue flap to provide a blood supply. Through this

strategy, and using the characteristics of epithelization (26), an affiliation could be achieved

between the fibrous tissues and the tissue flap. The tissue flap

could be prepared using the design principle of filling the lining

of the cavity fascia and wrapping the outer cavity with muscle to

adhere to the tissue-engineered cartilage. The complex could then

be used to reconstruct the laryngeal cartilage with scaffold

functions according to the common nearest transfer or graft method

(27–31). This technique is likely to overcome

the problems in vascularization, mucosalization and support in

cartilage repair and reconstruction for laryngeal cartilage.

Based on the above idea, the present study attempted

to take a fascia tissue lining and use myofascial tissue flap

filling and wrapping technology to build a predetermined, hollow,

semi-flared, tissue-engineered laryngeal cartilage. In the

experimental procedure, the myofascial tissue of the fascial

portion was placed on the surface of the proposed cartilage

construction for contact. Fascia poration not only enhanced blood

circulation, but was also conducive to adhesion between the

structures. Experimentally designed muscle flap was filled with a

rich blood supply, while the seperated flap, which remained in the

recessed part, also formed an equally rich blood supply. The

cultured chondrocyte-hollow, semi-flared PHBHH composite was placed

off the depression of the tissue flap and cultured for a certain

period of in vitro. The cavity was filled with fascia and

muscle lining, and the periphery was supported by the tissue around

depression or recessed slots. The upper part of the complex was

covered and wrapped with myofascial tissues. The results of the

study showed that the application of myofascial tissue with a flap

blood supply with functional filling and wrapping technology could

successfully lead to the generation of hollow, semi-flared,

tissue-engineered laryngeal cartilage. Difficulties may arise,

however, in avoiding the collapse of the samples, considering the

multiple steps in the construction of the hollow, semi-flared,

tissue-engineered laryngeal cartilage.

This study has raised the potential for a common

transfer transplantation with complex of the tissue flap and

hollow, semi-flared, tissue-engineered cartilage, and has indicated

the success of the myofascial flap filling and wrapping method in

generating hollow, semi-flared, tissue-engineered laryngeal

cartilage for functional repair and reconstruction. The study has

also demonstrated the potential of the mucosal epithelial

transformation of an ideal hollow cartilage surface; however, the

results of this study are preliminary, and the design of laryngeal

cartilage scaffolds based on this design concept, and the

construction, transplantation and practical applications of the

composite tissues, should be the direction of future studies.

References

|

1

|

Sterodimas A and de Faria J: Human

auricular tissue engineering in an immunocompetent animal model.

Aesthet Surg J. 33:283–289. 2013. View Article : Google Scholar : PubMed/NCBI

|

|

2

|

Cheng NC, Estes BT, Young TH and Guilak F:

Engineered cartilage using primary chondrocytes cultured in a

porous cartilage-derived matrix. Regen Med. 6:81–93. 2011.

View Article : Google Scholar :

|

|

3

|

Fishman JM, De Coppi P, Elliott MJ, Atala

A, Birchall MA and Macchiarini P: Airway tissue engineering. Expert

Opin Biol Ther. 11:1623–1635. 2011. View Article : Google Scholar : PubMed/NCBI

|

|

4

|

Fisher MB and Mauck RL: Tissue engineering

and regenerative medicine: recent innovations and the transition to

translation. Tissue Eng Part B Rev. 19:1–13. 2013. View Article : Google Scholar :

|

|

5

|

Lu T, Li Y and Chen T: Techniques for

fabrication and construction of three-dimensional scaffolds for

tissue engineering. Int J Nanomedicine. 8:337–350. 2013. View Article : Google Scholar : PubMed/NCBI

|

|

6

|

Deng Y, Lin XS, Zheng Z, Deng JG, Chen JC,

Ma H and Chen GQ: Poly(hydroxybutyrate-co-hydroxyhexanoate)

promoted production of extracellular matrix of articular cartilage

chondrocytes in vitro. Biomaterials. 24:4273–4281. 2003. View Article : Google Scholar : PubMed/NCBI

|

|

7

|

Veleirinho B, Coelho DS, Dias PF,

Maraschin M, Ribeiro-do-Valle RM and Lopes-da-Silva JA: Nanofibrous

poly (3-hydroxybutyrate-co-3-hydroxyvalerate)/chitosan scaffolds

for skin regeneration. Int J Biol Macromol. 51:343–350. 2012.

View Article : Google Scholar : PubMed/NCBI

|

|

8

|

Mikos AG, Sarakinos G, Leite SM, Vacanti

JP and Langer R: Laminated three-dimensional biodegradable foams

for use in tissue engineering. Biomaterials. 14:323–330. 1993.

View Article : Google Scholar : PubMed/NCBI

|

|

9

|

Zhang R and Ma PX:

Poly(alpha-hydroxylacids)/hydroxyaptite porous composites for

bone-tissue engineering. I Preparation and morphology. J Biomed

Mater Res. 44:446–455. 1999. View Article : Google Scholar : PubMed/NCBI

|

|

10

|

Gilpin DA, Weidenbecher MS and Dennis JE:

Scaffold-free tissue-engineered cartilage implants for

laryngotracheal reconstruction. Laryngoscope. 120:612–617. 2010.

View Article : Google Scholar : PubMed/NCBI

|

|

11

|

Shahin K and Doran PM: Improved seeding of

chondrocytes into polyglycolic acid scaffolds using semi-static and

alginate loading methods. Biotechnol Prog. 27:191–200. 2011.

View Article : Google Scholar : PubMed/NCBI

|

|

12

|

El Sayed K, Marzahn U, John T, et al:

PGA-associated heterotopic chondrocyte cocultures: implications of

nasoseptal and auricular chondrocytes in articular cartilage

repair. J Tissue Eng Regen Med. 7:61–72. 2013. View Article : Google Scholar

|

|

13

|

Chaim IA, Sabino MA, Mendt M, Müller AJ

and Ajami D: Evaluation of the potential of novel PCL-PPDX

biodegradable scaffolds as support materials for cartilage tissue

engineering. J Tissue Eng Regen Med. 6:272–279. 2012. View Article : Google Scholar

|

|

14

|

Xue J, Feng B, Zheng R, et al: Engineering

ear-shaped cartilage using electrospun fibrous membranes of

gelatin/polycaprolactone. Biomaterials. 34:2624–2631. 2013.

View Article : Google Scholar : PubMed/NCBI

|

|

15

|

Vacanti CA and Upton J: Tissue-engineered

morphogenesis of cartilage and bone by means of cell

transplantation using synthetic biodegradable polymer matrices.

Clin Plast Surg. 21:445–462. 1994.PubMed/NCBI

|

|

16

|

Cohen SB, Meirisch CM, Wilson HA and

Diduch DR: The use of absorbable co-polymer pads with alginate and

cells for articular cartilage repair in rabbits. Biomaterials.

24:2653–2660. 2003. View Article : Google Scholar : PubMed/NCBI

|

|

17

|

Baek CH and Ko YJ: Characteristics of

tissue-engineered cartilage on macroporous biodegradable PLGA

scaffold. Laryngoscope. 116:1829–1834. 2006. View Article : Google Scholar : PubMed/NCBI

|

|

18

|

Zhijun L and Wanming W: Latest progress in

biological scaffold materials for tissue engineered cartilage.

Zhongguo zu zhi gong cheng yan jiu. 11:3625–3628. 2007.

|

|

19

|

Asti A and Gioglio L: Natural and

synthetic biodegradable polymers: different scaffolds for cell

expansion and tissue formation. Int J Artif Organs. 37:187–205.

2014.PubMed/NCBI

|

|

20

|

Zhao K, Deng Y, Chun Chen J and Chen GQ:

Polyhydroxyalkanoate (PHA) scaffolds with good mechanical

properties and biocompatibility. Biomaterials. 24:1041–1045. 2003.

View Article : Google Scholar

|

|

21

|

Ye C, Hu P, Ma MX, Xiang Y, Liu RG and

Shang XW: PHB/PHBHHX scaffolds and human adipose-derived stem cells

for cartilage tissue engineering. Biomaterials. 30:4401–4406. 2009.

View Article : Google Scholar : PubMed/NCBI

|

|

22

|

Sun AK, Li WT, Meng QY, Liu SB, Chen W and

Tang WW: Fabrication of larynx-shape tissue engineered cartilage by

means of filling together with wrapping with pedicle myofascial

flap. Zhonghua Er Bi Yan Hou Tou Jing Wai Ke Za Zhi. 46:1019–1023.

2011.(In Chinese).

|

|

23

|

Nomoto Y, Okano W, Imaizumi M, Tani A,

Nomoto M and Omori K: Bioengineered prosthesis with allogenic

heterotopic fibroblasts for cricoid regeneration. Laryngoscope.

122:805–809. 2012. View Article : Google Scholar : PubMed/NCBI

|

|

24

|

Lange P, Fishman JM, Elliott MJ, De Coppi

P and Birchall MA: What can regenerative medicine offer for infants

with laryngotracheal agenesis? Otolaryngol Head Neck Surg.

145:544–550. 2011. View Article : Google Scholar : PubMed/NCBI

|

|

25

|

Kanemaru S, Hirano S, Umeda H, et al: A

tissue-engineering approach for stenosis of the trachea and/or

cricoid. Acta Otolaryngol Suppl. 563:79–83. 2010. View Article : Google Scholar : PubMed/NCBI

|

|

26

|

Glatz F, Neumeister M, Suchy H, Lyons S,

Damikas D and Mowlavi A: A tissue-engineering technique for

vascularized laryngotracheal reconstruction. Arch Otolaryngol Head

Neck Surg. 129:201–206. 2003. View Article : Google Scholar : PubMed/NCBI

|

|

27

|

Aslim EJ, Rasheed MZ, Lin F, Ong YS and

Tan BK: Use of the anterolateral thigh and vertical rectus

abdominis musculocutaneous flaps as utility flaps in reconstructing

large groin defects. Arch Plast Surg. 41:556–561. 2014. View Article : Google Scholar : PubMed/NCBI

|

|

28

|

Fang SL, Wang YY, Chen WL and Zhang DM:

Use of extended vertical lower trapezius island myocutaneous flaps

to cover exposed reconstructive plates. J Oral Maxillofac Surg.

72:209.e1–7. 2014. View Article : Google Scholar

|

|

29

|

Zhi L, Wenli W, Pengfei G, et al:

Laryngotracheal reconstruction with autogenous rib cartilage graft

for complex laryngotracheal stenosis and/or anterior neck defect.

Eur Arch Otorhinolaryngol. 271:317–322. 2014. View Article : Google Scholar

|

|

30

|

Chanowski EJ, Haxer MJ and Chepeha DB:

Microvascular cricoid cartilage reconstruction with the

thoracodorsal artery scapular tip autogenous transplant.

Laryngoscope. 122:282–285. 2012. View Article : Google Scholar

|

|

31

|

Zhao Y, Zhang W, Zhao J, Li Z and He S:

Reconstruction of soft tissue defects in oral and maxillofacial

regions after tumors surgery using cervical pedicle tissue flaps.

Zhogguo Xiu Fu Chong Jian Wai Ke Za Zhi. 19:780–783. 2005.

|