Introduction

Computed tomography (CT) has been widely used in

clinical diagnoses and treatments. In many CT scanners, standard

12-bit depth images have been commonly utilized, and 4,096 CT

values ranging from −1,024 HU to 3,071 HU have been established.

This range can accurately represent different tissues in patients

under normal conditions. However, CT values significantly exceed

the upper limit of 3,071 HU because of the presence of metal

implants in a patient's body. Therefore, different metal implants

cannot be distinguished in 12-bit images. In patients with common

hip prostheses, implants are characterized by either a high atomic

number or high-density metals. The exact CT values of such

prostheses cannot also be determined through conventional CT scan;

consequently, the calculated dose distributions of radiation are

affected (1,2). Therefore, 16-bit CT images are

reconstructed by extending the bit depth of CT (3–5), and this

reconstruction generates a wide range of CT values. Coolens

(6) also observed that stainless

steel, titanium, and other hip prostheses can be differentiated in

16-bit CT images. Metal regions can also be distinguished by

adjusting the window width and window level.

In radiotherapy, dose distribution is calculated on

the basis of a patient's CT image (7)

in a treatment planning system (TPS). In the TPS, a CT image is

converted to the corresponding electron density on the basis of a

calibrated CT with a relative electron density (CT-ED) curve, which

is obtained under a certain standard scanning condition. Patients

are usually examined under different scanning conditions depending

on clinical requirements. The frequent upgrades of hardware and

software for CT scanners and TPS may require recalibration

procedures, which are hard to satisfy. In practice, a conversion

table is usually fixed and a scanning condition similar to a

standard condition is selected whenever possible. Nevertheless,

this procedure may cause errors in dose delivery. Varying CT

scanning conditions may alter the CT value of the same material

(8). For instance, Zurl (9) demonstrated that a change in tube voltage

results in variations of up to 20% in HU and thus yields a maximum

dose error of 1.5%. However, dose errors may increase remarkably in

patients with high-density metal implants, and such errors are

detrimental to patients undergoing radiotherapy. In the present

study, stainless steel and titanium rods, which are commonly used

implanted materials, were scanned and analyzed under various CT

scanning conditions. Differences in dose distributions for CT

images were further analyzed.

Materials and methods

Experimental materials

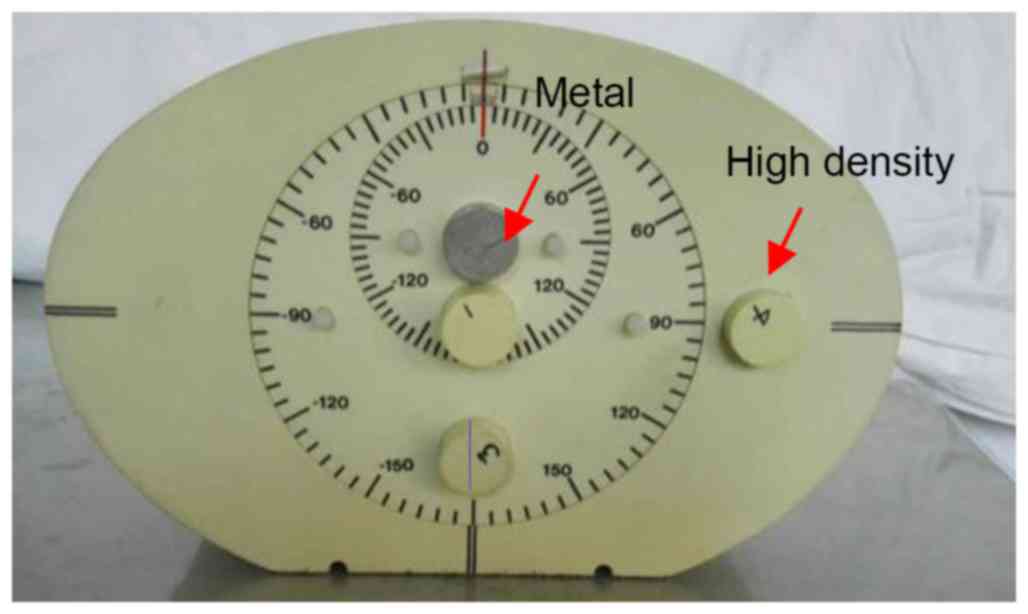

We used a computerized imaging reference system

(CIRS) intensity-modulated radiation therapy-verified phantom

(Fig. 1) produced by CIRS, Inc., USA.

A cylindrical metal rod, a stainless steel rod, or a titanium alloy

rod was inserted into the center of the phantom. A high-density rod

with a bone-like tissue and two cylindrical rods composed of a

material similar to that of the phantom were also utilized. The

phantom was scanned with SOMATOM Definition Flash CT (SIEMENS). The

extended bit depth function was chosen, and a 16-bit CT image was

reconstructed. The axial scanning mode was applied. The collimator

width was 64.0×0.6 mm and the X-ray tube rotation time was 0.5

s/rotation. The scanning layer thickness was 2 mm, and the image

reconstruction matrix was 512×512.

Experimental method

After the metal rod was inserted into the phantom,

the tube voltages or currents were altered and the other scanning

conditions were unchanged. The CT images were obtained under

different conditions during the experiment. The tube current was

fixed at 230 mA, and the tube voltages were 100, 120, and 140 kV.

The tube voltage was fixed at 120 kV, and the tube currents were

set to 180, 230, and 280 mA. CT image data in DICOM format were

inputted into MATLAB 8.3. The relationship between the CT value

distribution of the metal parts and the scanning conditions was

analyzed. The standard scanning conditions were set as 120 kV and

230 mA, and the absolute and relative differences in CT values were

calculated when the tube voltage and tube current were changed.

d=x–x120kV,230mA

r=dx120kV,230mA×100%.

where × is the CT value of the material under each

scanning condition, x120kV,230mA is the CT value of the

material under the standard scanning conditions 120 kV and 230 mA,

d is the absolute difference between these values, and r is the

relative difference between these values. Throughout this text, the

CT values are the theoretical Hounsfield number (HU) plus 1,000

(6,10); i.e., air =0 and water =1,000. The CT

value of the phantom is similar to water.

The densities of the titanium alloy and stainless

steel rods were high, and their corresponding CT values were

significantly higher than that of normal tissues. The metal parts

could be segmented on the basis of 4000 HU threshold. In the

phantom, the CT value of the metal parts fluctuated greatly because

of the serious ‘cupping artifact’ and inaccuracy. For the

cylindrical metal rod, the maximum CT value at the edge of the

metal region is close to the actual value (5). To correct the ‘cupping artifact’, we

uniformly set the CT values of the segmented metal area to the

maximum CT value of the metal region. The corrected CT images were

then inputted into the Varian treatment planning system (Varian

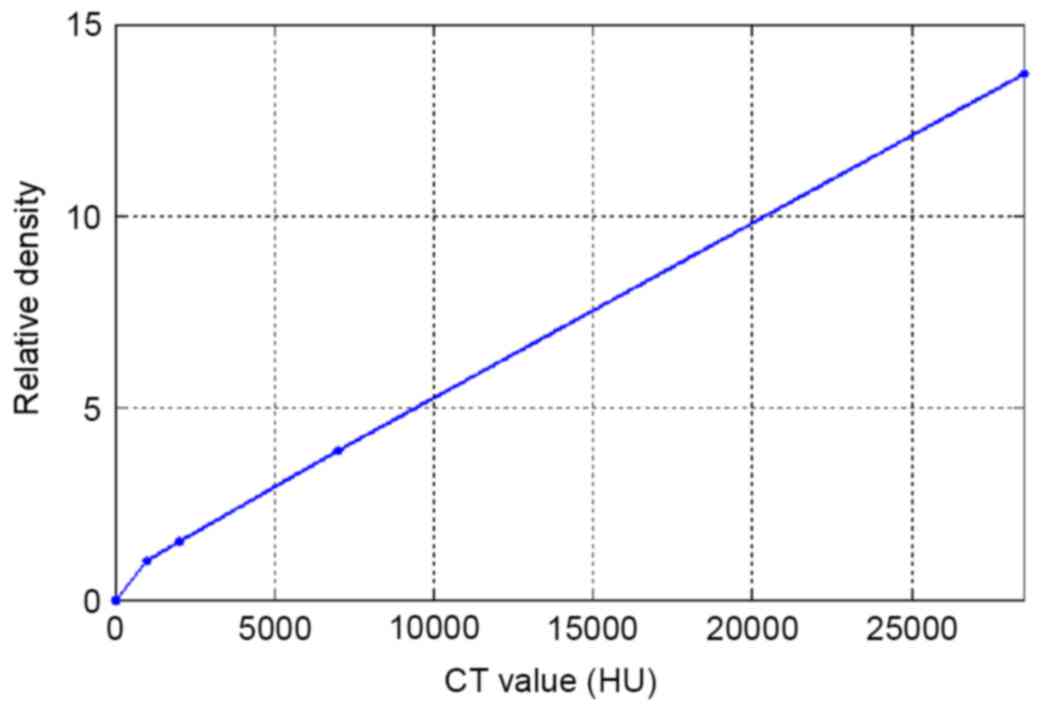

Eclipse edition 11.0). In the TPS, the CT-ED curve (Fig. 2) calibrated at 120 kV and 230 mA was

used in dose calculation. A radiotherapy treatment plan was

designed on the basis of these images. A 0° single irradiation

field was used, the source to skin distance (SSD) was 100 cm, and

the machine output quality was 200 MU. The radiation field was

10×10 cm, and the X-ray energy was 6 MV. Dose distribution was

calculated using an anisotropic analytic algorithm.

Results

CT value distribution in the

phantom

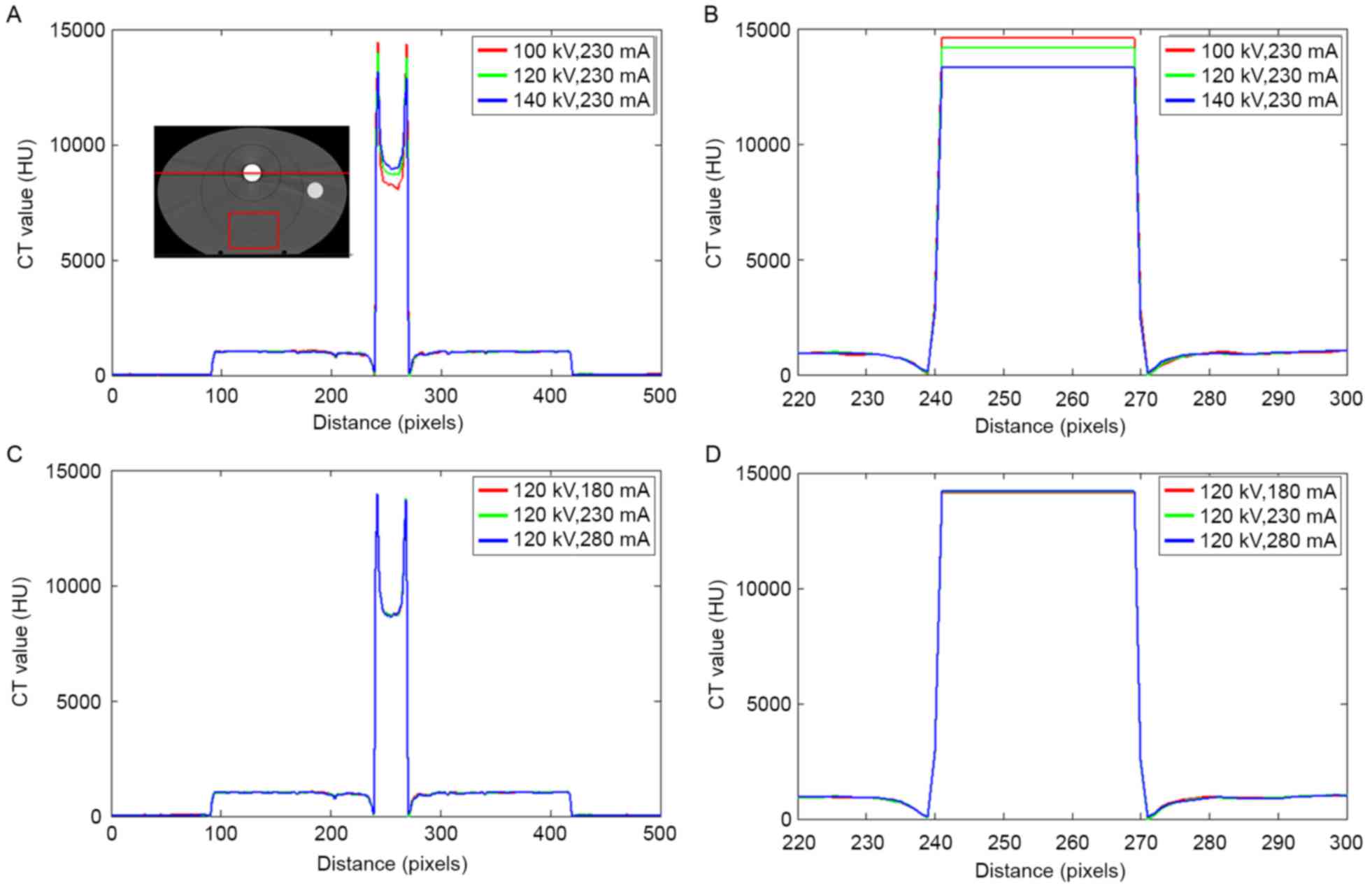

Fig. 3 depicts the CT

value distribution in the phantom with a stainless steel rod under

different scanning conditions. The serious ‘cupping artifact’ was

observed in uncorrected CT images Fig. 3A

and C. The tube voltage ranged from 100–140 kV, and the CT

values of the metals varied significantly. On the edge of the metal

area, the largest CT value was detected at 100 kV and the smallest

CT value was recorded at 140 kV. By contrast, the CT value of the

metal center was decreased at 100 kV and increased at 140 kV. The

changes in the tube current resulted in slight deviations in the

metal region.

A region of interest (ROI) in the phantom, as shown

in the rectangular red region far from the metal in Fig. 3A, was analyzed. The mean CT values of

the ROI were 999, 998, and 997 HU when the tube voltages were 100,

120, and 140 kV, respectively. The changes in the tube voltage

resulted in a slight variation of the CT values at low densities.

These findings are consistent with those in a previous study

(9). For the bone

equivalent insert, the mean CT values were 1,811, 1,741, and 1,700

HU when the tube voltages were 100, 120, and 140 kV, respectively.

The changes in the tube voltage resulted in larger deviations as

density increased.

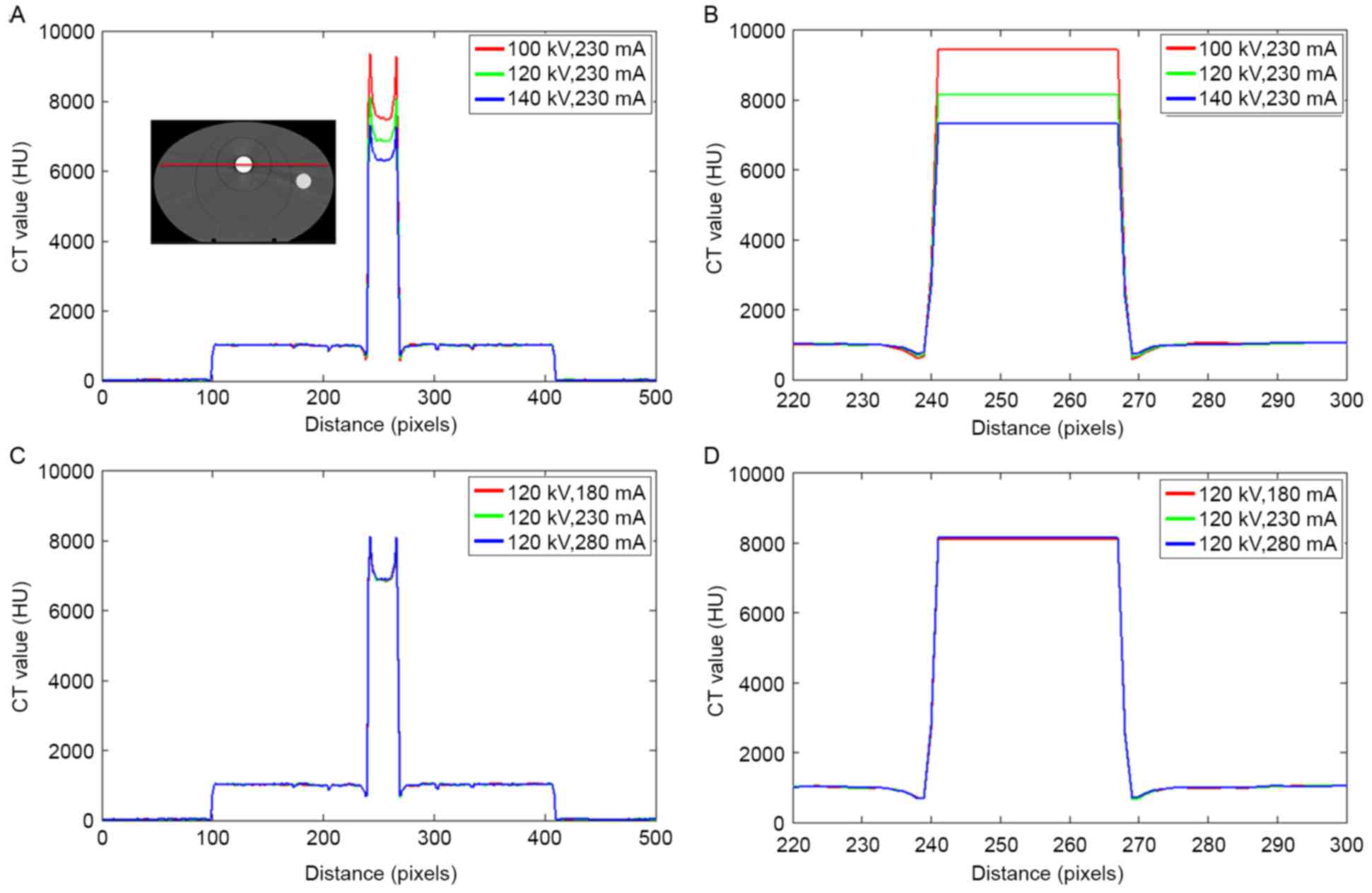

The CT value in the phantom with a titanium rod is

illustrated in Fig. 4. Similar to

those shown in Fig. 3, large

deviations were observed in the titanium rod as the tube voltage

changed. The CT value of the metal was slightly influenced by the

tube current.

The differences in the CT values of stainless steel

and titanium under various scanning conditions are shown in

Table I. The CT value of the metals

was corrected with the maximum CT values in the metal region. With

different tube voltages, the deviations in HU reached 5.89 and

15.72% for stainless steel and titanium, respectively. Variations

smaller than 1% in HU were caused by changes in the tube currents

for both stainless steel and titanium.

| Table I.Maximum CT values of stainless steel

and titanium under various scanning conditions. Differences

calculated through Eqs. (1) and

(2). |

Table I.

Maximum CT values of stainless steel

and titanium under various scanning conditions. Differences

calculated through Eqs. (1) and

(2).

|

| Stainless steel | Titanium |

|---|

|

|

|

|

|---|

| Scanning

conditions | CT value | d (HU) | r (%) | CT value | d (HU) | r (%) |

|---|

| 120 kV, 230 mA | 14,127 | – | – | 8,140 | – | – |

| 100 kV, 230 mA | 14,568 | 441 | 3.12 | 9,420 | 1,280 | 15.72 |

| 140 kV, 230 mA | 13,295 | −832 | −5.89 | 7,310 | −830 | −10.20 |

| 120 kV, 180 mA | 14,107 | −20 | −0.14 | 8,080 | −60 | −0.74 |

| 120 kV, 280 mA | 14,183 | 56 | 0.40 | 8,140 | 0 | 0 |

Dose distribution in the phantom

In the TPS, the CT image was converted to the

corresponding electron density via the CT-ED curve (11–13)

calibrated at 120 kV and 230 mA, and dose distribution was

calculated.

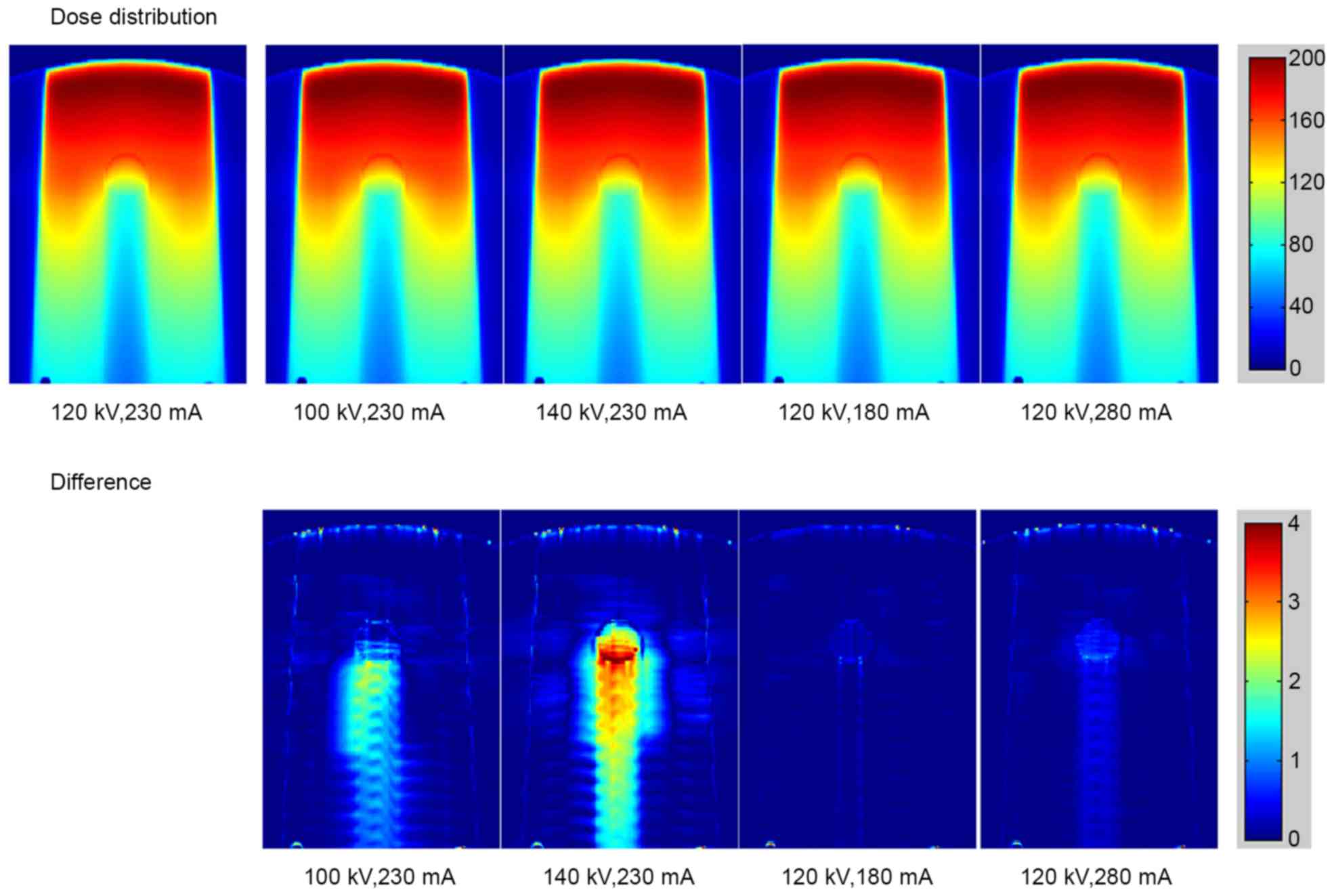

The calculated dose distributions in the phantom

with stainless steel rod under different scanning conditions are

shown in Fig. 5 (top row). The bottom

row in Fig. 5 reveals the dose

difference under various scanning conditions compared with the

standard conditions of 120 kV and 230 mA. The dose distribution for

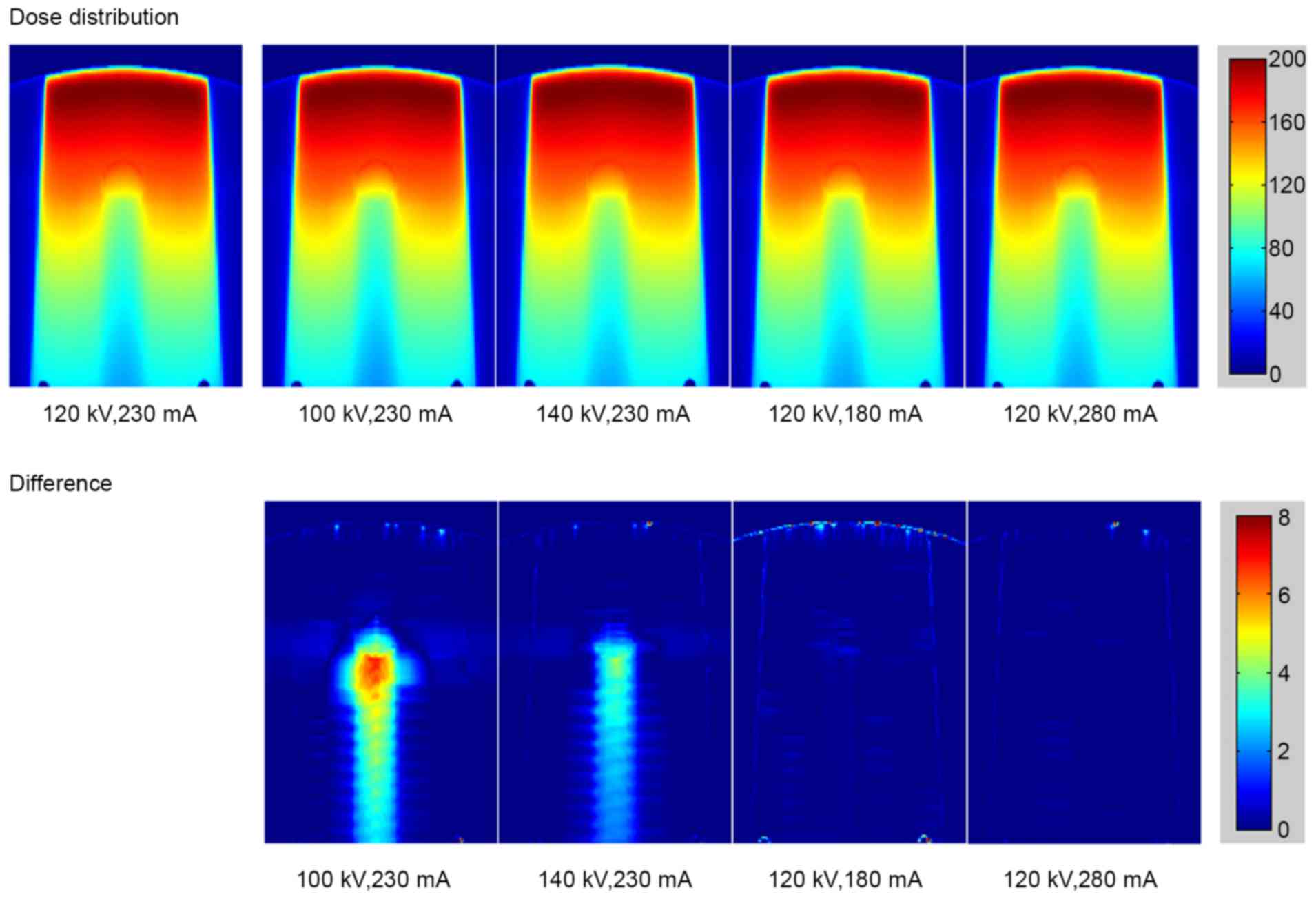

titanium rod is displayed in Fig. 6.

As the tube voltage changed, the dose errors resulting from the

deviations of CT values were observed in stainless steel and

titanium. The major error was detected in the region downstream of

the metal rod. Small errors caused by the tube current were also

detected.

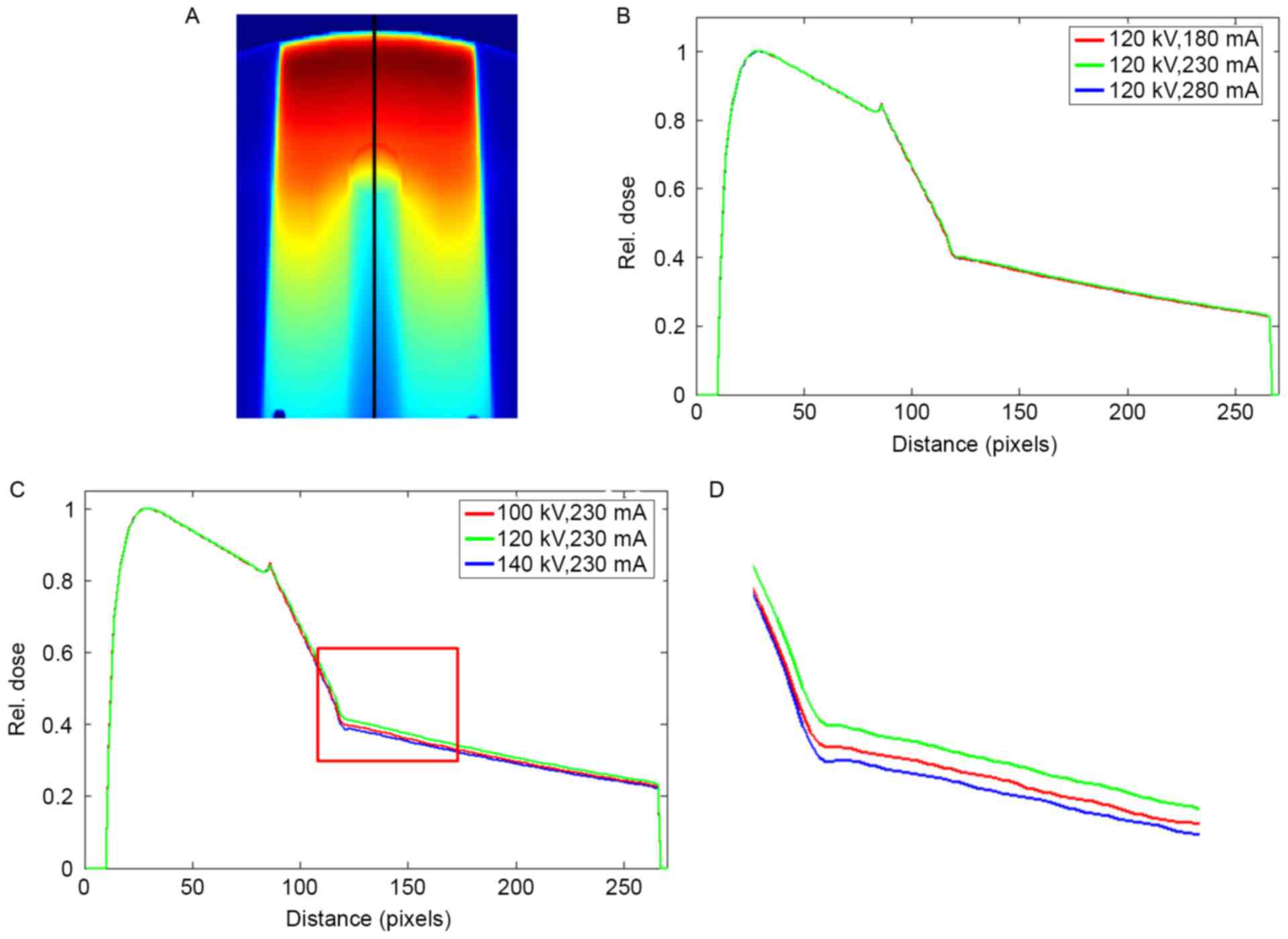

Fig. 7 summarizes the

dose profiles following the beam trajectory in the phantom with

stainless steel under different scanning conditions. The profiles

were normalized to the maximum dose before they were compared. A

peak was observed at the tissue-metal interface. At different tube

currents, the curves of the dose profiles almost completely

overlapped. As the tube currents changed to 180 and 280 mA, the

respective maximum dose errors were 0.55 and 0.98%. The changes in

tube voltages resulted in visible differences in the profiles. The

maximum dose errors of 2.85 and 5.70% were observed at 100 and 140

kV, respectively. The mean dose errors in the downstream of the

metal rod were 1.99 and 4.72% at 100 and 140 kV, respectively.

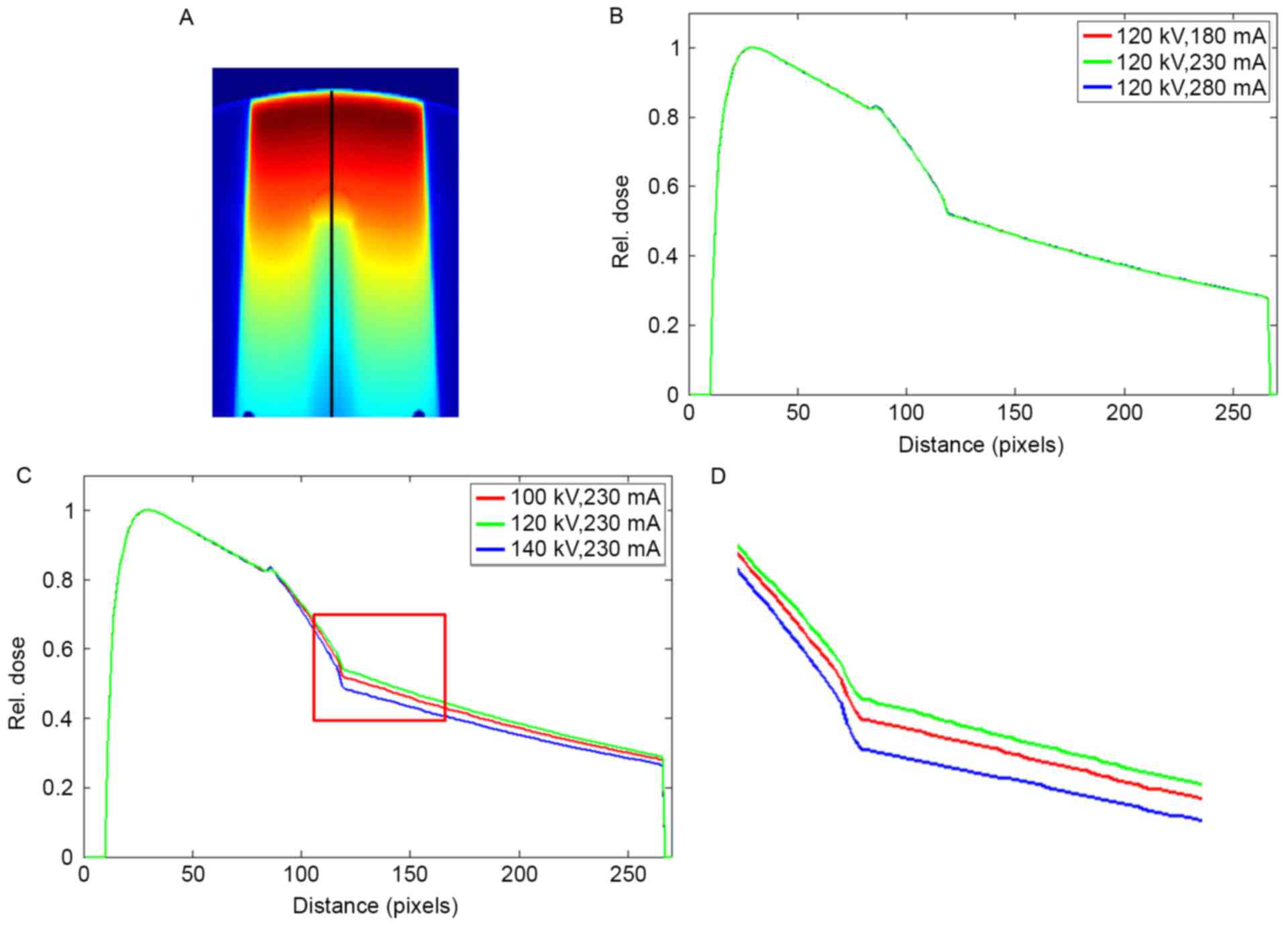

The dose profile in the phantom with titanium rod is

displayed in Fig. 8. Similar to

Fig. 7, the dose profiles almost

overlapped as the tube current changed, and significant differences

in the profiles were attributed to the variations in tube voltages.

The maximum dose errors of 0.61 and 0.09% were observed at 180 and

280 mA, respectively. The CT values of titanium did not vary as the

tube current was changed to 280 mA (Table

I). A dose error of up to 0.09% was a random error, not a

result of the changes in tube current. The maximum dose errors of

6.62 and 4.37% were observed at 100 and 140 kV, respectively. The

mean dose errors in the downstream of the metal rod were 5.26 and

3.31% at 100 and 140 kV, respectively.

Discussion

The dependence of CT values on scanning conditions

has been extensively investigated in normal tissues (14,15). Dose

errors caused by different scanner settings should be considered in

TPS (16). For metal implants,

variations in CT values as a result of different scanning

conditions are larger than those in normal tissues. Consequently,

dose errors are increased.

The present study aimed to evaluate the effects of

different scanning conditions on CT values and dose errors. For

stainless steel and titanium rods, CT values were slightly

influenced by tube currents. Thus, a maximum dose error of less

than 1% was obtained. However, the influence of the changes in tube

voltage on CT values should also be determined. In this study, the

CT values of the metal decreased as the tube voltage increased. As

the tube voltage was changed, the energy of the X-ray photon

emitted by a CT machine was altered. Attenuation coefficients

varied with X-ray energies. As a result, CT values varied. For

high-density materials, a decrease in tube voltage causes a

reduction of X-ray photon energy, and the attenuation coefficient

of a material is increased as CT values increase. For commonly used

implant materials, such as stainless steel and titanium, changes in

tube voltages affected CT values. Thus, evident dose errors were

obtained. The changes in the tube voltage yielded maximum dose

errors of 5.70 and 6.62% for stainless steel and titanium,

respectively. These findings were much larger than those in a

previous study (9), which showed a

maximum dose error of 1.5% in normal tissues.

Metal CT values can be determined through 16-bit CT

imaging. This method can also be applied to distinguish stainless

steel, titanium, and other metal implants with different densities.

The CT value of a metal implant changes significantly and the dose

distributions based on CT images considerably differ when tube

voltage is altered during CT imaging. The CT value of a metal

changes slightly when tube current is altered to a certain extent.

Thus, dose distributions slightly vary. In the radiotherapy of

patients with metal implants, CT scanning should be executed under

a fixed tube voltage to ensure accuracy of the calculated dose. The

tube voltage must be same as the condition under which the CT-ED

relationship was calibrated.

Acknowledgements

The present study was supported by the Natural

Science Foundation of Jiangsu Province Research of China (grant no.

BK20151181), High-Level Medical Talents Training.

Project of Changzhou (grant no: 2016CZLJ004) and the

Municipal Social Development Project of the Changzhou City, Jiangsu

Province, China (grant no. CJ20160029).

References

|

1

|

Keall PJ, Chock LB, Jeraj R, Siebers JV

and Mohan R: Image reconstruction and the effect on dose

calculation for hip prostheses. Med Dosim. 28:113–117. 2003.

View Article : Google Scholar : PubMed/NCBI

|

|

2

|

Keall PJ, Siebers JV, Jeraj R and Mohan R:

Radiotherapy dose calculations in the presence of hip prostheses.

Med Dosim. 28:107–112. 2002. View Article : Google Scholar

|

|

3

|

Glide-Hurst C, Chen D, Zhong H and Chetty

IJ: Changes Realized from extended bit-depth and metal artifact

reduction in CT. Med Phys. 40:0617112013. View Article : Google Scholar : PubMed/NCBI

|

|

4

|

Link TM, Berning W, Scherf S, Joosten U,

Joist A, Engelke K and Daldrup-Link HE: CT of metal implants:

Reduction of artifacts using an extended CT scale technique. J

Comput Assist Tomogr. 24:165–172. 2000. View Article : Google Scholar : PubMed/NCBI

|

|

5

|

Paudel MR, Mackenzie M, Fallone BG and

Rathee S: Evaluation of normalized metal artifact reduction (NMAR)

in kVCT Using MVCT prior images for radiotherapy treatment

planning. Med Phys. 40:0817012013. View Article : Google Scholar : PubMed/NCBI

|

|

6

|

Coolens C and Childs PJ: Calibration of CT

Hounsfield units for radiotherapy treatment planning of patients

with metallic hip prostheses: The use of the extended CT-scale.

Phys Med Biol. 48:1591–1603. 2003. View Article : Google Scholar : PubMed/NCBI

|

|

7

|

Schneider U, Pedroni E and Lomax A: The

calibration of CT hounsfield units for radiotherapy treatment

planning. Phys Med Biol. 41:111–124. 1996. View Article : Google Scholar : PubMed/NCBI

|

|

8

|

Thomas SJ: Relative electron density

calibration of CT scanners for radiotherapy treatment planning. Br

J Radiol. 72:781–786. 1999. View Article : Google Scholar : PubMed/NCBI

|

|

9

|

Zurl B, Tiefling R, Winkler P, Kindl P and

Kapp KS: Hounsfield units variations: Impact on CT-density based

conversion tables and their effects on dose distribution.

Strahlenther Onkol. 190:88–93. 2014. View Article : Google Scholar : PubMed/NCBI

|

|

10

|

Newhauser WD, Giebeler A, Langen KM,

Mirkovic D and Mohan R: Can megavoltage computed tomography reduce

proton range uncertainties in treatment plans for patients with

large metal implants? Phys Med Biol. 53:2327–2344. 2008. View Article : Google Scholar : PubMed/NCBI

|

|

11

|

Ebert MA, Lambert J and Greer PB: CT-ED

conversion on a GE Lightspeed-RT scanner: Influence of scanner

settings. Australas Phys Eng Sci Med. 31:154–159. 2008. View Article : Google Scholar : PubMed/NCBI

|

|

12

|

Saw CB, Loper A, Komanduri K, Combine T,

Huq S and Scicutella C: Determination of CT-to-density conversion

relationship for image-based treatment planning systems. Med Dosim.

30:145–148. 2005. View Article : Google Scholar : PubMed/NCBI

|

|

13

|

Constantinou C, Harrington JC and DeWerd

LA: An electron density calibration phantom for CT-based treatment

planning computers. Med Phys. 19:325–327. 1992. View Article : Google Scholar : PubMed/NCBI

|

|

14

|

Skrzyński W, Zielińska-Dabrowska S,

Wachowicz M, Slusarczyk-Kacprzyk W, Kukołowicz PF and Bulski W:

Computed tomography as a source of electron density information for

radiation treatment planning. Strahlenther Onkol. 186:327–333.

2010. View Article : Google Scholar : PubMed/NCBI

|

|

15

|

Zabel-du Bois A, Ackermann B, Hauswald H,

Schramm O, Sroka-Perez G, Huber P, Debus J and Milker-Zabel S:

Influence of intravenous contrast agent on dose calculation in 3-D

treatment planning for radiosurgery of cerebral arteriovenous

malformations. Strahlenther Onkol. 185:318–324. 2009. View Article : Google Scholar : PubMed/NCBI

|

|

16

|

Ramm U, Damrau M, Mose S, Manegold KH,

Rahl CG and Böttcher HD: Influence of CT contrast agents on dose

calculations in a 3D treatment planning system. Phys Med Biol.

46:2631–2635. 2001. View Article : Google Scholar : PubMed/NCBI

|