Introduction

Calcaneal fractures constitute approximately 2% of

all fractures presenting to the emergency room. Most of them are

highly comminuted and involve the posterior subtalar joint

(1-4).

The optimal treatment remains controversial, with conservative and

surgical procedures still in use to date (5-7).

The preferred method of the present research group

is surgical reduction with the addition of an autologous bone graft

from the iliac crest. However, the high morbidity of this type of

fracture is well known; most patients returning to work after a

lengthy period, while some are unable to work even after one year.

This fact produces physical and psychological disabilities for the

patient, as well as increased costs to society (8-10).

Bone healing is a biological and physiological

process controlled by biochemical, hormonal and mechanical factors.

The bone is a continuous evolving entity through remodeling. Bone

deposition and resorption is dependent on the blood supply, the

cells that promote healing and the stability of the fixation, in

case of fractures (11).

Autologous bone grafts were the first choice for

numerous years. In theory, they have the characteristics required

for bone healing and integration. However, the resources for bone

grafts are limited, and second interventions increase residual pain

for the patient (12-14).

In addition, due to the fact that bone grafting from

the iliac crest is a painful limited procedure with complications

ranging from nerve injury, infection, persistent pain to cosmetic

deformity, a safe and solid alternative was investigated (15).

In recent years, new materials have been developed

to replace natural bone. The widely used products were composed of

calcium phosphate ceramics and other biosynthetic composites. In

clinical trials, these types of grafts were revealed to be too weak

and with limited osteoinduction (16-20).

The calcaneus fracture occurs in one of the few

places in the human body where the stress shielding is limited at

low levels. Moreover, it requires at least 3 months to heal

properly, thus a slow resorption graft is required. All these

characteristics promote the use of magnesium (Mg) as a grafting

option.

Mg has acceptable mechanical properties and it is

one of the most important elements, stored in bones and essential

in metabolic processes. Daily doses of Mg are provided continuously

in regular food, in a sufficient amount that can stimulate bone

cell growth and can improve the healing time of the bone. Mg is

eliminated from the body in the presence of chlorine throughout the

kidneys (21,22).

Since massive Mg alloy grafts are not commonly used,

the calcaneus is in our opinion a perfect site for a structural

graft in a preclinical study. An anticipated successful result will

allow us to preserve a markedly favorable graft donor site for more

life threatening pathologies, including malignancies, and to reduce

morbidity of the lower foot. In the future, this type of synthetic

graft can be used for an increasing number of different

pathologies.

The data in specialty literature is vast, thus, the

most important Mg alloys are considered and reviewed for their

properties and a direct clinical future approach is focused on by

finding the appropriate design for the need of patients in this

preclinical study.

Materials and methods

From a therapeutic point of view, calcaneal

fractures represent a challenge. Most of the highly comminuted

injuries require bone grafts to restore Bohler's angle. This

variable represents the degree of inclination of the articular

surfaces of the calcaneus. A lateral approach is required to access

the smashed bone. After open reduction, a large ‘missing’ bone is

found. At this level, a graft is generally used to restore and hold

the height of the calcaneus and to correct varus deviation

(23). The need for using a plate

is frequent, fixing it with screws. This is, in our opinion, a

perfect place for the usage of a synthetic graft. There is no major

blood supply and the artificial metal graft does not come in

contact with the steel plate, thus avoiding the risk of metallosis.

The graft is protected and is held in place by a proposed design

and hidden behind the lateral wall of the calcaneus. This design

for the grafts, presented in the following section, is reproducible

and can be used in this form and dimension to all Sanders 3 and 4

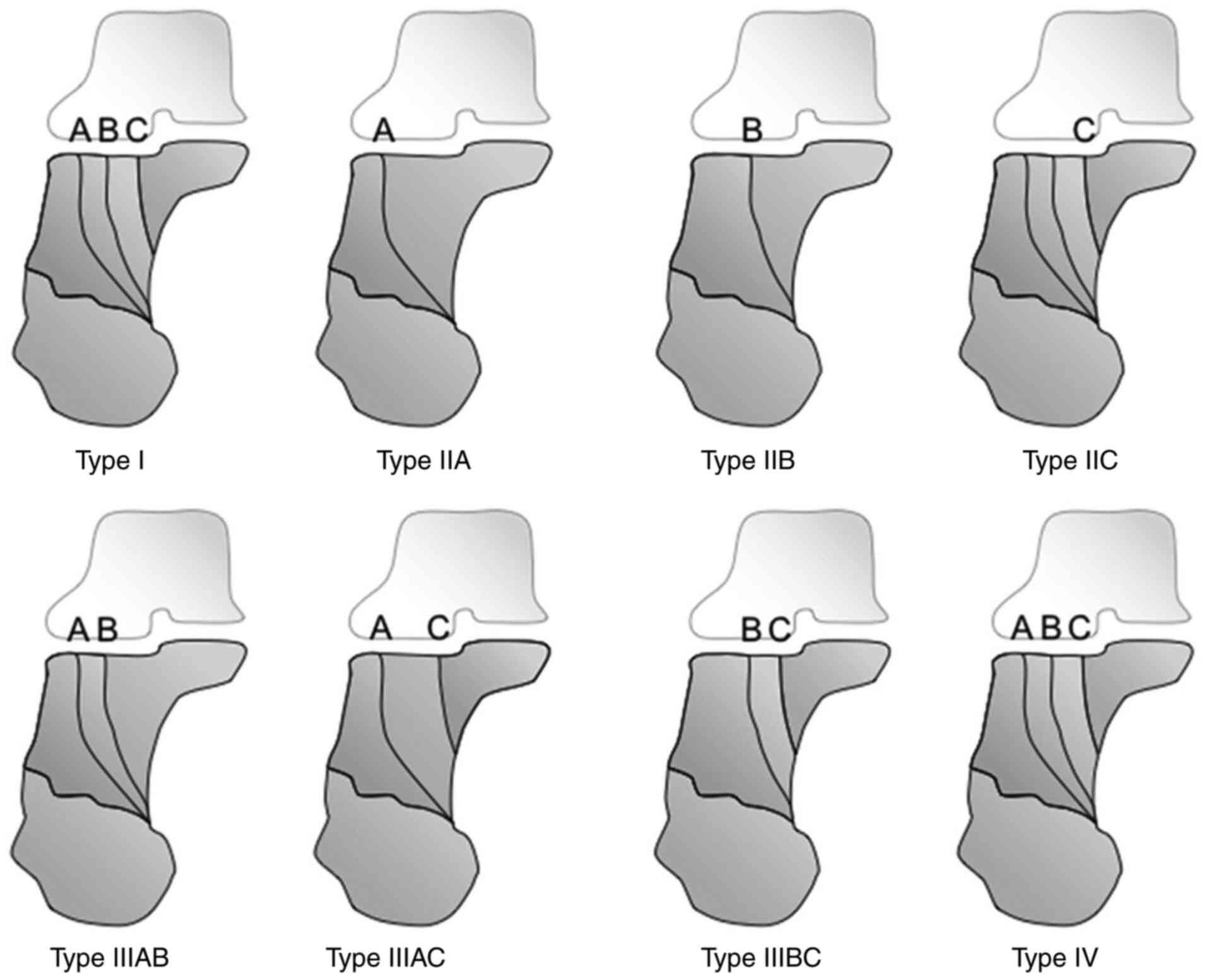

of the calcaneal fractures (Sanders classification) (Fig. 1) (24).

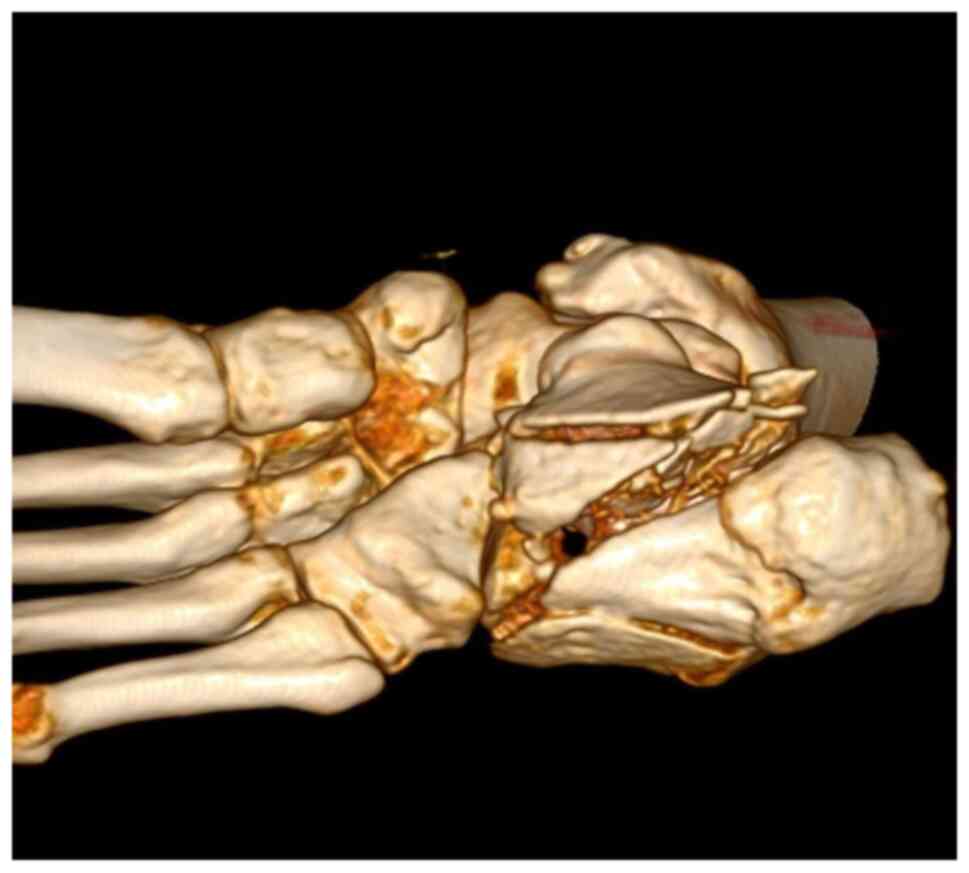

A CT scan with 3D reconstruction is absolutely

necessary in evaluating the degree of comminution and assessing the

decision to use a graft (Fig. 2,

Fig. 3 and Fig. 4). Thus, using these CT scans and

measurements, and taking into consideration that most patients with

comminuted calcaneal fractures are males, men between 30 to 60

years old and non-smokers, should be selected as the perfect

candidates, to prevent skin necrosis, for the next, clinical phase

of this study.

Mg alone has a high corrosion rate (25-30),

thus in theory, it could not be used in orthopedics. Nevertheless,

alloys have markedly improved characteristics including

biodegradation, resistance to fatigue, ductility or strength being

required as to be fully used in vivo.

In addition, Mg structures are potentially

compatible to the human body because they are osteoconductive and

biodegradable. The mechanical properties are similar to that of

bones and the most important aspect is the capacity to stimulate

the formation of new bone. However, the rapid degradation of this

material, faster than bone healing and its formation, can lead to

gas cavities, osteolysis and poor clinical results (25). Therefore, the appropriate type of Mg

alloy had to theoretically be identified for our application and

the optimal surface appearance of the design had to be decided.

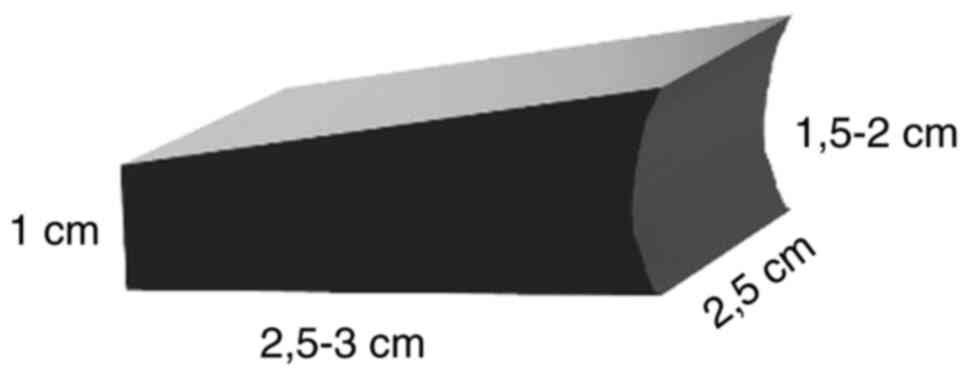

Using CT reconstruction, multiple angle x-rays and our surgical

experience, a 3D model similar to the iliac graft was developed in

Windows 3D Viewer (Microsoft Corporation).

Previous research, in vitro, which suggested

the appearance of red blood cell lysis and decreased survival of

mesenchymal stromal cells, when using some Mg alloys, was

considered (26), because of the

tendency for tissue damage.

An attempt was also made to identify the

relationship between Mg alloy products and bacterial load, since

calcaneal fractures are prone to skin necrosis and septic

complications.

Results

In the first stage of finding the appropriate alloy,

the already commercially available products were identified and the

data from literature was used to include them in further tests.

After a close review of international prestigious publications

(21,22,25-45),

the mechanical properties of Mg1Ca and MgYREZr were selected and

compared to normal cortical and cancellous bone. For references,

Ti6Al4V and a markedly close to pure form of Mg were also assessed.

Results are presented in the Table

I.

| Table IMechanical properties of test

prototypes and bone. |

Table I

Mechanical properties of test

prototypes and bone.

| Tissue | Tensile strength

(MPa) | Young's modulus

(GPa) | Density

(g/cm3) |

|---|

| Cortical Bone | 35-280 | 5-22 | 1.8-2.0 |

| Cancellous Bone | 1-40 | 0.01-1.58 | 1.0-1.4 |

| Pure Mg | 90 | 44 | 1.74 |

| MgYREZr | 250-280 | 44-46 | 1.84 |

| Mg1Ca | 75-240 | - | 1.73 |

| Ti6Al4V | 895-930 | 110-114 | 4.43 |

Clearly, from a mechanical point of view, the

synthetic graft needs to be as strong as the bone, in order to

maintain the correction of the Bohler's angle to a normal range of

20˚ to 40˚.

The fixation of the graft is not necessary because

it will be covered and kept in place by the superior calcaneus

fragments and the lateral wall. A plate is required to stabilize

the fragments. Since the construction of an Mg alloy plate is

beyond our capabilities at the moment, but may be attempted in a

future study, a 3D render with the design is presented in Fig. 5.

Due to the corrosion issue, a selenium-containing

coating using micro-arc oxidation was selected. Data from

literature clearly indicated that improved corrosion resistance was

achieved in this manner (27). In

theory, a minimum of a 3-month period of implant and reduction

stability is required until the external shell of the calcaneus is

healed. After this period, the full strength of the alloy graft is

not required anymore. Tensile strength is the main reason why

MgYREZr was selected, since Mg1Ca has a tensile strength as low as

75 MPa.

In addition, a small Mg alloy graft implanted in a

female mouse (4 months old; weight, 31 g; provided by the

Experimental Medicine Center of the Faculty of Veterinary Medicine

of Bucharest), that was already infected with Pseudomonas

for antibiotic testing, was also assessed. During the experiment

the mouse was maintained in a cage specially designed for this type

of species. The cage was placed in a controlled environment with a

10-h light/14-h dark cycle, a temperature between 18-22˚C and

40-50% humidity. Food and water were available ad libitum.

The use of the animal was approved by the Ethics Committee of the

Faculty of Veterinary Medicine of Bucharest (Bucharest, Romania).

No changes in response to the antibiotics were observed, however

this test was not sufficient in our opinion. Considering data from

literature, caution should be taken when affirming that Mg alloys

do not influence the antibacterial response of the biological

matter (28). Since calcaneal

fractures are prone to infections, the need for extra antibacterial

procedures and antibiotic prophylaxis is highlighted.

Discussion

AZ alloys have been recently tested, especially AZ31

(Mg3Al1Zn) and AZ91 (Mg9Al1Zn), in vitro and in vivo.

Both release large quantities of hydrogen on biodegradation in

organic matter, increasing the pH and Mg concentration (29-32).

In a small study, Witte et al determined that a Ca phosphate

coating could stimulate bone formation around the graft and

decrease absorption (33).

Magnesium alloys containing rare earth elements have

excellent corrosion resistance due to the formation of an oxide

film (rare earth oxide film) in a ‘humid’ environment. WE54 (4.85

Yttrium, 1.58 Neodymium, 0.28 Zirconium, 0.08 Cerium, 0.13

Gadolinium, 0.16 Erbium and Mg balanced) has an improved rate of

degradation in vitro than Mg alone if heat treatment is

applied. WE43 (4.16 Yttrium, 3.80 RE, 0.36 Zirconium, 0.20 Zinc,

and 0.13 Manganese) has good biocompatibility, but it increases

aluminum ions in the brain, increasing the risk of Alzheimer's

disease. Rare-earth elements are associated with severe

hepatotoxicity (34,35).

ZK40 (Mg4Zn0.5Zr) and ZK60 (Mg6Zn0.5Zr) have

excellent biocompatibility and small doses of daily zinc are safe

for humans, thus, Mg-Zinc alloys are better than alloys that

contain aluminum. However, these materials have high rates of

degradation and are not candidates for orthopedic use (36,37).

Medical Mg alloys, used before in orthopedic

surgeries include calcium, strontium, zinc or a combination of

rare-earth elements. Alloys containing Ca as a grain-refining

agent, and strontium (similar proprieties to calcium) are used to

increase the compatibility with the human bone combined with low

toxicity (38). Strontium alloys

are known to be the slowest in degrading. In data published, Zhao

et al (39) concluded that

Mg2Sr has the highest corrosion resistance with high tensile

strength and good compatibility (40).

Zinc is present in the human body, it has almost no

toxicity and it can be used to strengthen the Mg alloy through

solid solution hardening. Therefore, biocompatibility is excellent

(41).

Some elements in the Mg alloy implants form

second-phase particles which can precipitate in grains, conferring

better mechanical properties by strengthening the material

(42-44).

When selecting Mg alloy implants as bone grafts, the

stability and strength of second phases and the Mg matrix in

vivo conditions, can influence the degradation time and

biological response of the body concerning the implant. Yang et

al used the Dmol3 calculation method (44) for determining the stability of four

second-phase Mg-Ca, Mg-Sr, Mg-Zn-Zr, Mg-Al-Zn alloys, these having

higher phase stability than the Mg matrix. In the Mg-Al-Zn alloy,

the Mg17Al12 second phase had good

cytocompatibility in vitro and did not induce hemolysis

(42).

Also, not all alloys form second phase particles.

For example, in high quantities, Yttrium does not form second-phase

particles due to the high solid solubility in Mg, thus presenting

under the form of solid solutions and achieving solid solution

strengthening (41-43).

This solid solution strengthening affects also the degradation of

the Mg alloys improving the corrosion rate because of reducing the

internal galvanic corrosion between the second phase and Mg matrix

(45).

One important aspect in designing and proposing this

Mg alloy for medical use, is the problem of impurities. During

casting, impurities are introduced in the alloy, especially iron,

nickel and copper. They can influence the corrosion characteristics

of the product and can also be toxic for the human body. For

example, nickel is extremely toxic for the human body. Copper has a

high toxicity on the cell membrane. Therefore, when casting, molds

without such elements should be used (21,46,47).

Since a surgical approach to the calcaneus is prone

to skin complications and sometimes sepsis, antibiotic prophylaxis

should always be used. Vancomycin 1-1.5 g, one dose, 2 h before

surgery is recommend. After surgery, the lower limb should be

rested at a higher body level, in a fiber cast. Ice should be

applied daily to prevent hematoma (48).

Data in literature regarding any bond between Mg

implants and hematoma could not be found, but attention should also

be paid to the prevention of infections.

The goal of the present study was to determine a

close to perfect site location for artificial metal grafts. Since

the iliac crest is a markedly favorable graft, being used in

extremely complicated diseases and it exists in limited quantity,

it is considered that the novelty of using large magnesium alloy

implants is beneficial (11).

In conclusion, artificial materials are the future

in medicine replacing the body-limiting grafting capabilities. They

are safe and incur less comorbidities (49). This method could pave the way in

reducing the discomfort and increasing the satisfaction of

patients. Although further testing is required, this research

represents a great starting point (50).

Numerous aspects have to be refined until this

solution can be widely used. Our goal is not only patient

satisfaction, but also the decrease of hospital charges and

markedly faster rehabilitation. Patients can go back to work

faster, in theory, without extra risks associated. Another problem

that is often encountered is that a great number of patients are

not in favor of the bone grafting therapeutic option. A fixation

for this type of injury, without grafting is less stable and more

prone to failure and dissatisfaction (1,3,5). Using

an Mg alloy graft assists this issue and appears to be a safe

‘fix’.

In addition, in the case of failure, there is always

the option of second-stage bone grafting or talo-calcaneal

arthrodesis (51).

It is considered that the future of Mg alloys in

orthopedics and in general medicine is certain, but more studies

are required, for refining and testing and multi-disciplinary teams

should work together to discover and demonstrate the best

options.

The present study represents a starting point, by

finding a favorable biological site for Mg grafts. A suitable Mg

alloy was revealed, appropriate for our strategy. The present study

is not an ending, but a beginning.

Acknowledgements

Professional editing, linguistic and technical

assistance was performed by Irina Radu, Individual Service

Provider, certified translator in Medicine and Pharmacy

(certificate credentials: Series E no. 0048).

Funding

Funding: No funding was received.

Availability of data and materials

All data generated or analyzed during this study are

included in this published article.

Author's contributions

SD planned the clinical study, contributed to the

conception and design of the study, and the acquisition, analysis

and interpretation of the data. DCC contributed to the analysis and

interpretation of the data and the critical revision for important

intellectual content. CDMD contributed to the conception and design

of the study, analysis of data, the drafting of the manuscript and

its critical revision for important intellectual content. CS

contributed to the conception and design of the study and the

critical revision of the manuscript for important intellectual

content. CIS contributed to the conception and design of the study,

the interpretation of the data and the critical revision of the

manuscript for important intellectual content. All authors read and

approved the final version of the manuscript and agree to be

accountable for all aspects of the study.

Ethics approval and consent to

participate

The study on the one mouse used was approved by the

Ethics Committee from the Faculty of Veterinary Medicine in

Bucharest (Bucharest, Romania) with respect to the current

legislation regarding the protection of laboratory animals.

Patient consent for publication

Not applicable.

Competing interests

The authors declare that they have no competing

interests.

References

|

1

|

Schepers T, van Lieshout EM, van Ginhoven

TM, Heetveld MJ and Patka P: Current concepts in the treatment of

intra-articular calcaneal fractures: Results of a nationwide

survey. Int Orthop. 32:711–715. 2008.PubMed/NCBI View Article : Google Scholar

|

|

2

|

Atkins RM, Allen PE and Livingstone JA:

Demographic features of intra-articular fractures of the calcaneum.

Foot Ankle Surg. 7:77–84. 2001.

|

|

3

|

Soeur R and Remy R: Fractures of the

calcaneus with displacement of the thalamic portion. J Bone Joint

Surg Br. 57:413–421. 1975.PubMed/NCBI

|

|

4

|

Slatis P, Kiviluoto O, Santavirta S and

Laasonen EM: Fractures of the calcaneum. J Trauma. 19:939–943.

1979.PubMed/NCBI View Article : Google Scholar

|

|

5

|

Buckley R, Tough S, McCormack R, Pate G,

Leighton R, Petrie D and Galpin R: Operative compared with

nonoperative treatment of displaced intra-articular calcaneal

fractures: A prospective, randomized, controlled multicenter trial.

J Bone Joint Surg Am. 84:1733–1744. 2002.PubMed/NCBI View Article : Google Scholar

|

|

6

|

Essex-Lopresti P: The mechanism, reduction

technique, and results in fractures of the os calcis. Br J Surg.

39:395–419. 1952.PubMed/NCBI View Article : Google Scholar

|

|

7

|

Rak V, Ira D and Masek M: Operative

treatment of intra-articular calcaneal fractures with calcaneal

plates and its complications. Indian J Orthop. 43:271–280.

2009.PubMed/NCBI View Article : Google Scholar

|

|

8

|

Bajammal S, Tornetta P III, Sanders D and

Bhandari M: Displaced intra-articular calcaneal fractures. J Orthop

Trauma. 19:360–364. 2005.PubMed/NCBI

|

|

9

|

Brauer CA, Manns BJ, Ko M, Donaldson C and

Buckley R: An economic evaluation of operative compared with

nonoperative management of displaced intra-articular calcaneal

fractures. J Bone Joint Surg Am. 87:2741–2749. 2005.PubMed/NCBI View Article : Google Scholar

|

|

10

|

Pozo JL, Kirwan EO and Jackson AM: The

long-term results of conservative management of severely displaced

fractures of the calcaneus. J Bone Joint Surg Br. 66:386–390.

1984.PubMed/NCBI View Article : Google Scholar

|

|

11

|

Stark JG: Use of selective estrogen

receptor modulator for joint fusion and other healing of connective

tissue. US Patent 8,501,690 B2, Filed April 30, 2010; issued August

6, 2013.

|

|

12

|

Liu C, Wan P, Tan LL, Wang K and Yang K:

Preclinical investigation of an innovative magnesium-based bone

graft substitute for potential orthopaedic applications. J Orthop

Translat. 2:139–148. 2014.

|

|

13

|

Calori GM, Mazza E, Colombo M and

Ripamonti C: The use of bone-graft substitutes in large bone

defects: Any specific needs? Injury. 42 (Suppl 2):S56–S63.

2011.PubMed/NCBI View Article : Google Scholar

|

|

14

|

Van der Stok J, Van Lieshout EM,

El-Massoudi Y, Van Kralingen GH and Patka P: Bone substitutes in

the Netherlands-a systematic literature review. Acta Biomater.

7:739–750. 2011.PubMed/NCBI View Article : Google Scholar

|

|

15

|

Almaiman M, Al-Bargi HH and Manson P:

Complication of anterior iliac bone graft harvesting in 372 adult

patients from May 2006 to May 2011 and a literature review.

Craniomaxillofac Trauma Reconstr. 6:257–266. 2013.PubMed/NCBI View Article : Google Scholar

|

|

16

|

Böstman O and Pihlajamäki H: Clinical

biocompatibility of biodegradable orthopaedic implants for internal

fixation: A review. Biomaterials. 21:2615–2621. 2000.PubMed/NCBI View Article : Google Scholar

|

|

17

|

Auer JA, Rechenberg BV, Bohner M and

Hofmann-Amtenbrink M: Bone grafts and bone replacements. Equine

Surg. 2012:1081–1096. 2012.

|

|

18

|

Dias AG, Lopes MA, Gibson IR and Santos

JD: In vitro degradation studies of calcium phosphate glass

ceramics prepared by controlled crystallization. J Non Cryst

Solids. 330:81–89. 2003.

|

|

19

|

Kim HM: Ceramic bioactivity and related

biomimetic strategy. Curr Opin Solid State Materials Sci.

7:289–299. 2003.

|

|

20

|

Giannoudis PV, Dinopoulos H and Tsiridis

E: Bone substitutes: An update. Injury. 36 (Suppl 3):S20–S27.

2005.PubMed/NCBI View Article : Google Scholar

|

|

21

|

Waizy H, Seitz JM, Reifenrath J, Weizbauer

A, Bach FW, Meyer-Lindenberg A, Denkena B and Windhagen H:

Biodegradable magnesium implants for orthopedic applications. J

Mater Sci. 48:39–50. 2013.

|

|

22

|

Seal CK, Vince K and Hodgson MA:

Biodegradable surgical implants based on magnesium alloys-A review

of current research. IOP Conf Ser: Mater Sci Eng: 4, 2009.

|

|

23

|

Su Y, Chen W, Zhang T, Wu X, Wu Z and

Zhang Y: Bohler's angle's role in assessing the injury severity and

functional outcome of internal fixation for displaced

intra-articular calcaneal fractures: A retrospective study. BMC

Surg. 13(40)2013.PubMed/NCBI View Article : Google Scholar

|

|

24

|

Sanders R, Fortin P, DiPasquale T and

Walling A: Operative treatment in 120 displaced in-traarticular

calcaneal fractures. Results using a prognostic computed

Tomogra-phy scan classification. Clin Orthop Relat Res. 290:87–95.

1993.PubMed/NCBI

|

|

25

|

Kuhlmann J, Bartsch I, Willbold E,

Schuchardt S, Holz O, Hort N, Höche D, Heineman WR and Witte F:

Fast escape of hydrogen from gas cavities around corroding

magnesium implants. Acta Biomaterialia. 9:8714–8721.

2013.PubMed/NCBI View Article : Google Scholar

|

|

26

|

Lukyanova E, Yu N, Yu AN, Martynenko AN,

Martynenko N and Estrin Y: Features of in vitro and in vivo

behaviour of magnesium alloy WE43. Materials Lett. 215:308–311.

2018.

|

|

27

|

Xiaoting S, Yuanyuan Z, Shufang Z,

Rongfang Z, Rongfa Z, Chen L and Yijia Z: Characteristics of

selenium-containing coatings on WE43 magnesium alloy by micro-arc

oxidation. Mater Lett. 261(126944)2020.

|

|

28

|

Rahim MI, Ullah S and Mueller PP: Advances

and challenges of biodegradable implant materials with a focus on

magnesium-alloys and bacterial infections. Metals. 8(532)2018.

|

|

29

|

Ding Y, Wen C, Hodgson P and Li Y: Effects

of alloying elements on the corrosion behavior and biocompatibility

of biodegradable magnesium alloys: A review. J Mater Chem B.

2:1912–1933. 2014.PubMed/NCBI View Article : Google Scholar

|

|

30

|

Wang H and Shi Z: In vitro biodegradation

behavior of magnesium and magnesium alloy. J Biomed Mater Res Part

B Appl Biomater. 98:203–209. 2011.PubMed/NCBI View Article : Google Scholar

|

|

31

|

Song Y, Shan D, Chen R, Zhang F and Han

EH: Biodegradable behaviors of AZ31 magnesium alloy in simulated

body fluid. Mater Sci Eng C. 29:1039–1045. 2009.

|

|

32

|

Yan T, Tan L, Xiong D, Liu X, Zhang B and

Yang K: Fluoride treatment and in vitro corrosion behavior of an

AZ31B magnesium alloy. Mater Sci Eng C. 30:740–748. 2010.

|

|

33

|

Witte F, Fischer J, Nellesen J, Crostack

HA, Kaese V, Pisch A, Beckmann F and Windhagen H: In vitro and in

vivo corrosion measurements of magnesium alloys. Biomaterials.

27:1013–1018. 2006.PubMed/NCBI View Article : Google Scholar

|

|

34

|

Witte F, Kaese V, Haferkamp H, Switzer E,

Meyer-Lindenberg A, Wirth CJ and Windhagen H: In vivo corrosion of

four magnesium alloys and the associated bone response.

Biomaterials. 26:3557–3563. 2005.PubMed/NCBI View Article : Google Scholar

|

|

35

|

Tan L, Yu X, Wan P and Yang K:

Biodegradable materials for bone repairs: A review. J Mater Sci

Technol. 29:503–513. 2013.

|

|

36

|

Hong D, Saha P, Chou DT, Lee B, Collins

BE, Tan Z, Dong Z and Kumta PN: In vitro degradation and

cytotoxicity response of Mg-4% Zn-0.5% Zr (ZK40) alloy as a

potential biodegradable material. Acta Biomater. 9:8534–8547.

2013.PubMed/NCBI View Article : Google Scholar

|

|

37

|

Gu XN, Li N, Zheng YF and Ruan L: In vitro

degradation performance and biological response of a Mg-Zn-Zr

alloy. Mater Sci Eng B. 176:1778–1784. 2011.

|

|

38

|

Li Z, Gu X, Lou S and Zheng Y: The

development of binary Mg-Ca alloys for use as biodegradable

materials within bone. Biomaterials. 29:1329–1344. 2008.PubMed/NCBI View Article : Google Scholar

|

|

39

|

Zhao C, Pan F, Zhang L, Pan H, Song K and

Tang A: Microstructure, mechanical properties, bio-corrosion

properties and cytotoxicity of as-extruded Mg-Sr alloys. Mater Sci

Eng C Mater Biol Appl. 70:1081–1088. 2017.PubMed/NCBI View Article : Google Scholar

|

|

40

|

Kannan MB: Influence of microstructure on

the in-vitro degradation behaviour of magnesium alloys. Mater Lett.

64:739–742. 2010.

|

|

41

|

Zhang S, Zhang X, Zhao C, Li J, Song Y,

Xie C, Tao H, Zhang Y, He Y, Jiang Y and Bian Y: Research on an

Mg-Zn alloy as a degradable biomaterial. Acta Biomater. 6:626–640.

2010.PubMed/NCBI View Article : Google Scholar

|

|

42

|

Liu C, He P, Wan P, Li M, Wang K, Tan L,

Zhang Y and Yang K: The in vitro biocompatibility and macrophage

phagocytosis of Mg17Al12 phase in Mg-Al-Zn alloys. J Biomed Mater

Res A. 103:2405–2415. 2015.PubMed/NCBI View Article : Google Scholar

|

|

43

|

Gao L, Chen RS and Han EH: Solid solution

strengthening behaviors in binary Mg-Y single phase alloys. J

Alloys Compd. 472:234–240. 2009.

|

|

44

|

Yang H, Liu C, Wan P, Tan L and Yang K:

Study of second phase in bioabsorbable magnesium alloys: Phase

stability evaluation via Dmol3 calculation. APL

Materials: Nov 8, 2013 (Epub ahead of print) doi:

org/10.1063/1.4828935.

|

|

45

|

Zhang X, Zhang K, Li X, Deng X, LI Y, Ma M

and Shi Y: Effect of solid-solution treatment on corrosion and

electrochemical behaviors of Mg-15Y alloy in 3.5 wt.% NaCl

solution. J Rare Earths. 30:1158–1167. 2012.

|

|

46

|

Südholz AD, Kirkland NT, Buchheit RG and

Birbilis N: Electrochemical properties of intermetallic phases and

common impurity elements in magnesium alloys. Electrochem Solid St

Lett. 14(C57)2011.

|

|

47

|

Hofstetter J, Martinelli E, Pogatscher S,

Schmutz P, Povoden-Karadeniz E, Weinberg AM, Uggowitzer PJ and

Löffler JF: Influence of trace impurities on the in vitro and in

vivo degradation of biodegradable Mg-5Zn-0.3Ca alloys. Acta

Biomater. 23:347–353. 2015.PubMed/NCBI View Article : Google Scholar

|

|

48

|

Crawford T, Rodvold KA and Solomkin JS:

Vancomycin for surgical prophylaxis? Clin Infect Dis. 54:1474–1479.

2012.PubMed/NCBI View Article : Google Scholar

|

|

49

|

Chen L, Peng W, Li LT, Kehong W and Ke Y:

Preclinical investigation of an innovative magnesium-based bone

graft substitute for potential orthopaedic applications. J Orthop

Translat. 2:139–148. 2014.

|

|

50

|

Sommar P, Granberg Y, Halle M, Skogh AC,

Lundgren KT and Jansson KÅ: Effects of a formalized collaboration

between plastic and orthopedic surgeons in severe extremity trauma

patients; a retrospective study. J Trauma Manag Outcomes.

9(3)2015.PubMed/NCBI View Article : Google Scholar

|

|

51

|

Buch BD, Myerson MS and Miller SD: Primary

subtalar arthrodesis for the treatment of comminuted calcaneal

fractures. Foot Ankle Int. 17:61–70. 1996.PubMed/NCBI View Article : Google Scholar

|