Introduction

Pure titanium (CP-Ti; α-type titanium alloy) and

Ti6Al4V (α+β-type titanium alloy), compared with other metallic

biomaterials, have attracted considerable attention for biomedical

applications due to their excellent specific corrosion resistance

and high biocompatibility with bone (1). However, although the elastic modulus

of the Ti6Al4V alloy (110 GPa) is substantially lower than that of

the Co-Cr-Mo alloy (230 GPa) and stainless steel (205 GPa), which

are used as biomaterials, it is still much higher than that of

human cortical bone (10–30 GPa) (2). A lower elastic modulus is important

for minimizing the undesirable complication of stress

shielding-bone resorption caused by unbalanced stress distribution

between the bone and implant. In addition, vanadium has been

previously found to be toxic to the human body (3,4).

Therefore, to resolve the drawbacks of the Ti6Al4V alloy, β-type Ti

alloys are increasingly being considered for use in medical

implants due to their lower elastic modulus and lack of toxic

elements.

In particular, a review of 15 titanium alloys,

including Ti6Al4V, CP-Ti, and β-type titanium alloys, showed that

the Young’s modulus of all β-type titanium alloys was lower than

that of α or α+β-type titanium alloys, and that the Ti35Nb5Ta7Zr

alloy showed the lowest Young’s modulus (55 GPa). With regard to

toxicity, β-type Ti alloys consist of β-stabilizing elements such

as Nb, Mn, Sn, Ta and Zr, which are considered safe for the human

body (5,6). Moreover, the biocompatibility of the

β-type Ti alloy has been extensively investigated. Miura et

al (7) reported that

osteoblasts cultured on the surface of the TiNbSn alloy and on

CP-Ti surface showed no significant differences in the relative

growth ratio and relative absorbance ratio, indicating that the

bone compatibility of the TiNbSn alloy is similar to that of

CP-Ti.

A new β-type alloy composed of nontoxic elements,

Ti35Nb2Ta3Zr, has been fabricated by vacuum consumable arc

remelting. Our preliminary experiments focused on the

microstructure and mechanical properties of Ti35Nb2Ta3Zr, and

showed that the new alloy exhibited a considerably low Young’s

modulus (approximately 48 GPa) and a high ultimate tensile strength

(approximately 880 MPa) after cold rolling (8,9);

therefore, it could be a suitable candidate for orthopedic

applications. For clinical applications, biological compatibility

must be evaluated in vitro and in vivo. Therefore,

the present study evaluated the bone tissue compatibility of the

new Ti35Nb2Ta3Zr alloy as a first step toward its use for

biomedical applications.

Materials and methods

Specimen preparation

The Ti35Nb2Ta3Zr alloy (wt %) was prepared by arc

melting a mixture of high-purity sponge Ti, Ti-Nb interalloy, and

high-purity Ta and Zr. The ingot was re-melted 3 times at 1,223 K

for 1 h under vacuum to ensure compositional homogeneity and then

forged into a quadrate cast with a width of 70 mm, thickness of 30

mm, and length of 100 mm. Following solid solution at 1,053 K for

0.5 h, the alloy was rolled to reduce its thickness by 99%.

Pure Ti, Ti6Al4V and Ti35Nb2Ta3Zr were machined to

disks with a diameter of 13 mm and a thickness of 1 mm to fit the

24-well plates. The surfaces of the disks were ground using a

series of water-resistant emery papers with various degrees of

coarseness up to 1,200 grit. All the disks were cleaned in an

ultrasonic bath with ethanol and deionized (Milli-Q) water,

followed by sterilization in an autoclave prior to cell

culture.

Surface characterization

The surface topography was imaged using a

field-emission scanning electron microscope (FESEM, FEI NOVA

NanoSEM). The surface roughness (Ra) was determined using atomic

force microscopy (AFM, Nanoscope 3; Bruker, Germany).

Energy-dispersive X-ray detection (EDX, X-Max 80; Oxford

Instruments, UK) was used to determine the elemental composition.

The contact angle was measured using a video contact-angle

measurement system.

Cell culture

MG63 cells (Cell Bank of the Chinese Science

Academy, China) were cultured in Dulbecco’s modified Eagle’s medium

(DMEM) supplemented with 10% (v/v) fetal bovine serum (Gibco) and

1% penicillin/streptomycin at 37°C in an atmosphere of 5%

CO2 and 95% air. The cells were cultured in osteogenic

media [the regular media described earlier, supplemented with 10 mM

β-glycerophosphate, 0.2 mM ascorbic acid, and 10−8 M

dexamethasone (Sigma)] to study cell differentiation. The culture

medium was replaced every 2 or 3 days. The cells were passaged by

lifting with trypsin/EDTA until they reached 80% confluence.

Cell adhesion

Osteoblasts were seeded on the samples at a density

of 1×104 cells/cm2. Following culture for 12

h, the non-adherent cells were removed by rinsing with

phosphate-buffered saline (PBS). The cells were fixed with 95%

alcohol and stained with 4′,6′-diamidino-2-phenylindole (DAPI). The

cells in 5 random fields were counted at low magnification under a

fluorescence microscope (Leica DM400).

Cell viability

The Cell Counting Kit-8 (CCK-8; Dojindo, Japan) was

used to determine the number of viable cells. In this assay,

2-(2-methoxy-4-nitrophenyl)-3-(4-nitrophenyl)-5-(2,4-disulfophenyl)-2H-tetrazolium,

monosodium salt (WST-8) is reduced by dehydrogenases in the cells

to provide an orange-colored product (formazan) that is soluble in

the tissue culture medium. The amount of the formazan dye generated

by the dehydrogenases in the cells is directly proportional to the

number of living cells. One milliliter of the cell suspension was

seeded onto each specimen with a density of 2×104

cells/ml. At 1, 4, 8 and 16 days after seeding, the samples were

gently rinsed 3 times with PBS, and 20 μl of prewarmed CCK-8

solution was added in 180 μl of culture medium. After 1 h of

further incubation, 100 μl of the working solution was

transferred to a new 96-well culture plate for measurement of the

absorbance using an ELISA reader at 450 nm.

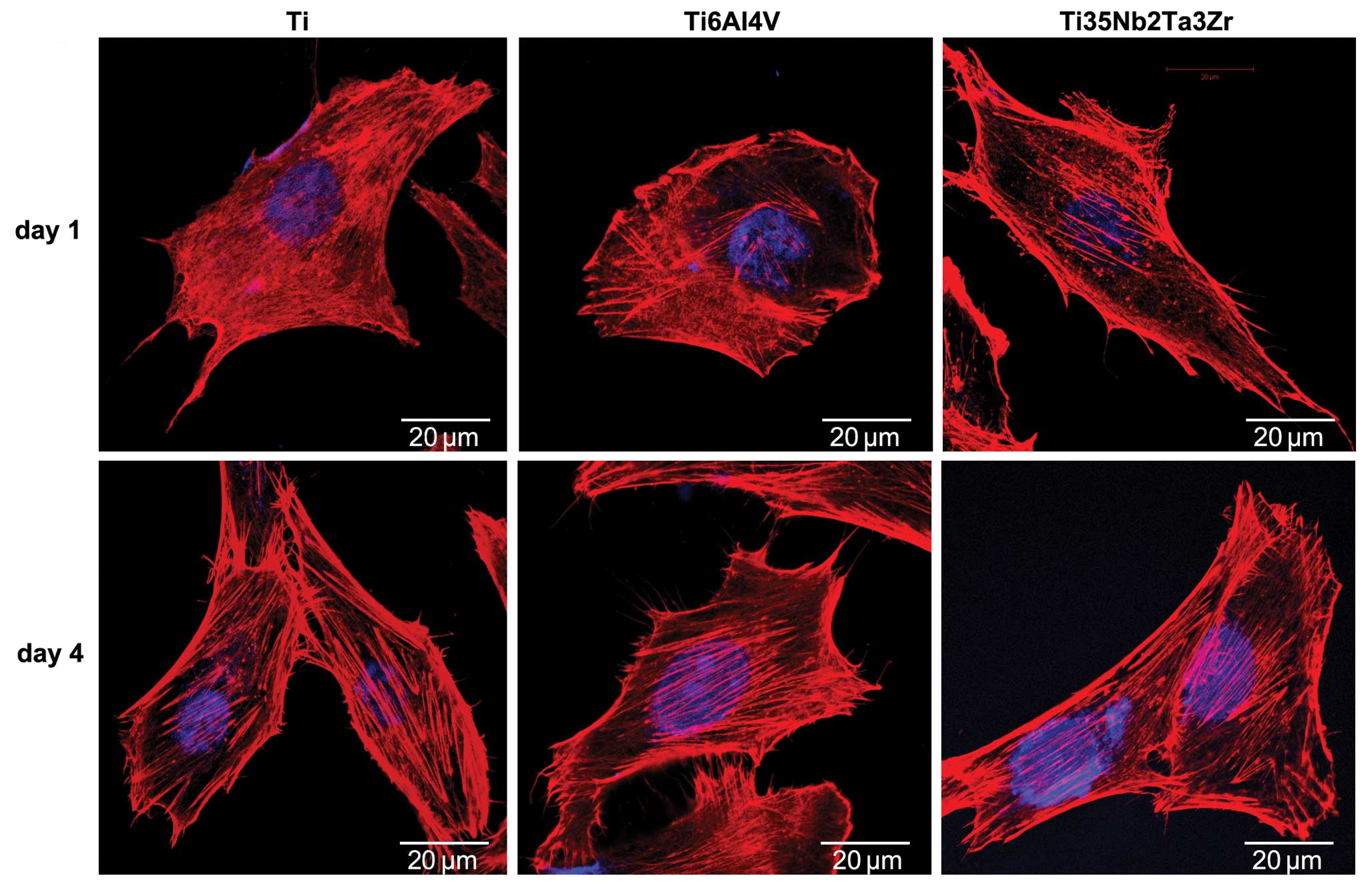

Cell morphology

MG63 cells were seeded on the samples for 1 and 4

days at a density of 1×104 cells/cm2. At the

prescribed time-points, the cells were fixed with 4%

paraformaldehyde (Sigma) and washed with PBS. They were then

permeabilized with 0.1% Triton X-100 and rinsed 3 times with PBS.

Nonspecific binding sites were blocked with 1% BSA in PBS.

Subsequently, the samples were incubated for 1 h with 200 μl

of TRITC-conjugated phalloidin (Molecular Probes, USA) in a

humidified chamber at room temperature in the dark. Finally, cell

nuclei were stained by incubation with 5 μg/ml DAPI

(Dojindo) followed by 2 PBS rinses. The morphology of the cells was

examined by confocal laser scanning microscopy (LSM-510; Carl

Zeiss, Germany).

Alkaline phosphatase (ALP) activity

MG63 cells were seeded on the samples at a density

of 1×104 cells/cm2. The ALP activity was

examined after the cells were cultured for 4, 8 and 16 days by

measuring the transformation of p-nitrophenyl-phosphate (pNPP) into

p-nitrophenol (pNP). Following the selected incubation periods, the

cells were rinsed 3 times with PBS and lysed in 0.1% Triton X-100

(Sigma) by using standard freeze-thaw cycling. Fifty microliters of

the sample were mixed with 50 μl of freshly prepared pNPP

substrate (1 mg/ml) and incubated at 37°C for 30 min. The reaction

was stopped by the addition of 50 μl of 0.2 M NaOH. The

amount of pNP produced was quantified by measuring the absorbance

at 405 nm in an ELISA reader. The total protein content was

measured using a BCA protein assay kit and calculated with respect

to a series of albumin (BSA) standards. Finally, the ALP activity

was normalized to the total protein content.

Calcium deposition

Mineralization was detected and quantified by

Alizarin Red S (ARS) staining at 8 and 16 days. Cells were seeded

on the samples at a density of 1×104

cells/cm2. At the indicated time-points, the samples

were washed 3 times in PBS and fixed in 4% paraformaldehyde for 30

min. The cells were then rinsed with ddH2O and stained

with ARS (40 mM) for 20 min at room temperature. After the

nonspecific staining was removed by rinsing with ddH2O,

the stain was desorbed with 10% cetylpyridinium chloride (Sigma).

Finally, the dye was transferred to a 96-well plate and quantified

using an ELISA reader at an absorbance of 590 nm.

Gene expression analysis by real-time

polymerase chain reaction (RT-PCR)

MG63 cells were seeded on the samples at a density

of 1×104 cells/cm2 and cultured for 16 days.

At the prescribed time-point, the adherent cells were lysed by

TRIzol (Invitrogen) and the total RNA was isolated according to the

TRIzol protocol. Subsequently, the total RNA was

reverse-transcribed to cDNA by using the RevertAid™ First Strand

cDNA Synthesis kit (Fermentas) following the manufacturer’s

instructions. Specific primers for the genes encoding

osteoblast-related proteins, ALP, osteocalcin (OC), and osteopontin

(OP), and the housekeeping gene GAPDH were synthesized commercially

(Generay, Shanghai, China). The specific primers are listed in

Table I. Quantitative RT-PCR was

then performed using SYBR®-Green Premix Ex Taq™ II

(Takara). Threshold cycle (Ct) values were obtained and the

amplification was determined. The GAPDH gene was used as a

reference control gene to normalize the expression values of the

target genes. The results are reported as the relative gene

expression calculated using the 2−ΔΔCt method.

| Table IPrimer sequences for polymerase chain

reaction. |

Table I

Primer sequences for polymerase chain

reaction.

| Gene | Primer sequences

(5′-3′) |

|---|

| ALP | F:

ATCGCCTACCAGCTCATG |

| R:

GTTCAGCTCGTACTGCATGTC |

| OC | F:

CTCACACTCCTCGCCCTATT |

| R:

GGTCAGCCAACTCGTCCAG |

| OP | F:

ACCTCACACATGGAAAGCGA |

| R:

CTGTGGAATTCACGGCTGAC |

| GAPDH | F:

TGACATCAAGAAGGTGGTGA |

| R:

TCCACCACCCTGTTGCTGTA |

Animal experiment

Twenty-four adult male New Zealand white rabbits

weighing 3.0–3.5 kg were used for the implantation study. This

animal experiment was approved by the Animal Care Committee of

Shanghai Sixth Hospital. The animals were anesthetized with

pentobarbital (25 mg/kg) by intravenous injection, and were

administered cefazolin sodium (20 mg/kg) by intravenous injection

prior to surgery. The distal medullary canal of the femur was used

as the implantation site. Prior to the surgical procedure, the area

surrounding the incision site was shaved and the skin was

sterilized using iodophor disinfectant. A longitudinal incision was

performed medially at the patella, and a 2.0-mm drill bit was used

to open the medullary canal through the intercondylar notch of the

distal femur. The distal medullary canal was then gently reamed

through a series of increasing drill bits (3, 4 and 4.5 mm). After

the medullary canal was rinsed with normal saline, the implants

were implanted into the medullary canal until the distal portion of

the implant was at the same level as the entry hole. The implants

were inserted into both femurs of each rabbit; the left femurs were

used for the push-out test and the right femurs were used for the

histological study. All rabbits were allowed to move freely using

the operated limbs without any limitation after the operation, and

the rabbits were observed daily for activity and weight-bearing on

the operated limbs. The new bone formed was double labeled by

tetracycline (30 mg/kg) and calcein (5 mg/kg) (Sigma), which were

intraperitoneally injected 14 and 3 days, respectively, before the

animals were sacrificed. The animals were sacrificed by an overdose

of intravenous pentobarbital sodium 4, 8 and 12 weeks following rod

implantation, with 4 animals in each group.

Radiographic evaluation

X-ray radiography was performed after the rabbits

were sacrificed at 12 weeks to evaluate the osseointegration

between the implants and surrounding bone tissue.

Pull-out test

The pull-out test was performed within 12 h after

the animals were sacrificed. The femur implanted with the rod was

excised, and the protruding portion of the implant was exposed for

attachment to the testing machine (Instron 5569; Instron, USA). The

maximum pull-out force was recorded at 4, 8 and 12 weeks to

indicate the quality of the attachment to the bone tissue.

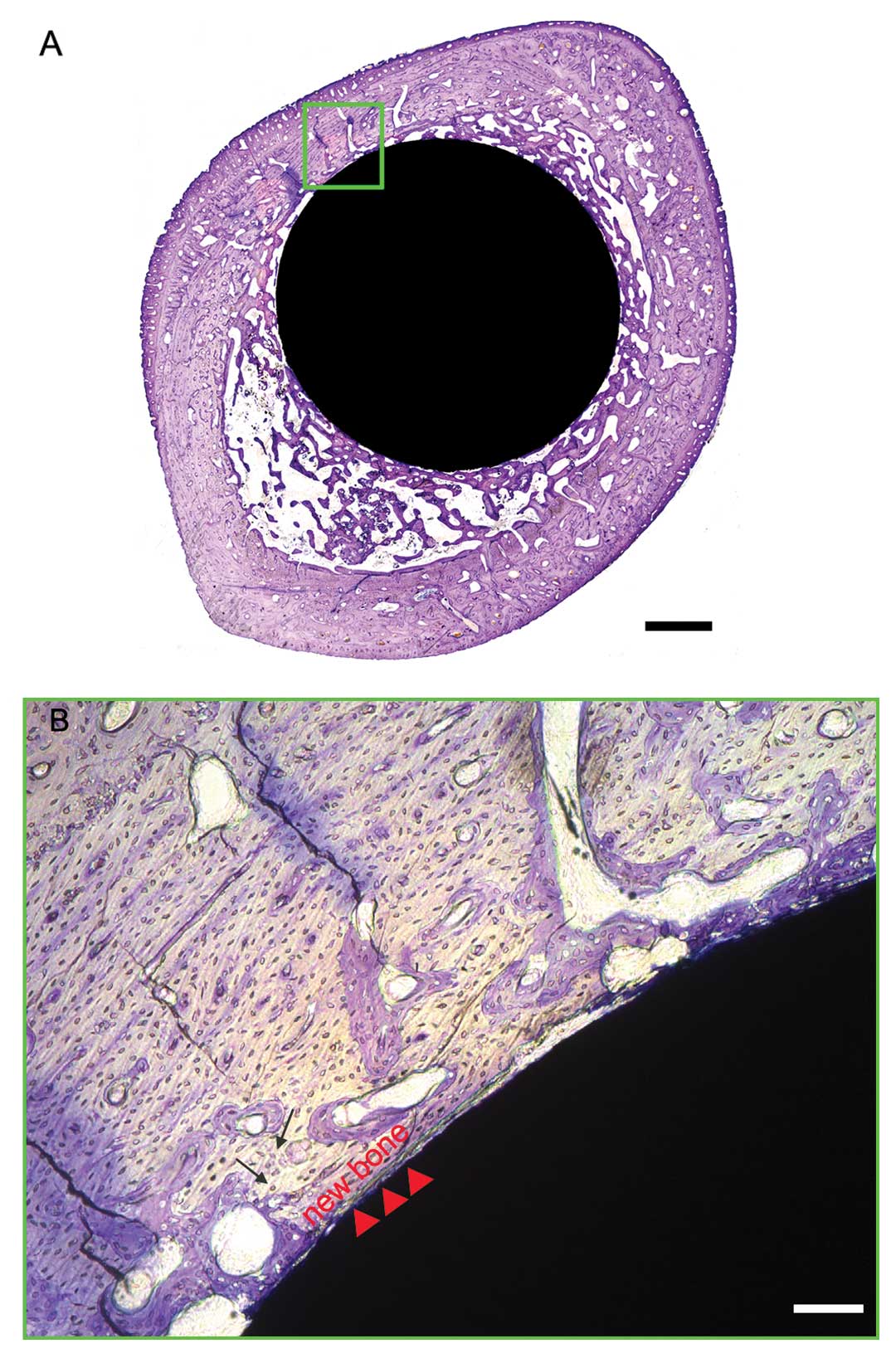

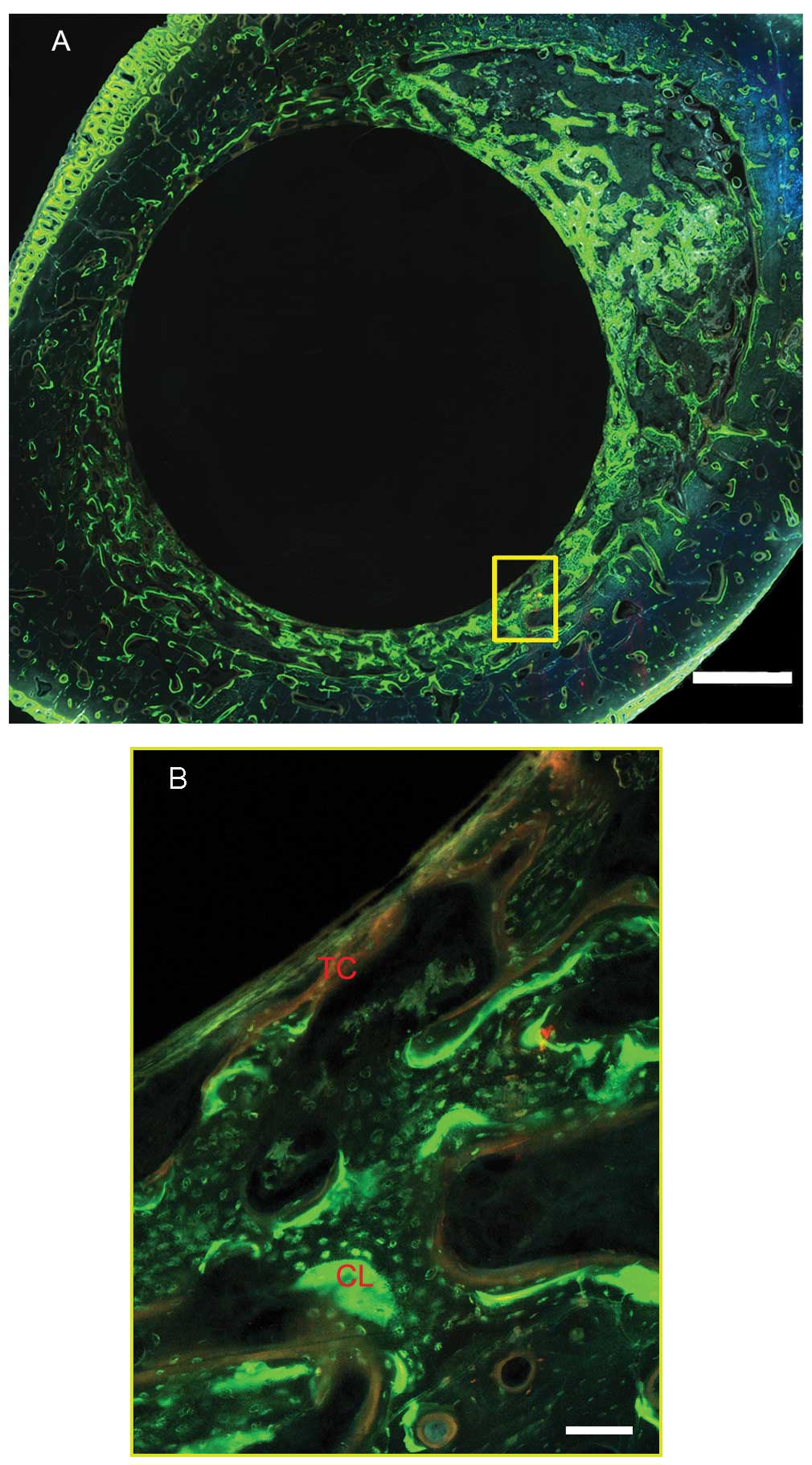

Histological evaluation

After the animals were sacrificed at the prescribed

time-points, the bone with the implant was fixed in acetone for 7

days, dehydrated in ascending grades of ethanol for 3 days each,

and embedded in methyl methacrylate without decalcification.

Sections (150 μm) were cut from each sample using a bone saw

(Leica SP1600) with the blade placed perpendicular to the long axis

of the implant at 3 levels (proximal, middle and distal) of the

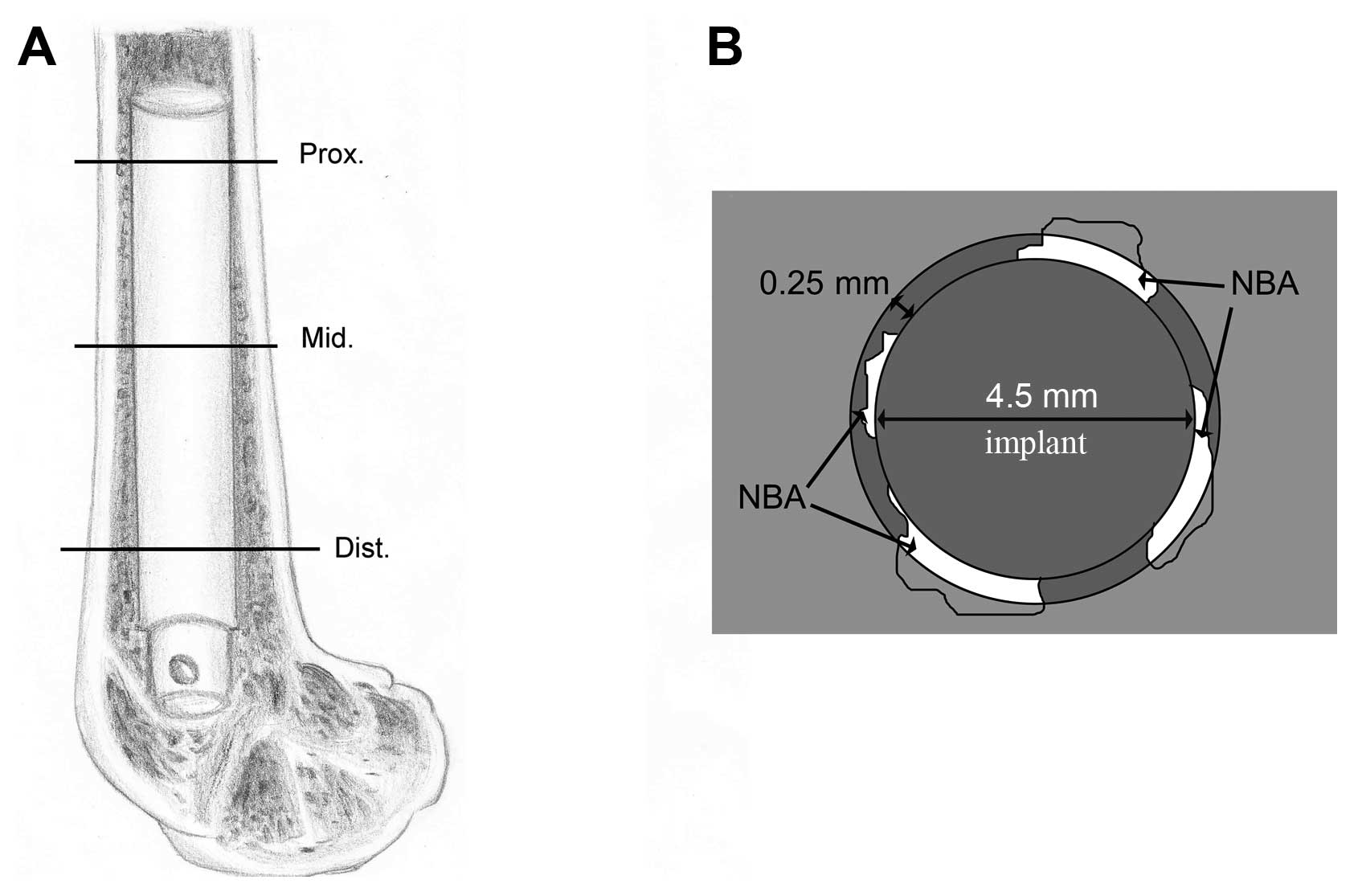

femur (Fig. 1A). Subsequently,

the sections were mounted on plastic slides and manually ground to

a thickness of 50–100 μm. Finally, the specimens were

stained with 1% methylene blue. The stained sections were observed

using a Leica microscope (Leica DM400), and the fluorochrome

markers were evaluated using a fluorescent microscope (Leica

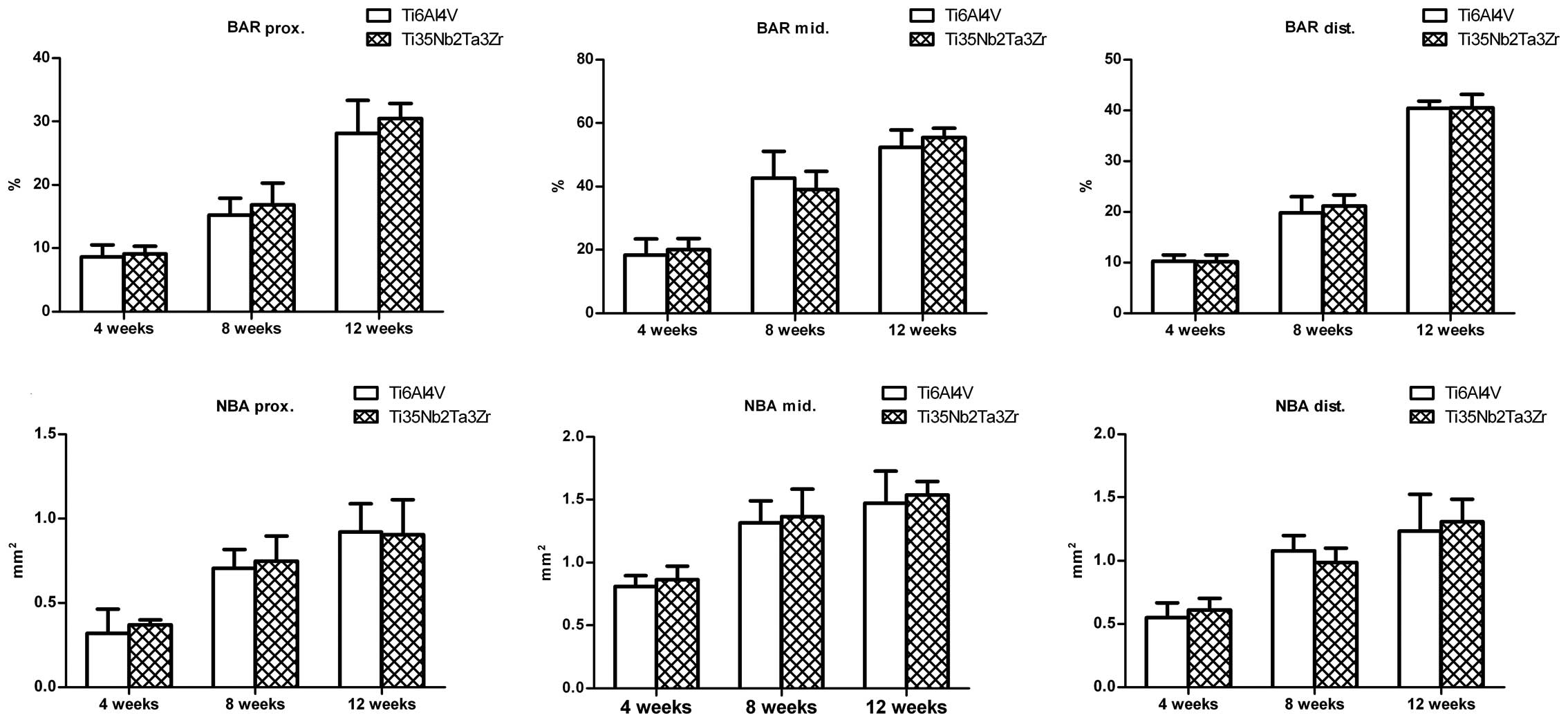

DMI6000B). The surface bone apposition ratio [BAR (%)] and the new

bone area [NBA (mm2)] surrounding the implant were

measured to evaluate the osseointegration. The circumference of the

implant was recorded to calculate the percentage of the surface

that was in direct contact with the bone in each section, and the

BAR was defined as the percentage of the implant surface in direct

contact with the bone. The area of the new bone tissue was measured

in a circumferential area within 0.25 mm from the rod surface

(Fig. 1B), and the NBA was

determined by observing the methylene blue staining and labeling

with tetracycline and calcein.

Statistical analysis

Statistical analyses were conducted using SPSS 16.0.

The data were obtained from 3 independent experiments and expressed

as the means ± standard deviation. Differences among groups for the

in vitro experiments were analyzed by one-way analysis

(ANOVA). Two-way factorial ANOVA and Bonferroni post-hoc tests were

used for the in vivo experiments. A P-value of <0.05 was

considered to indicate statistically significant differences.

Results

Surface characterization

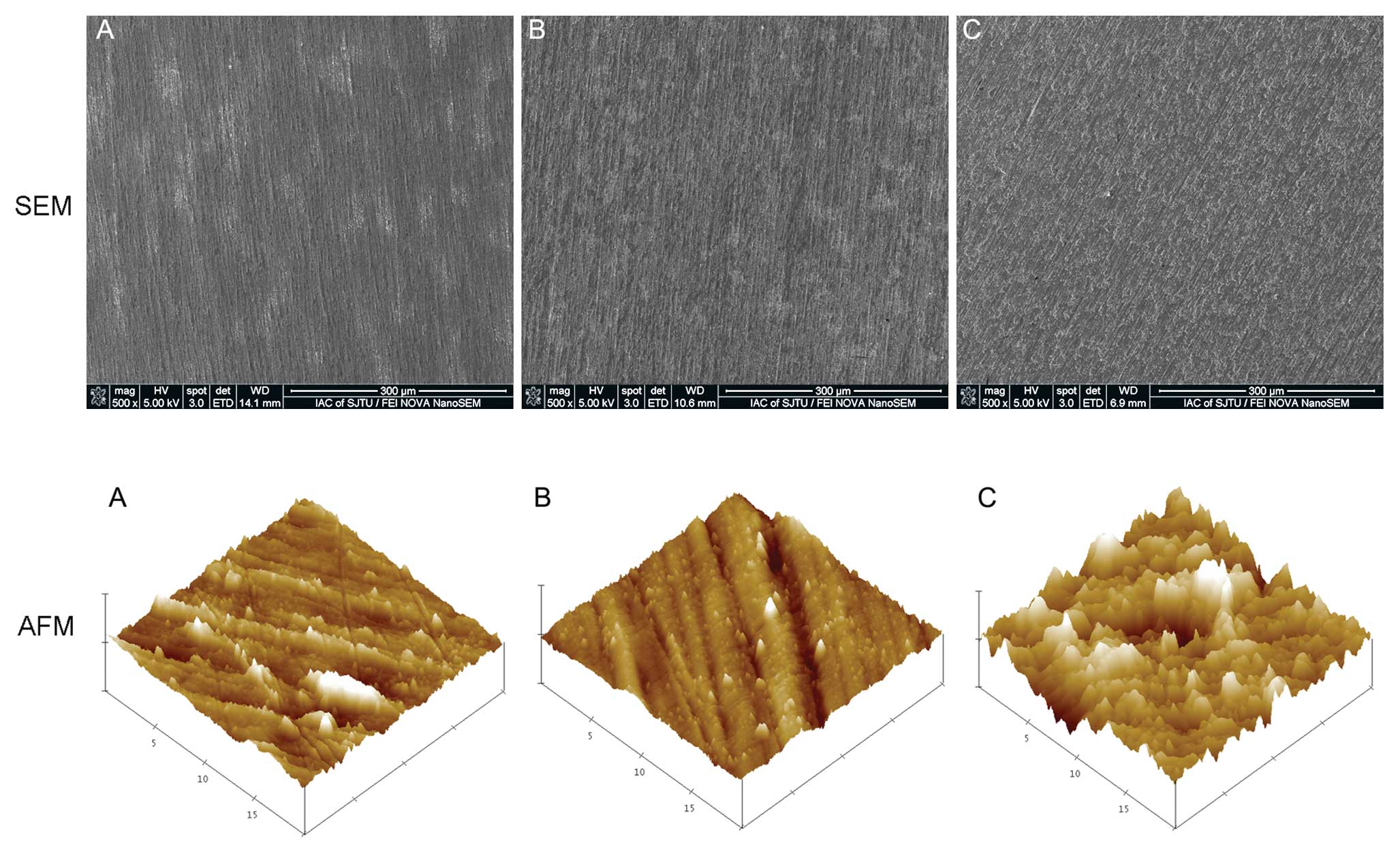

The SEM micrographs of Ti, Ti6Al4V, and Ti35Nb2Ta3Zr

are presented in Fig. 2. The

element composition measured by EDX was as follows: Ti, 59.55%; Nb,

35.44%; Ta, 2.14%; and Zr, 2.86%. The EDX results show that the

Ti35Nb2Ta3Zr alloy consisted of Ti, Nb, Ta and Zr; Al and V were

not observed. The Ra of the Ti, Ti6Al4V and Ti35Nb2Ta3Zr samples

determined by AFM (Fig. 2) is

summarized in Table II. The Ra of

Ti35Nb2Ta3Zr was the highest among the 3 samples. The surface

wettability measured as the water contact angle is also listed in

Table II; the surface of

Ti35Nb2Ta3Zr was found to be more hydrophilic than that of Ti and

Ti6Al4V.

| Table IIComparison among Ti, Ti6Al4V and

Ti35Nb2Ta3Zr in terms of surface properties. |

Table II

Comparison among Ti, Ti6Al4V and

Ti35Nb2Ta3Zr in terms of surface properties.

| Ra (nm) | Contact angle

(°) |

|---|

| Ti | 31.933±3.61 | 39.8±2.6 |

| Ti6Al4V | 24.235±4.28 | 41.3±1.9 |

| Ti35Nb2Ta3Zr | 49.667±8.02 | 32.1±2.0 |

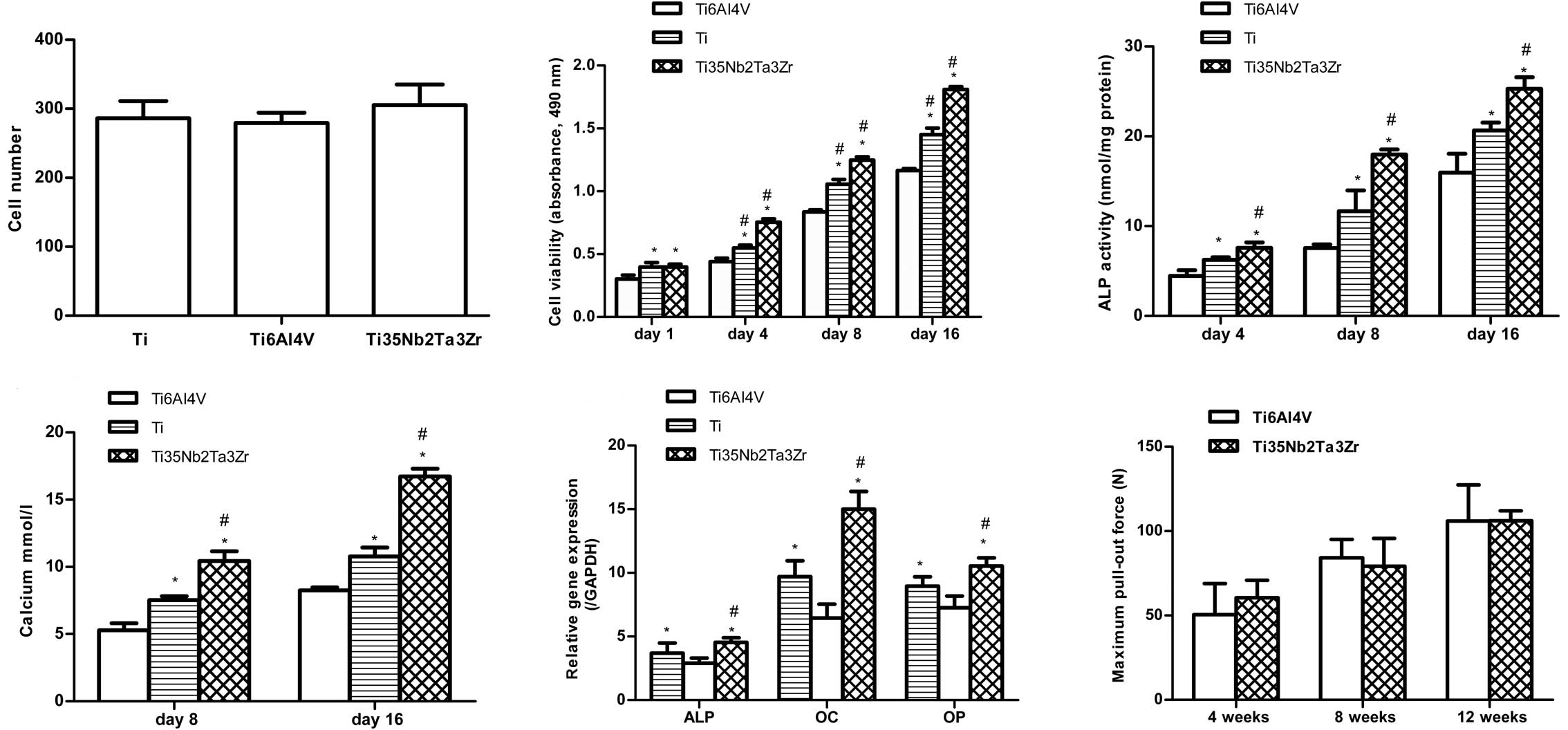

Cell adhesion and viability

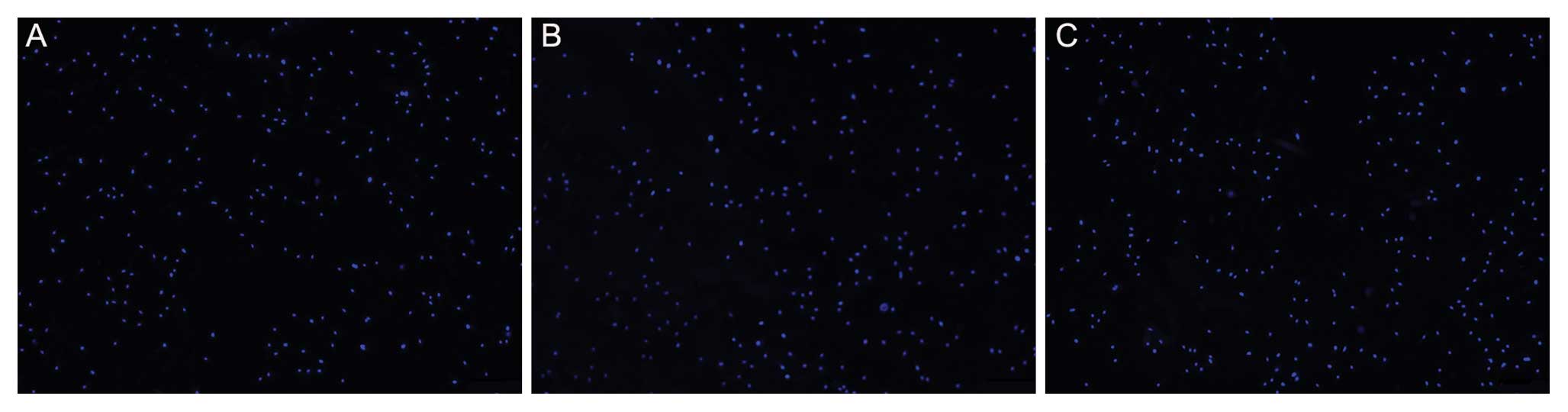

The fluorescence micrographs of cells stained with

DAPI indicate cell attachment (Figs.

3 and 4). No significant

differences were observed among the substrates after 12 h of

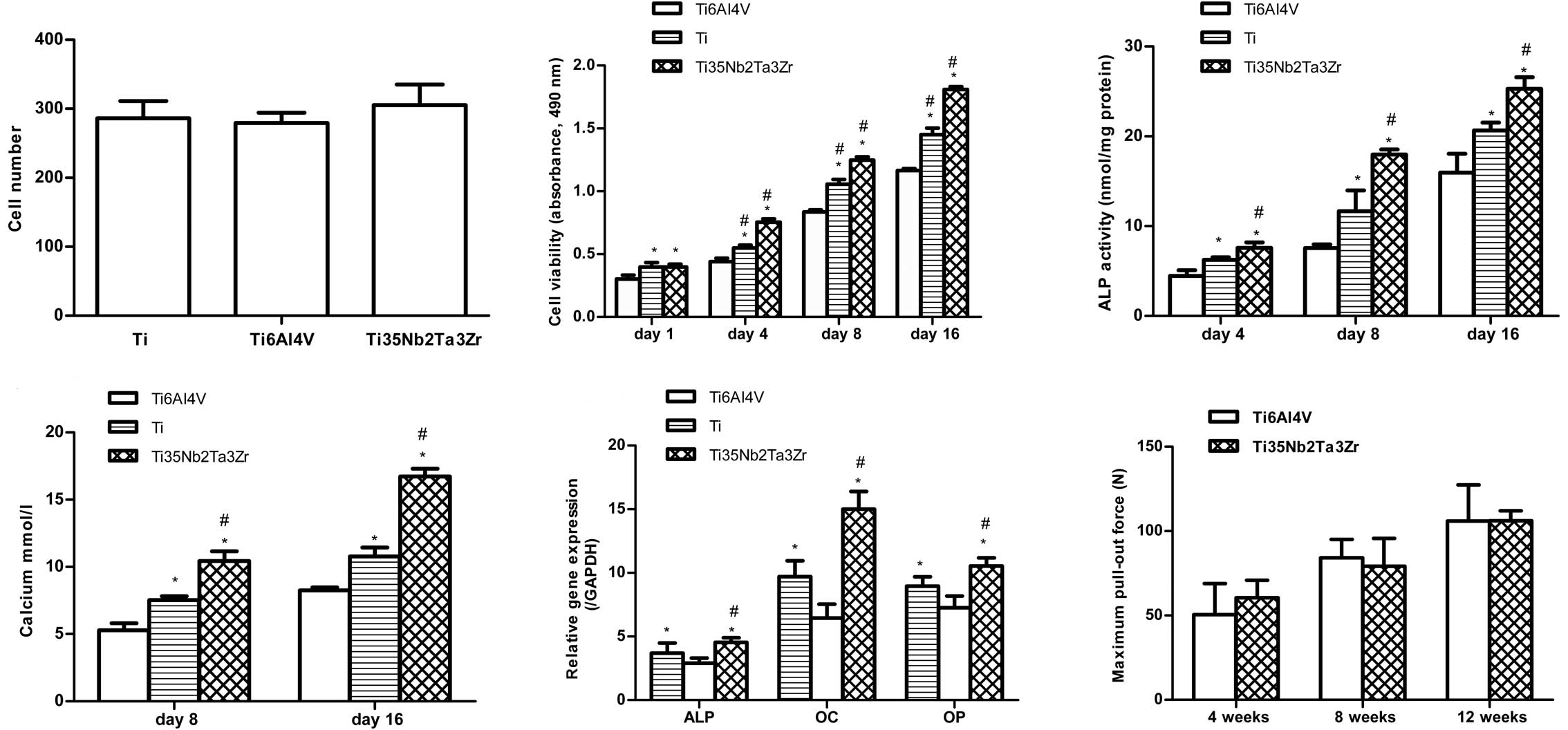

culture. Fig. 4 shows the

viability of MG63 cells as measured by CCK8 following culture for

1, 4, 8 and 16 days on the 3 different alloys. The cell viability

increased with time on all substrates. On Day 1, the cell

proliferation was higher on Ti and Ti35Nb2Ta3Zr than on Ti6Al4V but

it did not differ between Ti and Ti35Nb2Ta3Zr. From Day 4, cells

cultured on Ti35Nb2Ta3Zr proliferated more rapidly than those

cultured on Ti, and significant differences were observed between

Ti and Ti35Nb2Ta3Zr on Days 4, 8 and 16.

| Figure 4Osteoblast adhesion measured by cell

counting at 12 h, cell viability of MG63 cells after 1, 4, 8 or 16

days of culture, ALP activity (normalized to total protein amounts)

at 4, 8 and 16 days, calcium deposition after culture for 8 and 16

days and osteogenic mRNA expression (ALP, OC and OP) after culture

for 16 days on Ti, Ti6Al4V and Ti35Nb2Ta3Zr surfaces. The

failure-load values of Ti6Al4V and Ti35Nb2Ta3Zr alloys at 4, 8 and

12 weeks following implantation measured by the pull-out test. Data

are shown as the means ± SD. *P<0.05 compared with

Ti6Al4V; #P<0.05 compared with Ti. ALP, alkaline

phosphatase; OC, osteocalcin; OP, osteopontin. |

Cell morphology

Fig. 5 shows the

morphology of osteoblasts with dual staining of actin filaments and

nuclei following culture on the surfaces of the Ti, Ti6Al4V and

Ti35Nb2Ta3Zr samples. On Day 1, round or fusiform cells were

observed on the samples, and several pseudopodia of the osteoblasts

were clearly observed on the surface of Ti35Nb2Ta3Zr. On Day 4, the

osteoblasts had spread well and showed a polygonal shape, and actin

filaments were clearly observed on all the samples.

ALP activity and calcium deposition

Fig. 4 shows the

ALP activity of osteoblasts cultured on Ti, Ti6Al4V and

Ti35Nb2Ta3Zr samples on 4, 8 and 16 days. The findings for ALP

activity were similar to those for cell viability. Among the 3

samples, Ti35Nb2Ta3Zr exhibited the highest ALP activity at all

time-points (P<0.05). The Alizarin Red assay was used to

determine the extent of calcium mineralization. Fig. 4 shows that the amount of calcium

on all 3 different samples increased in a time-dependent manner,

and the Ti35Nb2Ta3Zr surfaces, compared to Ti and Ti6Al4V, had

significantly high calcium levels after 8 and 16 days of culture

(P<0.05).

Real-time polymerase chain reaction

analysis

The gene expression of MG63 cells grown on Ti,

Ti6Al4V and Ti35Nb2Ta3Zr surfaces for 16 days was analyzed using

RT-PCR (Fig. 4). Significantly

higher mRNA levels of ALP, OC and OP were observed on the

Ti35Nb2Ta3Zr surfaces on Day 16 than on the Ti and Ti6Al4V surfaces

(P<0.05), which indicates that the osteoblast differentiation

was enhanced on Ti35Nb2Ta3Zr surfaces compared with Ti and Ti6Al4V

surfaces.

Radiographic evaluation

Fig. 6 shows

typical radiographs of rabbit femurs 12 weeks following

implantation with Ti6Al4V and Ti35Nb2Ta3Zr. The implants were

located in the medullary canal, and no fractures were observed in

the operated bone. New bone tissue was observed around the implants

as indicated by the arrow in Fig.

6. No significant differences were observed among the

radiographs for the different conditions.

Pull-out test

Fig. 4 shows the

failure loads. The failure-load values gradually increased with

time in both groups. However, there were no significant differences

between the 2 alloys at any time.

Histological evaluation

Figs. 7 and

8 show representative

histological images of the middle section of the Ti35Nb2Ta3Zr alloy

at 12 weeks after implantation. Newly formed bone tissue was

clearly observed around the surface of both the alloys. The dynamic

process of new bone formation was observed by light microscopy and

fluorescence microscopy (Fig. 8).

As shown in Fig. 7, good contact

was observed between the bone tissue and the Ti35Nb2Ta3Zr alloy.

Under fluorescence microscopy, a double line of tetracycline and

calcein was clearly observed, indicating new bone formation. The

formation of osteocytes (indicated by the arrows in Fig. 7) in the lamellar bone matrix was

irregular, indicating that the bone tissue grew well on the surface

of the alloys. The BAR and NBA at the surface of the Ti6Al4V and

Ti35Nb2Ta3Zr alloys gradually increased in the 3 sections of the

femur. The BAR and NBA did not differ between the 2 groups in all

sections of the femur at 4, 8 and 12 weeks (Fig. 9).

Discussion

In the present study, the in vitro and in

vivo biocompatibility of a β-type Ti35Nb2Ta3Zr alloy with a low

elastic modulus of approximately 48 GPa was evaluated.

In vitro biological properties

A direct-contact culture test was performed to

assess the in vitro biocompatibility of Ti35Nb2Ta3Zr

(10–13). Ti6Al4V and Ti were used as

controls as they are known to be biocompatible. The proliferation

of MG63 cells was higher on Ti35Nb2Ta3Zr than on Ti6Al4V and Ti

after culture for 4 days and remained high until Day 16. The dual

staining of the actin filaments and nuclei of osteoblasts indicated

that the cells had spread well on the 3 samples. Significant

increases in the ALP activity and calcium deposition were observed

at all time-points, consistent with the mRNA expression of the

genes encoding the osteogenic proteins ALP, OC and OP.

Roughness and hydrophilicity are key factors in the

response of cells to biomaterials. Rough, hydrophilic surfaces on

Ti implants may increase the viability, ALP activity, and calcium

deposition of osteoblasts in vitro (14–17). The molecular mechanisms

responsible for the enhancement of osteogenic properties by surface

topography have been evaluated in several studies. Zhuang et

al (18) demonstrated that

cells cultured on smooth surfaces treated with PD98095 (an ERK1/2

inhibitor) or rough SLA surfaces (sand-blasted acid-etched

surfaces) without PD98095 treatment showed reduced extracellular

signal-regulated kinase 1/2 (ERK1/2) phosphorylation and increased

expression levels of osteogenic genes (i.e., Runx2, OSX, OPN and

OCN). Thus, the effect of surface roughness on osteoblastic

differentiation may be mediated through the inhibition of the

ERK1/2 pathway, which is consistent with the findings of other

studies (19,20). Olivares-Navarrete et al

(21) reported that the mRNA

level of non-canonical pathway ligands, receptors, and

intracellular signaling molecules was higher in cells cultured on

SLA surfaces than in those cultured on smooth surfaces. In

particular, increased ALP activity and osteocalcin production were

observed after osteoblasts were treated with Wnt5a (a non-canonical

pathway activator), suggesting that the non-canonical pathway was

involved in the differentiation of osteoblasts on microstructured

titanium surfaces. Similarly, Vlacic-Zischke et al (22) showed, using a whole-genome

analysis, that the TGF-β/BMP signaling pathway members BMP2, BMP6

and ACVR1 were upregulated in osteoblasts cultured on SLA and

modSLA (hydrophilic SLA). The expression of miRNAs has also been

investigated in relation to the modulation of osteogenic gene

expression by SLA and modSLA surfaces. Target predictions for the

differentially regulated miRNAs indicated that 35 and 10 miRNAs

were downregulated and upregulated, respectively, on modSLA

surfaces, and 32 and 9 miRNAs were downregulated and upregulated,

respectively, on SLA surfaces. Additionally, several genes involved

in the TGF-β/BMP and non-canonical Wnt/Ca2+ pathways

were identified as potential targets for the miRNAs during

differentiation on modSLA and SLA surfaces. These mechanisms may

also be involved in the enhanced proliferation and differentiation

of osteoblasts that we observed on Ti35Nb2Ta3Zr surfaces, which, as

described above, had rougher and more hydrophilic surfaces.

Tantalum and zirconium may have also contributed to

the observed effects on osteoblast cells, since the positive

effects of Ta and Zr on cell attachment, proliferation, and

differentiation have been well documented (23–28). Stiehler et al (23) reported that mesenchymal stem cells

cultured on Ta surfaces had a significantly increased mean cellular

area and cell-specific ALP activity compared with those cultured on

Ti and chromium surfaces. Additionally, Sista et al

(26) showed that the adhesion,

proliferation, and differentiation of MC3T3-E1 osteoblast cells

were better on TiZr than on TiNb or Ti. A key factor for this

difference was the presence of Zr in the TiZr alloy (26). A microRNA microarray analysis

showed that NOG, SHOX, IGF1, BMP1 and FGFR1 are differentially

regulated in osteoblasts exposed to zirconium (29). In the present study, Ta and Zr

were confirmed to be present on the surface of Ti35Nb2Ta3Zr by EDX.

Therefore, it is plausible that the presence of surface Ta and Zr

may have contributed to the enhanced osteoblast function observed

on Ti35Nb2Ta3Zr.

In vivo biomechanical and biological

properties

In an in vivo study, intramedullary rods were

inserted into rabbit femurs, and the bone compatibility of the

Ti35Nb2Ta3Zr alloy was assessed in comparison to Ti6Al4V, which is

considered bioinert material and has been widely used in medical

fields. The failure load gradually increased with time following

implantation in both groups, but there were no significant

differences between the failure loads of the Ti6Al4V and

Ti35Nb2Ta3Zr alloys at any time-point. These results are in

agreement with those of previous studies. Miura et al

(7) evaluated the pull-out

strength of Ti6Al4V and TiNbSn alloys at 3, 6 and 12 weeks

following implantation and reported that the failure loads of the 2

alloys increased with time, with no differences observed between

the alloys.

The methylene blue staining and double labeling of

tetracycline and calcein were used to evaluate new bone formation

at the bone-implant interface. The BAR and NBA of the Ti6Al4V and

Ti35Nb2Ta3Zr alloys gradually increased with time, and the values

did not differ between the 2 alloys. These results are similar to

those of previous studies. Miura et al (7) reported that the BAR and NBA of

Ti6Al4V and TiNbSn beneath cortical bone increased with time, but

the NBA of TiNbSn rapidly increased up to 6 weeks and reached a

peak. Lin et al (30)

evaluated Ti6Al4V and Ti7.5Mo alloys and obtained similar results.

However, the NBA of Ti6Al4V surrounded by cancellous bone decreased

with time after a peak at 12 weeks, and the NBA of Ti7.5Mo

continually increased after 12 weeks. No peak was observed in our

study. Although there was no significant difference in the BAR and

NBA between Ti6Al4V and Ti35Nb2Ta3Zr, the values of BAR and NBA

were higher for Ti35Nb2Ta3Zr, indicating that the in vivo

biocompatibility of Ti35Nb2Ta3Zr is equal to that of Ti6Al4V, which

has been widely used in biomedical fields. The lesser stiffness of

Ti35Nb2Ta3Zr may facilitate new bone formation.

In conclusion, the in vitro assay showed that

the adhesion, proliferation, and differentiation of osteoblasts

were better on Ti35Nb2Ta3Zr than on Ti and Ti6Al4V. The in

vivo study showed that the extent of new bone formation around

the Ti35Nb2Ta3Zr implants was equal to that around the Ti6Al4V

implants. In summary, the Ti35Nb2Ta3Zr alloy with a lower elastic

modulus has notable bone tissue compatibility in vitro and

in vivo, and may therefore be useful biomedical material in

the future.

Acknowledgements

This study was supported by the

National Natural Science Foundation of China (grant no. 81171688),

the Interdisciplinary (Engineering-Medical) Research Fund of

Shanghai Jiao Tong University (grant no. YG2011MS30), and the

Shanghai Municipal Health Bureau Science Fund for Young Scholars

(grant no. 2010QJ036A).

References

|

1

|

Rack H and Qazi J: Titanium alloys for

biomedical applications. Mater Sci Eng C. 26:1269–1277. 2006.

View Article : Google Scholar

|

|

2

|

Snyder SM and Schneider E: Estimation of

mechanical properties of cortical bone by computed tomography. J

Orthop Res. 9:422–431. 1991. View Article : Google Scholar : PubMed/NCBI

|

|

3

|

Rae T: The toxicity of metals used in

orthopaedic prostheses. An experimental study using cultured human

synovial fibroblasts. J Bone Joint Surg Br. 63-B:435–440.

1981.PubMed/NCBI

|

|

4

|

Hallab NJ, Vermes C, Messina C, Roebuck

KA, Glant TT and Jacobs JJ: Concentration- and

composition-dependent effects of metal ions on human MG-63

osteoblasts. J Biomed Mater Res. 60:420–433. 2002. View Article : Google Scholar : PubMed/NCBI

|

|

5

|

Guillemot F: Recent advances in the design

of titanium alloys for orthopedic applications. Expert Rev Med

Devices. 2:741–748. 2005. View Article : Google Scholar : PubMed/NCBI

|

|

6

|

Long M and Rack HJ: Titanium alloys in

total joint replacement -a materials science perspective.

Biomaterials. 19:1621–1639. 1998. View Article : Google Scholar : PubMed/NCBI

|

|

7

|

Miura K, Yamada N, Hanada S, Jung TK and

Itoi E: The bone tissue compatibility of a new Ti-Nb-Sn alloy with

a low Young’s modulus. Acta Biomater. 7:2320–2326. 2011.PubMed/NCBI

|

|

8

|

Wang LQ, Lu WJ, Qin JN, Zhang F and Zhang

D: Change in microstructures and mechanical properties of

biomedical Ti-Nb-Ta-Zr system alloy through cross-rolling. Mater

Trans. 49:1791–1795. 2008. View Article : Google Scholar

|

|

9

|

Wang LQ, Lu WJ, Qin JN, Zhang F and Zhang

D: Microstructure and mechanical properties of cold-rolled TiNbTaZr

biomedical beta titanium alloy. Mater Sci Eng A Struct Mater.

490:421–426. 2008. View Article : Google Scholar

|

|

10

|

Zhu L, Wang H, Xu J, Lin J and Wang X:

Effects of nacre-coated titanium surfaces on cell proliferation and

osteocalcin expression in MG-63 osteoblast-like cells. Afr J

Biotechnol. 10:15387–15393. 2011.

|

|

11

|

Lee MH, Kang JH and Lee SW: The

significance of differential expression of genes and proteins in

human primary cells caused by microgrooved biomaterial substrata.

Biomaterials. 33:3216–3234. 2012. View Article : Google Scholar : PubMed/NCBI

|

|

12

|

Hu Y, Cai K, Luo Z, et al: Regulation of

the differentiation of mesenchymal stem cells in vitro and

osteogenesis in vivo by microenvironmental modification of titanium

alloy surfaces. Biomaterials. 33:3515–3528. 2012. View Article : Google Scholar : PubMed/NCBI

|

|

13

|

Schliephake H, Boetel C, Foerster A,

Schwenzer B, Reichert J and Scharnweber D: Effect of

oligonucleotide mediated immobilization of bone morphogenic

proteins on titanium surfaces. Biomaterials. 33:1315–1322. 2012.

View Article : Google Scholar : PubMed/NCBI

|

|

14

|

Qu Z, Rausch-Fan X, Wieland M, Matejka M

and Schedle A: The initial attachment and subsequent behavior

regulation of osteoblasts by dental implant surface modification. J

Biomed Mater Res A. 82:658–668. 2007. View Article : Google Scholar : PubMed/NCBI

|

|

15

|

Rausch-fan X, Qu Z, Wieland M, Matejka M

and Schedle A: Differentiation and cytokine synthesis of human

alveolar osteoblasts compared to osteoblast-like cells (MG63) in

response to titanium surfaces. Dent Mater. 24:102–110. 2008.

View Article : Google Scholar : PubMed/NCBI

|

|

16

|

Zhao G, Raines A, Wieland M, Schwartz Z

and Boyan B: Requirement for both micron-and submicron scale

structure for synergistic responses of osteoblasts to substrate

surface energy and topography. Biomaterials. 28:2821–2829. 2007.

View Article : Google Scholar : PubMed/NCBI

|

|

17

|

Padial-Molina M, Galindo-Moreno P,

Fernandez-Barbero JE, et al: Role of wettability and nanoroughness

on interactions between osteoblast and modified silicon surfaces.

Acta Biomater. 7:771–778. 2011. View Article : Google Scholar : PubMed/NCBI

|

|

18

|

Zhuang LF, Jiang HH, Qiao SC, et al: The

roles of extracellular signal-regulated kinase 1/2 pathway in

regulating osteogenic differentiation of murine preosteoblasts

MC3T3-E1 cells on roughened titanium surfaces. J Biomed Mater Res

A. 100:125–133. 2012. View Article : Google Scholar

|

|

19

|

Higuchi C, Myoui A, Hashimoto N, et al:

Continuous inhibition of MAPK signaling promotes the early

osteoblastic differentiation and mineralization of the

extracellular matrix. J Bone Miner Res. 17:1785–1794. 2002.

View Article : Google Scholar : PubMed/NCBI

|

|

20

|

Kono S, Oshima Y, Hoshi K, et al: Erk

pathways negatively regulate matrix mineralization. Bone. 40:68–74.

2007. View Article : Google Scholar : PubMed/NCBI

|

|

21

|

Olivares-Navarrete R, Hyzy SL, Hutton DL,

et al: Role of non-canonical Wnt signaling in osteoblast maturation

on microstructured titanium surfaces. Acta Biomater. 7:2740–2750.

2011. View Article : Google Scholar : PubMed/NCBI

|

|

22

|

Vlacic-Zischke J, Hamlet SM, Frus T,

Tonetti MS and Ivanovski S: The influence of surface microroughness

and hydrophilicity of titanium on the up-regulation of TGFβ/BMP

signalling in osteoblasts. Biomaterials. 32:665–671.

2011.PubMed/NCBI

|

|

23

|

Stiehler M, Lind M, Mygind T, et al:

Morphology, proliferation, and osteogenic differentiation of

mesenchymal stem cells cultured on titanium, tantalum, and chromium

surfaces. J Biomed Mater Res A. 86:448–458. 2008. View Article : Google Scholar : PubMed/NCBI

|

|

24

|

Balla VK, Bodhak S, Bose S and

Bandyopadhyay A: Porous tantalum structures for bone implants:

fabrication, mechanical and in vitro biological properties. Acta

Biomater. 6:3349–3359. 2010. View Article : Google Scholar : PubMed/NCBI

|

|

25

|

Balla VK, Banerjee S, Bose S and

Bandyopadhyay A: Direct laser processing of a tantalum coating on

titanium for bone replacement structures. Acta Biomater.

6:2329–2334. 2010. View Article : Google Scholar : PubMed/NCBI

|

|

26

|

Sista S, Wen C, Hodgson PD and Pande G:

The influence of surface energy of titanium-zirconium alloy on

osteoblast cell functions in vitro. J Biomed Mater Res A. 97:27–36.

2011. View Article : Google Scholar : PubMed/NCBI

|

|

27

|

Hempel U, Hefti T, Kalbacova M,

Wolf-Brandstetter C, Dieter P and Schlottig F: Response of

osteoblast-like SAOS-2 cells to zirconia ceramics with different

surface topographies. Clin Oral Implants Res. 21:174–181. 2010.

View Article : Google Scholar : PubMed/NCBI

|

|

28

|

Ramaswamy Y, Wu C, Van Hummel A, Combes V,

Grau G and Zreiqat H: The responses of osteoblasts, osteoclasts and

endothelial cells to zirconium modified calcium-silicate-based

ceramic. Biomaterials. 29:4392–4402. 2008. View Article : Google Scholar : PubMed/NCBI

|

|

29

|

Palmieri A, Pezzetti F, Brunelli G, et al:

Zirconium oxide regulates RNA interfering of osteoblast-like cells.

J Mater Sci Mater Med. 19:2471–2476. 2008. View Article : Google Scholar : PubMed/NCBI

|

|

30

|

Lin DJ, Chuang CC, Chern Lin JH, Lee JW,

Ju CP and Yin HS: Bone formation at the surface of low modulus

Ti-7.5Mo implants in rabbit femur. Biomaterials. 28:2582–2589.

2007. View Article : Google Scholar : PubMed/NCBI

|