Introduction

Despite the development of novel implants based on

biomechanical principles, the mechanical complications of

osteosynthesis exhibit high rates of 1-32% (1-8).

In order to optimize the surgical treatment and the implant used,

biomechanical testing remains the gold standard. There is a

multitude of biomechanical studies on the osteosynthesis of

proximal femoral fractures, performed on both cadaveric and

composite bone, in different loading modes, with heterogeneous

results (1-7,9,10).

Although cadaveric bone has long been considered a ‘gold standard’

for biomechanical testing (3,11),

composite bone is an increasingly used alternative (9).

Knowing the area of contact of the hip joint and the

distribution of pressure during daily activities is important in

predicting the mechanism of mechanical complications after

osteosynthesis, providing biomechanical reasons for preoperative

planning and postoperative rehabilitation (12). While walking, the pressure on the

femoral head is not constant or evenly distributed. Yoshida et

al (12) stated that during

walking, the peak pressure is located on the side roof of the

acetabulum. During standing and sitting and while bending the

knees, the peak pressures are located at the edge of the posterior

horn (12). When climbing the

stairs, the maximum pressure is found on the side roof, and this is

higher than that when going down the stairs (12). Most studies (2-6,9,10)

perform the loading directly on the femoral head or through a metal

piece that concentrates the force on a limited area of the head,

thus not respecting the hip joint contact area (2,9,10). The

present study was performed to generate loading/unloading cups

similar to the human acetabulum with similar biomechanical

properties compared with the hip cartilage using additive

technology in order to simulate the in vivo conditions while

walking.

Materials and methods

Materials

After a comparative analysis of the materials

compatible with the Stratasys FORTUS 250 mc machine, acrylonitrile

butadiene styrene M30 (ABS-M30), a synthetic material with similar

mechanical properties compared with the cartilage at the level of

the adult hip (Table I), was

selected (13). The characteristics

of the ABS-M30 material were taken from the datasheet published by

Stratasys, Ltd. The characteristics of the hip cartilage were taken

from data reported in the literature (1). Acrylonitrile butadiene styrene (ABS)

is a thermoplastic polymer of fossil source obtained through the

polymerization of styrene and butadiene in the presence of

acrylonitrile, which allows the manufacturing of models using

additive manufacturing technology (14,15).

| Table ICharacteristics of the ABS and ASA

material vs. hip cartilage (1,2). |

Table I

Characteristics of the ABS and ASA

material vs. hip cartilage (1,2).

| | Material |

|---|

| Characteristics | ABS-P400 | ASA | ABS-M30 | Hip cartilage |

|---|

| Tensile strength,

MPa | 22 | 32.8 | 36 | 80 |

| Tensile modulus,

MPa | 1,627 | 1,450-2,800 | 2,400 | 2,210 |

To simulate the articular cartilage at the level of

the femoral head and condyles and to achieve a uniform distribution

of the compression forces, the loading was carried out using two

3D-printed parts made on a Stratasys FORTUS 250 mc computer

numerical control (CNC) machine (Stratasys, Ltd.) using ABS-M30

(Stratasys, Ltd.).

Methods

For biomechanical testing, forces between 208 and

1,400 N with frequencies between 0.2 and 1 Hz were used to simulate

the normal gait of a 70 kg adult in vivo. The contact

surface of the femoral head with the loading cup was 27.7

cm2. At maximum load (1,400 N), the force to be

supported was 51.85 N/cm2, which was lower than the

tension modulus of the ABS-M30 material (2.4x105 N/cm²),

allowing its elastic deformation.

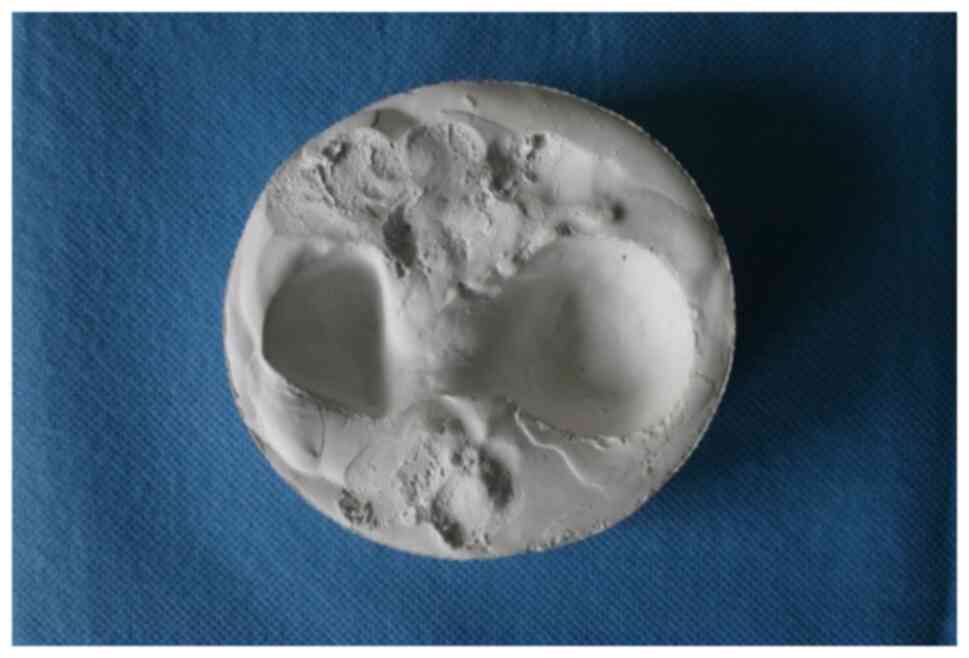

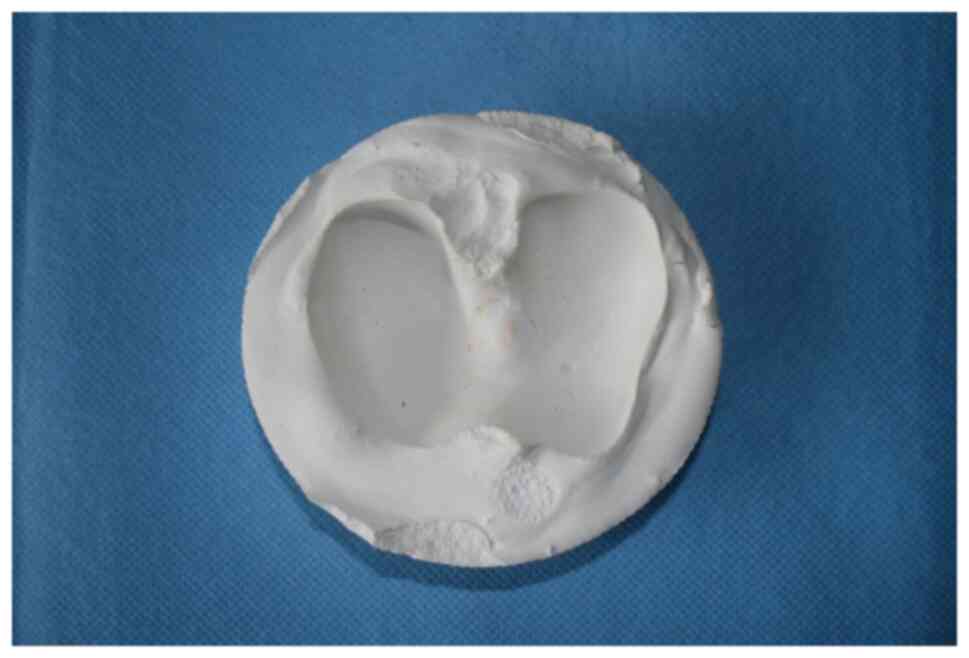

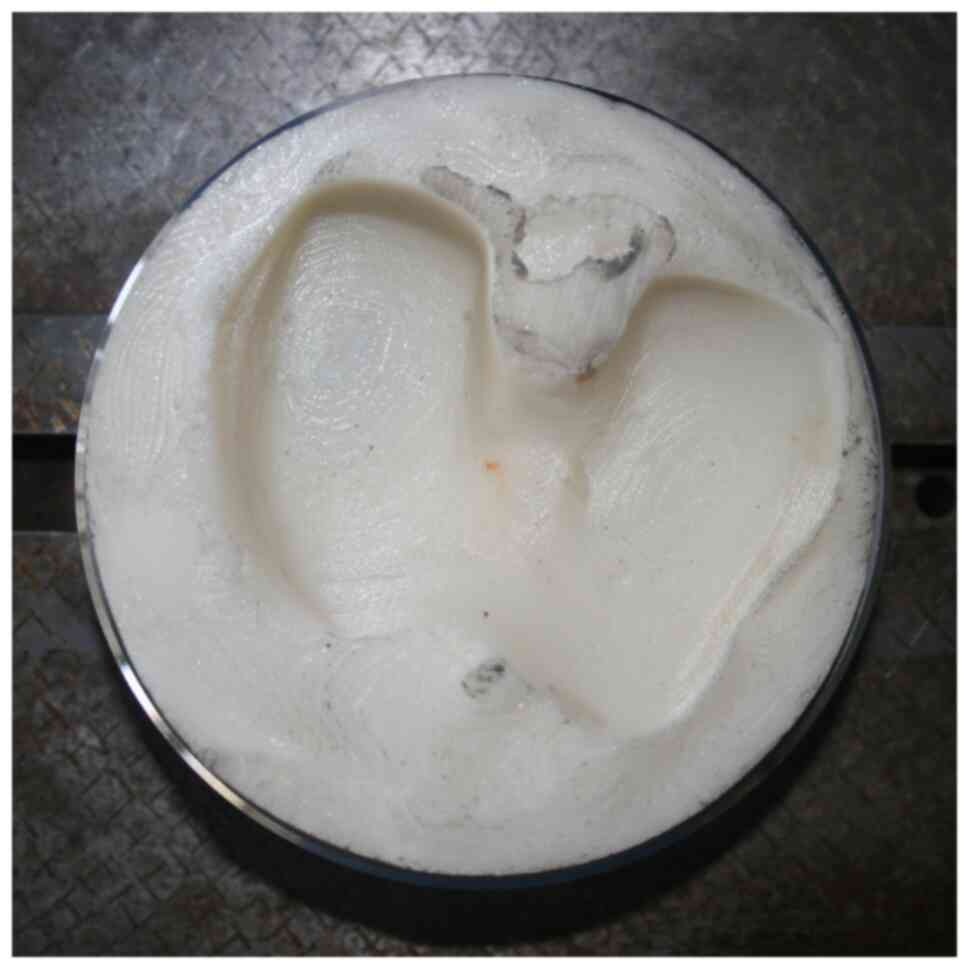

The loading/unloading cups were made through the

impression of a Sawbones® (Pacific Research

Laboratories, Inc.) femur model in casting gypsum (Figs. 1 and 2), which had been vacuum mixed for

degasification. After the impression was performed and the casts

were dried, the casts were painted for scanning using 3D Scan Spray

(Helling GmbH).

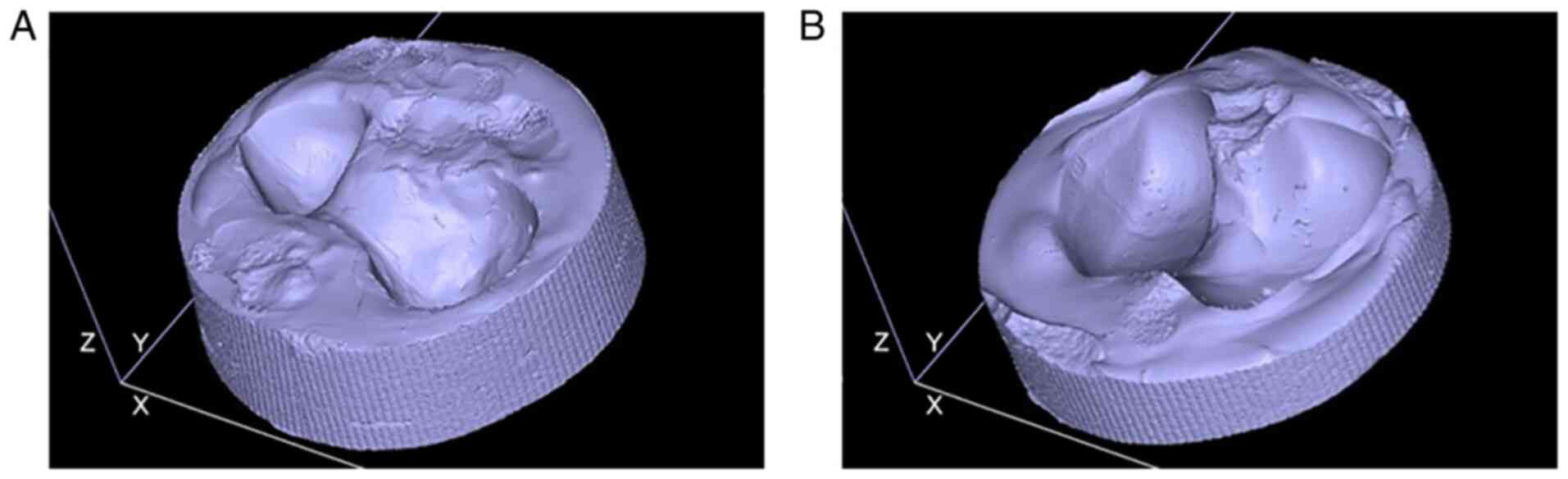

These casts were then scanned using a 3D scanner,

Creaform HandySCAN3D 300 (Ametek, Inc.) (Fig. 3), with a volumetric accuracy of 0.02

mm, obtaining 3D digital models in STL format using the Creaform

VXelements 1 software (https://www.creaform3d.com/en/metrology-solutions/3d-applications-software-platforms/vxmodel-scan-cad-software-module;

Fig. 4).

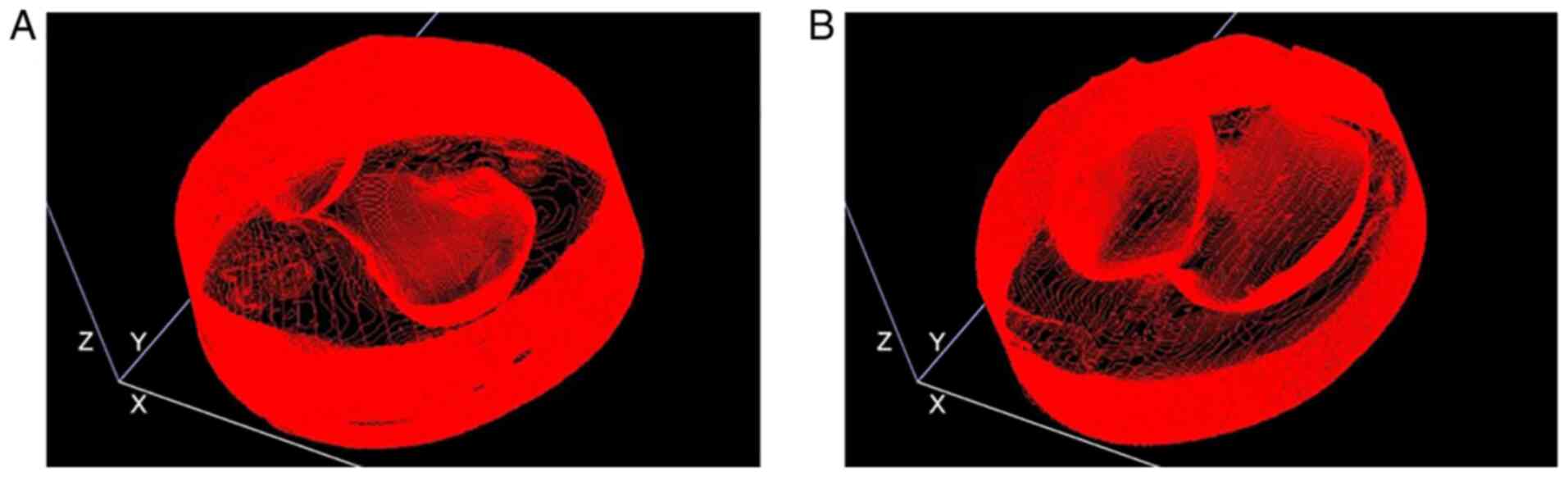

3D digital models in STL format were processed using

Insight software (v15.9; Stratasys, Ltd.; Figs. 4 and 5).

Results

Fig. 6, Fig. 7 and Fig.

8 show models obtained after processing, with the CNC

trajectories of the 3D printing head, in a thermally controlled

atmosphere. The distance between the printed layers was 0.127

mm.

The loading/unloading cups designed in this manner

simulated the acetabular cavity and the tibial plateaus

anatomically and could represent a good technical solution in order

to optimize the distribution of the loading/unloading forces in the

context of biomechanical experiments

Discussion

Most studies have attempted the loading directly on

the femoral head, thus failing to respect the in vivo model

(2,9,10).

Therefore, these studies (2-6,9,10)

have opted for loading the femoral head using a metallic plate that

shows limited contact with the femoral head. Other authors have

used a cadaveric hemipelvis, which was prepared to be tested

(7). In a biomechanical study on a

cadaveric femur (1), the femoral

head was loaded using a methyl polymethacrylate cup. Unlike the

aforementioned studies (2-6,9,10),

which attempted to load the femoral head by means of a rigid part

with limited contact, Kane et al (8) understood the necessity of a uniform

distribution of the mechanical stress at the level of the femoral

head and used a urethane polymer (Smooth-Cast1 Urethane Series 300;

Smooth-On, Inc.) to manufacture the loading cup. Although it

ensures a uniform distribution of mechanical tension in the femoral

head, the urethane polymer has properties similar to those of

natural rubber and fails to transmit forces naturally (https://us.misumi-ec.com/maker/misumi/mech/product/ur/detail/detail.html).

The ABS material was used by Reddy et al

(16) to design models of human

bones using additive manufacturing technology. They used CT to scan

various models of dry human bones and converted the resulting files

into the STL format, which was used to reconstruct the digital

model required for the 3D printing (16). Unlike Reddy et al (16), the present study used laser scanning

to create the 3D model, which is a faster and less costly

method.

It is well-known that, at the level of the femoral

head, the articular cartilage exhibits a phenomenon of progressive

degeneration following the loss of elasticity of the collagen fiber

network (17). Research conducted

by Kempson (17) and confirmed by

Silver et al (18) has

demonstrated that, at the level of the femoral head, the

superficial layer of the cartilage exhibits a decrease in pressure

resistance from 150 MPa at the age of 7 years to 80 MPa at the age

of 90 years and from 60 MPa at the age of 7 years to 10 MPa at the

age of 85 years. In a subsequent study, Silver et al

(13) identified an elastic module

of the articular cartilage at the level of the femoral head with

values of 7.0 GPa at parallel stress and 2.21 GPa at perpendicular

stress. In the present study, the ABS-M30 material used to design

the loading cup exhibited an elasticity module of 2.4 GPa, which

resembles the mechanical properties of adult hip cartilage.

3D printing is currently widely used in orthopedic

practice, particularly for pre-surgery planning in arthroplasties

and traumatology. Tack et al (14), in a systematic literature review

published in 2016, which analyzed the utility of 3D printing in

medical practice, identified 227 articles whose authors used

additive manufacturing technology in the current practice. Tack

et al (14) identified the

advantages of this technique: reduction of surgical time,

improvement of outcome and decrease of intra-surgery irradiation

time. In the field of research of orthopedics, notable progress has

been made regarding the mathematic modelling of the haversian

structure of the bone in view of designing experimental models

using additive manufacturing technology (15). Nevertheless, the authors of the

present study admit that there are important limitations related to

the printing material. Biomechanical studies simulating human

cartilage using additive manufacturing technology were not

identified in the literature. The selected material exhibits

similar tensile strength and tensile modulus compared with the

cartilage at the level of the adult human hip, thus mimicking the

mechanical properties of adult hip cartilage.

In conclusion, manufacturing the loading cups from

the ABS-M30 material using the method proposed in the present study

allowed the realistic reproduction of the anatomy and the

distribution of the forces at the level of the hip in in

vitro biomechanical studies simulating walking.

Acknowledgements

Not applicable.

Funding

Funding: No funding was received.

Availability of data and materials

All data generated or analyzed during this study are

included in this published article.

Authors' contributions

EC and TSG conceived the study. EC, TSG, PDS and BP

developed the methodology. OA, AF and PDS performed formal

analysis. AF, NF and MGP performed data curation. TSG and NF wrote

the initial draft of the manuscript. EC and PDS confirm the

authenticity of all the raw data. OA, BP EC and PDS revised the

manuscript in light of the literature findings. All authors

provided resources. All authors have read and approved the final

manuscript.

Ethics approval and consent to

participate

Not applicable.

Patient consent for publication

Not applicable.

Competing interests

The authors declare that they have no competing

interests.

References

|

1

|

Wang J, Ma JX, Jia HB, Chen Y, Yang Y and

Ma XL: Biomechanical evaluation of four methods for internal

fixation of comminuted subtrochanteric fractures. Medicine

(Baltimore). 95(e3382)2016.PubMed/NCBI View Article : Google Scholar

|

|

2

|

Schaefer TK, Spross C, Stoffel KK and

Yates PJ: Biomechanical properties of a posterior fully threaded

positioning screw for cannulated screw fixation of displaced neck

of femur fractures. Injury. 46:2130–2133. 2015.PubMed/NCBI View Article : Google Scholar

|

|

3

|

Röderer G, Moll S, Gebhard F, Claes L and

Krischak G: Side plate fixation vs. intramedullary nailing in an

unstable medial femoral neck fracture model: A comparative

biomechanical study. Clin Biomech (Bristol, Avon). 26:141–146.

2011.PubMed/NCBI View Article : Google Scholar

|

|

4

|

Windolf M, Braunstein V, Dutoit C and

Schwieger K: Is a helical shaped implant a superior alternative to

the Dynamic Hip Screw for unstable femoral neck fractures? A

biomechanical investigation. Clin Biomech (Bristol, Avon).

24:59–64. 2009.PubMed/NCBI View Article : Google Scholar

|

|

5

|

Strauss E, Frank J, Lee J, Kummer FJ and

Tejwani N: Helical blade versus sliding hip screw for treatment of

unstable intertrochanteric hip fractures: A biomechanical

evaluation. Injury. 37:984–989. 2006.PubMed/NCBI View Article : Google Scholar

|

|

6

|

Rosenblum SF, Zuckerman JD, Kummer FJ and

Tam BS: A biomechanical evaluation of the Gamma nail. J Bone Joint

Surg Br. 74:352–357. 1992.PubMed/NCBI View Article : Google Scholar

|

|

7

|

Santoni BG, Nayak AN, Cooper SA, Smithson

IR, Cox JL, Marberry ST and Sanders RW: Comparison of femoral head

rotation and varus collapse between a single lag screw and

integrated dual screw intertrochanteric hip fracture fixation

device using a cadaveric hemi-pelvis biomechanical model. J Orthop

Trauma. 30:164–169. 2016.PubMed/NCBI View Article : Google Scholar

|

|

8

|

Kane P, Vopat B, Heard W, Thakur N, Paller

D, Koruprolu S and Born C: Is tip apex distance as important as we

think? A biomechanical study examining optimal lag screw placement.

Clin Orthop Relat Res. 472:2492–2498. 2014.PubMed/NCBI View Article : Google Scholar

|

|

9

|

Basso T, Klaksvik J and Foss OA:

Statistical consequences of using bone mineral density to pair

cadaver femurs in comparative ex vivo hip fracture studies. Bone

Joint Res. 3:317–320. 2014.PubMed/NCBI View Article : Google Scholar

|

|

10

|

Basso T, Klaksvik J, Syversen U and Foss

OA: A biomechanical comparison of composite femurs and cadaver

femurs used in experiments on operated hip fractures. J Biomech.

47:3898–3902. 2014.PubMed/NCBI View Article : Google Scholar

|

|

11

|

Deneka DA, Simonian PT, Stankewich CJ,

Eckert D, Chapman JR and Tencer AF: Biomechanical comparison of

internal fixation techniques for the treatment of unstable

basicervical femoral neck fractures. J Orthop Trauma. 11:337–343.

1997.PubMed/NCBI View Article : Google Scholar

|

|

12

|

Yoshida H, Faust A, Wilckens J, Kitagawa

M, Fetto J and Chao EY: Three-dimensional dynamic hip contact area

and pressure distribution during activities of daily living. J

Biomech. 39:1996–2004. 2006.PubMed/NCBI View Article : Google Scholar

|

|

13

|

Silver FH, Bradica G and Tria A: Elastic

energy storage in human articular cartilage: Estimation of the

elastic modulus for type II collagen and changes associated with

osteoarthritis. Matrix Biol. 21:129–137. 2002.PubMed/NCBI View Article : Google Scholar

|

|

14

|

Tack P, Victor J, Gemmel P and Annemans L:

3D-printing techniques in a medical setting: A systematic

literature review. Biomed Eng Online. 15(115)2016.PubMed/NCBI View Article : Google Scholar

|

|

15

|

Robles-Linares JA, Ramírez-Cedillo E,

Siller HR, Rodríguez CA and Martínez-López JI: Parametric modeling

of biomimetic cortical bone microstructure for additive

manufacturing. Materials (Basel). 12(913)2019.PubMed/NCBI View Article : Google Scholar

|

|

16

|

Reddy MV, Eachempati K, Gurava Reddy AV

and Mugalur A: Error analysis: How precise is fused deposition

modeling in fabrication of bone models in comparison to the parent

bones? Indian J Orthop. 52:196–201. 2018.PubMed/NCBI View Article : Google Scholar

|

|

17

|

Kempson GE: Age-related changes in the

tensile properties of human articular cartilage: A comparative

study between the femoral head of the hip joint and the talus of

the ankle joint. Biochim Biophys Acta. 1075:223–230.

1991.PubMed/NCBI View Article : Google Scholar

|

|

18

|

Silver FH, Bradica G and Tria A:

Relationship among biomechanical, biochemical, and cellular changes

associated with osteoarthritis. Crit Rev Biomed Eng. 29:373–391.

2001.PubMed/NCBI View Article : Google Scholar

|