Introduction

Olfactory ensheathing cells (OECs) have an important

role as seed cells in central nervous system (CNS) repair (1–3). OECs

secrete a variety of neurotrophic factors, including nerve growth

factors, as well as extracellular matrix molecules, to improve the

microenvironment after nerve injury, reduce glial scarring and

prevent neuronal apoptosis (4).

Previous studies using animal models have also reported that OEC

transplantation significantly promoted nerve fiber regeneration and

partial functional recovery (5).

However, at present, the efficacy of cell

transplants in repairing the CNS is not ideal as inflammatory

substances and glial scar formation has been demonstrated to

inhibit the secretion of extracellular matrix components and cell

scaffolds (6). In recent years,

promising tissue-engineered biomaterial scaffolds have been

demonstrated to have the capacity to improve the repair of CNS

injury. The ideal biomaterials should have biodegradability,

biocompatibility, excellent mechanical properties and flexibility

(7,8). Natural biodegradable materials include

chitosan, polypeptide hydrogel, poly L-lactic acid (PLL),

chitosan/polyethylene stents and non-cellular scaffolds, which have

been considered for the repair of nerve damage (9–11). Our

group has been working on natural Tussah silk fibroin (TSF)

biomedical materials for numerous years (12). TSF is a natural protein with a

polymer structure. Its amino acid composition is characterized by a

large number of arginine-glycine-aspartic acid (RGD) tripeptide

sequences. This RGD tripeptide sequence structure is known to

facilitate cell adhesion. TSF also has good biocompatibility, with

no toxic effects on cells and organisms, and a low likelihood of

inflammatory reaction or immune rejection (13–16).

In recent years, the use of this electrospinning

technology has led to great progress in the preparation of

tissue-engineered materials. The diameter, structure distribution,

molecular conformation and crystallinity of TSF may be controlled

using electrospinning technology (17). When the fiber diameter is decreased

from microns to nanometers, the material properties are improved

accordingly.

A previous study by our group indicated that TSF

scaffolds prepared by electrostatic spinning have good

biocompatibility with OECs and may support their growth and

migration (12). However, the study

also suggested that the diameter of nanoscale fibers affects the

biological effects of OECs. Previous studies have demonstrated that

the diameter of electrospun nanofibers has a significant effect on

cell behavior (18–20). In one study, fibers with a diameter

of 400 and 1,200 nm were prepared for evaluating their effect on

cell behavior (21), and the results

suggested that the diameter of the scaffold had a marked impact on

neural cell behavior, with a significant increase in the

cell-spreading area observed on 400-nm silk fibroin (SF). A

significantly enhanced migration efficiency of astrocytes grown on

SF scaffolds was demonstrated, which highlighted the effects of SF

nanofibers to enhance cell migration. As it was indicated that the

diameter of SF nanofibers may be an important factor in the

construction of biomimetic microenvironments suitable for cell

growth, the present study aimed to assess the ideal diameter of TSF

as a tissue engineering scaffold material.

Materials and methods

Materials and sample preparation

TSF nanofibers were prepared as previously reported

(22). In brief, TSF fibers were

boiled in 0.5% (w/w) Na2CO3 aqueous solution

for 30 min twice for degumming, followed by thorough rinsing with

sufficient deionized water to remove the glue-like sericin. The

degummed TSF fibers were dissolved in 16 M lithium thiocyanate

solution and the mixture was heated with hotplate stirrers at 50°C

for 1 h, followed by dialysis with cellulose tubular membranes in

distilled water for 3 days (molecular weight cut-off, 8,000–14,000

kDa). A TSF film was prepared by spreading the TSF solution onto a

polyethylene plastic board and leaving it to dry at room

temperature. The electrospinning solution was prepared by

dissolving the TSF film in hexafluoroisopropanol with hotplate

stirrers for 1 week at 25°C. The spin solution was transferred to a

10-ml syringe with an 18 G needle. The flow rate was 0.5 ml/h, the

voltage was gradually increased to 16 kV and the collection

distance was 12 cm. TSF nanofibers with diameters of 400 and 1,200

nm were generated using spin solutions with concentrations of 8 and

16wt%, respectively. The as-spun TSF nanofibers were immersed in

75% (v/v) ethanol/water for 30 min to induce a structural change,

and then dried at room temperature for 24 h. Finally, the TSF

nanofibers were X-rayed prior to use. X-ray diffraction experiments

were measured on X'Pert Pro MPD (PANalytical B.V., Almelo,

Netherlands) in transmittance mode to investigate the crystalline

structure of samples at a wavelength of 0.154 nm. Lastly, the

intensity of the incident beam, the sample absorption and the

background were corrected for changes (23).

Material characterization

The samples were cut into squares of 1

mm2 and fixed on copper chips. After spraying with gold,

they were observed using a scanning electron microscope (SEM)

(23,24). In order to calculate the diameter of

the nanofibers, SEM images of >100 independent fibers were

analyzed by ImageJ software (version 1.47; National Institutes of

Health, Bethesda, MD, USA). Fourier Transform Infrared Spectroscopy

(FTIR) is a powerful and commonly used tool for secondary structure

analysis; the conformational changes and secondary structure of TSF

nanofibers after ethanol treatment were determined by FTIR

(24,25).

In vitro primary cultured OECs on TSF

scaffolds

All animal experiments of the present study were

approved by the Ethics Committee of the Second Affiliated Hospital

of Soochow University (Suzhou, China) and performed in accordance

with the Guidelines for the Welfare of Animals of Soochow

University (Suzhou, China) (12) as

well as the National Institute of Health's Guide for the Care and

Use of Laboratory Animals (26).

Primary cultures of OECs were prepared from 30 male Sprague Dawley

rats (weight, 100–150 g; age, 4–5 weeks; Experimental Animal Center

of Soochow University) as reported previously (12). The culture medium for OECs consisted

of Dulbecco's modified Eagle's medium (DMEM)/F-12 (Gibco; Thermo

Fisher Scientific, Inc., Waltham, MA, USA) with 10% fetal bovine

serum (FBS; Gibco; Thermo Fisher Scientific, Inc.), 1% glutamine

(Sigma-Aldrich; Merck KGaA, Darmstadt, Germany) and 2%

penicillin-streptomycin (Harbin Pharmaceutical Group Co., Ltd.,

Harbin, China). The culturing condition was as follows: 37°C in a

humidified atmosphere containing 5% CO2. After 10 days

in culture, OECs were used for a biocompatibility evaluation with

TSF nanofibers. The OECs were detached with 0.1% trypsin

(Sigma-Aldrich; Merck KGaA) at 37°C for 10 min, centrifuged at 157

× g for 5 min and then resuspended. Subsequently, the OECs

(1.0×105) were seeded on coverslips coated with 400-nm

or 1,200-nm TSF fibers or PLL (Sigma-Aldrich; Merck KGaA) that had

been pre-wetted with culture medium in 35-mm Petri dishes (Corning

Inc., Corning, NY, USA), the dimensions of TSF fibers were 10×10×1

mm, the thickness was 1 mm; PLL served as a positive control. The

nanofibers were incubated in 1 ml complete culture medium at 37°C

for 30 min prior to seeding. Cell suspension (1 ml) was placed on

the fibers in each dish, and 1 ml culture medium was added after 4

h. The culture medium was changed every 3 days. After culture for 4

days, the samples were observed with an inverted phase-contrast

microscope and SEM, using the same method of SEM as described

above.

Immunofluorescence staining and

quantitative analysis for OECs on TSF scaffolds

OECs were seeded on the TSF nanofibers or PLL-coated

coverslips as described above, and their identity was confirmed by

immunostaining. Cells on the fibers and PLL were fixed for 30 min

at room temperature with 4% paraformaldehyde (Zhongde Chemical

Products Trade Co., Ltd., Tianjin, China) and then blocked for 30

min in PBS containing 3% bovine serum albumin (BSA), 0.2% Triton

X-100 and 0.02% NaN3 (v/v) (all from Sigma-Aldrich;

Merck KGaA). The cells were incubated with rabbit polyclonal

anti-nerve growth factor receptor (NGFR) p75 (cat. no. BA0514-2;

Wuhan Boster Biological Technology, Ltd., Wuhan, China), diluted to

1:200 in PBS, at 4°C overnight. Following three washes with PBS,

cells were incubated with fluorescein isothiocyanate-conjugated

goat anti-rabbit secondary antibodies (cat. no. BA1105; Wuhan

Boster Biological Technology, Ltd.) diluted 1:70 in PBS for 1 h at

room temperature. Following three washes with PBS, cell nuclei were

stained with Hoechst 33258 diluted 1:100 in PBS at room temperature

for 15 min. Cover slips were washed with PBS, mounted with 50%

glycerin in PBS and imaged with an AF6000 fluorescence microscope

(Leica Microsystems GmbH, Wetzlar, Germany).

To evaluate the growth of OECs on TSF nanofibers,

the spreading area and the longest cellular process of OECs on TSF

nanofibers were quantified at 1, 4 and 7 days. In brief, at least

10 individual cells from three randomly selected fields were

measured with ImageJ 1.47 software on the basis of NGFR p75

immunostaining. At least five coverslips were included for each

experimental group. Experiments were repeated three times.

Crystal violet staining for cell

adhesion assays

The attachment test for OECs on TSF nanofibers was

performed as previously described (27). In brief, 500 µl OEC suspension

(1×105 cells/ml) was seeded into TSF nanofibers and a

24-well PLL-coated plate. Plates were coated with PLL by adding 1

ml 0.1% mg/ml PLL solution to each well at room temperature

overnight. The PLL solution was aspirated and the plates were left

to dry on a clean bench. OECs were incubated for 1 or 3 h in an

atmosphere of 5% CO2 at 37°C. The loose and unadhered

cells were removed. The wells were gently washed twice with PBS.

The adherent cells were fixed with 15% formalin in PBS for 15 min.

Once the fixation was completed, the wells were washed twice with

PBS and stained with 0.05 g/ml crystal violet at 37°C for 15 min.

In each well, the number of cells was counted in five microscopic

fields (magnification, ×200) and images were captured under an

Olympus microscope (Olympus Corp., Tokyo, Japan).

MTT cell proliferation assay

The proliferation of OECs on TSF and PLL was

examined at 1, 4, 7 and 10 days. At each time-point, 20 µl MTT

(Sigma-Aldrich; Merck KGaA) dissolved in PBS at 5 mg/ml was added

to each well, followed by incubation at 37°C for 4 h. Then, the

medium was discarded and 150 µl dimethyl sulfoxide (Sigma-Aldrich;

Merck KGaA) was added to each well to dissolve the dark blue

crystals with agitation for 10 min. The absorbance was measured at

490 nm with a microplate reader (iMark™ Microplate

Absorbance Reader-168-1130; Bio-Rad Laboratories, Inc., Hercules,

CA, USA).

Live/Dead Kit cell viability

analysis

The Live/Dead viability/cytotoxicity kit (cat. no.

L3224; Invitrogen; Thermo Fisher Scientific, Inc.), including 0.5

mM calcein AM and 0.5 mM ethidium homodimer-1 (Ethd-1) dissolved in

1 ml DMEM/F-12, was used for quantitative cell viability analysis

after 6 days of culture on PLL or TSF scaffolds in a 6-well plate.

In live cells, calcein displays bright green fluorescence, while in

dead cells, Ethd-1 binding to nucleic acids results in red

fluorescence. Live/dead reagent was added to cells, followed by

incubation at 37°C for 30 min and subsequent washing with PBS twice

and observation under a fluorescence microscope. In each well,

~3,000 cells were counted from randomly selected fields.

Live-cell imaging for migration

assay

The migration of OECs on TSF nanofibers was assayed

by timelapse video microscopy. An environmental chamber was used to

maintain optimal growth conditions for OECs at 37°C. In brief,

coverslips with cells were loaded and observed every 5 min using a

10X objective under a Leica DMI 6000 B microscope for a period of

400 min. The forward migration index (FMI) was calculated as the

ratio of forward progress (the net distance a cell progressed) to

the total path length (total distance a cell traveled through the

field).

Statistical analysis

Values are expressed as the mean ± standard error of

the mean. Statistical analysis was performed using analysis of

variance followed by a Dunn-Bonferroni post-hoc test for multiple

group comparisons using GraphPad Prism 6.0 software (GraphPad

Software, Inc., La Jolla, CA, USA). P<0.05 was considered to

indicate a statistically significant difference.

Results

Morphology and structure of TSF

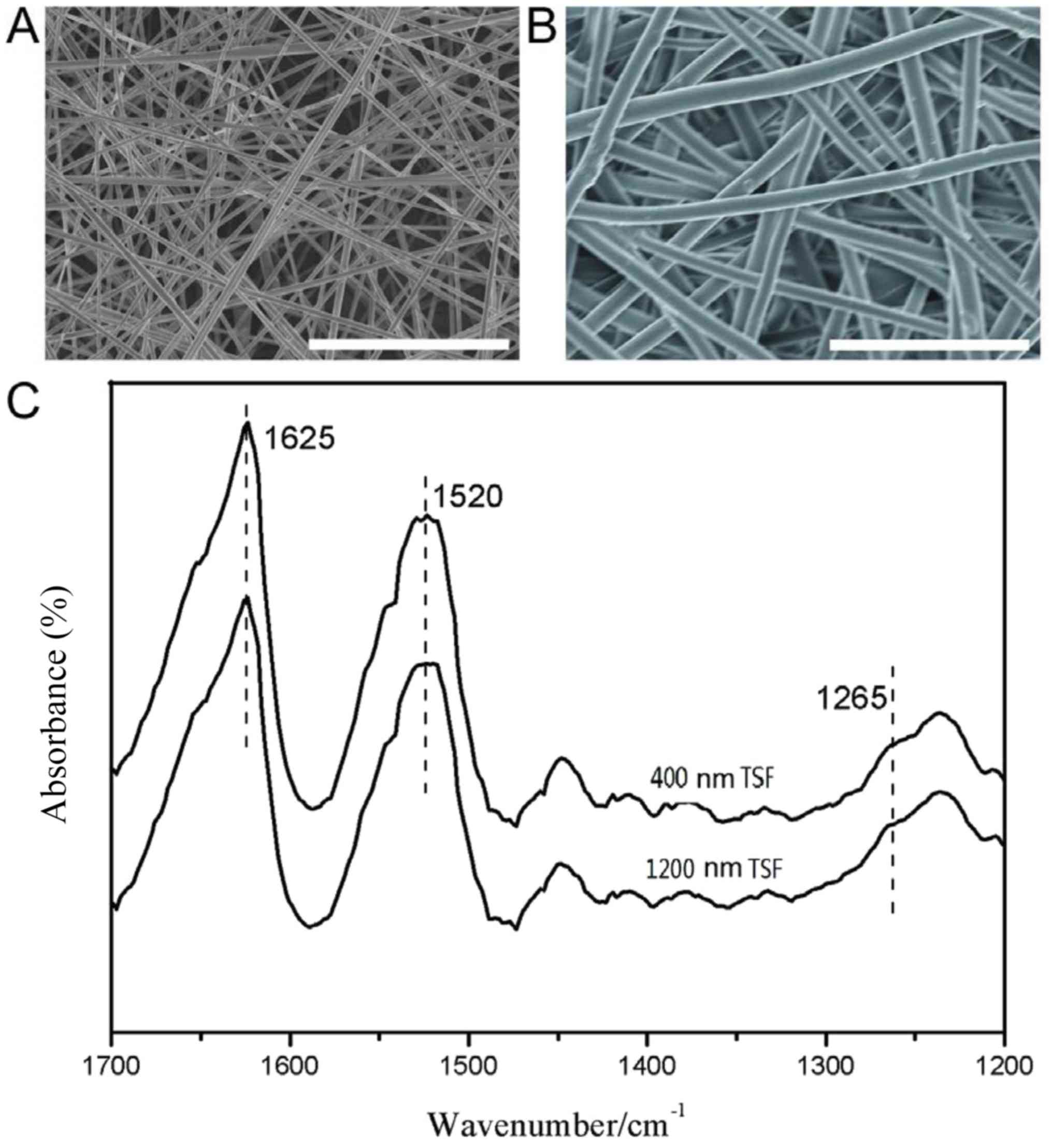

In order to assess the role of the nanofiber

diameter in regulating cell behavior, TSF nanofibers of different

diameter were prepared. As presented in Fig. 1A and B, the diameters of the two

types of TSF nanofiber were 400±44 and 1,200±95 nm, respectively;

the nanofibers exhibited a smooth surface with micro-sized pores to

allow for cell proliferation and penetration. Although native silk

fibroin is stable in water, the regenerated silk material is

usually post-treated with a solvent to achieve stability. In the

present study, 75% ethanol was employed to treat as-spun TSF

nanofibers and induce this structural change.

As presented in Fig.

1C, the FTIR spectra of TSF nanofibers exhibited absorption

bands at 1,625 cm−1 (amide I), 1,520 cm−1

(amide II) and 1,265 cm−1 (amide III), attributed to a

β-sheet structure. The crystalline β-sheet structure is the basis

for the water stability and strength of the TSF nanofibers. Thus,

water-stable TSF nanofibers with different diameters were

successfully prepared.

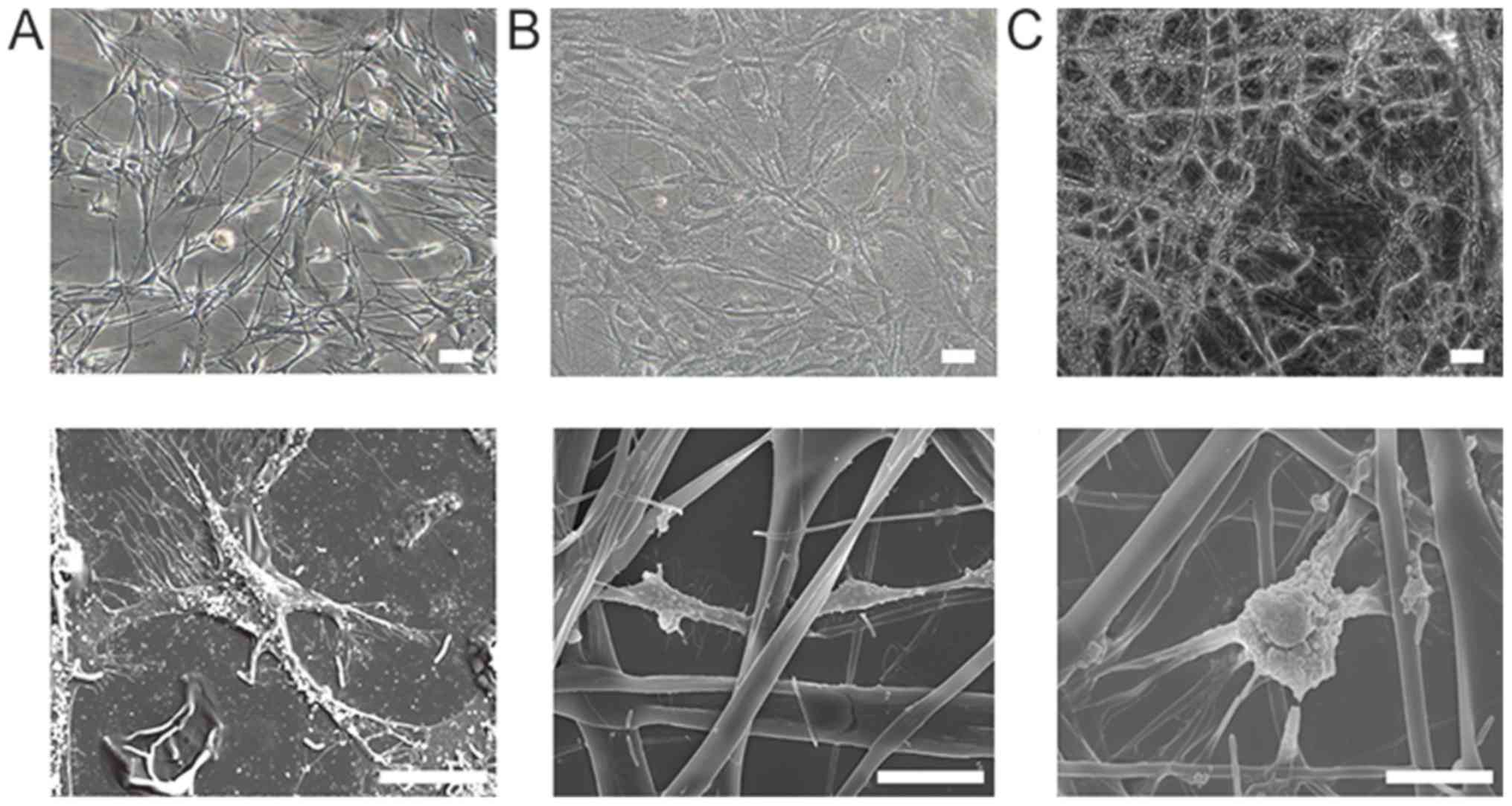

Morphology and structure of OECs on

TSF

An inverted-phase contrast microscope was used to

observe the OECs cultured on PLL and TSF (400 and 1,200 nm) after 4

days (Fig. 2A-C). Most OECs

presented with a bipolar or tripolar morphology, with excellent

refraction. The cells on PLL were connected through cell processes.

The OECs on TSF followed the fiber direction, and adjacent cells

formed connections through neurites. As presented in Fig. 2D and E, SEM revealed that OECs grew

on the surface and pores of the TSF microfibers after 4 days of

culture. The surfaces of the cells produced different cellular

processes, crossing the microporous surface to form intercellular

connections. In addition, extracellular matrix production was

observed in gaps in the material. Most of the OECs on the 400-nm

TSF displayed flat cell bodies and elongated protuberances, with

the cells tightly linked. The cellular connections of OECs on

1,200-nm TSF were fewer than those on 400-nm TSF.

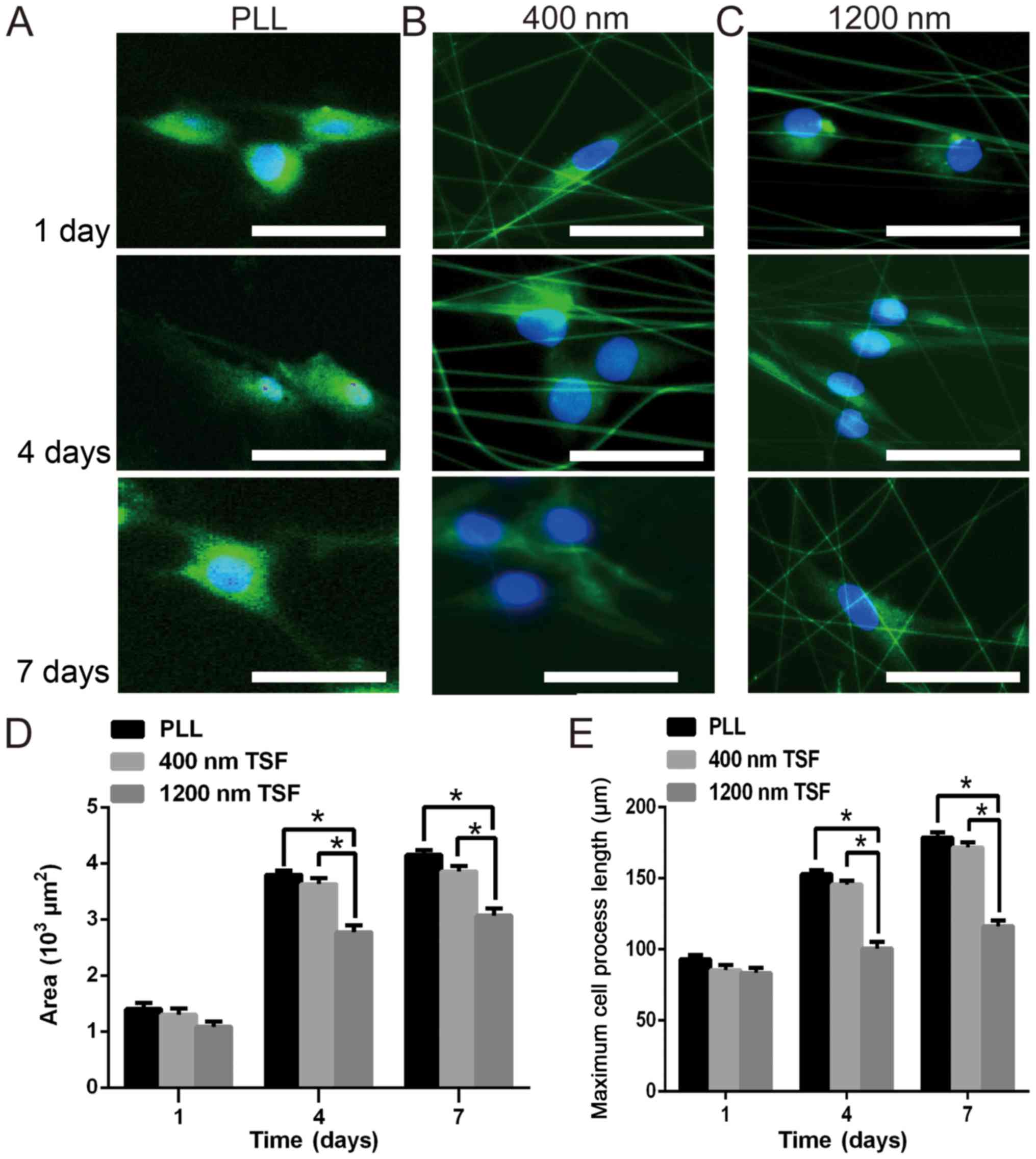

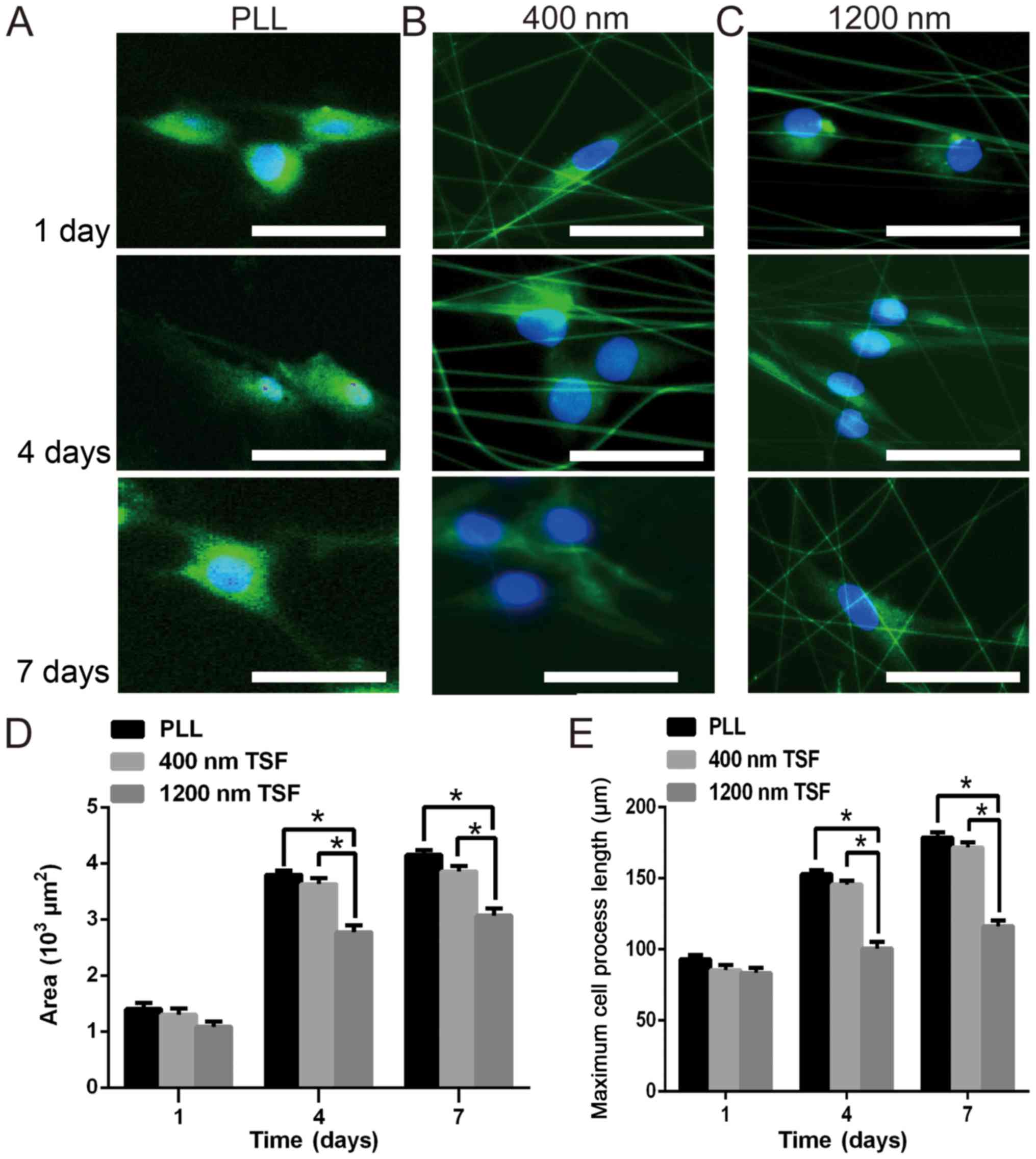

Immunostaining and growth parameters

of OECs on TSF

NGFR p75 staining indicated that OECs on TSF

retained their phenotype. Hoechst 33258 staining revealed that the

nuclei of the OECs were round or oval; no chromatin condensation or

apoptotic body formation was observed and the staining was uniform,

indicating that there were no obvious apoptotic phenomena of OECs

grown on TSF nanofibers of either diameter.

As presented in Fig.

3, the difference in the area of OEC spreading on the two types

of TSF nanofiber after 1 day was relatively small

(0.9–1.5×103 µm2). After 4 days, the area of

cell spreading on 400 nm TSF fibers reached 3.8×103

µm2, which was significantly higher than that on 1,200

nm TSF (3×103 µm2; P<0.05). Significant

differences in the spreading area between the OECs grown on PLL or

400 nm TSF fibers and the 1,200 nm TSF fibers were obtained at 7

days (P<0.05). Quantitative analysis also indicated that the

maximum process length of OECs on 400 nm TSF fibers was

significantly longer than that of OECs on 1,200 nm fibers at 4 and

7 days (P<0.05).

| Figure 3.Effect of the TSF scaffold diameter

on the growth and spread of OECs. Immunocytochemistry staining of

OECs with anti-NGFR p75 antibodies (green) and Hoechst 33258

(blue). OECs were cultured on (A) PLL and (B and C) TSF nanofibers

with a diameter of (B) 400 nm and (C) 1,200 nm, and were observed

at 1, 4 and 7 days (scale bar, 25 µm) using a fluorescence

microscope. (D) The spreading area and (E) the longest process of

OECS was quantified at 1, 4 and 7 days. The area of OECs on the

400-nm TSF fibers reached 3.8×103 µm2, which

was significantly higher than on 1,200-nm TSF, which reached

3.0×103 µm2. There were also significant

differences in the spread area of cells between PLL fibers and

1,200 nm TSF fibers at 7 days. In addition, the longest process of

OECs on 400-nm TSF was significantly longer than that of OECs on

1,200-nm TSF on days 4 and 7. *P<0.05. TSF, Tussah silk fibroin;

OECs, olfactory ensheathing cells; PLL, poly-L-lysine. |

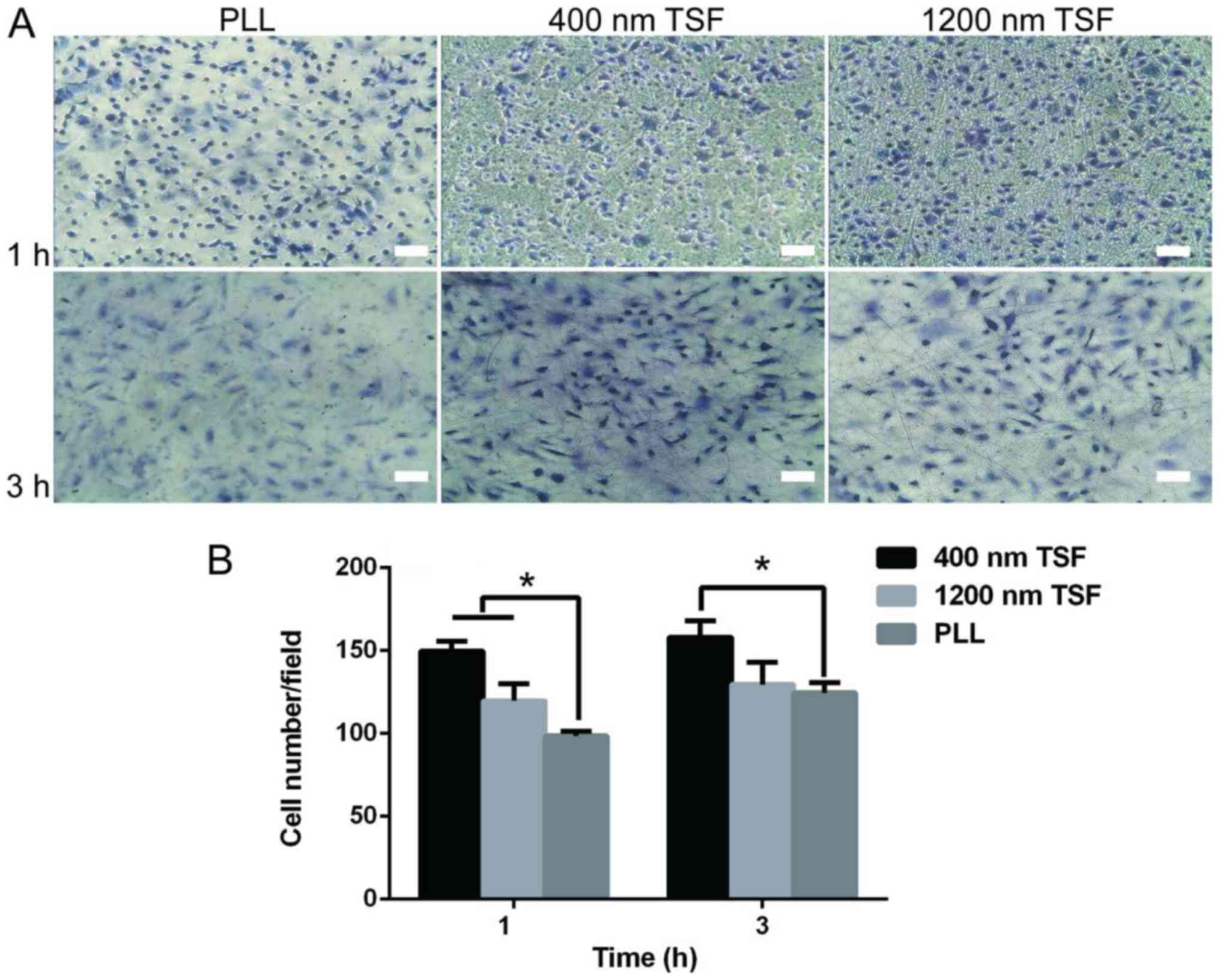

Cell adhesion of OECs on TSF

The cell adhesion on 400 nm TSF was greater than

that on PLL or 1,200 nm TSF (P<0.05). The cell adhesion on PLL

was the lowest (Fig. 4). This may be

due to TSF containing more RGD sequences.

Proliferation and viability of OECs on

TSF

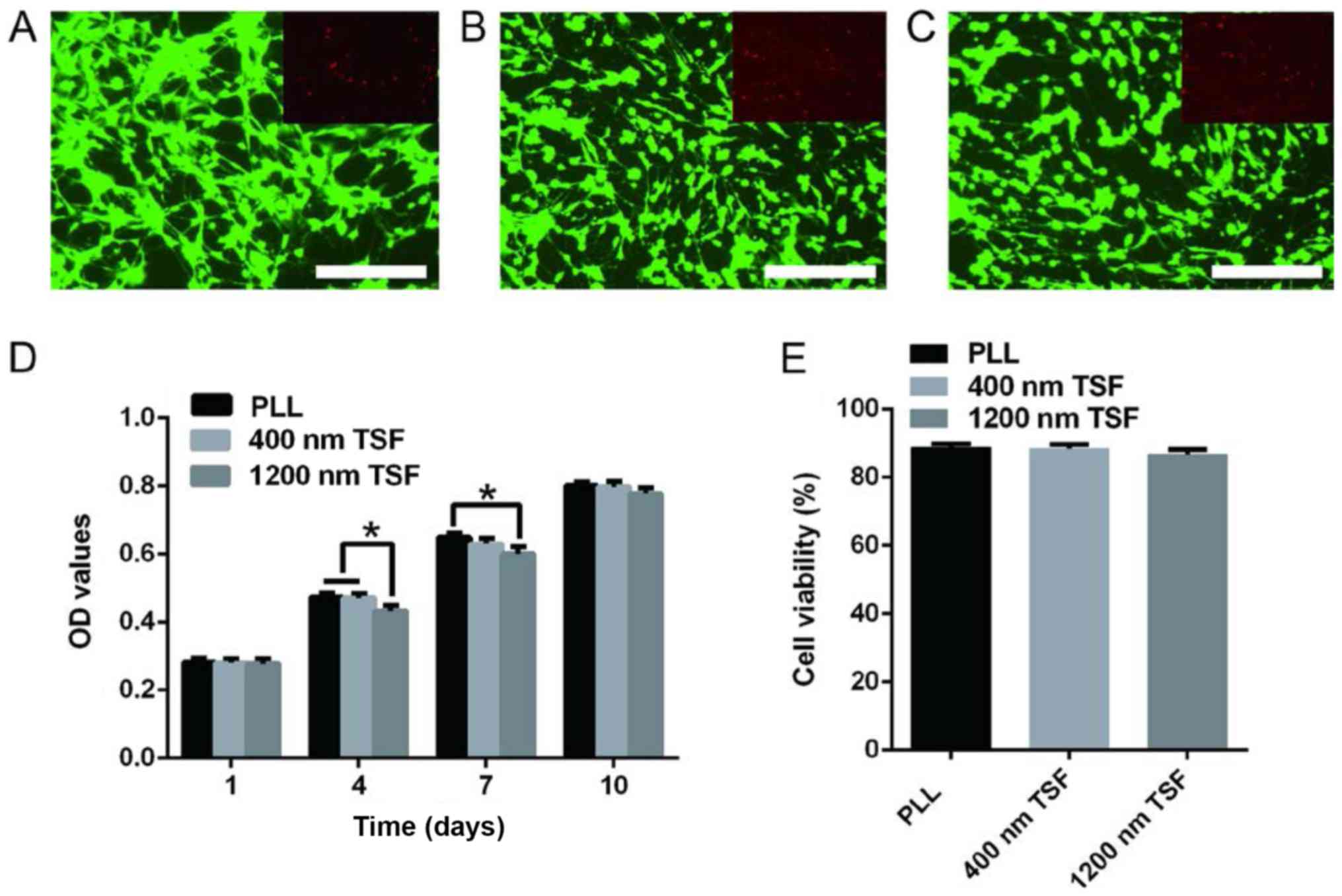

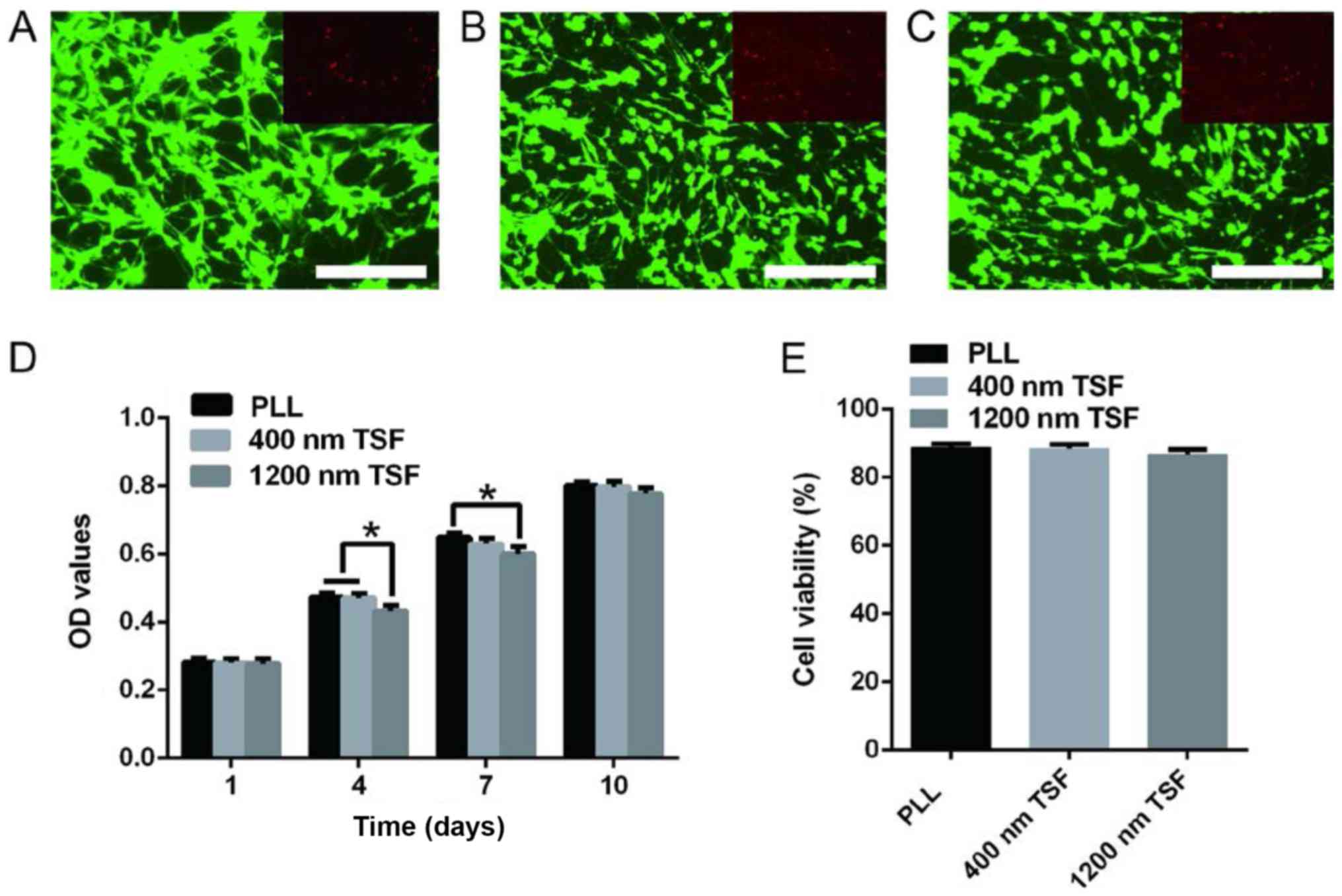

As presented in Fig.

5A-C, the morphology of OECs on TSF was normal. The majority of

the cells were distributed along the fiber and evenly distributed.

According to an MTT assay (Fig. 5D),

the absorbance value in the 1,200 nm TSF group was significantly

less than that in the 400 nm TSF and PLL groups at 4 days (both

P<0.05), and the absorbance value of the 1,200 nm TSF group was

significantly less than that of the PLL group at 7 days

(P<0.05). However, there were no differences between the groups

at 1 and 10 days. These results indicate that, compared with PLL,

TSF has good biocompatibility and did not induce any marked

cytotoxicity on OECs.

| Figure 5.Effects of (A) PLL, (B) 400-nm TSF

and (C) 1,200-nm TSF on OEC proliferation and viability. (D) After

4 days of culture, the absorbance value in the 1,200-nm TSF group

was significantly lower than that in the 400-nm TSF or the PLL

group, as well as the PLL group at 7 days. Scale bar, 250 µm. (E)

Live/dead cell staining revealed no significant differences between

the groups. *P<0.05. TSF, Tussah silk fibroin; OECs, olfactory

ensheathing cells; PLL, poly-L-lysine; OD, optical density. |

The cell viability and death rates were not

significantly different in the TSF groups (Fig. 5E). These results indicated that TSF

nanofibers successfully supported the survival, growth and

proliferation of OECs.

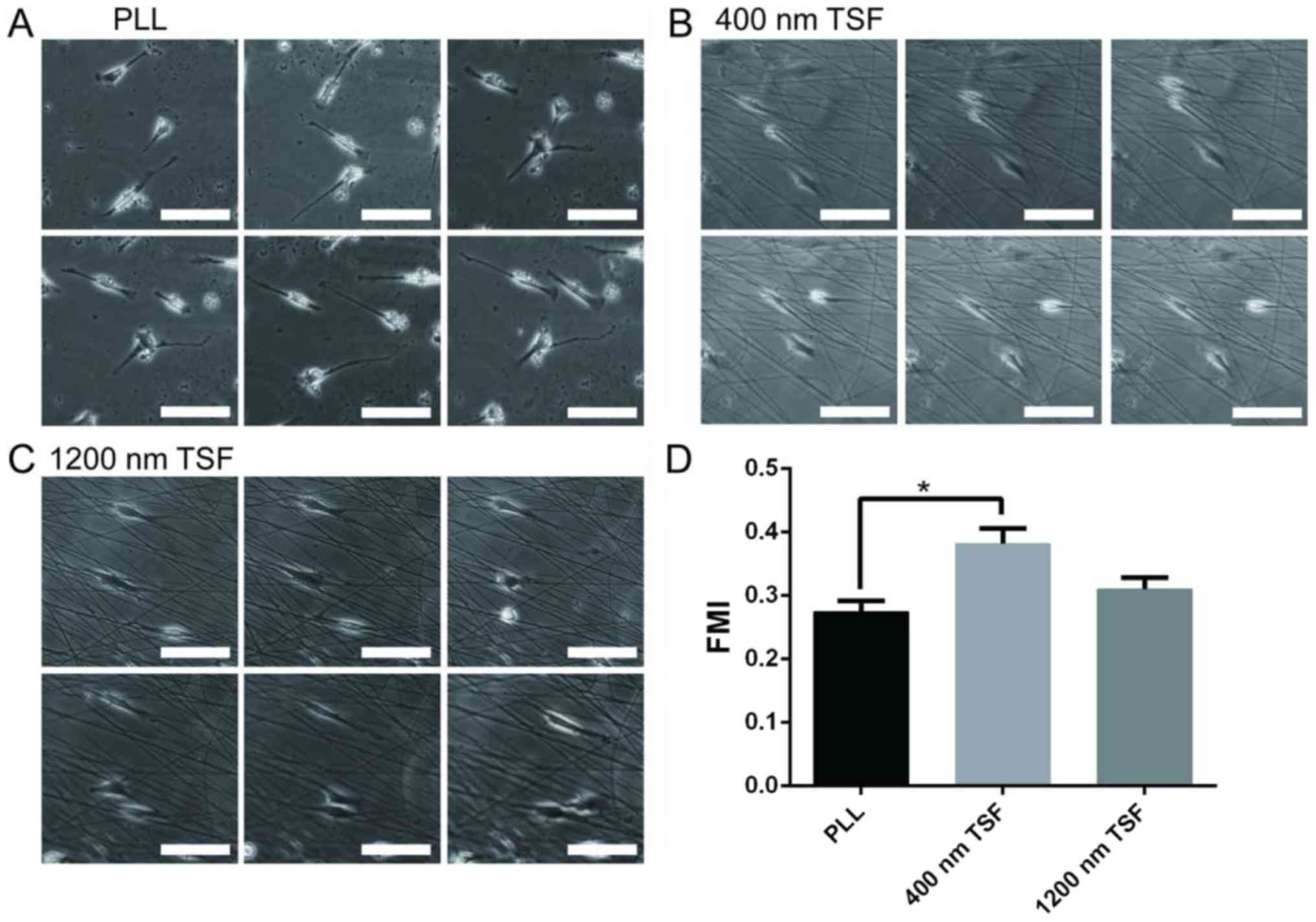

Cell migration of OECs on TSF

Cell migration was analyzed by single-cell

trajectories. The starting point of each cell migration was

standardized to the intersection point of the X- and Y-axes. OECs

on PLL migrated in random directions, whereas those on 400- and

1,200-nm TSF moved along the fiber. In order to measure cell

motility, the FMI was calculated and analyzed (Fig. 6). Quantitative analysis suggested

that the FMI of OECs in the 400-nm TSF group was significantly

higher than that in the PLL group (P<0.05).

Discussion

It has been verified that TSF has good

biocompatibility, permeability and biodegradability, with a low

inflammatory response and other favorable qualities (28,29). TSF

supports cell growth, proliferation and differentiation; in

vivo studies have also reported that it facilitates tissue

repair (30,31). A further advantage of TSF is that it

promotes cell adhesion and migration through the RGD tripeptide

sequence, a biometric signal (32).

It has been reported that TSF was beneficial for the adhesion and

growth of fibroblasts and bone marrow mesenchymal stem cells in a

mouse model (33,34).

The present study indicates that the diameter of

nanofibers has an important role in the arrangement and specific

biological behavior of cells. OECs were observed to be well-aligned

on 400-nm TSF, while cells were randomly arranged on 1,200-nm TSF.

This result suggests that a smaller diameter (400 nm) of TSF

nanofibers may promote cell alignment when compared with a larger

diameter (1,200 nm). This result is similar that of a previous

study by our group on OECs cultured on fabricated SF scaffolds of

different diameters (35). The RGD

tri-peptide sequence structure of TSF has been demonstrated to

facilitate cell adhesion (13). TSF

has also been shown to possess good biocompatibility with no toxic

effects on cells and organisms, and a low likelihood of

inflammatory reaction or immune rejection (15). Through the current study, it was

speculated that a smaller diameter of TSF nanofibers is more

similar to the microenvironment created by the natural

extracellular matrix, which is suitable for cell survival and

proliferation. However, the specific biochemical effects and

directional guidance of TSF nanofibers, as well as the underlying

mechanisms, still require further study.

Based on the above results, it may be speculated

that the precise control of the direction of nanofibers may control

the arrangement and directional migration of cells to promote the

regeneration of axons and the repair of central nerve injury. This

may be facilitated by the application of physical or chemical

stimuli, including electrical stimulation or growth factor release

(36).

In conclusion, through electrospinning, a

three-dimensional TSF scaffold material with a controllable

diameter, smooth surface and uniform pore spacing was prepared.

These TSF nanofibers do not affect the phenotype of OECs, and

support their adhesion, migration, growth and proliferation. The

performance of the 400-nm TSF fibers, including OEC adhesion,

proliferation and migration, was improved relative to that of the

1,200-nm TSF fibers. This indicates that TSF nanofibers with a

diameter of 400-nm may be a superior scaffold material for

repairing nerve injury. However, the mechanisms of this effect

require further study.

Acknowledgements

The authors would like to thank Professor Huanxiang

Zhang (Department of Cell Biology, Jiangsu Key Laboratory of Stem

Cell Research, Medical College of Soochow University, Suzhou,

China) for the guidance provided during the experiment.

Funding

This work was supported by the National Natural

Science Foundation of China (grant no. 81271723) and the Applied

Basic Research Project of Suzhou (grant no. SYS201622).

Availability of data and materials

The analyzed data sets generated during the study

are available from the corresponding author on reasonable

request.

Authors' contributions

YS conceived and designed the experiments. PW, HZ

and PZ performed the experiments and wrote the paper. XW collected

data. XD and JC analyzed the data. BZ interpreted the results and

revised the manuscript. All authors discussed and approved the

final manuscript.

Ethical approval and consent to

participate

All animal experiments of the present study were

approved by the Ethics Committee of the Second Affiliated Hospital

of Soochow University (Suzhou, China).

Patient consent for publication

Not applicable.

Competing interests

The authors declare that they have no competing

interests regarding this study.

References

|

1

|

Voronova АD, Stepanova OV, Valikhov MP,

Chadin AV, Dvornikov АS, Reshetov IV and Chekhonin VP: Preparation

of human olfactory ensheathing cells for the therapy of spinal cord

injuries. Bull Exp Biol Med. 164:523–527. 2018. View Article : Google Scholar : PubMed/NCBI

|

|

2

|

Straley KS, Foo CW and Heilshorn SC:

Biomaterial design strategies for the treatment of spinal cord

injuries. J Neurotrauma. 27:1–19. 2010. View Article : Google Scholar : PubMed/NCBI

|

|

3

|

Gu M, Gao Z, Li X, Zhao F, Guo L, Liu J

and He X: Feasibility of diffusion tensor imaging for assessing

functional recovery in rats with olfactory ensheathing cell

transplantation after contusive spinal cord injury (SCI). Med Sci

Monit. 23:2961–2971. 2017. View Article : Google Scholar : PubMed/NCBI

|

|

4

|

Gu M, Gao Z, Li X, Guo L, Lu T, Li Y and

He X: Conditioned medium of olfactory ensheathing cells promotes

the functional recovery and axonal regeneration after contusive

spinal cord injury. Brain Res. 1654:43–54. 2017. View Article : Google Scholar : PubMed/NCBI

|

|

5

|

Au E and Roskams AJ: Olfactory ensheathing

cells of the lamina propria in vivo and in vitro. Glia. 41:224–236.

2003. View Article : Google Scholar : PubMed/NCBI

|

|

6

|

Khankan RR, Griffis KG, Haggerty-Skeans

JR, Zhong H, Roy RR, Edgerton VR and Phelps PE: Olfactory

ensheathing cell transplantation after a complete spinal cord

transection mediates neuroprotective and immunomodulatory

mechanisms to facilitate regeneration. J Neurosci. 36:6269–6286.

2016. View Article : Google Scholar : PubMed/NCBI

|

|

7

|

Führmann T, Anandakumaran PN and Shoichet

MS: Combinatorial therapies after spinal cord injury: How can

biomaterials help? Adv Healthc Mater. 6:2017.(doi:

10.1002/adhm.201601130). View Article : Google Scholar

|

|

8

|

Zhang Q, Yan S, You R, Kaplan DL, Liu Y,

Qu J, Li X, Li M and Wang X: Multichannel silk protein/laminin

grafts for spinal cord injury repair. J Biomed Mater Res A.

104:3045–3057. 2016. View Article : Google Scholar : PubMed/NCBI

|

|

9

|

Zhu S, Ge J, Wang Y, Qi F, Ma T, Wang M,

Yang Y, Liu Z, Huang J and Luo Z: A synthetic oxygen

carrier-olfactory ensheathing cell composition system for the

promotion of sciatic nerve regeneration. Biomaterials.

35:1450–1461. 2014. View Article : Google Scholar : PubMed/NCBI

|

|

10

|

Kabiri M, Oraee-Yazdani S, Dodel M,

Hanaee-Ahvaz H, Soudi S, Seyedjafari E, Salehi M and Soleimani M:

Cytocompatibility of a conductive nanofibrous carbon nanotube/poly

(L-Lactic acid) composite scaffold intended for nerve tissue

engineering. EXCLI J. 14:851–860. 2015.PubMed/NCBI

|

|

11

|

Zhou M, Qiao W, Liu Z, Shang T, Qiao T,

Mao C and Liu C: Development and in vivo evaluation of

small-diameter vascular grafts engineered by outgrowth endothelial

cells and electrospun chitosan/poly(ε-caprolactone) nanofibrous

scaffolds. Tissue Eng Part A. 20:79–91. 2014. View Article : Google Scholar : PubMed/NCBI

|

|

12

|

Fan Z, Shen Y, Zhang F, Zuo B, Lu Q, Wu P,

Xie Z, Dong Q and Zhang H: Control of olfactory ensheathing cell

behaviors by electrospun silk fibroin fibers. Cell Transplant. 22

Suppl 1:S39–S50. 2013. View Article : Google Scholar : PubMed/NCBI

|

|

13

|

Sofia S, McCarthy MB, Gronowicz G and

Kaplan DL: Functionalized silk-based biomaterials for bone

formation. J Biomed Mater Res. 54:139–148. 2001. View Article : Google Scholar : PubMed/NCBI

|

|

14

|

Pavoni E, Tozzi S, Tsukada M and Taddei P:

Structural study on methacrylamide-grafted Tussah silk fibroin

fibres. Int J Biol Macromol. 88:196–205. 2016. View Article : Google Scholar : PubMed/NCBI

|

|

15

|

Gao Y, Shao W, Qian W, He J, Zhou Y, Qi K,

Wang L, Cui S and Wang R: Biomineralized poly (l-lactic-co-glycolic

acid)-tussah silk fibroin nanofiber fabric with hierarchical

architecture as a scaffold for bone tissue engineering. Mater Sci

Eng C Mater Biol Appl. 84:195–207. 2018. View Article : Google Scholar : PubMed/NCBI

|

|

16

|

Asakura T, Nishi H, Nagano A, Yoshida A,

Nakazawa Y, Kamiya M and Demura M: NMR analysis of the fibronectin

cell-adhesive sequence, Arg-Gly-Asp, in a recombinant silk-like

protein and a model peptide. Biomacromolecules. 12:3910–3916. 2011.

View Article : Google Scholar : PubMed/NCBI

|

|

17

|

Min BM, Lee G, Kim SH, Nam YS, Lee TS and

Park WH: Electrospinning of silk fibroin nanofibers and its effect

on the adhesion and spreading of normal human keratinocytes and

fibroblasts in vitro. Biomaterials. 25:1289–1297. 2004. View Article : Google Scholar : PubMed/NCBI

|

|

18

|

Yang F, Murugan R, Wang S and Ramakrishna

S: Electrospinning of nano/micro scale poly(L-lactic acid) aligned

fibers and their potential in neuronal tissue engineering.

Biomaterials. 26:2603–2610. 2005. View Article : Google Scholar : PubMed/NCBI

|

|

19

|

Smeal RM, Rabbitt R, Biran R and Tresco

PA: Substrate curvature influences the direction of nerve

outgrowth. Ann Biomed Eng. 33:376–382. 2005. View Article : Google Scholar : PubMed/NCBI

|

|

20

|

Smeal RM and Tresco PA: The influence of

substrate curvature on neurite outgrowth is cell type dependent.

Exp Neurol. 213:281–292. 2008. View Article : Google Scholar : PubMed/NCBI

|

|

21

|

Qu J, Wang D, Wang H, Dong Y, Zhang F, Zuo

B and Zhang H: Electrospun silk fibroin nanofibers in different

diameters support neurite outgrowth and promote astrocyte

migration. J Biomed Mater Res A. 101:2667–2678. 2013. View Article : Google Scholar : PubMed/NCBI

|

|

22

|

Wang J, Ye R, Wei Y, Wang H, Xu X, Zhang

F, Qu J, Zuo B and Zhang H: The effects of electrospun TSF

nanofiber diameter and alignment on neuronal differentiation of

human embryonic stem cells. J Biomed Mater Res A. 100:632–645.

2012. View Article : Google Scholar : PubMed/NCBI

|

|

23

|

Panda N, Bissoyi A, Pramanik K and Biswas

A: Development of novel electrospun nanofibrous scaffold from P.

Ricini and A. Mylitta silk fibroin blend with improved surface and

biological properties. Mater Sci Eng C Mater Biol Appl. 48:521–532.

2015. View Article : Google Scholar : PubMed/NCBI

|

|

24

|

Khamhaengpol A and Siri S: Composite

electrospun scaffold derived from recombinant fibroin of weaver ant

(Oecophylla smaragdina) as cell-substratum. Appl Biochem

Biotechnol. 183:110–125. 2010. View Article : Google Scholar

|

|

25

|

Yang R, Wu P, Wang X, Liu Z, Zhang C, Shi

Y, Zhang F and Zuo B: A novel method to prepare tussah/Bombyx mori

silk fibroin-based films. RSC Adv. 8:22069–22077. 2018. View Article : Google Scholar

|

|

26

|

Parker J: The protection of laboratory

animals: A response to Stephenson. J Med Philos. 19:389–394. 1994.

View Article : Google Scholar : PubMed/NCBI

|

|

27

|

Min BM, Jeong L, Nam YS, Kim JM, Kim JY

and Park WH: Formation of silk fibroin matrices with different

texture and its cellular response to normal human keratinocytes.

Int J Biol Macromol. 34:281–288. 2004. View Article : Google Scholar : PubMed/NCBI

|

|

28

|

Zhuang Y, Zhang Q, Feng J, Wang N, Xu W

and Yang H: The effect of native silk fibroin powder on the

physical properties and biocompatibility of biomedical polyurethane

membrane. Proc Inst Mech Eng H. 231:337–346. 2017. View Article : Google Scholar : PubMed/NCBI

|

|

29

|

Qi Y, Wang H, Wei K, Yang Y, Zheng RY, Kim

IS and Zhang KQ: A review of structure construction of silk fibroin

biomaterials from single structures to multi-level structures. Int

J Mol Sci. 18:pii: E237. 2017. View Article : Google Scholar

|

|

30

|

Zhang W, Chen L, Chen J, Wang L, Gui X,

Ran J, Xu G, Zhao H, Zeng M, Ji J, et al: Silk fibroin biomaterial

shows safe and effective wound healing in animal models and a

randomized controlled clinical trial. Adv Healthc Mater.

6:2017.(doi: 10.1002/adhm.201700121). View Article : Google Scholar

|

|

31

|

Fernández-García L, Marí-Buyé N, Barios

JA, Madurga R, Elices M, Pérez-Rigueiro J, Ramos M, Guinea GV and

González-Nieto D: Safety and tolerability of silk fibroin hydrogels

implanted into the mouse brain. Acta Biomater. 45:262–275. 2016.

View Article : Google Scholar : PubMed/NCBI

|

|

32

|

Zhang Z, Yoo R, Wells M, Beebe TP Jr,

Biran R and Tresco P: Neurite outgrowth on well-characterized

surfaces: Preparation and characterization of chemically and

spatially controlled fibronectin and RGD substrates with good

bioactivity. Biomaterials. 26:47–61. 2005. View Article : Google Scholar : PubMed/NCBI

|

|

33

|

Luan XY, Wang Y, Duan X, Duan QY, Li MZ,

Lu SZ, Zhang HX and Zhang XG: Attachment and growth of human bone

marrow derived mesenchymal stem cells on regenerated antheraea

pernyi silk fibroin films. Biomed Mater. 1:181–187. 2006.

View Article : Google Scholar : PubMed/NCBI

|

|

34

|

Minoura N, Aiba S, Gotoh Y, Tsukada M and

Imai Y: Attachment and growth of cultured fibroblast cells on silk

protein matrices. J Biomed Mater Res. 29:1215–1221. 1995.

View Article : Google Scholar : PubMed/NCBI

|

|

35

|

Shen Y, Qian Y, Zhang H, Zuo B, Lu Z, Fan

Z, Zhang P, Zhang F and Zhou C: Guidance of olfactory ensheathing

cell growth and migration on electrospun silk fibroin scaffolds.

Cell Transplant. 19:147–157. 2010. View Article : Google Scholar : PubMed/NCBI

|

|

36

|

Aznar-Cervantes S, Pagán A, Martínez JG,

Bernabeu-Esclapez A, Otero TF, Meseguer-Olmo L, Paredes JI and

Cenis JL: Electrospun silk fibroin scaffolds coated with reduced

graphene promote neurite outgrowth of PC-12 cells under electrical

stimulation. Mater Sci Eng C Mater Biol Appl. 79:315–325. 2017.

View Article : Google Scholar : PubMed/NCBI

|