Introduction

Osteoporosis is a common disease in the elderly, and

its incidence continues to rise. With the aging of the population

in China, there are increasing number of patients with

osteoporosis. For spinal surgeons, internal fixation (1) is a routine treatment for osteoporosis

requiring nerve decompression and instrumented fusion such as

posterior lumbar interbody fusion (PLIF), which enables successful

fusion of the spine. The posterior spinal instrumentation subjects

the pedicle screw-bone interface to greater stress and affects the

stability of the pedicle screw. A number of studies have shown that

the stability of pedicle screws depends on the quality of the bone,

so patients with osteoporosis are more prone to instrumentation

failure (2-4). At

present, fatigue tests and withdrawal force testing of screws at

different bone densities indicate that the quality of the compact

trabecular bone enhances firm fixation of the screws, and

osteoporosis increases the failure rate of the internal fixation

(5-10).

The cement-reinforced [e.g. polymethylmethacrylate (PMMA) or

calcium-based bone cement] pedicle screw technology can enhance the

stability of the internal fixation system. However, after the bone

cement is strengthened, loosening of the screws may occur

again.

In order to address this problem, a new type of

spine-expansion pedicle screw was invented by Lei and Wu (11). According to a large number of

experimental studies on the biomechanics of animal vertebral

specimens, it was found that the axial withdrawal force of the new

expandable pedicle screws is significantly enhanced compared with

the conventional pedicle screw. In a large number of intact animal

experiments (12), the new

expandable pedicle screws and bone formed a staggered structure,

which increased the stability of the screw. This type of expansion

screw has been shown to be safe, effective, and practical through

biomechanical testing, imaging evaluation, and epidemiological

investigation (13). The expansion

screw has obtained a number of patents and is used in clinical

practice (14). Following the

development of the expansion screw, we also developed a composite

screw-bone cement anchor bolt, and biomechanical and animal

experiments have proven that this new bone cement screw has good

fixation strength and low cement leakage rate (15), but it is not effective for complex

osteoporosis. We therefore established a three-dimensional frame

structure to ensure stability. This study analyzed the stability of

a three-dimensional frame structure based on cemented screw

reinforcement through biomechanical testing.

Materials and methods

Screws and augmentation materials

A composite threaded bone cement anchoring screw

(Shandong Weigao Orthopedic Device Company) was used. The details

of the screw: diameter 6.5 mm x length 45 mm, proximal 9 threads,

distal 10 threads, total 19 threads. The thread density is

increased at the proximal end. At the distal end the depth of the

thread is increased, the pitch is increased, and a V-shaped nail is

present. The screw is hollow with an inner diameter of 1.6 mm. The

screw has a total of 6 side holes, with the side holes enlarged

from the proximal end to the distal end. The two apertures are

symmetrically distributed within one thread. Mendec Spine PMMA bone

cement is produced by TECRES. Denture base material resin type II

was used (self-curing denture acrylic: 100 g x 7 bottles and liquid

for denture acrylic 500 ml x 1 bottle) Shanghai Medical Devices

Co., Ltd. holding.

Specimen

Seven intact human spine specimens (T12-L5) from

people with an average age of 72 years were used. The bone mineral

density of the specimens was detected by dual energy X-ray

absorptiometry (DEXA method). The test results showed that all of

the specimens were osteoporotic.

The study was approved by the Ethics Committee of

Xijing Hospital (Xi’an, China), and written informed consents were

signed by the patients and/or the guardians.

Experimental apparatus.

Screw insertion devices including hole openers, hand

drills, nail holders, staple handles and other instruments were

provided by Shandong Weigao Orthopedic Device Co., Ltd. Digital

X-ray machines (Philips) and 64-row spiral CT (Picker PQ6000) were

provided by the Department of Radiology of the Fourth Military

Medical University. The biomechanical experimental instrument was a

microcomputer-controlled electronic universal testing machine,

provided by the Mechanics Laboratory of the Mechanical College of

Xi'an Jiaotong University.

Methods

Experimental grouping

Three specimens were separated into 18 vertebral

bodies for the biomechanical testing of a single screw. Nine

vertebral bodies were randomly selected and bone cement screws were

implanted on both sides. Bone cement was used to form a bridge at

the front end of the two screws (single vertebral group A).

The other nine vertebral bodies were implanted with

cement screws on both sides, but the front ends of the two screws

were not bridged (single vertebral group B).

The remaining spine specimens were used for

biomechanical testing of the overall stability of the

three-dimensional frame.

The four specimens were osteotomized, then two

specimens were randomly selected. Bone cement screws were implanted

on both sides of the vertebral body, and a bone cement bridge was

formed at the front end of the two screws to establish a

three-dimensional frame structure (multi-vertebral group A).

The other two spine specimens were implanted with

cement screws on both sides of the vertebral body, but the front

ends of the two screws were not bridged (multi-vertebral group B)

(Table I).

| Table IExperimental grouping. |

Table I

Experimental grouping.

| Group | Group A | Group B |

|---|

| Single vertebral | 9 (triangular sTable

structure) | 9 |

| Multi-vertebral | 2 (three-dimensional

frame) | 2 |

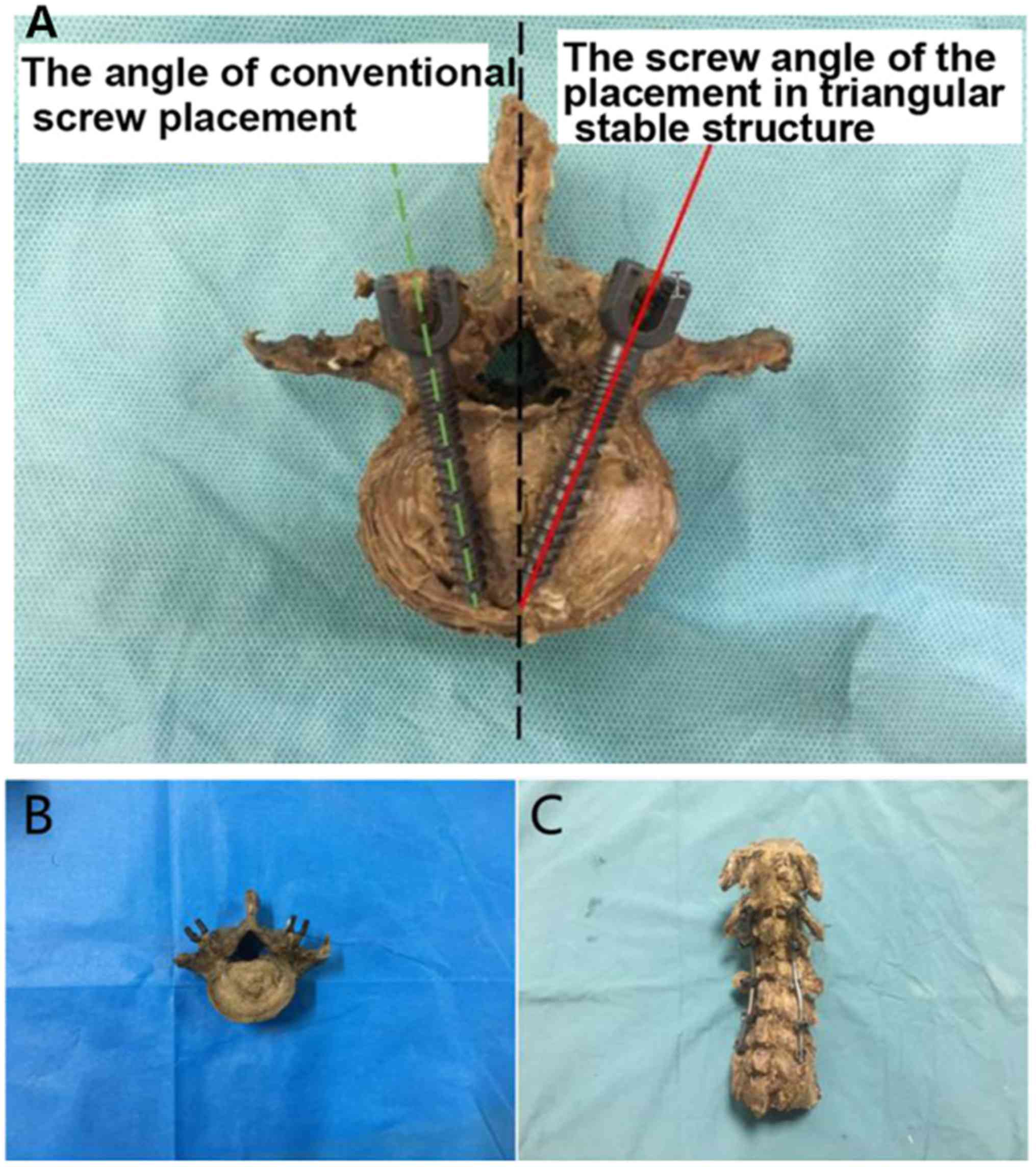

Screw placement. According to the standard

surgical procedure for this clinical operation, following the

herringbone crest vertex technique, the specimen was first fixed,

and an open cone was used to punch the vertex of the specimen at

the Herringbone crest vertex. A nail path was prepared with a depth

of 40 mm and perpendicular to the side of the specimen. A composite

threaded bone cement anchoring screw was inserted into the

cancellous bone of the specimen at an angle to the vertebral

specimen until the screw was fully screwed into the specimen.

During the screw placement process, the vertebral specimen should

be prevented from moving as that would destroy the structure. The

experimental vertebral specimens could not be pre-tapped to avoid

affecting the stability of the screws. The PMMA bone cement powder

and the water agent were uniformly mixed in the formulated ratio,

and the mixture was injected into the injection device during the

spinning period. During the cement injection process, the bone

cement flows out from the side holes and diffuses into the

cancellous bone around the screw. Attention should be paid to the

presence or absence of bone cement leakage from the rear end of the

screw. The above operations of screw placement were performed by a

clinically experienced spine surgeon. Following the methodology of

a previous study, all vertebral bodies were infused with 2.5 PMMA

for intensification, and the amount of bone cement in the hollow

part of the screw was subtracted (Fig.

1).

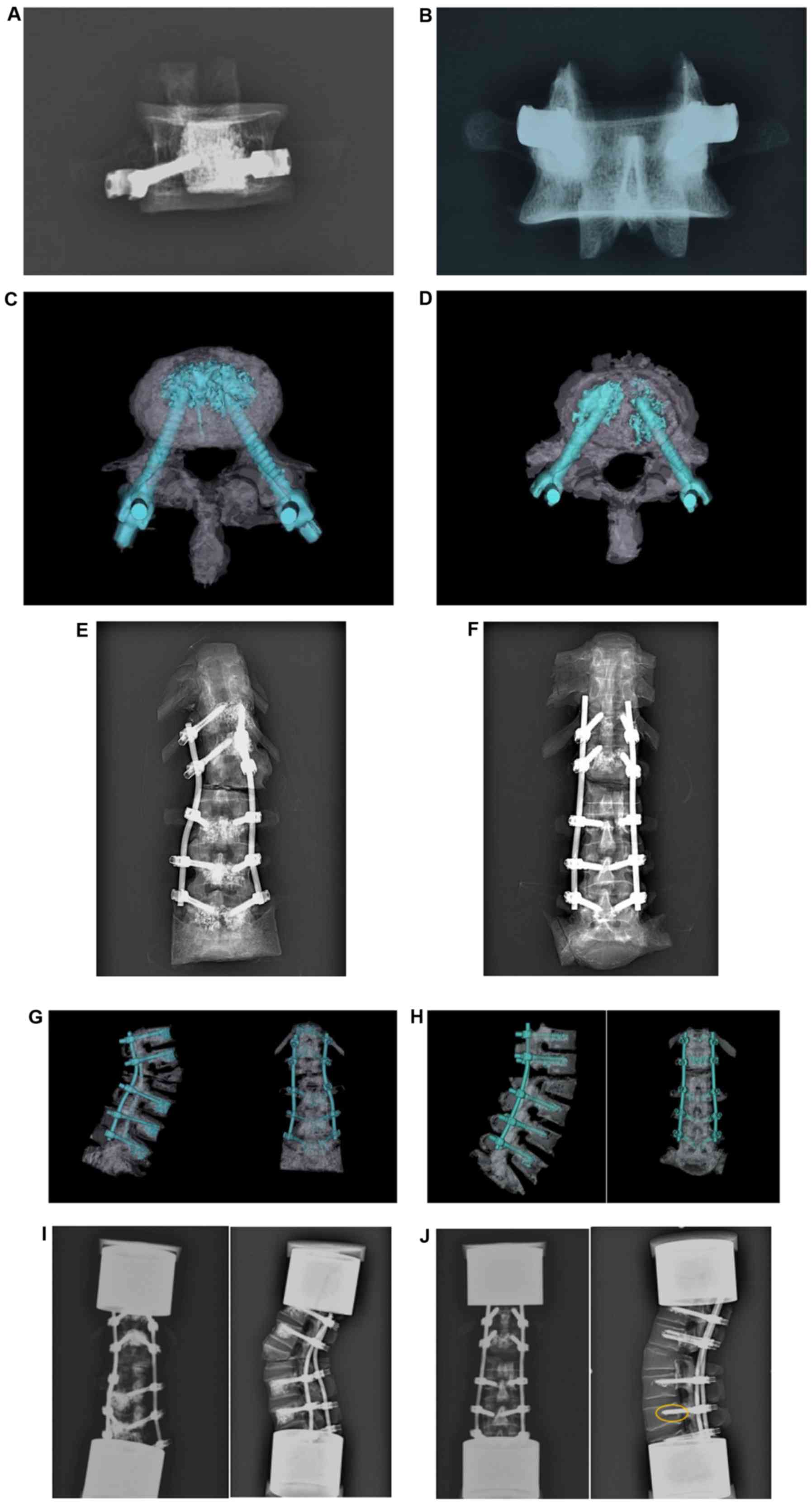

Radiographic evaluation. When the bone cement

screw placement and bone cement filling of the vertebral body

specimens was completed, the vertebral body specimens were allowed

to stand at room temperature for 24 h. After the bone cement in the

vertebral body specimen was completely solidified, CT scanning was

performed using an X-ray machine and 64-slice spiral CT (parameter:

200 mA, 130 KV, 1 mm slice thickness). In the later stage of the

experiment, the three-dimensional reconstruction of the bone cement

screw and the bone cement was performed using Mimics software, and

the positional relationship of the bone cement screw, the bone

cement and the cancellous bone of the vertebral body specimen was

observed. In this way, the shape of the bone cement in the

vertebral body, the position of the cement screw, and whether the

bone cement screw and the bone cement formed a bridge were

studied.

The axial withdrawal force test. The axial

pull-out force experiment was performed on a single vertebral

specimen with the help of a microcomputer-controlled electronic

universal testing machine. The vertebral body specimen was attached

to a special fixture, which was then fixed to the base of the

testing machine. The direction of the specimen was adjusted so that

the long axis direction of the bone cement screw was consistent

with the direction of the robot arm of the testing machine. The

arms and screw tails were secured by the upper clamp. The

extraction rate of the cement screw was set to a constant rate of 5

mm/min, and continued until the pull-out force decreased,

indicating that the cement screw was completely withdrawn. The

computer automatically recorded the load signal data of the test

machine and generated the load-displacement curve. The maximum

pullout strength (Fmax) of the cement screw was calculated by the

corresponding computer software (Fig.

2).

Cyclic loading test. Four spine specimens of

multiple vertebral bodies were embedded, and the lower end of the

spine specimen was trimmed, keeping the specimen erect and slightly

forward. The specimen was placed in an 8.6 cm-diameter embedding

tank, and embedded in a ratio of 2:1 with 100 g of a foundation

base material resin type II (self-curing denture acrylic) and 100

ml of liquid for denture acrylic. The specimen was kept up and down

horizontally for self-condensation. The specimen was then fixed on

a LETRY biomechanical fatigue testing machine. The upper end of the

specimen was fixed to the center of the groove of the embedding

block to provide an anterior flexion load for the test, and the

angle of the vise was adjusted to form the flexion angle required

for the cyclic load test. The fatigue testing machine was set to a

cyclic loading state with the following loading schedule: 3 h

total, cycle of 60/min, 10,000 revolutions, initial pressure of 300

N, peak pressure of 3,000 N, front flexion of 8˚ (Fig. 3).

Statistical analysis

The axial withdrawal force and cyclic load

experimental data were analyzed by SPSS 13.0 statistical software.

The measurement data were expressed as average ± standard deviation

(mean ± SD). Two independent sample t-tests were used for

comparison between groups. P<0.05 was considered statistically

significant.

Results

Imaging results

Through imaging analysis, all 9 specimens of the

single vertebral body group A were seen to have formed a triangular

stable structure by increasing the angle during the process of

screw placement. Nine specimens of the single vertebral body group

B were prepared according to the conventional screw placement and

did not have a front end bridge. In the multi-vertebral group A

(stereoscopic frame structure), the three-dimensional frame

structure was observed. The absence of obvious bone cement leakage

was confirmed by X-ray and CT three-dimensional reconstruction. The

multi-vertebral group B did not have a three-dimensional frame

structure (Fig. 4).

The result of maximal axial pull-out

strength test

The maximal pull-out force of the single-vertebral

group A, the screw front-end bridging group, was experimentally

measured as 1395.693±85.775. The maximal pull-out force of the

single-vertebral group B was 889.62±63.5. A statistically

significant difference (P<0.05) was found. The triangular

structure of the single vertebral body group A was stable, so the

maximum extraction force of the pedicle screw was higher.

The result of cyclic loading test

After the cyclic load test, the strain and

displacement of both groups increased, the stiffness decreased, and

the stability of the entire lumbar vertebra decreased. However, by

comparing the two groups, it was found that the screws of

multi-vertebral group A (stereoscopic frame) did not loosen

(Fig. 4I), while screw loosening

occurred in multi-vertebral group B (Fig. 4J). When compared with multi-vertebral

body group B, the stability of the spine in multi-vertebral group A

is better. As the cyclic loading force increases, this trend tends

to be obvious. The reason may be that an osteotomy specimen is used

for testing, which can more realistically simulate the clinical

situation. The biomechanical effects of the specimens are less

pronounced when subjected to smaller cyclic loads. As the cyclic

load increases, the influence becomes increasingly obvious,

resulting in the biomechanical instability of the spine and screw

loosening.

Discussion

An increasing challenge in spinal surgery is to

achieve optimal fixation of pedicle screws in poor bone conditions,

such as severe osteoporosis.

The restricted area is still a problem for some

patients with complex osteoporosis. In this study, the theory of

triangular stability of the single vertebral body was proposed, and

a three-dimensional framework structure was used to solve this

medical problem.

Studies have shown that under normal physiological

conditions, the various structures of the spine maintain their

normal positional relationship with each other and do not cause

compression and damage to the spinal cord or spinal nerve roots,

which is called ‘clinical stability’. When the spine loses this

function, it is termed ‘clinical instability’. The common method of

internal fixation cannot be used to sustain the stability of a

spine that is destroyed through serious osteoporosis and spinal

deformity.

This study proposes a theory that the triangular

stability of a single vertebral body and the three-dimensional

frame structure of multiple vertebral bodies can achieve the

stability of spinal internal fixation. The structure of internal

fixation used in clinical practice has been considered as a

quadrilateral structure of a single vertebral body. However, a

triangle is more stable compared with a quadrilateral when the edge

length and three angles of the triangle are fixed. As early as

1303, Zhu Shijie, an outstanding Chinese mathematician, published

this famous theory of triangles in his writing named Jade Mirror of

the Four Unknowns. When the two edges of a triangle are selected

randomly and the non-common endpoints of the two edges are

connected by the third side that is not flexible or bent, the

distance between the two ends and the angle between the two edges

is fixed. This is the explanation for the stability of a triangle.

If two adjacent edges of an n (n≥4)-sided polygon are selected

randomly, the non-common endpoints of the two sides are connected

by more than one edge. Therefore, the distance between the two

endpoints and the angle between the two edges is not fixed,

indicating that the n (n≥4)-sided polygon is unstable. In real

life, there are numerous buildings, designs and equipment using

triangles to achieve better stability. The frame of a bicycle,

fixing of doors and windows and the construction of buildings and

bridges, have all used the stability of triangles. In this study,

the triangular stability is used in the field of spinal internal

fixation to propose a theory of the triangular stability of a

single vertebral body and the three-dimensional frame structure of

multiple vertebral bodies.

The model was established through imaging analysis

of single vertebral triangular stability models and multiple

vertebral three-dimensional frame structure models, and the safe

dose of bone cement injection that was calculated using the finite

element model from previous experiments. By examining the X-ray and

CT three-dimensional reconstruction of the model, it could be seen

that the two bone cement screw front ends of the single vertebral

body were bridged and the multiple vertebral spine model had

established a three-dimensional frame structure, indicating that

the model was constructed successfully.

Patients with complex osteoporosis cannot be

operated on because of the loosening of screws. In addition, the

maximum axial pull-out strength of the spine is an important

indicator. Kiner et al (16)

compared the application of 8 mm diameter pedicle screws with

PMMA-enhanced 6 mm diameter pedicle screws in the vertebral body by

cyclic constant loading test. They found that the initial and final

stiffness of the larger diameter screws increased after cyclic

constant loading test. However, the 8 mm diameter pedicle screws

may be difficult to implant into all vertebral segments. Similarly,

Frankel et al (17) tested

the reconstructed thoracolumbar osteoporotic vertebral internal

fixation, and found that the cementation resulted in a 1.6-fold

increase in axial pull-out force. In addition, Moore et al

(18) and Renner et al

(19) both found that PMMA screw

reinforcement increased the axial pull-out force to 1.5 times the

normal pull-out force.

These studies have shown that there are two methods

to increase the axial pull-out strength of the screw. One is to

increase the diameter of the screw, which can make it difficult to

implant into all spinal segments. The other is to inject PMMA,

which can increase the maximum pull-out strength of the screw.

However, there is a risk of leakage if the amount of bone cement is

increased, and the pull-out strength of the screw will plateau when

the amount of bone cement reaches a certain dose value.

In this study, the front ends of the two screws were

bridged by controlling the angle of screw implantation and the

amount of bone cement. According to the experimental results, the

maximum pull-out strength of the single-vertebral group A, that is

the screw front-end bridging group, was 1395.693±85.775, and the

maximum pull-out strength of the single-vertebral group B was

889.62±63.5. The difference between the two groups was

statistically significant (P<0.05). The single vertebral body

group A was triangular stable, and the maximum pull-out strength of

the pedicle screw was stronger than that of group B, which made the

screw more stable.

The reason for patients with severe spinal deformity

having a surgical exclusion zone is that there is no strong, stable

internal fixation system to support the spine after surgery, and

structural stability is difficult to establish. Chiang et al

(20) isolated the lumbar vertebrae

and fractured vertebral bodies of three cadavers, and performed

vertebroplasty on the injured vertebral body alone or on the upper

level, applying cyclic compression force. When prophylactic

vertebroplasty was not performed in the vertebral segment, greater

height loss was observed in its vicinity. The authors hypothesized

that the non-reinforced vertebral body deformed more than the

articular surface, which resulted in increased bending moments and

greater height loss. Kebaish et al (21) used 18 spine specimens and managed

T10-L5 with internal fixation. In one group, the first fixed

segment of the uppermost of the segments to be internally fixed was

reinforced. The first fixed segment and the upper vertebral body of

the segment requiring internal fixation were cemented with bone

cement in all specimens. The reinforced and non-reinforced groups

were then compared, with vertical compression applied to both

experimental groups until the internal fixation failed. In the

non-reinforced group, the fracture rate at the proximal junction

was reduced by 33%. In the reinforced group, the fracture rate of

the proximal joint was reduced by 83%. In another study on internal

fixation biomechanics, Tan et al (22) confirmed that cement augmentation of

pedicle screws resulted in the most stable vertebral reconstruction

compared to a separate posterior screw-rod system, while flexible

rod extension minimized changes in range of motion at both adjacent

rod extension and distal non-instrumented levels. Finally, in a

finite element model of the posterior-lateral pedicle screw

structure of the short segment around a thoracolumbar burst

fracture, vertebroplasty reduces the stress applied to the screws

and rods (23).

Cement-reinforced pedicle screws clearly have an

effect on the vertebral body and biomechanical studies on the

spine. In addition to simple screw fixation, the factors of total

spinal stability should also be considered. It is important not

only to stabilize the pedicle screw of a single centrum, but also

to establish an effective internal fixation frame structure. This

study proposes a multi-vertebral space frame structure. A

three-dimensional frame spine model was established and a

controlled cyclic loading experiment was performed on a LETRY

biomechanical fatigue testing machine. In this study, the

three-dimensional frame spine model was subjected to cyclic loading

to simulate the daily stress of human spine, including axial and

buckling load external forces, in order to validate the multiple

vertebral three-dimensional frame structure. The results showed

that the height of intervertebral discs in both groups decreased

after cyclic constant loading test. An increase in displacement,

and a decrease in stiffness and the stability of the whole lumbar

spine also occurred in both groups. However, the stability of the

spine in group A was higher than that in group B. With the increase

of cyclic constant loading strength, the stability of the spine in

group A improved. This may be due to the use of osteotomy specimens

in the cyclic constant loading test, which was more realistic in

simulating the clinical situation. The effect of biomechanics is

not obvious when the specimens are subjected to small cyclic

constant loading strength, but it becomes more obvious with the

increase of cyclic constant loading strength, which leads to a

biomechanical instability of the spine.

We verified the triangular stability of a single

vertebral body and the availability of three-dimensional frame

theory through imaging evaluation, pull-out strength test and

cyclic constant loading test, which can provide a novel treatment

for patients with serious osteoporotic spinal diseases.

In conclusion, the results showed that the stability

of screws was significantly improved after the cement screw front

ends of the single vertebral body were bridged, and the stability

of a multiple vertebral spine was significantly improved after a

three-dimensional frame structure was established. This study can

provide a new method to improve the stability and reliability of

internal fixation in patients with serious osteoporotic spinal

diseases.

Acknowledgements

Not applicable.

Funding

The study was funded by National Natural Science

Foundation of China (no. 81301292).

Availability of data and materials

The datasets used and/or analyzed during the present

study are available from the corresponding author on reasonable

request.

Authors' contributions

JX wrote the manuscript. JX and TB performed Axial

Withdrawal Force Test. YY and ZW were responsible for Cyclic

Loading Test. ZY and WL contributed to observation indexes

analysis. The final version was read and adopted by all the

authors. All authors read and approved the final manuscript.

Ethics approval and consent to

participate

The study was approved by the Ethics Committee of

Xijing Hospital (Xi’an, China) and written informed consents were

signed by the patients and/or guardians.

Patient consent for publication

Not applicable.

Competing interests

The authors declare that they have no competing

interests.

References

|

1

|

Bernhardt M, Swartz DE, Clothiaux PL,

Crowell RR and White AA III: Posterolateral lumbar and lumbosacral

fusion with and without pedicle screw internal fixation. Clin

Orthop Relat Res. 284:109–115. 1992.PubMed/NCBI

|

|

2

|

Wray S, Mimran R, Vadapalli S, Shetye SS,

McGilvray KC and Puttlitz CM: Pedicle screw placement in the lumbar

spine: Effect of trajectory and screw design on acute biomechanical

purchase. J Neurosurg Spine. 22:503–510. 2015.PubMed/NCBI View Article : Google Scholar

|

|

3

|

La Maida GA, Luceri F, Gallozzi F, Ferraro

M and Bernardo M: Complication rate in adult deformity surgical

treatment: Safety of the posterior osteotomies. Eur Spine J. 24

(Suppl 7):879–886. 2015.PubMed/NCBI View Article : Google Scholar

|

|

4

|

Galbusera F, Volkheimer D, Reitmaier S,

Berger-Roscher N, Kienle A and Wilke HJ: Pedicle screw loosening: A

clinically relevant complication? Eur Spine J. 24:1005–1016.

2015.PubMed/NCBI View Article : Google Scholar

|

|

5

|

Law M, Tencer AF and Anderson PA:

Caudo-cephalad loading of pedicle screws: Mechanisms of loosening

and methods of augmentation. Spine. 18:2438–2443. 1993.PubMed/NCBI View Article : Google Scholar

|

|

6

|

Chao KH, Lai YS, Chen WC, Chang CM,

McClean CJ, Fan CY, Chang CH, Lin LC and Cheng CK: Biomechanical

analysis of different types of pedicle screw augmentation: A

cadaveric and synthetic bone sample study of instrumented vertebral

specimens. Med Eng Phys. 35:1506–1512. 2013.PubMed/NCBI View Article : Google Scholar

|

|

7

|

Higashino K, Kim JH, Horton WC and Hutton

WC: A biomechanical study of two different pedicle screw methods

for fixation in osteoporotic and nonosteoporotic vertebrae. J Surg

Orthop Adv. 21:198–203. 2012.PubMed/NCBI View Article : Google Scholar

|

|

8

|

Hamasaki T, Tanaka N, Kim J, Okada M, Ochi

M and Hutton WC: Pedicle screw augmentation with polyethylene tape:

A biomechanical study in the osteoporotic thoracolumbar spine. J

Spinal Disord Tech. 23:127–132. 2010.PubMed/NCBI View Article : Google Scholar

|

|

9

|

Tsai KJ, Murakami H, Horton WC, Fei Q and

Hutton WC: Pedicle screw fixation strength: A biomechanical

comparison between 4.5-mm and 5.5-mm diameter screws in

osteoporotic upper thoracic vertebrae. J Surg Orthop Adv. 18:23–27.

2009.PubMed/NCBI

|

|

10

|

Becker S, Chavanne A, Spitaler R, Kropik

K, Aigner N, Ogon M and Redl H: Assessment of different screw

augmentation techniques and screw designs in osteoporotic spines.

Eur Spine J. 17:1462–1469. 2008.PubMed/NCBI View Article : Google Scholar

|

|

11

|

Lei W and Wu Z: Biomechanical evaluation

of an expansive pedicle screw in calf vertebrae. Eur Spine J.

15:321–326. 2006.PubMed/NCBI View Article : Google Scholar

|

|

12

|

Liu D, Wu ZX, Gao MX, Wan SY, Shi L, Fu

SC, Wang J and Lei W: A new method of partial screw augmentation in

sheep vertebrae in vitro: Biomechanical and interfacial evaluation.

J Spinal Disord Tech. 24:318–324. 2011.PubMed/NCBI View Article : Google Scholar

|

|

13

|

Wan SY, Lei W, Wu ZX, Lü R, Wang J, Li B,

Fu SC and Zhan C: Micro-CT evaluation and histological analysis of

screw-bone interface of expansile pedicle screw in osteoporotic

sheep. Zhonghua Wai Ke Za Zhi. 45:1271–1273. 2007.(In Chinese).

PubMed/NCBI

|

|

14

|

Hao YX, Wu ZX and Yang Z: The clinical

application of expandable pedicle screws in the short segment

lumber fusion surgery in osteoporosis patients. Zhongguo Ji Zhu Ji

Sui Za Zhi. 27:136–141. 2017.(In Chinese).

|

|

15

|

Liu D, Shi L, Lei W, Wei MQ, Qu B, Deng SL

and Pan XM: Biomechanical comparison of expansive pedicle screw and

polymethylmethacrylate-augmented pedicle screw in osteoporotic

synthetic bone in primary implantation: An experimental study. Clin

Spine Surg. 29:E351–E357. 2016.PubMed/NCBI View Article : Google Scholar

|

|

16

|

Kiner DW, Wybo CD, Sterba W, Yeni YN,

Bartol SW and Vaidya R: Biomechanical analysis of different

techniques in revision spinal instrumentation: Larger diameter

screws versus cement augmentation. Spine. 33:2618–2622.

2008.PubMed/NCBI View Article : Google Scholar

|

|

17

|

Frankel BM, D'Agostino S and Wang C: A

biomechanical cadaveric analysis of

polymethylmethacrylate-augmented pedicle screw fixation. J

Neurosurg Spine. 7:47–53. 2007.PubMed/NCBI View Article : Google Scholar

|

|

18

|

Moore DC, Maitra RS, Farjo LA, Graziano GP

and Goldstein SA: Restoration of pedicle screw fixation with an in

situ setting calcium phosphate cement. Spine. 22:1696–1705.

1997.PubMed/NCBI View Article : Google Scholar

|

|

19

|

Renner SM, Lim TH, Kim WJ, Katolik L, An

HS and Andersson GB: Augmentation of pedicle screw fixation

strength using an injectable calcium phosphate cement as a function

of injection timing and method. Spine. 29:E212–E216.

2004.PubMed/NCBI View Article : Google Scholar

|

|

20

|

Chiang CK, Wang YH, Yang CY, Yang BD and

Wang JL: Prophylactic vertebroplasty may reduce the risk of

adjacent intact vertebra from fatigue injury: An ex vivo

biomechanical study. Spine. 34:356–364. 2009.PubMed/NCBI View Article : Google Scholar

|

|

21

|

Kebaish KM, Martin CT, O'Brien JR, LaMotta

IE, Voros GD and Belkoff SM: Use of vertebroplasty to prevent

proximal junctional fractures in adult deformity surgery: A

biomechanical cadaveric study. Spine J. 13:1897–1903.

2013.PubMed/NCBI View Article : Google Scholar

|

|

22

|

Tan JS, Singh S, Zhu QA, Dvorak MF, Fisher

CG and Oxland TR: The effect of cement augmentation and extension

of posterior instrumentation on stabilization and adjacent level

effects in the elderly spine. Spine. 33:2728–2740. 2008.PubMed/NCBI View Article : Google Scholar

|

|

23

|

Xu G, Fu X, Du C, Ma J, Li Z and Ma X:

Biomechanical effects of vertebroplasty on thoracolumbar burst

fracture with transpedicular fixation: A finite element model

analysis. Orthop Traumatol Surg Res. 100:379–383. 2014.PubMed/NCBI View Article : Google Scholar

|