|

1

|

Vacanti CA and Upton J: Tissue-engineered

morphogenesis of cartilage and bone by means of cell

transplantation using synthetic biodegradable polymer matrices.

Clin Plast Surg. 21:445–62. 1994.PubMed/NCBI

|

|

2

|

Liao J, Shi K, Ding Q, Qu Y, Luo F and

Qian Z: Recent developments in scaffold-guided cartilage tissue

regeneration. J Biomed Nanotechnol. 10:3085–3104. 2014. View Article : Google Scholar : PubMed/NCBI

|

|

3

|

Feng L, Wu HEL, Wang D, Feng F, Dong Y,

Liu H and Wang L: Effects of vascular endothelial growth factor 165

on bone tissue engineering. PLoS One. 8:e829452013. View Article : Google Scholar : PubMed/NCBI

|

|

4

|

Zou D, Zhang Z, Ye D, Tang A, Deng L, Han

W, Zhao J, Wang S, Zhang W, Zhu C, et al: Repair of critical-sized

rat calvarial defects using genetically engineered bone

marrow-derived mesenchymal stem cells overexpressing

hypoxia-inducible factor-1α. Stem Cells. 29:1380–1390.

2011.PubMed/NCBI

|

|

5

|

Sun S, Ren Q, Wang D, Zhang L, Wu S and

Sun XT: Repairing cartilage defects using chondrocyte and

osteoblast composites developed using a bioreactor. Chin Med J

(Engl). 124:758–763. 2011.PubMed/NCBI

|

|

6

|

Fridenshtein AI: Stromal bone marrow cells

and the hematopoietic microenvironment. Arkh Patol. 44:3–11.

1982.(In Russian). PubMed/NCBI

|

|

7

|

Xue K, Qi L, Zhou G and Liu K: A two-step

method of constructing mature cartilage using bone marrow-derived

mesenchymal stem cells. Cells Tissues Organs. 197:484–495. 2013.

View Article : Google Scholar : PubMed/NCBI

|

|

8

|

Intini G: The use of platelet-rich plasma

in bone reconstruction therapy. Biomaterials. 30:4956–4966. 2009.

View Article : Google Scholar : PubMed/NCBI

|

|

9

|

Fréchette JP, Martineau I and Gagnon G:

Platelet-rich plasmas: Growth factor content and roles in wound

healing. J Dent Res. 84:434–439. 2005. View Article : Google Scholar : PubMed/NCBI

|

|

10

|

Lacoste E, Martineau I and Gagnon G:

Platelet concentrates: Effects of calcium and thrombin on

endothelial cell proliferation and growth factor release. J

Periodontol. 74:1498–1507. 2003. View Article : Google Scholar : PubMed/NCBI

|

|

11

|

Hoffman R, Benz EJJ, Shattil SJ, Furie B,

Cohen HJ, Silberstein LE LE and McGlave P: Hematology: Basic

principles and practice. Churchill Livingstone (Philadelphia).

2000.

|

|

12

|

Thiede MA, Smock SL, Petersen DN, Grasser

WA, Thompson DD and Nishimoto SK: Presence of messenger ribonucleic

acid encoding osteocalcin, a marker of bone turnover, in bone

marrow megakaryocytes and peripheral blood platelets.

Endocrinology. 135:929–937. 1994. View Article : Google Scholar : PubMed/NCBI

|

|

13

|

Landesberg R, Moses M and Karpatkin M:

Risks of using platelet rich plasma gel. J Oral Maxillofac Surg.

56:1116–1117. 1998. View Article : Google Scholar : PubMed/NCBI

|

|

14

|

Xie L, Yu H, Deng Y, Yang W, Liao L and

Long Q: Preparation, characterization and in vitro dissolution

behavior of porous biphasic α/β-tricalcium phosphate bioceramics.

Mater Sci Eng C Mater Biol Appl. 59:1007–1015. 2016. View Article : Google Scholar : PubMed/NCBI

|

|

15

|

El-Fiqi A, Kim JH and Kim HW:

Osteoinductive fibrous scaffolds of biopolymer/mesoporous bioactive

glass nanocarriers with excellent bioactivity and long-term

delivery of osteogenic drug. ACS Appl Mater Interfaces.

7:1140–1152. 2015. View Article : Google Scholar : PubMed/NCBI

|

|

16

|

Cheng L, Ye F, Yang R, Lu X, Shi Y, Li L,

Fan H and Bu H: Osteoinduction of hydroxyapatite/beta-tricalcium

phosphate bioceramics in mice with a fractured fibula. Acta

Biomater. 6:1569–1574. 2010. View Article : Google Scholar : PubMed/NCBI

|

|

17

|

Marx RE, Carlson ER, Eichstaedt RM,

Schimmele SR, Strauss JE and Georgeff KR: Platelet-rich plasma:

Growth factor enhancement for bone grafts. Oral Surg Oral Med Oral

Pathol Oral Radiol Endod. 85:638–646. 1998. View Article : Google Scholar : PubMed/NCBI

|

|

18

|

Dwyer SD and Meyers KM: Anesthetics and

anticoagulants used in the preparation of rat platelet-rich-plasma

alter rat platelet aggregation. Thromb Res. 42:139–151. 1986.

View Article : Google Scholar : PubMed/NCBI

|

|

19

|

Kasten P, Vogel J, Geiger F, Niemeyer P,

Luginbühl R and Szalay K: The effect of platelet-rich plasma on

healing in critical-size long-bone defects. Biomaterials.

29:3983–3992. 2008. View Article : Google Scholar : PubMed/NCBI

|

|

20

|

Livak KJ and Schmittgen TD: Analysis of

relative gene expression data using real-time quantitative PCR and

the 2−ΔΔCt method. Methods. 25:402–408. 2001. View Article : Google Scholar : PubMed/NCBI

|

|

21

|

Wiltfang J, Kloss FR, Kessler P, Nkenke E,

Schultze-Mosgau S, Zimmermann R and Schlegel KA: Effects of

platelet-rich plasma on bone healing in combination with autogenous

bone and bone substitutes in critical-size defects. An animal

experiment. Clin Oral Implants Res. 15:187–193. 2004. View Article : Google Scholar : PubMed/NCBI

|

|

22

|

Dugrillon A and Klüter H: Topical

application of platelets for improved wound healing. Blood Ther

Med. 3:21–26. 2002.

|

|

23

|

Fennis JP, Stoelinga PJ and Jansen JA:

Mandibular reconstruction: A histological and histomorphometric

study on the use of autogenous scaffolds, particulate

cortico-cancellous bone grafts and platelet rich plasma in goats.

Int J Oral Maxillofac Surg. 33:48–55. 2004. View Article : Google Scholar : PubMed/NCBI

|

|

24

|

Gandhi A, Dumas C, O'Connor JP, Parsons JR

and Lin SS: The effects of local platelet rich plasma delivery on

diabetic fracture healing. Bone. 38:540–546. 2006. View Article : Google Scholar : PubMed/NCBI

|

|

25

|

Kawase T, Okuda K, Wolff LF and Yoshie H:

Platelet-rich plasma-derived fibrin clot formation stimulates

collagen synthesis in periodontal ligament and osteoblastic cells

in vitro. J Periodontol. 74:858–864. 2003. View Article : Google Scholar : PubMed/NCBI

|

|

26

|

Yamada Y, Ueda M, Naiki T, Takahashi M,

Hata K and Nagasaka T: Autogenous injectable bone for regeneration

with mesenchymal stem cells and plateletrich plasma:

Tissue-engineered bone regeneration. Tissue Eng. 10:955–964. 2004.

View Article : Google Scholar : PubMed/NCBI

|

|

27

|

Marx RE: Platelet-rich plasma: Evidence to

support its use. J Oral Maxillofac Surg. 62:489–496. 2004.

View Article : Google Scholar : PubMed/NCBI

|

|

28

|

Freymiller EG and Aghaloo TL:

Platelet-rich plasma: Ready or not? J Oral Maxillofac Surg.

62:484–488. 2004. View Article : Google Scholar : PubMed/NCBI

|

|

29

|

Ouyang XY and Qiao J: Effect of

platelet-rich plasma in the treatment of periodontal intrabony

defects in humans. Chin Med J (Engl). 119:1511–1521.

2006.PubMed/NCBI

|

|

30

|

Man D, Plosker H and Winland-Brown JE: The

use of autologous platelet-rich plasma (platelet gel) and

autologous platelet-poor plasma (fibrin glue) in cosmetic surgery.

Plast Reconstr Surg. 107:229–237; discussion 238–239. 2001.

View Article : Google Scholar : PubMed/NCBI

|

|

31

|

Mazor Z, Peleg M, Garg AK and Luboshitz J:

Platelet-rich plasma for bone graft enhancement in sinus floor

augmentation with simultaneous implant placement: Patient series

study. Implant Dent. 13:65–72. 2004. View Article : Google Scholar : PubMed/NCBI

|

|

32

|

Kassolis JD, Rosen PS and Reynolds MA:

Alveolar ridge and sinus augmentation utilizing platelet-rich

plasma in combination with freeze-dried bone allograft: Case

series. J Periodontol. 71:1654–1661. 2000. View Article : Google Scholar : PubMed/NCBI

|

|

33

|

Choi BH, Zhu SJ, Kim BY, Huh JY, Lee SH

and Jung JH: Effect of platelet-rich plasma (PRP) concentration on

the viability and proliferation of alveolar bone cells: An in vitro

study. Int J Oral Maxillofac Surg. 34:420–424. 2005. View Article : Google Scholar : PubMed/NCBI

|

|

34

|

Graziani F, Ivanovski S, Cei S, Ducci F,

Tonetti M and Gabriele M: The in vitro effect of different PRP

concentrations on osteoblasts and fibroblasts. Clin Oral Implants

Res. 17:212–219. 2006. View Article : Google Scholar : PubMed/NCBI

|

|

35

|

Fennis JP, Stoelinga PJ and Jansen JA:

Mandibular reconstruction: A clinical and radiographic animal study

on the use of autogenous scaffolds and platelet-rich plasma. Int J

Oral Maxillofac Surg. 31:281–286. 2002. View Article : Google Scholar : PubMed/NCBI

|

|

36

|

Intini G, Andreana S, Intini FE, Buhite RJ

and Bobek LA: Calcium sulfate and platelet-rich plasma make a novel

osteoinductive biomaterial for bone regeneration. J Transl Med.

5:132007. View Article : Google Scholar : PubMed/NCBI

|

|

37

|

Cenni E, Perut F, Ciapetti G, Savarino L,

Dallari D, Cenacchi A, Stagni C, Giunti A, Fornasari PM and Baldini

N: In vitro evaluation of freeze-dried bone allografts combined

with platelet rich plasma and human bone marrow stromal cells for

tissue engineering. J Mater Sci Mater Med. 20:45–50. 2009.

View Article : Google Scholar : PubMed/NCBI

|

|

38

|

Lieberman JR, Daluiski A and Einhorn TA:

The role of growth factors in the repair of bone. Biology

andclinical applications. J BoneJoint Surg Am. 84:1032–1044.

2002.

|

|

39

|

Froum SJ, Wallace SS, Tarnow DP and Cho

SC: Effect of platelet-rich plasma on bone growth and

osseointegration in human maxillary sinus grafts: Three bilateral

case reports. Int J Periodontics Restorative Dent. 22:45–53.

2002.PubMed/NCBI

|

|

40

|

Bruder SP, Kraus KH, Goldberg VM and

Kadiyala S: The effect of implants loaded with autologous

mesenchymal stem cells on the healing of canine segmental bone

defects. J Bone Joint Surg Am. 80:985–996. 1998.PubMed/NCBI

|

|

41

|

Roldán JC, Jepsen S, Miller J, Freitag S,

Rueger DC, Açil Y and Terheyden H: Bone formation in the presence

of platelet-rich plasma vs. bone morphogenetic protein-7. Bone.

34:80–90. 2004. View Article : Google Scholar : PubMed/NCBI

|

|

42

|

Damsky CH: Extracellular matrix-integrin

interactions in osteoblast function and tissue remodeling. Bone.

25:95–96. 1999. View Article : Google Scholar : PubMed/NCBI

|

|

43

|

Garcia AJ and Reyes CD: Bio-adhesive

surfaces to promote osteoblast differentiation and bone formation.

J Dent Res. 84:407–413. 2005. View Article : Google Scholar : PubMed/NCBI

|

|

44

|

Weiss RE and Reddi AH: Role of fibronectin

in collagenous matrix-induced mesenchymal cell proliferation and

differentiation in vivo. Exp Cell Res. 133:247–254. 1981.

View Article : Google Scholar : PubMed/NCBI

|

|

45

|

Moursi AM, Damsky CH, Lull J, Zimmerman D,

Doty SB, Aota S and Globus RK: Fibronectin regulates calvarial

osteoblast differentiation. J Cell Sci. 109:1369–1380.

1996.PubMed/NCBI

|

|

46

|

Zimmerman D, Jin F, Leboy P, Hardy S and

Damsky C: Impaired bone formation in transgenic mice resulting from

altered integrin function in osteoblasts. Dev Biol. 220:2–15. 2000.

View Article : Google Scholar : PubMed/NCBI

|

|

47

|

Weibrich G, Gnoth SH, Otto M, Reichert TE

and Wagner W: Growth stimulation of human osteoblast-like cells by

thrombocyte concentrates in vitro. Mund Kiefer Gesichtschir.

6:168–174. 2002.(In German). View Article : Google Scholar : PubMed/NCBI

|

|

48

|

Intini G, Andreana S, Margarone JE III,

Bush PJ and Dziak R: Engineering a bioactive matrix by

modifications of calcium sulfate. Tissue Eng. 8:997–1008. 2002.

View Article : Google Scholar : PubMed/NCBI

|

|

49

|

Bateman J, Intini G, Margarone J III,

Goodloe S III, Bush P, Lynch SE and Dziak R: Platelet-derived

growth factor enhancement of two alloplastic bone matrices. J

Periodontol. 76:1833–1841. 2005. View Article : Google Scholar : PubMed/NCBI

|

|

50

|

Wang D, Jiang H, Wang S, Li H, Zhang H,

Zhao L, Peng T, Cao Z and Sun S: Construction of tissue-engineered

bone using a bioreactor and platelet-rich plasma. Exp Ther Med.

8:413–418. 2014. View Article : Google Scholar : PubMed/NCBI

|

|

51

|

Klein-Nulend J, van der Plas A, Semeins

CM, Ajubi NE, Frangos JA, Nijweide PJ and Burger EH: Sensitivity of

osteocytes to biomechanical stress in vitro. FASEB J. 9:441–445.

1995.PubMed/NCBI

|

|

52

|

Owan I, Burr DB, Turner CH, Qiu J, Tu Y,

Onyia JE and Duncan RL: Mechanotransduction in bone: Osteoblasts

are more responsive to fluid forces than mechanicalstrain. Am J

Physiol. 273:C8l0–C815. 1997.

|

|

53

|

Bakker AD, Soejima K, Klein-Nulend J and

Burger EH: The production of nitric oxide and prostaglandin E(2) by

primary bone cells is shear stress dependent. J Biomech.

34:671–677. 2001. View Article : Google Scholar : PubMed/NCBI

|

|

54

|

Wang Y, Kim UJ, Blasioli DJ, Kim HJ and

Kaplan DL: In vitro cartilage tissue engineering with 3D porous

aqueous-derived silk scaffolds and mesenchymal stem cells.

Biomaterials. 26:7082–7094. 2005. View Article : Google Scholar : PubMed/NCBI

|

|

55

|

Wang W, Itaka K, Ohba S, Nishiyama N,

Chung UI, Yamasaki Y and Kataoka K: 3D spheroid culture system on

micropatterned substrates for improved differentiation efficiency

of multipotent mesenchymal stem cells. Biomaterials. 30:2705–2715.

2009. View Article : Google Scholar : PubMed/NCBI

|

|

56

|

Song K, Wang H, Zhang B, Lim M, Liu Y and

Liu T: Numerical simulation of fluid field and in vitro

three-dimensional fabrication of tissue-engineered bones in a

rotating bioreactor and in vivo implantation for repairing

segmental bone defects. Cell Stress Chaperones. 18:193–201. 2013.

View Article : Google Scholar : PubMed/NCBI

|

|

57

|

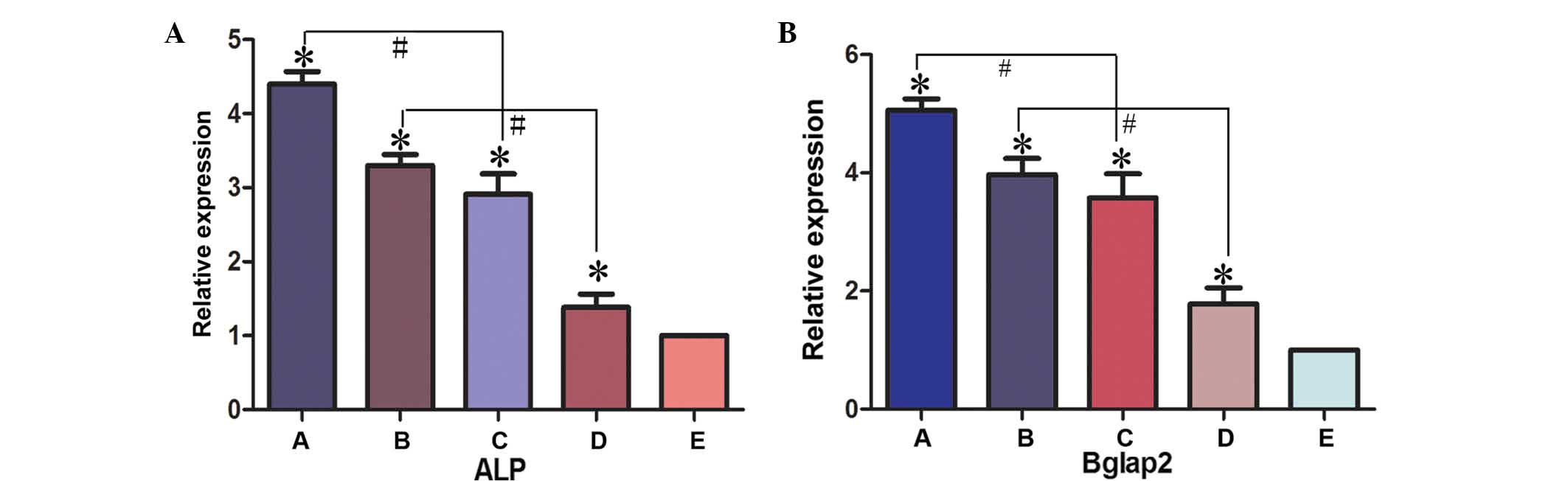

Song Z, Wu C, Sun S, Li H, Wang D, Gong J

and Yan Z: Quantitative analysis of factors influencing

tissue-engineered bone formation by detecting the expression levels

of alkaline phosphatase and bone γ-carboxyglutamate protein 2. Exp

Ther Med. 9:1097–1102. 2015.PubMed/NCBI

|