Introduction

Minimally invasive plate osteosynthesis (MIPO) has

been broadly applied clinically following the improved

understanding of the blood supply and local biological environment

of fractures. With the development of clinical technology in China,

MIPO technology has gradually matured. It is a new development for

internal fixation using biological osteosynthesis (BO), in which

direct exposure of the fracture site is not necessary. MIPO

involves indirect reduction and fixation, which minimizes regional

damage to soft tissues and the blood supply of the periosteum, as

well as the incidence of nonunion and infection, and so is

beneficial with regard to functional rehabilitation and clinical

therapeutic effects (1).

The principle of MIPO is biological fixation at the

near- and far-ends of the fracture site (2,3). It has

a number of advantages compared with traditional open reduction and

internal fixation, and intramedullary nail fixation. Firstly, it

has a relatively short surgery time (4,5).

Secondly, it effectively avoids complications (6,7).

Thirdly, it avoids nerve damage and reduces scarring. Fourthly, it

exhibits strong healing effects (8,9).

Fifthly, it effectively reduces damage of the soft tissues and

protects the blood supply of the fracture site (10). Finally, it is able to endure large

deformation forces (11).

However, there are many contentious aspects of MIPO

application in the treatment of tibial fractures, particularly the

length of the limited contact-dynamic compression plate (LC-DCP),

the number of screws and the fixing positions, and there are no

clear conclusions with regard to the optimum parameters.

Therefore, in the present study 60 tibias from

cadavers were used for the examination of tibial fractures by

biomechanical and finite element analysis, in order to provide

evidence regarding the treatment of middle tibial fractures using

MIPO with BO.

Materials and methods

Materials

Biomechanical testing

Wet tibial samples (n=60) were collected from

cadavers from individuals with an age at mortality of 20–40 years

at the Department of Human Anatomy of Xiangya School of Medicine,

Central South University (Changsha, China). Ethical approval was

obtained from the institution. The tibias were inspected and X-ray

examination was performed, in order to exclude damage and bone

pathology, prior to storage at −20°C. The fixation materials,

namely 6-hole LC-DCPs (model 4.5; length, 105 mm, width, 8 mm;

thickness, 3.5 mm), 10-hole LC-DCPs (model 4.5; length, 178 mm;

width, 8 mm; thickness, 3.5 mm), 14-hole LC-DCPs (model 4.5;

length, 250 mm; width, 8 mm; thickness, 3.5 mm), cortical stainless

steel bone screws (Φ, 4.5 mm), and AO internal fixing equipment

were obtained from Bangli Trading Co. (Yangjiang, China).

3D finite element analysis

Five tibias 30–38 cm in length (mean, 34 cm) were

collected from the Department of Human Anatomy of Xiangya School of

Medicine, Central South University. The other materials used were

the same as those described above.

Analytical instrumentation

Biomechanical testing

The MTS 858 Mini Bionix universal biomechanics

testing system (MTS Systems Corporation, Eden Prairie, MN, USA) was

supported by the Department of Human Anatomy of Southern Medical

University.

Three-dimensional (3D) finite element

analysis

Analysis was conducted using spiral computed

tomography (CT), a computer, AutoCAD software (Autodesk, Inc., San

Rafael, CA, USA) and finite element software Ansys 6.5.

Biomechanical testing methods

Middle and diagonal fracture models without defects

were established using the collected tibias. The tibias were

randomly grouped and analyzed by biomechanics and 3D finite element

methods. An analysis and comparison of LC-DCPs with different

lengths (6-, 10- and 14-hole) combined with 6 screws, 14-hole

LC-DCPs combined with different numbers of screws (6, 10 and 14),

and 14-hole LC-DCPs with 6 screws fixed at different positions was

conducted. The positions fixed were as follows (from top to

bottom): Group 1, holes 1, 2, 7, 8, 13 and 14; group 2, holes 1, 4,

7, 8, 11 and 14; group 3, holes 1, 3, 6, 9, 12 and 14; and group 4,

holes 1–3 and 12–14. Mechanical characteristics, including

compression, torsion and 3-point bending, respectively, were

evaluated. The load of vertical compression was 0–1,000 N, the

torsion angle was 0–3°, and the load of 3-point bending was 0–400

N. The strain values on torsion, and with 3-point bending and

compression were measured and analyzed.

3D reconstruction of tibial stem finite element

models. The tibias were scanned using spiral CT and continuous

cross-sectional images 1 mm in thickness were obtained. The images

were analyzed as lattice images and digitized. Using a graphic

boundary automatic recording program, created by the Laboratory of

Human Anatomy and Biomechanics of Southern Medical University

(China), the boundary conditions of the images were recorded as 2D

coordinates in all levels of the tibial images according to the

requirements for 3D reconstruction. With reference to the plane

distance and inter-lamellar space, the 2D coordinates were

converted into 3D coordinates following regulation to a suitable

spatial scale.

The mechanical values of the tibial materials were

searched and switched using the AutoCAD modeling software. The

middle tibial fracture model was established with internal fixation

using 3D Max.

Using the finite element software Ansys 6.5, the 3D

tibial spatial model was established according to modeling

principles on points, lines, regions and bodies from top to bottom.

CT scanning was conducted in cross-sectional directions in parallel

with the xy plane, with the longitudinal direction along the

z-axis.

In the digital tibia models, there were 265

reconstruction levels in total. The z-axis was established

according to the actual height. The corresponding junctions were

connected in each level and geometric models of the tibias were

formed. Different colors were used to distinguish different levels

and structures, and the element was then divided into different

gridding.

3D reconstruction of MIPO-treated

middle tibia fractures

Establishing middle tibial fractures with

internal fixation

Five tibias were used to create middle and diagonal

fracture models without defects. They were tilted 45° from the

tibial eminence backwards, with an average slope length of 35 mm. A

14-hole LC-DCP and 6 screws were used for fixation, with the

fracture line at the middle of the plate. From top to bottom, the

fixing positions were as follows: Tibia-1 model, 1st, 2nd, 3rd,

12th, 13th and 14th holes; tibia-2 model, 1st, 4th, 7th, 8th, 11th

and 14th holes; tibia-3 model, 1st, 3rd, 6th, 9th, 12th and 14th

holes; tibia-4 model, 1st, 2nd, 7th, 8th, 13th and 14th holes. In

the tibia-5 model, all 14 holes were fixed with screws.

3D reconstruction of tibial fractures with

internal fixation

The fixed tibias were scanned by spiral CT and

continuous cross-sectional images of 1 mm thickness were obtained.

The images were analyzed as lattice images, digitized and used to

establish digital tibia models with 265 reconstruction levels as

described above.

Loading the digital model of middle tibia

fracture internal fixation

The tibia-1 model with fixation positions at the

1st, 2nd, 3rd, 12th, 13th and 14th holes was loaded. i) Fixation of

the digital model was simulated. According to the anatomical

structure and biomechanical characteristics of the tibia, a 14-hole

plate and 6 screws were used for digital tibia model fixation. ii)

Axial compression of the digital model was detected. Following

fixation of the digital middle tibial fracture model with a 14-hole

plate and 6 screws, the LC-DCP was compressed with a load of

0–1,000 N vertically and evenly. Data were collected and the

vertical and lateral strain values were obtained. Data were

analyzed with the load of 1,000 N. iii) Torsion of the digital

model was detected. Following fixation of the digital middle tibial

fracture model with a 14-hole plate and 6 screws, torsional

stiffness of the left and right directions was detected using a

torsion rate of 2°/sec and angle of 3°. The torque was obtained

from the collecting system and analyzed statistically.

The tibia-2, −3, −4 and −5 models were each loaded

and analyzed according to the procedure described above.

Statistical analysis

All data were collected automatically and analyzed

using SPSS 12.0 software (SPSS, Inc., Chicago, IL, USA). Analysis

of variance was employed for pairwise comparisons, followed by

Tukey's post hoc testing. P<0.05 was considered to indicate a

statistically significant difference.

Results

Biomechanical effects of LC-DCP length

on middle tibial fractures

For vertical compression, the strain values for 6-,

10- and 14-hole LC-DCPs were 0.449±0.241, 0.093±0.003 and

0.139±0.005, respectively. The strain values for the 10- and

14-hole plates were significantly lower than those for the 6-hole

plate (P<0.01). The lateral strain values for 6-, 10- and

14-hole LC-DCPs were 0.120±0.000, 0.1275±0.010 and 0.237±0.000,

respectively. The lateral strain values for the 6- and 10-hole

LC-DCPs were significantly different from those for the 14-hole

LC-DCP (P<0.01); however, no significant difference was

identified between 6- and 10-hole LC-DCPs (P>0.05). The torques

of the 6-, 10- and 14-hole LC-DCPs were

5.066×10−3±2.715×10−3,

5.671×10−3±2.527×10−3 and

4.570×10−3±2.228×10−3 N·m, and the vertical

strain values of 3-point bending were 0.049±0.009, 0.124±0.017 and

0.062±0.009, respectively. Pairwise comparisons for LC-DCPs of

different lengths identified significant differences

(P<0.05).

Biomechanical effects of screw number

on middle tibial fractures

For vertical compression using 14-hole LC-DCPs, the

strain values for 6, 10 and 14 screws were 0.120±0.006, 0.111±0.012

and 0.116±0.008, respectively, with no significant difference

revealed by pairwise comparisons (P>0.05). The lateral strain

values for 6, 10 and 14 screws were 0.234±0.007, 0.234±0.000 and

0.179±0.002, respectively, without significant differences revealed

by pairwise comparisons (P>0.05). The torques for 6, 10 and 14

screws were 7.304×10−3±3.072×10−3,

6.069×10−3±3.086×10−3 and

7.1295×10−3±3.908×10−3 N·m, respectively,

without significant differences indicated by pairwise comparisons

(P>0.05). The vertical strain values of 3-point bending for 6,

10 and 14 screws were 0.149±0.098, 0.139±0.003 and 0.258±0.001,

respectively; the vertical strain values for 6 and 10 screws were

was significantly different from those for 14 screws (P<0.01),

while no significant difference was identified between 6 and 10

screws (P>0.05).

Biomechanical effects of fixing

positions on middle tibial fractures

For groups 1–4, the strain values of vertical

compression were 0.120±0.006, 0.033±0.003, 0.139±0.005 and

0.116±0.008, respectively, with significant differences between

group 2 and the other groups (P<0.01). The lateral strain values

in the four groups were 0.234±0.007, 0.237±0.0006, 0.187±0.002 and

0.217±0.002, respectively, with significant differences between

group 3 and the other groups (P<0.01). The torques were

7.304×10−3±3.072×10−3,

6.965×10−3±3.096×10−3,

4.570×10−3±2.228×10−3 and

2.086×10−3±0.998*10−3 N·m, respectively, with

significant differences identified between group 3 and the other

groups (P<0.01). The strain values of 3-point bending in the

four groups were 0.149±0.098, 0.184±0.002, 0.004±0.001 and

0.282±0.000, respectively. Values for groups 3 and 4 were indicated

to be significantly different compared with group 1 or 2 by

pairwise comparison (P<0.01). Group 4 was indicated to be

significantly different from the other groups by pairwise

comparisons (P<0.01). However, there was no significant

difference between groups 1 and 2 (P>0.05).

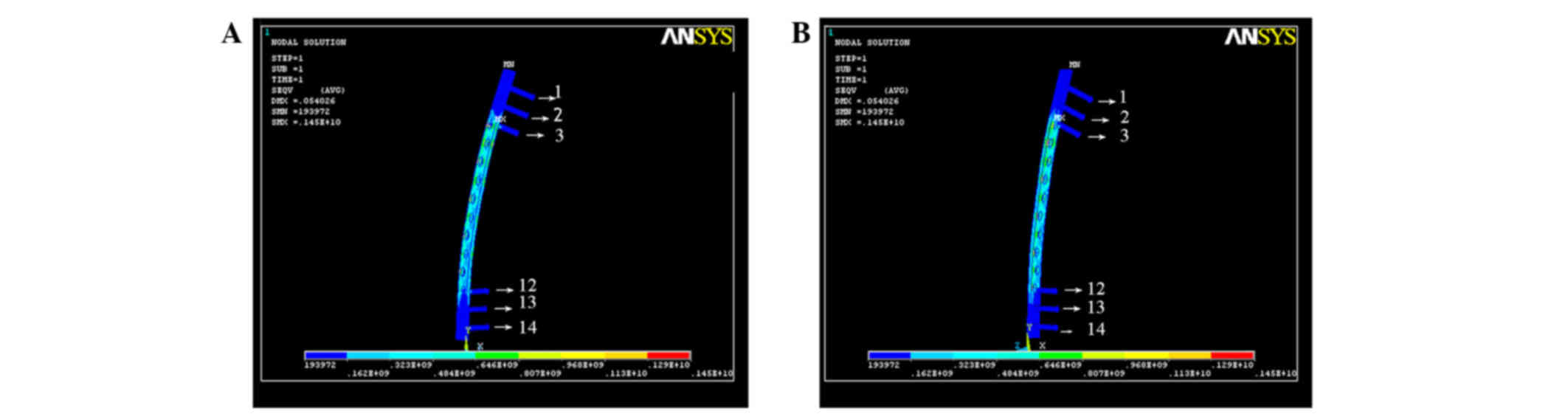

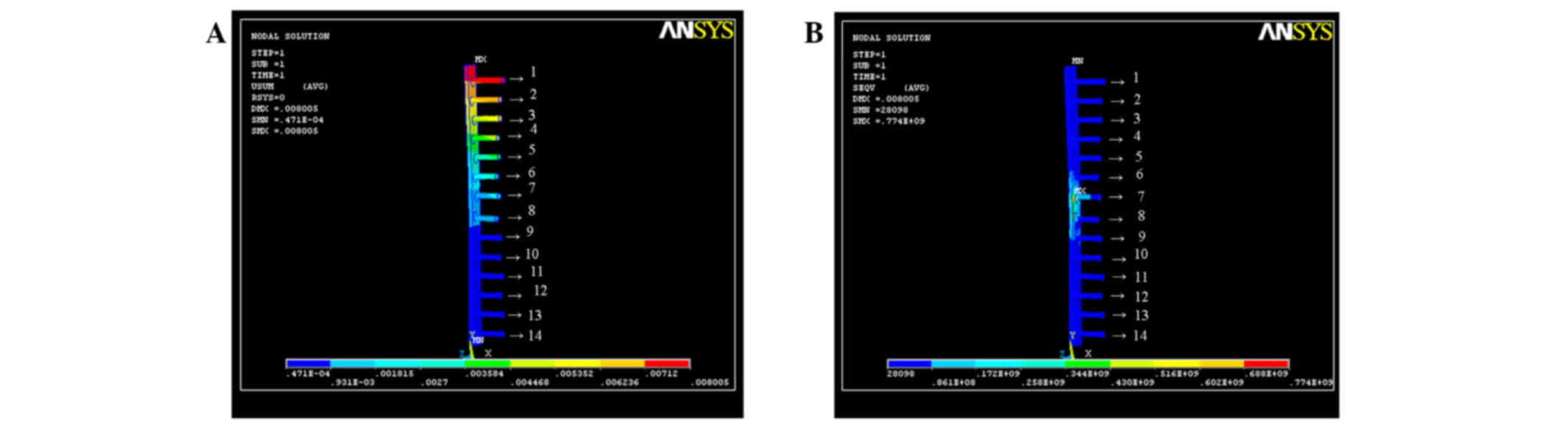

Stress sustained in the tibia-1

model

For axial compression, the compression and torsion

at the 3rd and 12th holes on the x- and y-axes were the greatest,

and accumulated on the fracture. There was no significant

difference in the stress on the z-axis among the various screw

positions. Thus, the stress on any individual screws was minimized.

The main strain was focused on the positions without fixation

(Fig. 1).

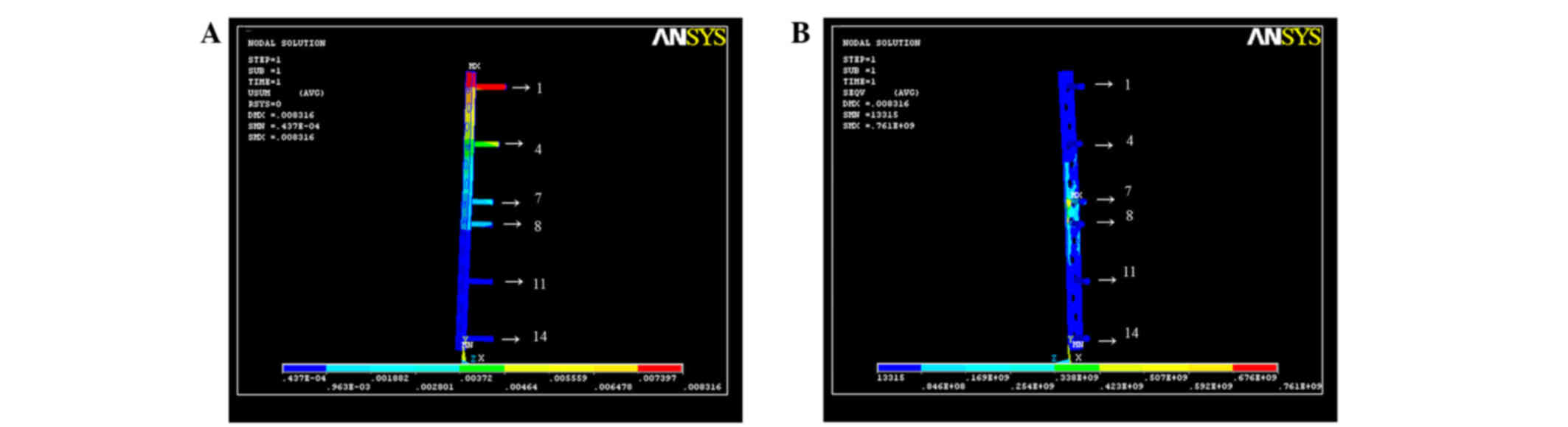

Stress sustained in the tibia-2

model

For axial compression, the stress on the 1st hole on

the x-, y- and z-axes was the greatest, followed by the 4th hole.

The stress decreased gradually from the top to the bottom of the

plate. With regard to torque, the stress on the 7th and 8th holes

on the x-, y- and z-axes was the greatest, and the stress tended to

decrease gradually from the middle of the fracture to the end. The

stress was mainly focused on the center of the plate (Fig. 2).

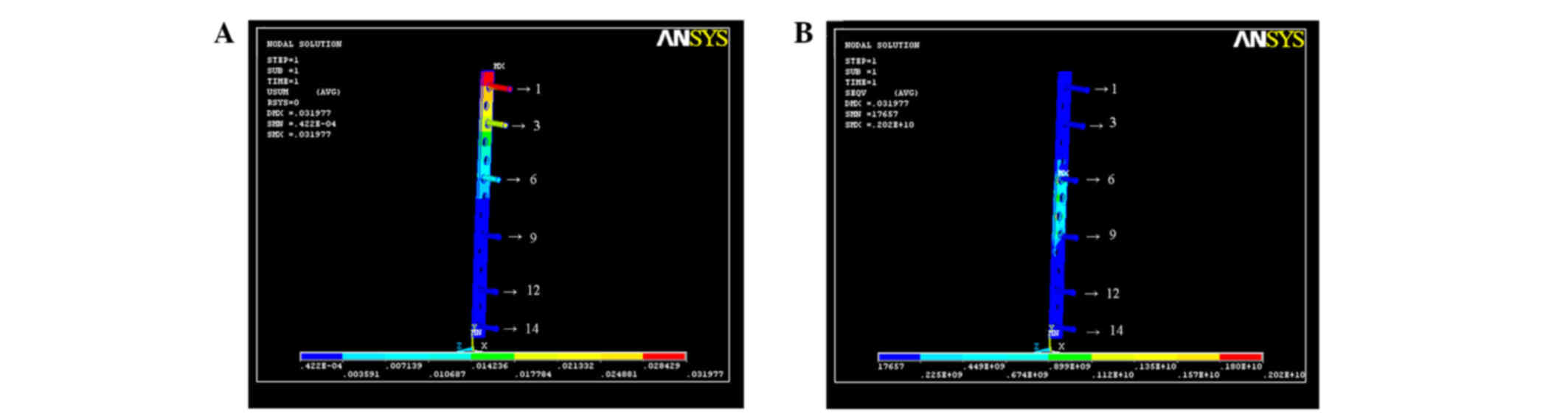

Stress sustained in the tibia-3

model

For axial compression, the stress on the 1st hole on

the x-, y- and z-axes was the greatest, followed by the 3rd hole.

The stress decreased gradually from the top to the bottom of the

plate. For torque, the stress on the 6th and 9th holes on the x-,

y- and z-axes was the greatest, with the greater strain on the

center without fixation (Fig.

3).

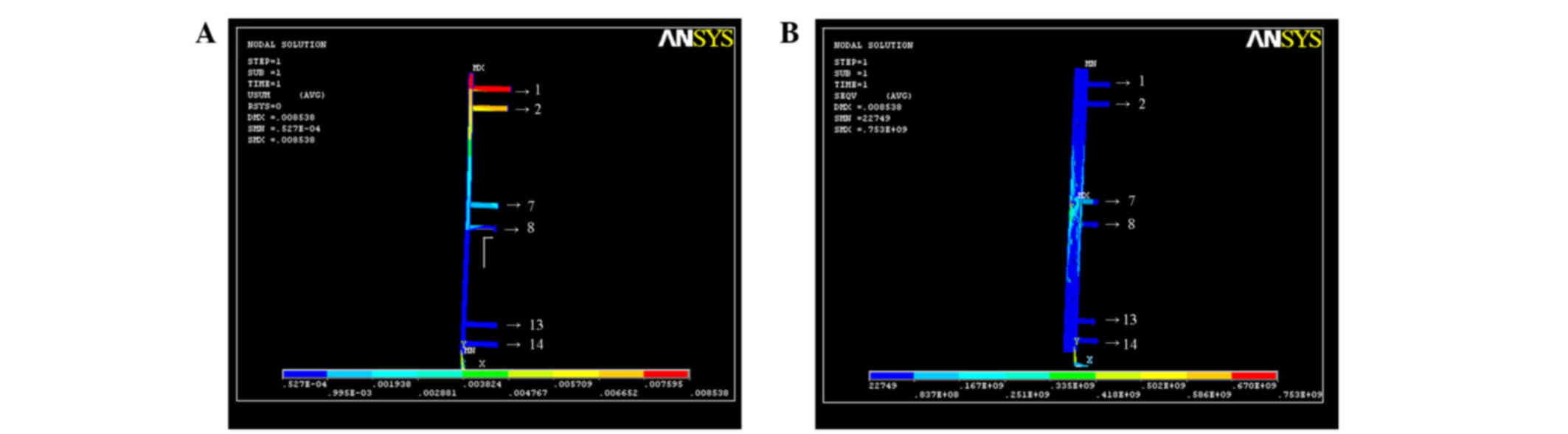

Stress sustained in the tibia-4

model

For axial compression, the stress on the 1st hole on

the x-, y- and z-axes was the greatest. The stress decreased

gradually from the top to the bottom of the plate. With regard to

torque, the stress on the 7th and 8th holes on the x-, y- and

z-axes was the greatest, but less than in the tibia-3 model, with a

balanced strain distribution (Fig.

4).

Stress sustained in the tibia-5

model

For axial compression, the stress on the 1st hole on

the x-, y and z-axes was the greatest, followed by the 2nd hole.

The stress decreased gradually from the top to the bottom of the

plate. For torque, the stress on the 7th and 8th holes on the x-,

y- and z-axes was the greatest. The strain was particularly focused

on the two screws in the center of the LC-DCP (Fig. 5).

Discussion

As increases in the energy or speed of damage have

occurred, for example, in traffic accidents, the incidence of

tibial fractures has notably increased; such fractures account for

10% of long bone fractures (12).

Tibial fractures are predominantly middle fractures (13–17).

Therefore, further investigations focused on middle tibial

fractures are warranted.

On the basis of the BO concept, investigations on

MIPO in the treatment of fractures have been performed and

therapeutic effects obtained. MIPO is a novel development for the

treatment of fractures, and has been conducted as follows: For

indirect reduction, a small incision was opened distally to the

fracture; a subcutaneous tunnel was established and the LC-DCP was

embedded with fixation (18,19). For broken ends of fractured bone

without exposure, the integrity of the soft tissue between the

broken ends of fracture bone was maintained thoroughly (20). The integration of soft tissue around

the fractured bone provides the healing with beneficial biotic

environment as an important co-factor for correcting and sustaining

the bone after fixation.

Numerous models have been used in orthopedic

biomechanics research, such as animal models, physical models,

cadaveric models and finite element analysis. However, there are

certain limitations for each kind of model (21–23).

Cadaveric models are advantageous in geometrical structure and

material characteristics, and are the most appropriate for

providing values on biomechanical properties, which are used in

surgery for evaluation; however, they lack certain biological

features, have higher experimental expense, may be difficult to

acquire and have low potential for repeated use, limiting their

application (24,25). Finite element analysis is a

repeatable and sustainable method of research, and is a relatively

novel method for studying orthopedic biomechanics. Finite element

analysis is able to reflect interactions regionally and internally,

with changes in subjective and material structures, in order to

provide a biomechanical evaluation and prognosis for different

kinds of disease and injury, fixture equipment and surgical methods

(26,27). Finite element analysis in the

biomechanical simulation of internal fracture fixation has been

widely used, in China and elsewhere. However, due to the complexity

of finite element analysis, particularly establishment of the

model, its application in orthopedic biomechanics is limited, with

confirmation between the results and the practical experiments

being necessary. Therefore, in the present study, biomechanics

combined with finite element analysis was used to mutually confirm

the results of MIPO in the treatment of tibial fractures, in order

to provide theoretical evidence for clinical treatment.

He et al (28)

studied the effects of screw number on the load of internally fixed

structures using a torsion test. Combining their observations with

those reported in the literature, they summarized that omitting 40%

of the screws of an LC-DCP had no significant effect on the

stiffness for one plate with internal fixation. Therefore, in the

present study, two positions at the ends of the LC-DCP were fixed,

in order to exclude the effect of length on internal stability.

In the analysis of screw breakage in steel plates

used to treat middle long bone fractures, Liu et al

(29) found that in addition to

anatomical restoration, stability was also critical in internal

fixation. It was considered that the stability of fractures was

associated with the length of the fixing material, which demanded

that the plate length was 5 times as long as the longest fracture

line and ≥4 cortices were fixed at one side of an ulnoradial

fracture, 6–8 cortices of a humeral fracture, and 8–10 cortices of

the tibial or femoral fracture. However, according to the study by

Laurence et al (19), 4

screws were sufficient for fixation of one plate with mechanical

stability. Rozbruch et al (20) recommended that the screws should be

fixed at the most appropriate position, and for one fracture

fragment, there should be 2 or 3 screws for fixation, where the

most appropriate position for fixation should enhance the

connection between the steel plate and the fracture site, to

provide a stable leverage effect. Thus, a 3-point and 6-screw

method, which involved fixing the ends of the steel plate with 2

screws and fixing the ends close to the fracture line with 1 screw,

could form lever balance fixation with 3 points. On the basis of

the analysis described above, a 14-hole LC-DCP was used for the

tibial fracture test in the present study. The long plate should be

able to correct rotation and angling deformities, and sustain the

tibial axis and length. By lengthening the plate, for example, by

prolonging the lever arm for increasing the strain distribution

instead of focusing on one position, the plate, screws, bone and

soft tissues could be combined into a mechanical structure with

greater stability.

The results of the present study showed that with

the same number of screws, increasing the plate length increased

the fixing stability. By analysis of the biomechanical stability,

it was identified that a long plate was better than a short one.

With the same plate length (14-hole LC-DCP), the stability against

bending was decreased as the screw number was increased to 14, but

it was unclear whether an excessive number of screws leads to a

reduction of overall stability. Field et al (30) found there was no significant

difference in the stability of the internal fixation structure

between a steel plate in which some holes had no screws and the

same steel plate in which all holes had screws. It has been

suggested that increasing the span between the 2 screws at the ends

of the plate contributed to higher stability than a plate with

shorter span and more screws (31).

A longer plate could eliminate the use of 40% of the screws, and

increased surface tension and bone healing promotion effects were

obtained without effect on fixation. Decreasing the number of

screws may reduce skeletal trauma. More importantly, increasing the

span between screws may neutralize the external instant stress on

the screws when they are extracted.

Ellis et al (27) found that for plates of the same

length, fixation with screws at the ends of the plate increased the

stiffness against torsion. Another previous study (32) showed that with the same plate length

and number of screws, the stability against bending was improved by

distributing the screws evenly, while it was reduced by

distributing the screws at the ends of the plate. In the present

study, a plate with the same material, length, width and number of

screws was used, and the fixing position was changed. The vertical

compression test showed that with the same plate length and screw

number, the stability against compression with fixation close to

the fracture line was optimum. The torsion test showed that with

the same plate length and screw number, the stability against

torsion with fixation close to the fracture line or with even

distribution was better that than when fixing screws were

distributed at the ends of the plate.

Finite element analysis is able to break up the

whole fracture and fixation system into parts, and combine the

parts into a whole. The basic principles are as follows: Breaking

up the bone sample continuous elastomer into finite elements;

connecting the elements with junctions and evaluating the

combination instead of the bone sample primary elastomer. The

unknown values of a point in the element are analyzed through

differences in the functional relationship selected by the number

of junctions. In the analysis of the element, for the simple

element shape, complex formulas between the junctions are

established. The formulas are combined into a general formula and

the boundary conditions added. The characteristics of each element

and the whole can then be investigated. The more compact the

element distribution, the more accurate the calculation, and the

higher the quantity of work (21–23).

In the present study, the tibias were scanned by CT

and data were collected. Therefore, the models used actual geometry

to create ideal models. The 3D tibial fracture model was

reconstructed based on the direct measurements made from images of

the real sample obtained by spiral CT scanning. The reconstructed

models were vivid and objective, were able to reflect the real

geometry and biomechanical characteristics of the tibia, and

enabled the application of finite element analysis for

biomechanical study of the tibia. In this study, we compensated for

the deficiency of the finite element analysis on lower body

mechanics, and supplied new basic models and ideas to analyze the

mechanical characteristics of tibias.

A complete 3D tibial model was constructed, which

was collected from scanning images 1 mm in thickness. There were a

total of 265 levels in the reconstruction of the tibial fracture

model with internal fixation. The z-axis was constructed according

to the real height of the tibia. The junctions were connected in

each level and the different levels and structures were

distinguished with different colors.

This study was successful in 3D tibial fracture

model reconstruction and finite element analysis using Ansys

software. However, due to the limited time available for the study,

only 3D finite element models of tibias were constructed. In future

studies, 3D finite element models of the knee and ankle are

required for further investigations.

With regard to the finite element analysis, the

results showed that when the mathematical model of tibia was fixed

with a load of 1,000 N, there was significant difference in the

strain distribution only between the tibia-5 model (14 screws) and

tibia-1 model (6 screws fixed at the 1st, 2nd, 3rd, 12nd, 13th and

14th holes), while there were no significant differences among the

tibia-2 (screws at the 1st, 4th, 7th, 8th, 11th and 14th holes),

tibia-3 (screws at the 1st, 3rd, 6th, 9th, 12th and 14th holes) and

tibia-4 (screws at the 1st, 2nd, 7th, 8th, 13th and 14th holes).

When testing the stability against torsion, the strain on the

middle of the plate with 14 screws was higher compared with that

for 6 screws in tibia-2, −3 and −4 models.

When different fixing positions were used, it was

found that the strain of a 1,000-N axial load was focused on the

screws at the center of the plate, with a gradually decreasing

trend from top to bottom. These results indicated that with the

axial load, the upper screws were easily compressed and broken,

which was consistent with the mechanism of clinical LC-DCP plating

and screw breakage.

Additionally, it was also found that the strain was

the largest when the screws were fixed distal to the fracture

(tibia-1 model), which was significantly different compared with

the other 6-screw models (tibia-2, tibia-3 and tibia-4 models).

Therefore, it is not recommended that the screws are distributed at

the ends of the plate in the MIPO treatment of tibial

fractures.

For the middle fracture, when 6 screws were used for

fixation in the tibia-2, tibia-3 and tibia-4 models, the results

showed that the tibia-4 model exhibited the greatest stability

against torsion.

The biomechanical results of the present study

demonstrated that using a long LC-DPC but fewer screws for fixation

of middle tibial fractures had superior biomechanical effects

In conclusion, the use of a 14-hole LC-DCP and with

6 screws for the treatment of middle tibial fractures via MIPO is

the most appropriate. The smallest strain per screw is obtained

when 2 screws are fixed close to the fracture line (one above and

one below the fracture), and a further 4 screws are fixed at the

ends of the plate (in the 1st, 2nd, 7th, 8th, 13th and 14th

holes).

References

|

1

|

Farouk O, Krettek C, Miclau T,

Schandelmaier P, Guy P and Tscherne H: Minimally invasive plate

osteosynthesis: does percutaneous plating disrupt femoral blood

supply less than the traditional technique? J Orthop Trauma.

13:401–406. 1999. View Article : Google Scholar : PubMed/NCBI

|

|

2

|

Huang CJ, Zhang YP and Meng SM: Treatment

of humerus fractures by closing reduction with locking compression

plate through a proximal modified incision. Gu Ke. 5:111–112.

2014.(In Chinese).

|

|

3

|

Tong W, Yang J, Zhu YJ, Xu PL and Shao JK:

Minimally invasive percutaneous locking plate osteosynthesis for

treatment of osteoporotic humeral fractures in the elderly. Lin

Chuang Gu Ke Za Zhi. 5:718–720. 2014.(In Chinese).

|

|

4

|

Feng T: Fixation with intramedullary nail

and plate in the treatment of adult humeral shaft

fracture:comparison of radial nerve injury and non-union rate.

Zhongguo Zu Zhi Gong Cheng Yan Jiu Yu Lin Chuang Kang Fu.

29:2086–2090. 2015.(In Chinese).

|

|

5

|

Zhang ZZ, Xiong Y and Zhao F: The clinical

research of new fixation system for treatment of multi-segmental

fractures of humerus. Zhongguo Yi Xue Chuang Xin. 27:135–138.

2014.(In Chinese).

|

|

6

|

Shen J, Yuang TZ, Chen DD, Chang LP and Ma

PG: Clinical efficacy of locking compression plate (LCP) with

minimally invasive approach in the treatment of humerus thrypsis.

Zhongguo Dang Dai Yi Yao. 21:182–183. 2014.(In Chinese).

|

|

7

|

Ma XC, Fu DZ, Lin S, Han YJ, Chen XL, Chen

SF, Pu FF and Shao ZW: Clinical research of the minimally invasive

percutaneous plate osteosynthesis for proximal humeral fractures.

Shiyong Gu Ke Za Zhi. 20:102–105. 2014.(In Chinese).

|

|

8

|

Niu XQ, Liu FY and Guo YC: Comparison of

three different devices for humeral shaft fracture. Zhonghua Shi

Yong Zhen Duan Yu Zhi Liao Zazhi. 28:869–870. 2014.(In

Chinese).

|

|

9

|

Huang Y, Xiang M, Hu XC, Chen H, Tang HZ

and Yang GY: Application of minimally invasive locking compression

plate in treatment of hypertrophic nonunion of humeral shaft

fracture for conservative treatment failure. Sichuan Yi Xue.

6:838–841. 2015.(In Chinese).

|

|

10

|

Morgan SJ and Jeray KJ: Minimally invasive

plate osteosynthesis in fractures of the tibia. Oper Tech Orthop.

11:195–204. 2001. View Article : Google Scholar

|

|

11

|

Gösling T, Schandelmaier P, Marti A,

Hufner T, Partenheimer A and Krettek C: Less invasive stabilization

of complex tibial plateau fractures: a biomechanical evaluation of

a unilateral locked screw plate and double plating. J Orthop

Trauma. 18:546–551. 2004. View Article : Google Scholar : PubMed/NCBI

|

|

12

|

Nobert N, Moremi N, Seni J, Ramesh DM,

Ngayomela IH, Mshana SE and Gilyoma JM: The effect of early versus

delayed surgical debridement on the outcome of open long bone

fractures at Bugando Medical Centre, Mwanza, Tanzania. J Trauma

Manag Outcomes. 10:62016. View Article : Google Scholar : PubMed/NCBI

|

|

13

|

Hu XJ, Lin BW, Xiao DM, Li WF and Zhang

XM: Treatment of tibia shaft fracture by minimally invasive plate

osteosynthesis. Shi Yong Yu Fang Yi Xue. 13:734–736. 2006.(In

Chinese).

|

|

14

|

Sun YH, Gong WH, Zhu ZN, Chen YQ and Dai

R: Treatment of distal tibial fractures using minimally invasive

percutaneous plate osteosynthesis. Lin Chuang Gu Ke Za Zhi. 7:9–11.

2004.(In Chinese).

|

|

15

|

Güven M, Unay K, Cakici H, Ozturan EK and

Ozkan NK: A new screw fixation technique for minimally invasive

percutaneous plate osteosynthesis. Acta Orthop Belg. 74:846–850.

2008.PubMed/NCBI

|

|

16

|

Lin BW, Xiao DM, Li WF, Wang J, Chen J,

Zhang XM, Mai HX, Lu XH and Xie WP: Treatment of tibial fracture

using minimally invasive percutaneous plate technique. Zhonghua

Chuang Shang Za Zhi. 18:551–553. 2002.(In Chinese).

|

|

17

|

Liu CZ, Wu LY, He XY and Wang C:

Technology of minimally invasive percutancous plate osteosynthesis

for the treatment of fractures of the distal tibia. Zhongguo Gu

Shang. 21:213–214. 2008.(In Chinese). PubMed/NCBI

|

|

18

|

Ji F, Tong D, Tang H, Cai X, Zhang Q, Li J

and Wang Q: Minimally invasive percutaneous plate osteosynthesis

(MIPPO) technique applied in the treatment of humeral shaft distal

fractures through a lateral approach. Int Orthop. 33:543–547. 2009.

View Article : Google Scholar : PubMed/NCBI

|

|

19

|

Laurence M, Freeman MAR and Swanson SAV:

Engineering considerations in the internal fixation of fractures of

the tibial shaft. J Bone Joint Surg Br. 51:754–768. 1969.PubMed/NCBI

|

|

20

|

Rozbruch SR, Müller U, Gautier E and Ganz

R: The evolution of femoral shaft plating technique. Clin Orthop.

354:195–208. 1998. View Article : Google Scholar

|

|

21

|

Guo SF: The measure of bony structure of

lumbar spinal canal and spinal stenosis. Zhonghua Wai Ke Za Zhi.

22:6311984.(In Chinese). PubMed/NCBI

|

|

22

|

Qian ZL, Tang TS, Yang HL and Wang YJ:

Three-dimension finite element analysis of lumbar intervertebral

disc. Suzhou Da Xue Xue Bao. 22:4–7. 2002.(In Chinese).

|

|

23

|

Wang H: Research of a new finite element

model of lumbar motion segment. Zhongguo Yi Xue Gong Cheng.

13:185–192. 2005.(In Chinese).

|

|

24

|

Haidukewych GJ: Innovations in locking

plate technology. Am Acad Orthop Surg. 12:205–212. 2004. View Article : Google Scholar

|

|

25

|

Kozień MS, Lorkowski J, Szczurek S, Hładki

W and Trybus M: Computer simulation of the isolated lesion of

tibiofibular an syndesmosis using the finite element method. Przegl

Lek. 65:50–53. 2008.(In Polish). PubMed/NCBI

|

|

26

|

Field JR, Edmonds-Wilson R and Stanley RM:

An evaluation of interface contact profiles in two low contact bone

plates. Injury. 35:551–556. 2004. View Article : Google Scholar : PubMed/NCBI

|

|

27

|

Ellis T, Bourgeault CA and Kyle RF: Screw

position affects dynamic compression plate strain in an in vitro

fracture model. J Orthop Trauma. 15:333–337. 2001. View Article : Google Scholar : PubMed/NCBI

|

|

28

|

He JY, Shu Y, Huang SH, Zhou RP, He CJ,

Huang J and Pang KJ: The effect of the number of the screw in

dynamic compression plates on the stability of plate and screw

structure in torsion. Jiangxi Yi Xue Yuan Xue Bao. 46:47–49.

2006.(In Chinese).

|

|

29

|

Liu JC, Yi N, Song XY and Tu ZQ: Causative

analysis of fatigue of plates and screws in fractures of shaft of

extremital long bone. Hua Xi Yi Xue. 15:187–188. 2000.(In

Chinese).

|

|

30

|

Field JR, Törnkvist H, Hearn TC,

Sumner-Smith G and Woodside TD: The influence of screws omission on

construction stiffness and bone surface strain in the application

of bone plate to cadaveric bone. Injury. 30:591–598. 1999.

View Article : Google Scholar : PubMed/NCBI

|

|

31

|

Helfet DL, Shonnard PY, Levine D and

Borrelli J Jr: Minimally invasive plate osteosynthesis of distal

fractures of the tibia. Injury. 28 Suppl 1:A42–A47. 1997.

View Article : Google Scholar : PubMed/NCBI

|

|

32

|

Baumgaertel F, Buhl M and Rahn BA:

Fracture healing in biological plate osteosynthesis. Injury. 29

Suppl 3:C3–C6. 1998. View Article : Google Scholar : PubMed/NCBI

|