1. Introduction

Orthopedic injuries and associated pathologies are

an important public health issue worldwide as well as a major

global burden of disability and suffering. It is estimated that the

musculoskeletal conditions affect approximately 1.71 billion

individuals globally (1). The

Global Burden of Disease, Injuries, and Risk Factors Study (GBD)

2019 reported for the 1990-2019 time period musculoskeletal

disorders as one of the 10 significant causes of enhancing burden

from teenage years to older age with a 30.7% increase in DALY rates

(Disability-Adjusted Life-Years) (2). These conditions or orthopedic trauma

often require surgery and the use of permanent, temporary or

biodegradable medical devices that include various natural or

synthetic biomaterials able to substitute or repair different

tissues (ligaments, tendons, cartilage, bone). The design of the

medical device, functional properties of biomaterials and the

bioresponse are some of the key players that determine the clinical

success of the orthopedic intervention. Apart from their

mechanical, microstructural and chemical characteristics,

biomaterials are screened for their innocuity, biocompatibility,

safety and efficacy for the clinical efficacy (3).

Biocompatibility, one of the most important features

of biomaterials, is defined as ‘the ability of a biomaterial to

perform its desired function with respect to a medical therapy,

without eliciting any undesirable local or systemic effects on the

recipient or beneficiary of that therapy, but meanwhile generating

the most optimized clinically relevant performance of that therapy’

or ‘the ability of a material to perform with an appropriate host

response in a specific situation’ (3,4). Thus,

biocompatibility testing is a primary requirement in the

development and the approval of orthopedic materials for clinical

use by regulatory agencies. Biomaterials need to meet basic

biocompatibility criteria as set by the International Standards

Organization (ISO 10993). They must be nontoxic, nonthrombogenic,

noncarcinogenic, nonantigenic and nonmutagenic in order to exhibit

an appropriate biological response (5).

In this regard, biocompatibility testing is a

complex process that include in vitro and in vivo

specific tests depending on the end-use application of the

biomaterials. The goal of this review is to provide a roadmap for

the practical approach to the biocompatibility testing for

orthopedic materials. The most important assays in this area are

discussed based on the current findings. In addition, the review

summarizes the main categories of biomaterials in orthopedics and

their biocompatibility issues.

2. Biomaterials in orthopedics

According to the American National Institute of

Health, a biomaterial is ‘any substance or combination of

substances, other than drugs, synthetic or natural in origin, which

can be used for any period of time, which augments or replaces

partially or totally any tissue, organ or function of body in order

to maintain or improve the quality of life of the individual’

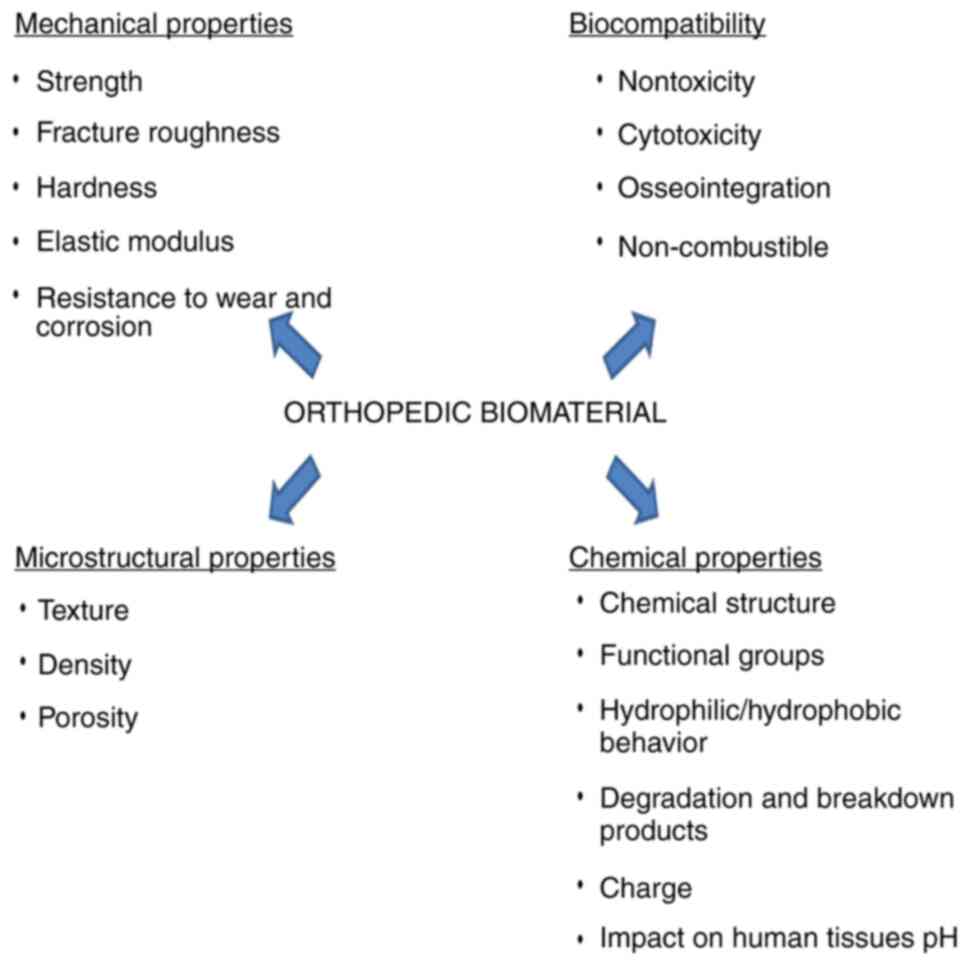

(6). The main required properties

of orthopedic biomaterials are good mechanical abilities including

high resistance to corrosion and wear, biocompatibility, chemical

stability and appropriate microstructural characteristics (Fig. 1) (7,8). A

high longevity of materials expressed by unaltered properties after

a long time of contact with the biological surroundings are

tremendously essential.

Depending on their nature, orthopedic materials can

be classified as metals, ceramics, polymers and composites.

Metallic materials

Due to their superior mechanical properties, metals

have been mostly used in prostheses stems, fracture plates, or as

load-bearing components in total joint replacement. The most

commonly used metals include stainless steels (316L), titanium and

titanium-base alloys (Ti-6Al-4V, TiAl4VELI, Ti6Al17Nb) and cobalt

alloys (Co-Cr-Mo) (Table I)

(7-9).

Among these, titanium and its alloys show an excellent corrosion

resistance and a high biocompatibility as well as good long-term

behavior (10). In addition, Co-Cr

based alloys exhibit good mechanical properties including excellent

wear resistance, but they have a low biocompatibility (11). The main biocompatibility issues

related to metallic materials and their alloys are bioactivity,

corrosion byproducts, hypersensitivity reactions (mostly in the

case of nickel alloys), and lipid uptake (5).

| Table IVarious important biomaterials used

in orthopedic applications. |

Table I

Various important biomaterials used

in orthopedic applications.

| Materials |

Characteristics | Disadvantages | Applications | (Refs.) |

|---|

| Metallic

materials | | | | |

|

Stainless

steel (316L) | Excellent corrosion

resistance | High modulus of

elasticity | Fracture

plates | (9,11) |

| | Relative good

biocompatibility | Rigidity | Screws | |

| | Relative low

cost | Allergic reactions

(nickel alloys) | Cerclage

cables | |

| | Easy

processing | | | |

|

Titanium and

its alloys (Ti, Ti6A14V) | Good corrosion

resistance | Bacterial

adherence | Prostheses

stems | (9,11,12) |

| | Moderate elastic

modulus | High hardness | | |

| | Good

mechano-chemical properties | Low wear

resistance | | |

| |

Osseointegration | | | |

| | Immunological

resistance | | | |

| | Excellent

biocompatiblity | | | |

|

Co-Cr-Mo

alloys | Excellent corrosion

resistance | Lower

biocompatibility | Prostheses

stems | (9,11) |

| | Good wear

resistance | Immunogenic | Load-bearing

components in | |

| | Superior fatigue

strength | Expensive to

manufacture | total joint

replacement | |

| | Low ductility | Limited

intra-operative manipulation | | |

| | High surface

smoothness | | | |

| Ceramics | | | | |

|

Alumina | Good corrosion

resistance | | Femoral head

implants | (8,11) |

| | Low friction/wear

coefficients | | | |

| | Surface

smoothness | | | |

|

Zirconia | Good fracture

toughness | | Hip

replacement | (8,11) |

| | High strength | | Bone

reconstruction | |

| | High

biocompatibility | | Endosseous

implants | |

|

Hydroxyapatite

(HA) | High compressive

strength | Low tensile | Coating of

orthopedic implants | (11,15, |

| | High

biocompatibility | Low fatigue

strength | Bone grafts | 18,19) |

| | Good

immunotolerance | | | |

| |

Osseoconduction | | | |

| |

Osseointegration | | | |

|

Tricalcium

phosphate (ß-TCP) | Bioresorbable | Poor mechanical

properties | Femoral knee | (13,17, |

| | Biocompatible | Brittleness | Hip prostheses | 20) |

| | Similar composition

to bone | | Tibial

components | |

| | Good

osteoconductive properties | | Bone plates and

screws | |

| Polymers | | | | |

|

Polyethylene

(PE), ultrahigh | Excellent

toughness | Low wear

resistance | Liner of acetabular

cups | (11,19) |

|

molecular

weight PE (UHMWPE) | Low density | Release of

particles and the occurrence of | in hip

arthroplasties | |

| | Availability | inflammatory

reactions/osteolysis | Bone joint

replacement (UHMWPE) | |

|

Poly(methylmethacrylate),

PMMA | Good

mechanical | Low tension

resistance | Orthopedic

surgeries | (11,12, |

| | properties | Thermal

degradation | Vertebroplasty | 21,22) |

| | Non-porous

structure | Systemic reactions

(inflammatory, embolism) | Space filler for

the proper | |

| | Excellent optical

properties | Poor

osseointegration | anchorage of the

implant to | |

| | Ease of

manipulation | | bone surface | |

| | Less expensive | | | |

|

Polylactic

acid (polylactide), |

Biodegradability | Weak thermal

stability | Bioabsorbable | (11,23) |

|

PA | Long term

biocompatibility | Low toughness | Fixation

devices | |

| | Thermoplastic

properties | Low ductility | Porous scaffolds

for the | |

| | | | grow of

neo-tissue | |

The coating of metals with bioactive ceramics and

the chemical modification of metal surface by binding of polymers

and biomolecules allow the biofunctionalization of metallic

materials and the control of the biodegradability rate and

biocompatibility (8,12). In this regard, magnesium alloys

(Mg-Ca, Mg-Zn) and magnesium matrix composites (Mg-calcium

phosphate particle, Mg-hydroxyapatite, Mg-tricalcium phosphate) are

one of the metallic materials which have recently attracted growing

interest due to their improved mechanical and biological properties

(9,13). Magnesium is ideal for biodegradable

orthopedic implants owing to its high biocompatibility,

osteogenesis ability and biodegradable behavior (14).

Ceramics

Ceramics represent a family of

inorganic/non-metallic products with a broad range of composition

that can be dense and resorbable like tricalcium phosphate or

dense, non-porous and chemically binding to the bone such as

hydroxyapatite (HA) (15,16). They are widely used in orthopedic

applications as bone replacement in hip and knee reconstruction.

The main advantages of these materials are high corrosion

resistance, hardness, wear resistance, low friction, significant

biocompatibility and osseointegration with the host tissue. On the

basis of tissue-material interface reaction, bioceramics are

generally classified into three categories: i) bioactive

(hydroxyapatite, bioactive glasses); ii) bioresorbable (calcium

phosphate) and iii) bioinert (alumina, zirconia) (Table I) (8,9,17-20).

It is of interest to modulate the chemistry of ceramics that they

become osteoinductive but also to enhance the bone regeneration

rate. The biocompatibility issues that could be considered in the

ceramics category are related to ADME profile (adsorption,

deposition, excretion, and metabolism), bioactivity, lipid uptake

and thromboresistance (5).

Polymers

Some of the most known polymers of first generation

are acrylic resins, polyethylene (PE) and ultrahigh molecular

weight PE (UHMWPE) and polymethacrylate (PMMA) (Table I) (11,12,19,21-23).

They are characterized by structural stability, low cost but a

relative biocompatibility. Their main use refers to joint

replacement, anchorage of prostheses and hip arthroplasties. The

second generation of polymers are biodegradable and resorbable

materials that are of interest in orthopedic practice for the

purpose of bone substitution, and repair of bone fractures,

cartilage, or membranes. Some examples of biodegradable polymers

include polyglicolide (PGA), polylactide (PLA), polydioxanone

(PDS), poly(e-caprolactone) (PCL) or chitosan (5,11). The

biocompatibility of polymeric materials is influenced by various

factors as structural properties (chemical structure, molecular

weight, functional groups, hydrophobicity), surface morphology,

wetting abilities, or electrical charge. Thus, the increase in

molecular weight of polyethylene glycol is associated with a

decrease in protein adsorption (9).

The biocompatibility issues associated with these biomaterials

differ slightly between the two polymer types; thus, in the case of

synthetic polymers, these issues refer to the calcification,

extractables, hypersensitivity reactions, lipid uptake, protein

adsorption and sterilization residuals. For the biodegradable

polymers, the biodegradation products, ADME, effect of infection

(acid pH on biodegradation particulates), effect of hematoma

(alkaline pH) are the specific biocompatibility issues (5).

Composite biomaterials

Composites comprise at least two components, namely

matrix material and a filler (reinforcement) and they are widely

used in structural and automotive applications. The addition of the

filler enhances structural properties, biocompatibility and

bioactivity of the matrix. These biomaterials have been classified

into metal matrix composites (Ti/HA, Mg/HA, Ti6Al4V/HA), ceramic

matrix composites (HA/stainless steel) and polymer matrix

composites (high density polyethylene/HA, carbon fiber/polyether

ether ketone). Fiber-reinforced polymers and PMMA-composites are

largely used in orthopedic devices (7,9,16,17).

The major biocompatibility issues described for composites include

hypersensitivity, lipid uptake, matching tissue biomechanics, and

surface exposure of compounded particles (5).

3. Biocompatibility testing

The designed materials for orthopedic uses should be

capable to function in vivo without exhibiting any

undesirable local or systemic effects as immune, allergic,

inflammatory and carcinogenic responses (5). Biocompatibility includes not only

bio-inertia, but also biofunctionality and biostability. It is a

key concept that strongly depends on the material properties

(texture, crystallinity, wettability, surface chemistry, breakdown

products, charges, stiffness), interaction with the biological

environment of targeted tissues (adsorption of proteins,

inflammatory processes, contact with blood), period of the device

application, and type of application (24-26).

Taking all this into account, the biological

evaluation of biomaterials includes a broad spectrum of in

vitro and in vivo tests related to the

cytocompatibility, genotoxicity, sensitization, irritation, acute

and chronic toxicity, hemocompatibility, reproductive and

developmental toxicity, carcinogenicity, implantation and

degradation as specified in different international standards

(Table II) (3).

| Table IIInternational standards for

biocompatibility testing of biomaterials (4,5). |

Table II

International standards for

biocompatibility testing of biomaterials (4,5).

| |

Standardsa |

|---|

| Biological

response | ISO | ASTM |

|---|

| Cytotoxicity | 10993-5 | F813-07; F895-84;

F1027-06 |

| Sensitization | 10993-10 | F720-81; F2147-01;

F2148-07 |

| Irritation | 10993-10 | F719-81;

F749-98 |

| Acute systemic

toxicity | 10993-11 | F750-87 |

| Subacute

toxicity | 10993-11 | - |

| Genotoxicity | 10993-3 | E1262-88 |

|

Immunoresponsiveness | 10993-20 | F1906-98 |

|

Hemocompatibility | 10993-4 | F756-08 |

| Chronic

toxicity | 10993-11 | - |

|

Carcinogenicity | 10993-3 | F1439-03 |

| Degradation | 10993-9;

10993-13 | F1983-14 |

| | 10993-14;

10993-15 | |

| Implantation | 10993-6 | F1408-97; F763-04;

F1904-98 F981-04; F1983-99 |

Before biocompatibility testing, the biomaterials

from a final form of the medical device, are extracted using a

semiphysiological medium (saline solution, cottonseed or sesame

seed oil) or cell culture medium in small tubes. Then, they are

usually incubated for 24-72 h at 37˚C. Furthermore, the resulting

extract solutions are decanted into sterile glass tubes and used in

the biological tests (3). The

extraction procedure is very gentle. Only some compounds from the

surface of materials can be extracted. Its main limitations include

low extraction yield (<10%), short-time contact between material

and cells/tissue fluids compared to the in vivo conditions,

and unsuitable extraction medium for organic hydrophobic compounds.

The use of the extraction vehicle with low concentrations of

dimethylsulphoxide (<0.5%) allows solubilization of both

hydrophilic and hydrophobic compounds (4).

Cytocompatibility tests

Cytocompatibility tests evaluate the biological

reactivity of living cells to the biomaterial extract solutions

including cell viability, growth, and metabolic activity (4). Toxic agents derived from biomaterials

such as metal ions, reactive agents, residual monomers, may exert

toxic effects on cell functions and viability. The cellular damage

involves structural disintegration and alteration of cell

morphology, reduction in cell adhesion and proliferation, decrease

in metabolic activity and cell lysis (27).

Cytotoxicity elution test

Cytotoxicity elution test (MEM elution) is an in

vitro qualitative assay. It involves the incubation of L-929

mouse fibroblast cells with an extract of the test material for 48

h. After incubation, the cells are microscopically examined in

terms of morphological changes (deformed and lysed cells). The cell

responses to material are scored on a scale of 0 to 4. The

biomaterial is considered biocompatible if the cell response to the

test material is not greater than grade 2 (mild reactivity)

(3).

MTT assay

MTT assay is the most commonly used test to evaluate

cell viability and proliferation. It relies on the enzymatic

reduction of yellow

3-(4,5-dimethylthiazol-2-yl)-2,5-diphenyl-2H-tetrazolium bromide

(MTT) to purple formazan in metabolically active cells. The color

intensity of formed formazan is directly proportional to the number

of viable cells. The measuring absorbance of formazan at 570 nm

allows quantitative evaluation of living cells. The material is

considered cytocompatible if the percentage of viable cells is

equal to or higher than 70% (3,28).

Although MTT is considered the ‘gold standard’ in cytotoxicity

studies, the test has several limitations. Thus, the cell culture

conditions may affect the metabolism and rate of MTT reduction, and

the interaction between test material and MTT can modify the final

results. The carbon nanotubes as well as calcium phosphate

scaffolds are able to reduce MTT. In addition, carbon nanotubes can

bind the formed formazan altering the test outcome (4,28).

Agar overlay assay

Agar overlay assay is a qualitative test that

evaluates cytotoxicity by indirect contact. Subconfluent cell

cultures (mouse fibroblasts L929, NIH 3T3) are overlaid by an agar

layer. The test material is placed on the agar layer and after

24-72 h exposure time, it is removed. Then, the cells under and

around the test material are exposed to Neutral Red

(3-amino-7-dimethylamino-2-methylphenazine hydrochloride) staining.

The detachment, vacuolization and lysis of cells can be

semi-quantitatively scored. Only the living cells accumulate the

Neutral Red dye and they appear red colored to light-microscope

analysis. The agar overlay assay is suitable for high density

biomaterials. The limits of the test are related to the short time

exposure to biomaterial (only acute cytotoxicity detection) and the

binding or adsorption of Neutral Red on test or released compounds

(3,4,29).

Genotoxicity evaluation

Genotoxicity evaluation is an essential part of the

safety assessment of biomaterials as damage of genetic material may

result in the induction of carcinogenesis or may alter the

reproductive function if germ cell DNA is impaired. The sensitive

genotoxicity endpoints comprise DNA damage, gene mutations and

chromosomal damage (30,31). The genotoxic risk assessment of

biomaterials is performed in mammalian and non-mammalian systems

(3).

Mouse lymphoma assay

Mouse lymphoma assay (MLN) is an in vitro

mammalian cell gene mutation test that is able to detect both gene

mutations (point mutations) and clastogenic injuries (deletions,

translocations, mitotic recombination/gene conversion, and

aneuploidy). Basically, the test quantifies alterations of

thymidine kinase (TK) gene expression located on chromosome

11. The L5178YTK+/--3.7.2 C mouse lymphoma cell line is

used for the assay. The cells deficient in the TK gene as a

result of the mutation TK+/- to TK-/- induced

by a genotoxicant are resistant to cytostatic activity of

pyrimidine analogue triflurothymidine (TFT). In the presence of TFT

in the medium, the mutant cells are able to survive and proliferate

whereas the normal cells are not. Cells are incubated with test

material for 3 to 4 h in the presence and absence on an metabolic

activation system. In addition, the cells are exposed to test agent

for 24 h without exogenous metabolic activation. A

co-factor-supplemented post-mitochondrial fraction obtained from

hepatic tissue of rodents is used for metabolic activation. After

treatments, the cells are subcultured for two days to allow

expression of the mutant phenotype. Then, the cells are seeded into

96-well plates with and without TFF to detect mutant cells and to

evaluate cloning efficiency. Previously, the dose range of the test

material is established depending on the cytotoxicity assessment.

The occurrence of mutant colonies (small and large colonies) and

the increase in mutant frequency (more than Global Evaluation

Factor, 126x10-6) is associated with the induction of

chromosomal aberrations and the mutagenicity of the test material.

The outcome of the test is significantly influenced by the cell

line viability per se, solubilization of the test material,

changes in the pH, osmolality, and high levels of cytotoxicity

(3,32,33).

In vitro chromosomal aberration

assay

In vitro chromosomal aberration assay

evaluates structural aberrations (chromosome/chromatid breaks;

chromosome/chromatid exchanges) but it also detects polyploidy and

endoreduplication. The test is performed in primary human

peripheral blood lymphocytes or in established cell lines such as

Chinese hamster ovary (CHO) cells or Chinese hamster fibroblasts.

In this method, the proliferating cells are exposed to the extract

test dilutions with and without metabolic activation for 3 to 6 h.

The same metabolic activation system as in the MLA test is used.

After exposure to the test material, the cell cultures are treated

for 1-3 h with a metaphase-arresting compound (colcemid) at

predetermined time intervals in relation with cell cycle length.

The cells are harvested for the preparation of chromosomes by

hypotonic treatment, fixation and staining with Giemsa. Chromosomal

aberrations (number and types) in the mitotic cells are scored. The

percentage of cells with this chromosomal damage is evaluated for

test material dilutions as compared to the value of the negative

controls. Test conditions (pH changes, osmolality) may influence

the final results leading to a positive outcome. In addition,

established cell lines should be characterized by stability in the

modal chromosome number. The solvent used for the extraction of

biomaterial should not interfere with the cell response (3,34,35).

Reverse mutation assay

Reverse mutation assay (Ames test) is a

nonmammalian test system that use mutagenicity in bacteria as an

end point. The assay is performed with strains of Salmonella

typhimurium and Escherichia coli that have point

mutations in the genes of the histidine and tryptophan operon,

respectively. The exposure of mutant bacterial cells to a mutagenic

agent causes a reversal of initial mutation (back mutation)

restoring the ability of the bacteria to grow on the media lacking

in histidine. Bacterial cultures are exposed to the biomaterial in

the presence and the absence of metabolic activation system, using

either plate incorporation or preincubation before plating. After 2

to 3 days of incubation at 37˚C, the revertant colonies are counted

compared to the control plates. An increased number of revertant

colonies indicates the mutagenic potential of the tested material.

The preincubation method is recommended for some materials such as

divalent metals (3,36,37).

Irritation (intracutaneous reactivity)

testing

Irritation (intracutaneous reactivity) testing is an

in vivo assay that evaluates the potential of biomaterials

to cause irritation on the exposed area of the body. Saline and

vegetable biomaterial extracts are administered by intracutaneous

injection into multiple sites on the back of albino rabbits. The

skin reactions (erythema, edema, scabbing, bleeding) are evaluated

24, 48 and 72 h following injection using a standardized scoring

scheme. The biomaterials meets the criteria of the test if the

difference between its average irritation score and the value of

control is 1 or <1. The use of rancid vegetable oil as a vehicle

for biomaterials could determine an extreme reactivity hiding the

true effect of the biomaterial (3,38).

Skin sensitization assay

Skin sensitization assay evaluates the allergenic

potential of biomaterials. Guinea pig maximization test is the most

commonly used assay. It is based on the induction of an immune

response of the skin and it comprises 3 phases. Stage I of the test

(Induction) implies an intradermal injection of the biomaterial

extract in guinea pigs on the test area. Then, a topical patch is

applied after 7 days (Phase II, Induction II) and 14 days (Phase

III, Challenge). Skin reactions (erythema, swelling) are evaluated

at 24 and 48 h following patch removal using a scoring system.

Sensitization potential is associated with a score value of 1 or

greater in the test group (3,39).

Acute systemic toxicity testing

Acute systemic toxicity testing estimates the hazard

potential of a biomaterial following short-time exposure in

animals. The extracts of the test material and negative controls

are injected intravenously (saline extract) or intraperitoneally

(cottonseed oil extract) into Swiss Albino mice. Then, the animals

are observed 4, 24, 48, and 72 h after treatment. The body weight,

survival, and animal behavior are recorded. The biomaterial meets

the test requirements if its biological reaction is lower than the

negative control (3).

Hemocompatibility

The biomaterial components of prosthetic devices in

contact with the bloodstream regardless of contact duration must be

hemocompatible; they do not cause clinically significant

blood-related adverse events such as thrombosis, hemolysis,

platelet and complement activation. Mostly the artificial surfaces

can induce clotting, and high levels of coagulation is associated

with acute thrombosis or thromboembolism that determine the failure

of biomaterials/device (40,41).

The hemocompatibility depends on the material characteristics but

also on the fluid mechanics of the device and the blood

coagulability. The key points in hemocompatibility testing are

coagulation, hemolysis, hematology, platelets, and complement

system. The assessment involves static, agitated or shear flow

in vitro models for the incubation of fresh human blood with

biomaterials. The hemocompatibility markers are determined before

and after the incubation of the test material (42).

Coagulation

Coagulation is evaluated in vitro by

measuring the rate of clot formation or the partial thromboplastin

time (PTT) of plasma exposed to the biomaterials during an

incubation time. A shortening of PTT induced by contact with

biomaterials compared to the negative control shows the activation

of the internal coagulation pathway. The amount of thrombin, the

main enzyme of the coagulation pathway can also be determined by

measuring thrombin-antithrombin complex (TAA) and prothrombin

fragment 1+2 using ELISA techniques. The TAA complex reflects a

functional state of the coagulation, and prothrombin fragments are

released during thrombin formation. An overall picture of the

clotting process can be obtained by thromboelastography, an in

vitro whole-blood viscoelastic test (40,42).

Hemolysis analysis. Hemolysis analysis deals with

the evaluation of the degree of erythrocyte lysis and the release

of hemoglobin induced by the tested biomaterial. The determination

of plasma hemoglobin is performed by spectrophotometric methods.

Immunonephelometry and ELISA techniques may be other options. For

device components having direct contact with the blood, hemolysis

testing is recommended by both direct and indirect methods. Only an

indirect method is indicated in the case of devices having indirect

contact with circulating blood. In direct testing, the blood is

incubated with biomaterial and in indirect method, the blood is

exposed to the biomaterial extract. Depending on the hemolysis

testing results, the material are classified as hemolytic (over 5%

hemolysis), slightly hemolytic (between 5 and 2%) and nonhemolytic

(below 2%) (40,42).

Hematology testing

Hematology testing includes the assessment of the

complete blood count and the activation of leukocytes as a result

of biomaterial-induced inflammatory response. Hematology analyzer

and ELISA method are used in this direction. Since the activation

of leukocytes leads to an enhanced oxygen metabolism, the excessive

reactive oxygen species generation can be evaluated using

fluorogenic or chemiluminogenic agents. In addition, the release of

polymorphonuclear leukocyte elastase, an another event induced by

leukocyte activation, can be quantified by ELISA or fluorescence

(40,42).

Platelet activation testing

Several points can be used for the evaluation of

undesired platelet activation induced by the blood-biomaterial

contact. They involve the quantification of degranulation proteins

(platelet factor 4, b-thromboglobulin, thromboxane B2) released

after platelet activation by ELISA, detection of P-selectin (CD62P)

or activated GPIIb/IIIa using flow cytometry (40,42).

Complement system activation

The complement system is an important component of

the innate immune response and it is primarily involved in the

first-line host defense against pathogenic factors through three

major pathways (classical, alternative and lectin pathway).

Biomaterials act primarily upon the alternative pathway of

complement, and the complement activation is associated with the

generation of complement proteins (C3, C5b, C6, C7, C8, C9) that

can be determined using ELISA. In addition, the complement

activation can be analyzed by the evaluation of the 50% complement

hemolytic activity (CH50). In general, the hydrophobic surfaces of

biomaterials cause an increased complement activation compared to

hydrophilic surfaces. The binding of complement components to the

biomaterial surfaces can reduce their plasma content and can alter

the final result (40,42).

Implantation tests

Implantation tests evaluate the local pathological

effects on living tissues that constitute the target of the

biomaterial/medical device used for implantation. The biological

response of the surrounding tissues (number and distribution of

inflammatory cells, vascularity of fibrous capsule, granuloma,

fatty infiltration, material debris, endothelialization, presence

of necrosis) is commonly characterized by histological analysis.

Both the tissue from the immediate vicinity of the implant and more

distant tissues are studied.

In implantation tests, the safety of materials is

assessed not only dose-dependently but also time-dependently. The

tests are performed using mice, rats, guinea pigs or rabbits for

short-term evaluation studies (12 weeks) (43-45).

The rabbits are preferred for the musculoskeletal implantation

studies since they have faster skeletal change, a high bone turn

over and are less expensive and easy to handle (12). The animals with relatively long life

expectancy such as dogs, sheep, goats, are used in longer-term

studies. The chemistry, size and the degradation pattern of the

materials significantly influence the biological response (43-45).

4. Conclusions

It is undeniable that the biocompatibility concept

is a major concern in the design of biomaterials in orthopedics. A

wide array of specific tests must be performed in order to ensure

safety and efficacy of the biomaterials as this paper has reviewed.

The development of new materials, the new paradigm of

biocompatibility (‘do no harm’ approach is transformed into one of

doing ‘good’) (5) and the

understanding of the role of biomaterial surface physicochemistry

accentuate the need for a calibration of regulatory criteria

depending on new technologies and concepts. The design of

biomaterials with high biocompatibility and functional properties

(antimicrobial, osteoinductive) is highly desirable.

Acknowledgements

Not applicable.

Funding

Funding: No funding was received.

Availability of data and materials

Not applicable.

Authors' contributions

BH wrote the initial draft of the manuscript,

contributed to the conception and design of the article and

performed the literature data collection. BP and RMN contributed to

the design of the article. BP, RMN, SG, GP and AF consulted

relevant references and performed the literature data collection.

OA and PDS revised the manuscript in light of the literature

findings. All authors have read and approved the final version of

the manuscript for publication.

Ethics approval and consent to

participate

Not applicable.

Patient consent for publication

Not applicable.

Competing interests

The authors declare that they have no competing

interests.

References

|

1

|

Cieza A, Causey K, Kamenov K, Hanson SW,

Chatterji S and Vos T: Global estimates of the need for

rehabilitation based on the global burden of disease study 2019: A

systematic analysis for the global burden of disease study 2019.

Lancet. 396:2006–2017. 2021.PubMed/NCBI View Article : Google Scholar

|

|

2

|

GBD 2019 Diseases and Injuries

Collaborators. Global burden of 369 diseases and injuries in 204

countries and territories, 1990-2019: A systematic analysis for the

global burden of disease study 2019. Lancet. 396:1204–1222.

2020.PubMed/NCBI View Article : Google Scholar

|

|

3

|

Assad M and Jackson N: Biocompatibility

evaluation of orthopedic biomaterials and medical devices: A review

of safety and efficacy models. In: Encyclopedia of Biomedical

Engineering. Vol 2. 1st edition. Narayan RJ (ed). Elsevier,

Amsterdam, pp281-309, 2019.

|

|

4

|

Bruinink A and Luginbuehl R: Evaluation of

biocompatibility using in vitro methods: Interpretation and

limitations. Adv Biochem Eng Biotechnol. 126:117–152.

2012.PubMed/NCBI View Article : Google Scholar

|

|

5

|

Helmus MN, Gibbons DF and Cebon D:

Biocompatibility: Meeting a key functional requirement of

next-generation medical devices. Toxicol Pathol. 36:70–80.

2008.PubMed/NCBI View Article : Google Scholar

|

|

6

|

Bergmann CP and Stumpf A: Biomaterials.

In: Dental ceramics. Topics in mining, metallurgy and materials

engineering. Bergmann CP (ed) Springer, Heidelberg, pp9-15,

2013.

|

|

7

|

Rodríguez-González ÁF: Biomaterials in

Orthopaedic Surgery. ASM International, pp1-10, 2009.

|

|

8

|

Shekhwat D, Singh A, Banerjee MK, Singh T

and Patnaik A: Bioceramics composites for orthopaedic applications:

A comprehensive review of mechanical, biological, and

microstructural properties. Ceram Int. 47:3013–3030. 2021.

|

|

9

|

Kiradzhiyaska DD and Mantcheva RD:

Overview of biocompatible materials and their use in medicine.

Folia Med (Plovdiv). 61:34–40. 2019.PubMed/NCBI View Article : Google Scholar

|

|

10

|

Gobbi SJ, Gobbi JV and Rocha Y:

Requirements for selection/development of a biomaterial. Biomed J

Sci Tech Res. 14:10674–10679. 2019.

|

|

11

|

Navarro M, Michiardi A, Castaño O and

Planell JA: Biomaterials in orthopaedics. J R Soc Interface.

5:1137–1158. 2008.PubMed/NCBI View Article : Google Scholar

|

|

12

|

Vandana U, Nancy D, Sabareeswaran A, Remya

NS, Rajendran N and Mohanan PV: Biocompatibility of strontium

incorporated ceramic coated titanium oxide implant indented for

orthopaedic applications. Mater Sci Eng B. 264(114954)2021.

|

|

13

|

Bommala VK, Krishna MG and Rao CT:

Magnesium matrix composites for biomedical applications: A review.

J Magnes Alloy. 7:72–79. 2019.

|

|

14

|

Kumar K, Das A and Prasad SB: Recent

developments in biodegradable magnesium matrix composites for

orthopaedic applications: A review based on biodegradability,

mechanical and biocompatibility perspective. Mater Today Proc.

44:2038–2042. 2021.

|

|

15

|

Nuss KMR and von Rechenberg B:

Biocompatibility issues with modern implants in bone-a review for

clinical orthopedics. Open Orthop J. 2:66–78. 2008.PubMed/NCBI View Article : Google Scholar

|

|

16

|

Victor SP and Muthu J: Polymer ceramic

composite materials for orthopedic applications-relevance and need

for mechanical match and bone regeneration. J Mechatron. 2:1–10.

2014.

|

|

17

|

Aherwar A, Singh AK and Patnaik A: Current

and future biocompatibility aspects of biomaterials for hip

prosthesis. AIMS Bioeng. 3:23–43. 2016.

|

|

18

|

Kattimani VS, Kondaka S and Lingameneni

KP: Hydroxyapatite-past, present, and future in bone regeration.

Bone Tissue Regen Insights: Sep 11, 2016 (Epub ahead of print).

|

|

19

|

Rufino Senra M and Marques FV: Synthetic

polymeric materials for bone replacement. J Compos Sci.

4(191)2020.

|

|

20

|

Liu B and Lun DX: Current application of

β-tricalcium phosphate composites in orthopaedics. Orthop Surg.

4:139–144. 2012.PubMed/NCBI View Article : Google Scholar

|

|

21

|

Samavedi S, Poindexter LK, Van Dyke M and

Goldstein AS: Synthetic biomaterials for regenerative medicine

applications. In: Regenerative Medicine Applications in Organ

Transplantation. Orlando G, Lerut J, Soker S and Stratta RJ (eds).

Academic Press, Boston, pp81-99, 2014.

|

|

22

|

Webb JC and Spencer RF: The role of

polymethylmethacrylate bone cement in modern orthopaedic surgery. J

Bone Joint Surg Br. 89:851–857. 2007.PubMed/NCBI View Article : Google Scholar

|

|

23

|

Cipurković A, Horozić E, Đonlagić N, Marić

S, Saletović M and Ademović Z: Biodegradable polymers: Production,

properties and application in medicine scientific review paper.

Technol Acta. 11:25–35. 2018.

|

|

24

|

Quinn J, McFadden R, Chan CW and Carson L:

Titanium for orthopedic applications: An overview of surface

modification to improve biocompatibility and prevent bacterial

biofilm formation. iScience. 28(10174)2020.PubMed/NCBI View Article : Google Scholar

|

|

25

|

Rahmati M, Silva EA, Reseland JE, Heyward

CA and Haugen HJ: Biological responses to physicochemical

properties of biomaterial surface. Chem Soc Rev. 49:5178–5224.

2020.PubMed/NCBI View Article : Google Scholar

|

|

26

|

Cvrček L and Horáková M: Plasma modified

polymeric materials for implant applications. In: Non-Thermal

Plasma Technology for Polymeric Materials. Applications in

Composites, Nanostructured Materials and Biomedical Fields. Thomas

S, Mozetič M, Cvelbar U, Špatenka P and Praveen KM (eds). Elsevier,

Amsterdam, pp376-407, 2019.

|

|

27

|

Groth T, Falck P and Miethke RR:

Cytotoxicity of biomaterials-basic mechanisms and in vitro test

methods: A review. ATLA. 23:790–799. 1995.

|

|

28

|

Iqbal HMN and Keshavarz T: The challenge

of biocompatibility evaluation of biocomposites. In: Woodhead

Publishing Series in Biomaterials, Biomedical composites (second

edition). Ambrosio L (ed). Woodhead Publishing, Cambridge,

pp303-334, 2017.

|

|

29

|

Li W, Zhou J and Xu Y: Study of the in

vitro cytotoxicity testing of medical devices. Biomed Rep.

3:617–620. 2015.PubMed/NCBI View Article : Google Scholar

|

|

30

|

Kohl Y, Rundén-Pran E, Mariussen E, Hesler

M, El Yamani N, Longhin EM and Dusinska M: Genotoxicity of

nanomaterials: Advances in vitro models and high throughput methods

for human hazard assessment-a review. Nanomaterials (Basel).

10(1911)2020.PubMed/NCBI View Article : Google Scholar

|

|

31

|

Raghavendra GM, Varaprasad K and

Jayaramudu T: Biomaterials: Design, development and biomedical

applications. In: Nanotechnology Applications for Tissue

Engineering. Thomas S, Grohens Y and Ninan N (eds). Elsevier,

Amsterdam, pp21-44, 2015.

|

|

32

|

Moore MM, Honma M, Clements J, Bolcsfoldi

G, Burlinson B, Cifone M, Clarke J, Delongchamp R, Durward R,

Fellows M, et al: Mouse lymphoma thymidine kinase gene mutation

assay: Follow-up meeting of the international workshop on

genotoxicity testing-aberdeen, scotland, 2003-assay acceptance

criteria, positive controls, and data evaluation. Environ Mol

Mutagen. 47:1–5. 2006.PubMed/NCBI View

Article : Google Scholar

|

|

33

|

OECD Guideline for the Testing of

Chemicals. In vitro mammalian cell gene mutation assays using the

thymidine kinase gene, 2014. Available from: https://www.oecd.org/env/ehs/testing/In%20Vitro%20Mammalian%20Cell%20Gene%20Mutation%20Thymidine%20Kinase%20.pdf.

|

|

34

|

OECD/OCED Guideline for the Testing of

Chemicals. In vitro mammalian chromosomal aberration test, 2016.

Available from: https://www.oecd-ilibrary.org/docserver/9789264264649-en.pdf?expires=1615635244&id=id&accname=guest&checksum=AD494BA2A538E6C1302075C64D4C7BA5.

|

|

35

|

Registre M and Proudlock R: The in vitro

aberration test. In: Genetic toxicology testing. Proudlock R (ed).

Academic Press, Amsterdam, pp207-267, 2016.

|

|

36

|

Jain AK, Singh D, Dubey K, Maurya R,

Mittal S and Pandey AK: Models and methods for in vitro toxicity.

In: In vitro Toxicology. Dhawan A and Kwon S (eds). Academic Press,

Amsterdam, pp45-65, 2018.

|

|

37

|

Guy RC: Ames test. In: Encyclopedia of

Toxicology. 2nd edition. Wexler P (ed). Elsevier, Amsterdam,

pp88-91, 2005.

|

|

38

|

De Jong WH, Caraway JW and Geertsma RE: In

vivo and in vitro testing for the biological evaluation of

biomaterials and medical devices. In: Woodhead Publishing Series in

Biomaterials, Biocompatibility and Performance of Medical Devices.

Boutrand JP (ed). Woodhead Publishing, Cambridge, pp120-158,

2012.

|

|

39

|

Kimber I, Basketter DA, Berthold K, Butler

M, Garrigue JL, Lea L, Newsome C, Roggeband R, Steiling W, Stropp

G, et al: Skin sensitization testing in potency and risk

assessment. Toxicol Sci. 59:198–208. 2001.PubMed/NCBI View Article : Google Scholar

|

|

40

|

Nalezinková M: In vitro hemocompatibility

testing of medical devices. Thromb Res. 195:145–190.

2020.PubMed/NCBI View Article : Google Scholar

|

|

41

|

Brănișteanu DE, Nichifor M, Dorobăț CM,

Brănișteanu DC, Petrariu FD, Molodoi AD, Radu DC and Boda D: Use of

textile biomaterials for the topic treatment of chronic venous

disease. Rom Biotechnol Lett. 20:10618–10625. 2015.

|

|

42

|

Weber M, Steinle H, Golombek S, Hann L,

Schlensak C, Wendel HP and Avci-Adali M: Blood-contacting

biomaterials: In vitro evaluation of the hemocompatibility. Front

Bioeng Biotechnol. 6(99)2018.PubMed/NCBI View Article : Google Scholar

|

|

43

|

Anderson JM and Schoen FJ: In vivo

assessment of tissue compatibility. In Biomaterials Science. 3rd

edition. Ratner BD, Hoffman AS, Schien FJ and Lemons JE (eds).

Academic Press, Amsterdam, pp609-617, 2013.

|

|

44

|

Anderson JM and Jiang S: Animal models in

biomaterial development. In: Encyclopedia of biomedical

engineering. Narayan R (ed). Elsevier, Amsterdam, pp237-241,

2019.

|

|

45

|

Hakimi O, Vollrath F and Carr AJ:

Evaluation of silk as a scaffold for musculoskeletal

regeneration-the path from the laboratory to clinical trials. In:

Comprehensive biotechnology. 2nd edition. Moo-Young M (ed).

Academic Press, Amsterdam, pp341-351, 2011.

|