Introduction

Typically, healthy body cells grow and divide under

restricted conditions to form new cells to match the body's needs.

All types of cancer however, exhibit continual uncontrolled

division of the cell, and this may occur almost anywhere in the

human body, with the potential to spread to other regions. Several

types of cancer form solid masses of tissue (tumors); however,

cancers of the blood, such as leukemias, are an exception (1,2). The

amino acid L-asparagine, is required for the survival of both

normal and cancer cells. Normal cells can synthesize L-asparagine

in amounts sufficient for their metabolic activities, but tumor

cells depend mainly on an exogenous supply of L-asparagine

(3). L-asparaginases (L-asparagine

amidohydrolase; EC 3.5.1.1) catalyzes the breakdown of the amide

group of the sidechain of L-asparagine into aspartic acid and

ammonia (4), reducing its

concentration, which is why regulating L-asparaginases is a

cornerstone of the treatment protocols for acute lymphoblastic

leukemia (2).

For several years, L-asparaginases have been broadly

used for the treatment of lymphoid systems malignancies, childhood

acute lymphoblastic leukemia, Hodgkin's lymphoma, lymphosarcoma,

and melanosarcoma (5). Apart from

its clinical use, L-asparaginases have been used as a diagnostic

biosensor for L-asparagine, due to the large amounts of ammonia

produced by the enzymatic reaction and its direct correlation with

the level of L-asparagine in a patient's blood (6). L-asparaginases have also been

characterized successfully as inhibitors of the formation of

acrylamide in heated food (7).

L-asparaginase is widely present in several

organisms, including plants, animals and microbes, but not in

humans. Microbes are the best source for the production of enzymes,

including L-asparaginase, as they are easy to cultivate and

manipulate (5). Microbes can

produce several different types of asparaginases that differ in

their cellular location and properties; namely periplasmic

asparaginase, extracellular asparaginase, intracellular

asparaginase and glutaminase-asparaginase, which all play a role in

basic metabolism (8).

In contrast to asparaginases obtained from fungi,

the longstanding use of bacterial L-asparaginases can cause

toxicity and hypersensitivity reactions, leading to anaphylaxis.

This may suggest that fungal asparaginases are more closely related

to those present in humans, as fungi are eukaryotic microorganisms.

Thus the chances of adverse effects and immunological reactions

against fungal L-asparaginases are expected to be lower (8). Another advantage of fungal

asparaginases is that they are produced extracellularly, and thus

it is considerably easier to separate and purify (4,8). Owing

to these advantages, fungi are considered to be the most suitable

organisms for production of L-asparaginase, and therefore, the

search for novel fungal producers is very important.

The utilization of agro-industrial-based products

has become of increasing importance in bio-industries, due to the

high nutrient content and low-cost (9-11).

Wheat bran (WB) as an example, has been reported in the literature

for the useful production of value-added biomolecules by

fermentation to reduce both the process cost and the environmental

waste (12).

The outer pericarp layer of WB, left as a by-product

after wheat grain milling, forms 13-17% of the entire organism

(13). WB is rich in minerals (such

as iron, zinc, manganese, magnesium and phosphorus), Vitamin-B

complex and bioactive compounds (such as phytic acid, ferulic acid

and vitamin E) (14). A total of

34-63% of the WB is formed of soluble and insoluble dietary fibers,

a complex compound made of edible plant polysaccharides (cellulose,

hemicelluloses and pentosan polymers) attached to proteins

(15.2-16.9%), lignin and other substances (15,16),

such as lipids (5.5-5.6%) (17).

The high nutritional value of WB makes it superior to other

agro-industrial candidates for enzyme production. Therefore, it was

used in the present study as a source of nutrient and physical

support during enzyme production.

Based on the consistency, culture media is

classified into one of three types; solid, semi-solid and liquid

medium. Solid-state fermentation (SSF) is defined as any

fermentation process where the growth of microorganisms takes place

on a solid substrate in the absence of free water. With SSF it is

possible to utilize renewable and low-cost natural resources

(18). However, when plants or crop

residues with low water and high sugar and nutrient contents are

utilized for SSF, the availability of its constituents may be low

or microbial growth may be inhibited, resulting in low system

productivity. Therefore, the SSF system was been modified by

increasing the water content to increase sugar and nutrient

availability. This system of semi-SSF ensures easier growth of

fungi and a higher efficiency of the biosynthetic process (19). Identification of a new and

affordable hyper-producer of L-asparaginases with fewer adverse

effects is of the utmost priority and a considerable challenge for

biotechnologists. Hence, in the present study, WB was used for

fermentation of Rhizopus oryzae AM16 as a novel source of

L-asparaginase grown under semi-SSF conditions, and the anticancer

activity of the fungal enzyme was assessed.

Materials and methods

Chemicals

All chemicals used in the present study were of

analytical grade and were obtained from Sigma-Aldrich; Merck KGaA

unless otherwise stated. WB was utilized as a solid substrate

during the fermentation process, and was kindly provided by the

South Cairo and Giza Mills Company.

Cell lines

In the present study, four tumor cell lines, HepG2

human liver cancer cells, MCF-7 breast cancer cells, HCT colon

carcinoma cells and A549 lung carcinoma cells were obtained from

Vacsera, Co. To ensure the authenticity of the cells used, all cell

lines used were confirmed using short Tandem Repeat DNA profiling

as previously described (20).

Sampling sites

Soil samples were collected from two Governorates in

Egypt; three form the Al Gharbia governorate, including from two

sites of cultivated soil, (Al-Dalgamon, N"22.67'30˚48

E"22.37'30˚50; Tanta, N"40.77'30˚47 E"59.94'31˚00; and one sample

obtained from soil contaminated with oil, the Oil & Soap

Company, N"20.82'30˚49 E"37.58'30˚49).

Soil from a total of five sites in the Al-Behira

governorate, including three cultivated soil sites (Al-Delengat,

N"31.94'30˚49 E"49.36'30˚32; and two sites from Itay El-baroud,

N"57.49'30˚52 E"09.76'30˚40 and N"06.87'30˚52 E"41.94'30˚39), a

non-cultivated site (Shubrakhit, N"55.38'31˚01 E"34.20'30˚42) and

one site from soil contaminated with oil obtained from Al-Delengat

(N"20.82'30˚49 E"37.58'30˚49) were obtained in the present

study.

Air-borne fungi were isolated from the same sites by

opening a Petri dish containing sterilized Czapek-Dox agar plates

for ~30 min in the open air, then incubated for 7 days at

28±2˚C.

Fungal isolation and screening of

L-asparaginase activity

Fungi were isolated on modified Czapek-Dox agar

plates composed of (in gl-1) agar powder supplemented

with L-asparagine (10.0 gl-1) and 3 ml/l 2.5% phenol red

dye as an indicator (21). Plates

were incubated at 28±2˚C for 3-5 days. Developed fungal isolates

surrounded by a pink zone were selected and grown on potato

dextrose slants. Fungal colonies isolated in the previous step were

descriptively screened for L-asparaginase capability using a rapid

plate assay, as described below. A 5-mm fungal mycelial plug was

inoculated onto the modified Czapek-Dox's agar in triplicates.

All plates were incubated at 28±2˚C for 3-5 days.

Positive asparaginolytic fungi were detected on the yellow-colored

medium based on the appearance of a pink zone around the fungal

colony, indicating L-asparaginase activity due to the change in

color of the phenol red indicator. The diameter of the pink zone

was measured and used to compare fungal isolates.

Identification of fungal isolates

For determination of morphological structures,

portions of fungal growth were mounted in lactophenol cotton blue

stain on clean slides, and the prepared slide was examined under a

light microscope at x40 and x100 magnification for vegetative

mycelium; septation, diameters, conidiophores (sporangiophores) and

the reproductive structures, conidia and sporangiospores amongst

others. Fungal colonies were examined at x10 magnification. The

colony size, texture and color of the colonies were assessed. The

fungal genera and species were identified according to their

cultural properties, using morphological and microscopical

screening as described previously (22-27).

Culturing technique and the assessed

parameters

The semi SSF was performed using WB. Unless

otherwise specified, the fermentation medium of L-asparaginase

production was composed of 1 g WB, moistened with 1 ml distilled

water placed in 250 ml Erlenmeyer flasks to yield a 1:1 (w/v)

growth medium. The medium was sterilized by autoclaving for 15 min

and inoculated with 1 ml fungal spore suspension (1x106

spores), such that the moisture content was equivalent to 66.7%.

Next, inoculated batch fermentation flasks were incubated under

static conditions at 28±2˚C.

The main parameters that were expected to influence

the production process were investigated by varying only a single

factor at a time, and keeping the remaining factors constant. The

studied factors were fermentation time (2-10 days), nitrogen source

at 2.5 mg nitrogen per gram of dry WB (gds), and its concentration

(based on the nitrogen-equivalent), the WB to water ratio (1:2,

1:4, 1:6, 1:8 and 1:10, w/v) and, finally, the moistener pH, using

citrate phosphate buffer (3.0-5.4) and sodium phosphate buffer (pH

5.8-7.8).

Extraction of L-asparaginase

After incubation, enzyme extraction was performed by

adding 10 ml sodium phosphate buffer (pH 7) to the fermented

substrate to a final volume of 20 ml to attain an equivalent volume

in each of the different flasks, shaken for 30 min on a rotary

shaker at 200 rpm and filtered through a Whatman No. 1 filter paper

(Whatman plc; GE Healthcare Life Sciences). The filtrate was then

centrifuged at 1,500 x g and 4˚C for 15 min.

Quantitative assay of L-asparaginase

activity

The resultant extraction was assayed for

L-asparaginase activity by quantifying ammonia formation

spectrophotometrically using Nessler's reagent as described

previously (28). One unit (U) of

L-asparaginase is expressed as the amount of enzyme per gram of WB

dry substrate that catalyzes the formation of one µmol ammonia per

min under the assay conditions. A standard curve was prepared with

ammonium chloride.

Partial purification and protein

estimation

The crude Rhizopus oryzae AM16

L-asparaginase, obtained after fermentation at the optimum

conditions, was precipitated by adding ammonium sulfate with

constant stirring until 80% saturation was achieved, and was then

incubated overnight at 4˚C to ensure that the precipitation had

completed. The precipitate was separated by centrifugation at 2,100

x g for 30 min at 4˚C. The protein precipitate was resuspended in

0.01 M Tris-HCl buffer (pH 7.2) and dialyzed overnight against the

same buffer. The concentration of protein was estimated using a

Bradford assay (28), with BSA as

the standard. The specific activity is defined as the units of

L-asparaginase per mg of protein.

Cell viability assay

MTT assays were used to assess the two

L-asparaginase preparations (crude and dialyzed), to determine

their cytotoxic effects against four tumor cell lines: HepG2,

MCF-7, HCT and A549 carcinoma cell lines.

When the cells reached 75-90% confluence, usually 24

h after passaging, the cell suspension was prepared in complete

growth medium (RPMI) supplemented with 50 mg/ml gentamycin.

Aliquots of 100 µl cell suspension (1x105 cells/ml) were

added to each well of a 96-well tissue culture plate. The blank

wells contained complete RPMI medium in place of cell

suspension.

The cells were incubated for 24 h at 37˚C in a

humidified incubator with 5% CO2. After the formation of

a complete monolayer cell sheet in each well of the plate, the

enzyme (crude and dialyzed) was added in concentrations ranging

from 15.63-500 µg/ml. Serial two-fold dilutions of the samples were

added into a 96-well tissue culture plate using a multichannel

pipette. After 24 h, the culture supernatant was replaced with

fresh medium. Next, the cells were incubated at 37˚C with 100 µl

MTT solution (5 mg/ml) for 4 h. Subsequently, the MTT solution was

removed and 100 µl DMSO was added to each well. The absorbance was

detected at 570 nm using a microplate reader (Tecan Group, Ltd.).

The absorbance of untreated cells was considered as 100%. The

experiments were repeated three times, independently the percentage

of cell viability was calculated. The tested sample was, then,

compared using the half-maximal inhibitory concentration

(IC50) value: The concentration of an individual

compound leading to 50% cell death that was estimated from

graphical plots of viable cells vs. enzyme concentrations (28-32).

Statistical analysis

Data are presented as the mean ± standard deviation

of at least three replicates. Statistical analysis was performed

using CoStat version 6.4 (CoHort Software).

Results

Isolation and screening of

L-asparaginolytic fungi

L-asparaginase-producing fungi were isolated from

the soil and air on modified Czapek-Dox agar plates supplemented

with L-asparagine as a sole nitrogen source. Fungi were screened

for L-asparaginase potential using a rapid plate assay, and were

detected based on the presence of a pink zone around the fungal

colony. Isolates that showed the largest diameter pink zones were

selected (data not shown). The developed pink color on the

yellow-colored medium indicates L-asparaginase activity, as

NH3 is liberated, and this changes the phenol red color

to pink (21). The highest positive

asparaginolytic fungi were chosen and identified. Based on the

growth characteristics and morphological features, 4 isolates, with

the highest qualitative L-asparaginase in the plate assays were

obtained: Aspergillus flavus, Penicillium expansum,

Rhizopus oryzae AM16 and Trichoderma viride.

Time vs. L-asparaginase

production

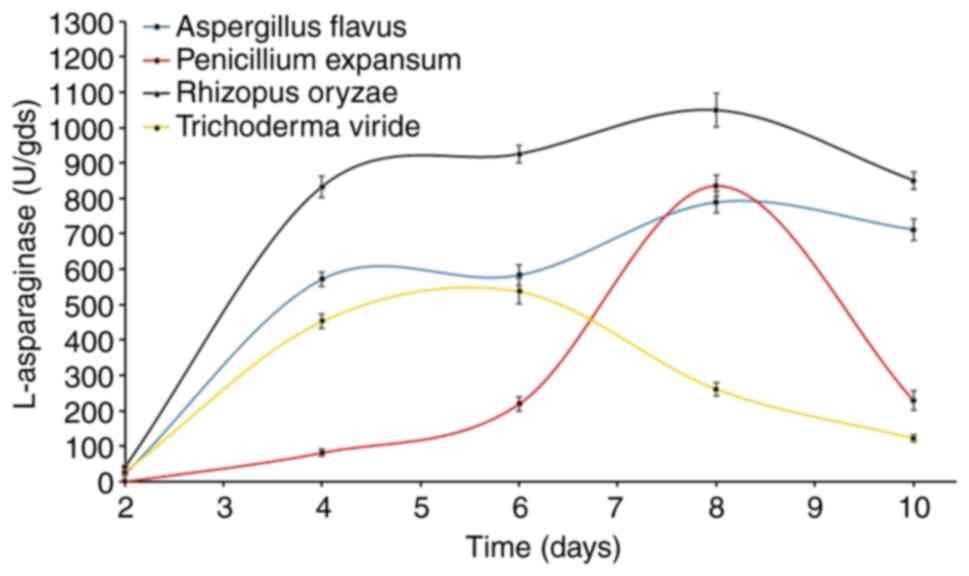

The time profile of L-asparaginase biosynthesis of

the four fungi was explored for extended time periods of up to 10

days on the WB-based medium (Fig.

1). The time course of enzyme production differs between fungal

species depending on the cultivation conditions and the

physiological properties of each specific species.

Another purpose of this current test was to select

the most active asparaginolytic fungus for further investigation.

The results showed that L-asparaginase started to accumulate after

two days of fermentation, and there were detectable levels of

L-asparaginase being produced by three of the four fungi, and for

Penicilliumexpansum, its asparaginolytic activity appeared after

the 4th day. However, maximum L-asparaginase biosynthesis was

observed after 10 (Aspergillus flavus), 8 (Penicillium

expansum), 8 (R. oryzae AM16) and 6 (Trichoderma

viride) days. Notably, R. oryzae AM16 was superior to

all other tested fungi, recording 1,048.6 U, followed by

P.expansum (836.5 U), A. flavus (789.4 U) and finally

T. viride (537.8 U). Based on these data R. oryzae

AM16 was chosen for further study of enzyme production.

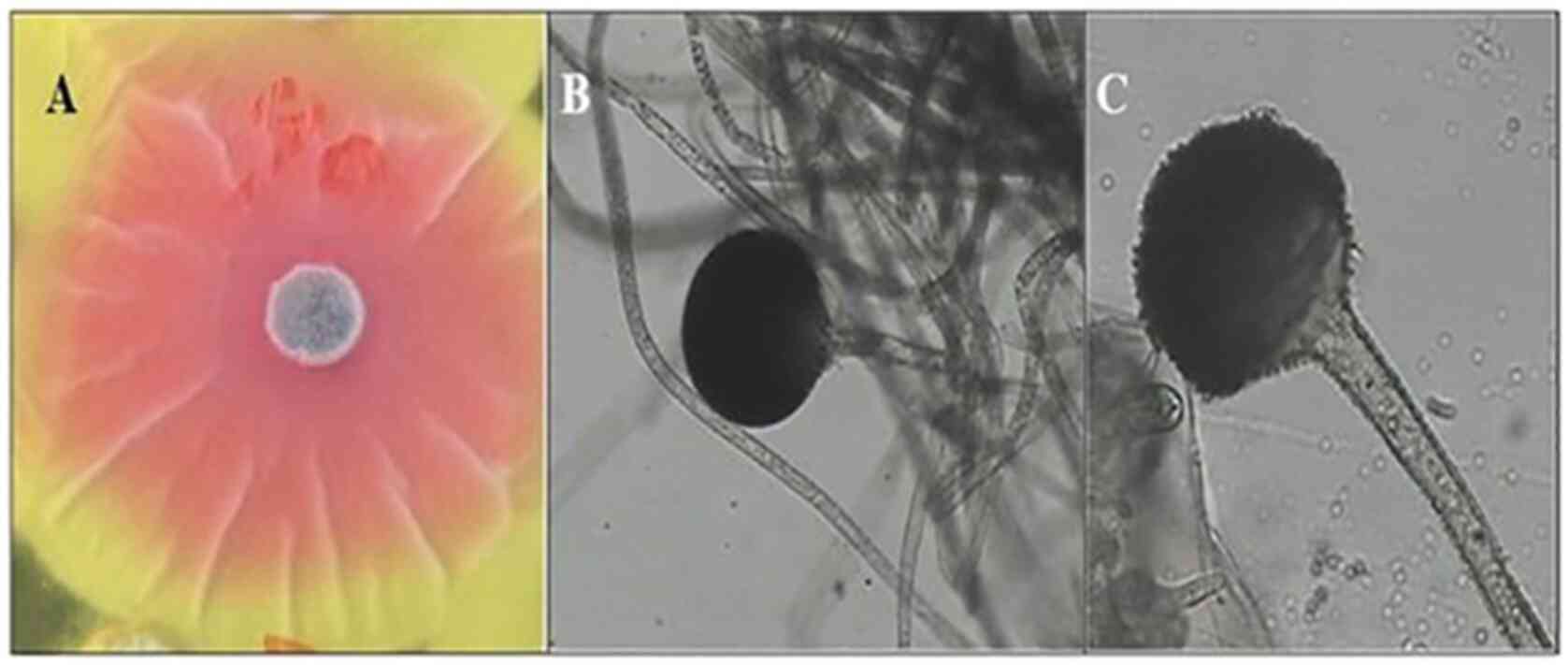

R. oryzae AM16 was selected as the most

active isolate, a representative image of the active isolate is

shown in Fig. 2. A pink zone around

the fungal colony was clearly visible (Fig. 2A). Colonies of R. oryzae AM16

appeared white initially, becoming brownish with age and grew to ~1

cm in thickness. The isolates can grow at temperatures between

7-44˚C with optimum growth at 37˚C. Sporangiospores are straight,

pale brown to brown, and grow between 210-2,500 µm in length and

5-18 µm in diameter (Fig. 2B and

C). The sporangia are globose or

sub-globose, wall spinous and black when mature, and 60-180 µm in

diameter. The columellae are globose, sub-globose. Sporangiospores

are elliptical, globose or polygonal, they are striated and grow

5-8 µm in length. The chlamydospores are abundant, globose, ranging

in 10-24 µm in diameter, elliptical and cylindrical.

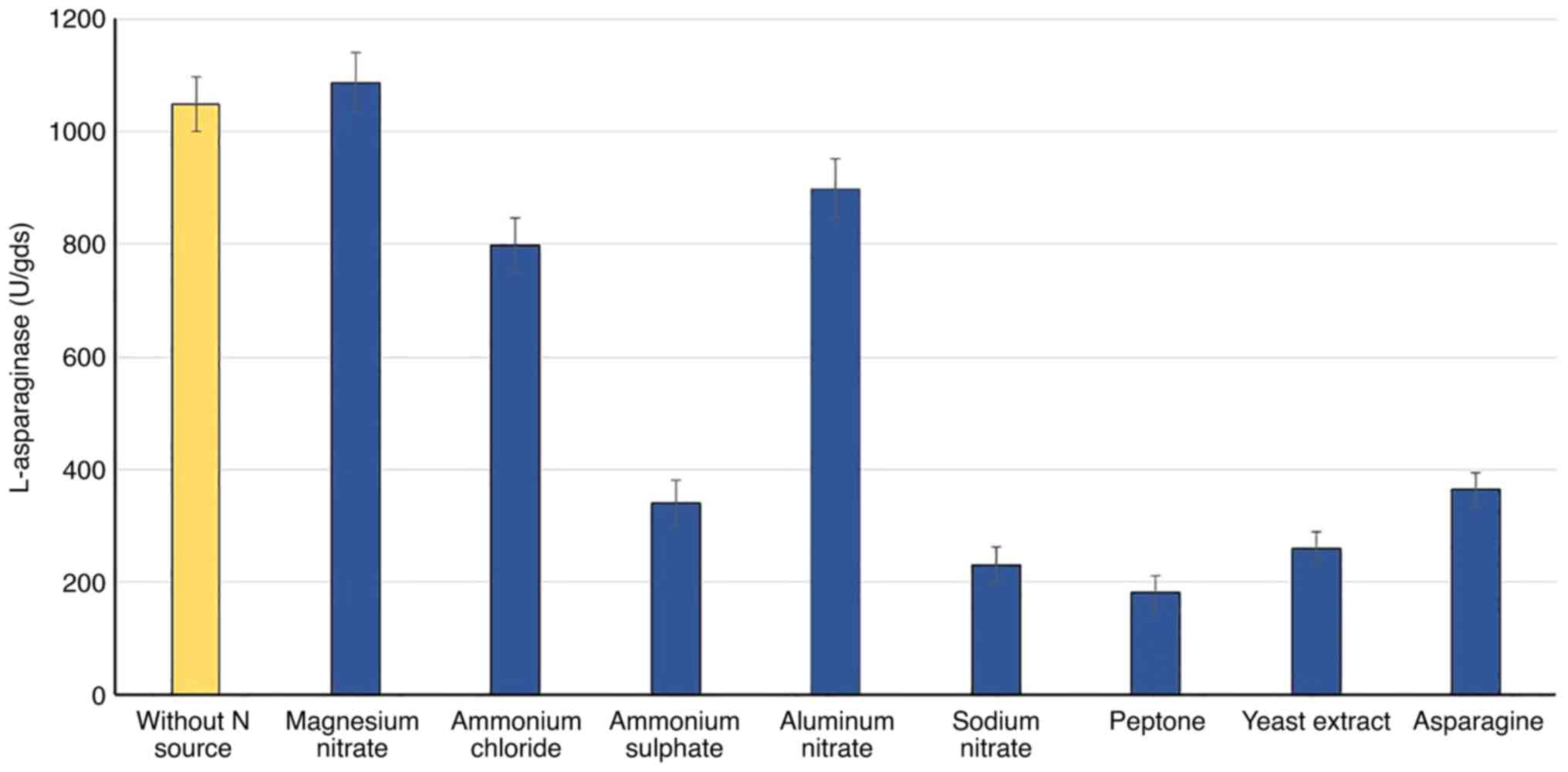

Nitrogen source

Various nitrogen sources were added separately,

based on the N-equivalent (5 mg N/gds), to WB fermented substrate

to study their effects on the accumulation of L-asparaginase. The

results in Fig. 3 show that the

enzyme biosynthesis by R. oryzae AM16 was considerably

influenced by the type of nitrogen source. Compared with the

control (without nitrogen source), all nitrogen sources were found

to suppress enzyme production, based on the lower values of

L-asparaginase production with the various N sources, apart from

magnesium nitrate. In comparison to organic nitrogen, the inorganic

nitrogen sources enhanced and stimulated the highest production of

L-asparaginase; magnesium nitrate (1,086 U) was superior, followed

by aluminum nitrate (899) and ammonium chloride (799 U).

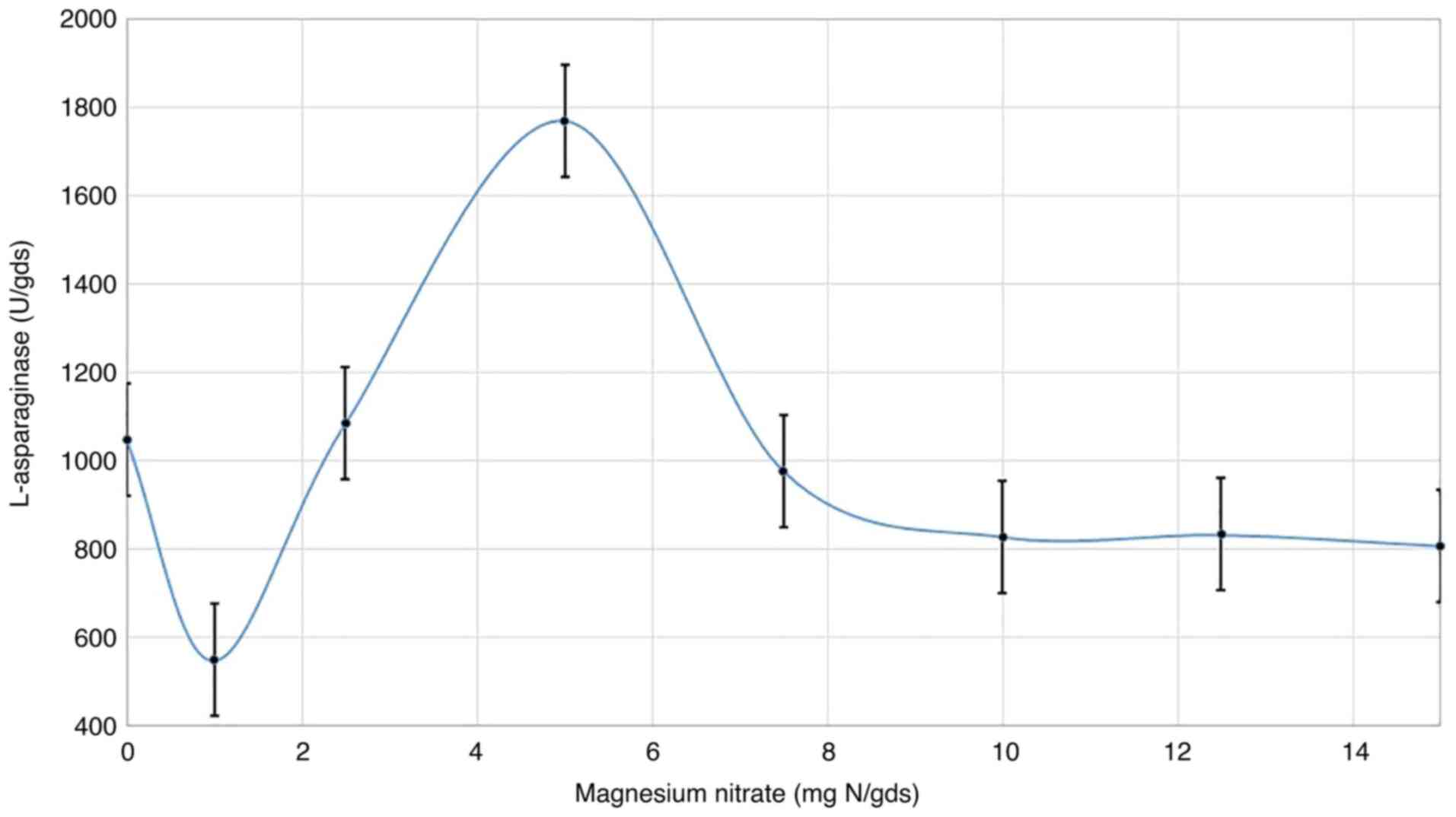

Magnesium nitrate concentration

Magnesium nitrate, as the best source of nitrogen,

was incorporated in the fermentation medium at various

concentrations. The results (Fig.

4) show that different concentrations of magnesium nitrate

notably influenced L-asparaginase synthesis. Although there was a

marked sharp decline at the initial concentration of magnesium

nitrate (1 mg N/gds) compared with the control (0 mg N/gds),

visible increases in enzyme production (1,770.8 U) were observed

with higher concentrations, up to 5 mg N/gds, before decreasing

again when the concentration was increased further. With 5 mg

N/gds, a reduction in L-asparaginase synthesis was observed.

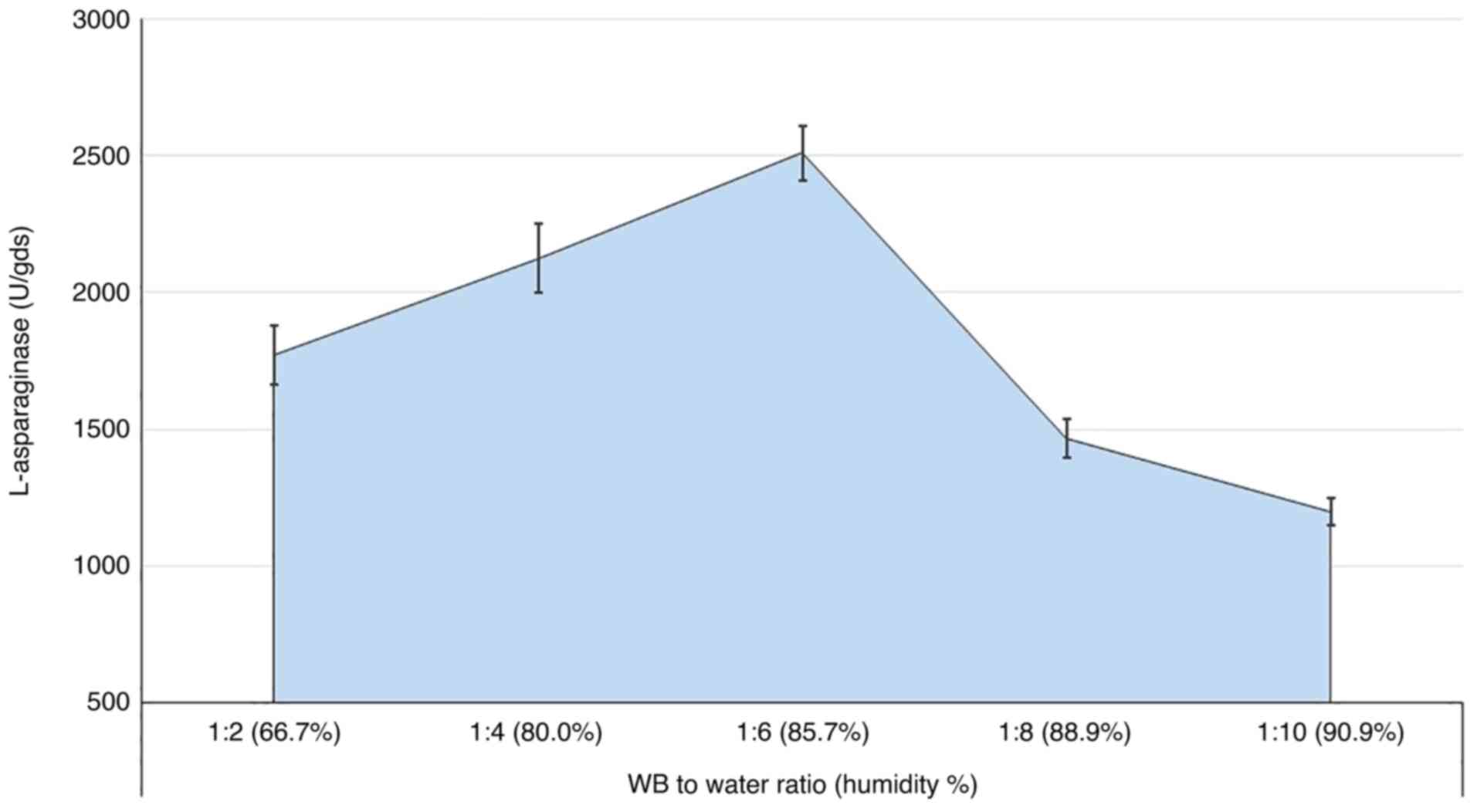

Medium humidity

The humidity of the medium is a determining factor

in the production process, even in SSF. Thus, the ratio between the

fermented substrate to the available water was explored in the

present study, with various ratios being investigated (Fig. 5). The results showed that increasing

the WB: water ratio to 1:6 (representing 85.7% moisture) increased

the secretion of the L-asparaginase levels gradually to 2,509.6 U.

Higher ratios sharply reduced the enzyme levels, although a marked

level of the enzyme secretion was still observed.

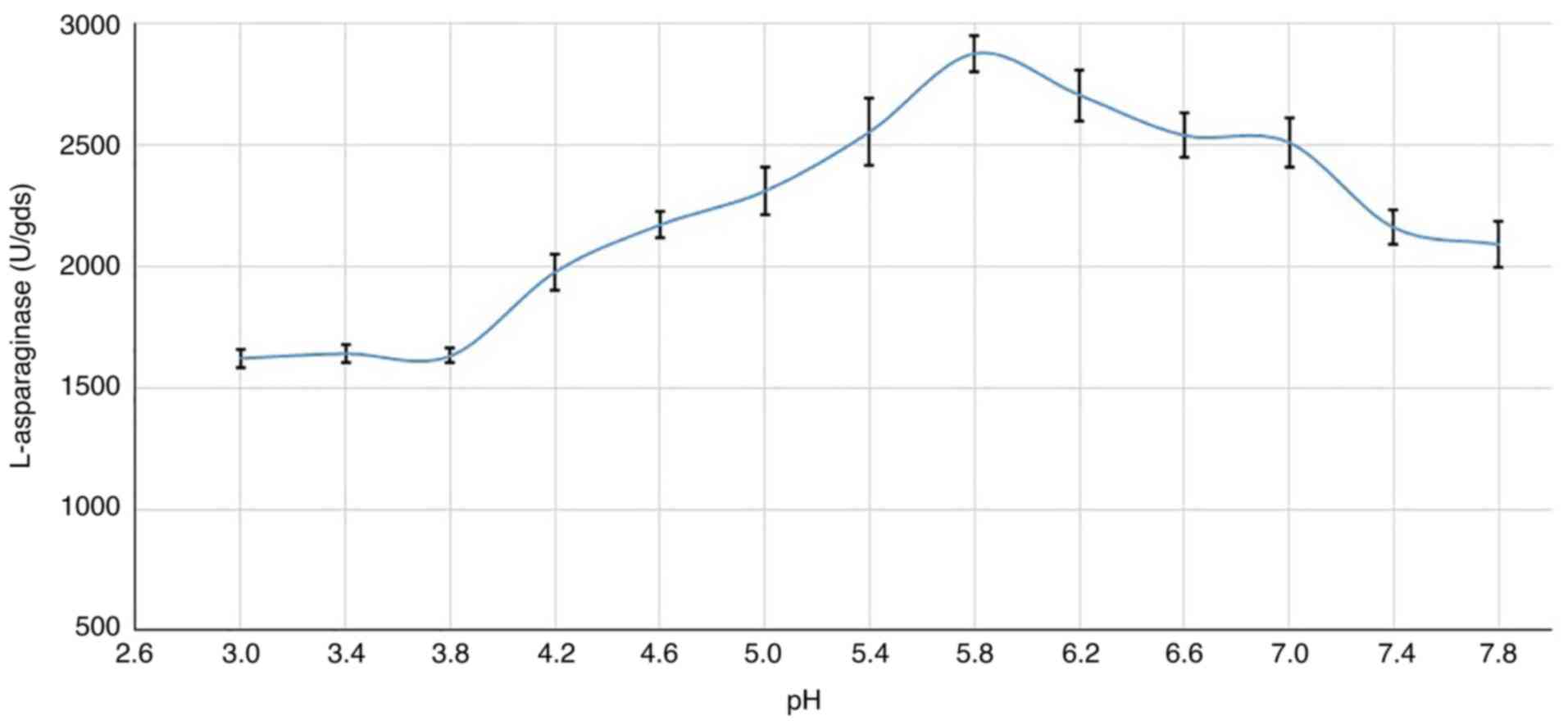

Culture pH

In the present study, maximal enzyme production was

observed at pH 5.8 (2,875.9 U) as shown in Fig. 6, and production at a pH higher or

lower than this resulted in a decrease in L-asparaginase production

by R. oryzae AM16. However, the fungus was still able to

secrete a reasonable amount of the enzyme in a wide range of pHs

(4.2-7.8).

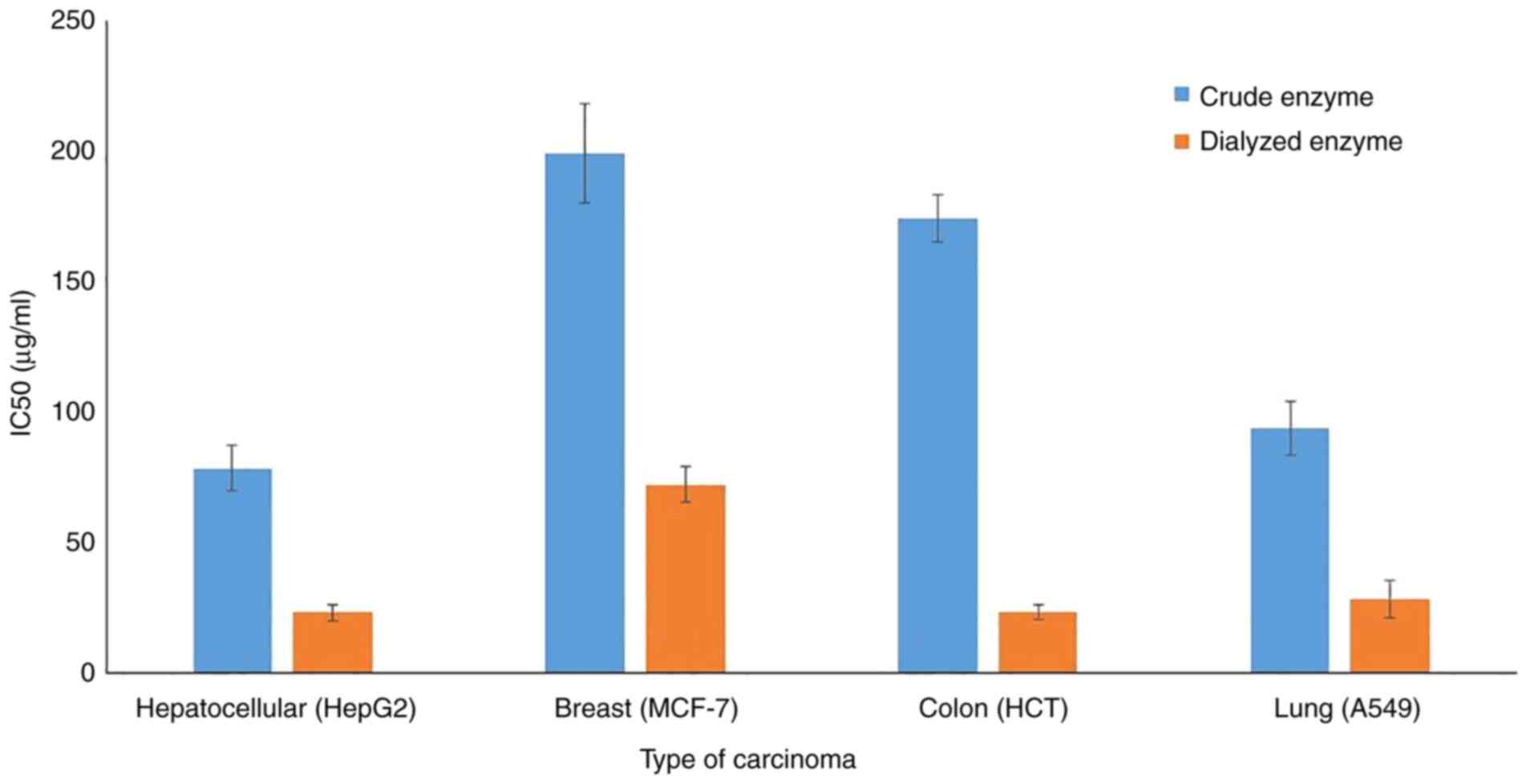

Anticancer activity

The in-vitro cytotoxic effect of crude and

partially purified L-asparaginase on the growth of four types of

human tumor cell lines were assessed. Dual incubation of carcinoma

cells with various doses of L-asparaginase in the tissue culture

medium revealed that the inhibition of human tumor cell lines was

dose-dependent. The dialyzed enzyme accomplished its inhibitory

effect at lower doses compared with the crude preparation; this

trend was true for all the tested cell lines (Fig. 7). The IC50 values of the

dialyzed enzyme were 23.4 (HepG2), 72.4 (MCF-7), 23.6 (HCT) and

28.6 (A549) µg/ml. It is hypothesized that the dialysis process

concentrated the enzyme protein without adverse impact on its

activity and performance. All cell lines were found to be sensitive

to the dialyzed protein, the sensitivity of cell lines in

descending order are HepG2 > HCT > A549 > MCF-7. However,

this order varied when using the crude protein, the HepG2 and HCT

cells were the most affected by both the crude and dialyzed

enzyme.

Discussion

Several microorganisms, such as bacteria, yeasts,

molds and filamentous fungi, have been reported to produce

L-asparaginase. Asparaginases of microbial origin have been shown

to be more stable than those from animal and plant sources. Despite

bacteria being the primary source of L-asparaginase, the enzymes

obtained from them have been shown to possess several adverse side

effects. Therefore, identifying a novel source of asparaginases is

of utmost importance for both clinical and biotechnology purposes.

Of the microbes, the most potent producers of asparaginases are

fungi (31). Thus, the aim of the

present study was to identify an L-asparaginase producing fungus

and determine the optimal fermentation conditions, as well as

studying its anticancer activity. For example, positive

asparaginolytic fungi were found to exist in marine environments

and endophytes of seaweed, belonging to the Alternaria,

Chaetomium, Cladosporium, Colletotrichum,

Curvularia, Nigrospora, Paecilomyces,

Phaeotrichoconis, Phoma and Pithomyces genera

(32). Moreover, terrestrial

endophytic fungi with positive asparaginolytic activity of the

genus Colletotrichum, Eupenicillium and

Talaromyces were also reported (32). Several asparaginolytic fungi, such

as Alternaria sp., Aspergillus nidulans, A. niger,

A. oryzae, A. tamarii, A. terreus,

Cylidrocapron obtusisporum, Mucor sp. and Fusarium

roseum have been described (4,8).

The R. oryzae AM16 investigated in the

present study was isolated from air. To the best of our knowledge,

this is the first report to describe the isolation of

asparaginolytic fungus from the air. It is also worth mentioning

that the fungus was able to secrete L-asparaginase constitutively

without the presence of an induction substrate. Although

fermentation conditions vary according to the microorganism, the

enzyme can be produced constitutively and/or after induction

(21,33).

For optimization of production conditions, the

incubation period is one of the most critical parameters in

microbial fermentation. As a general rule, the majority of the

microbial enzymes can only reach maximal production after a certain

period of incubation, which allows the culture to grow at a steady

state, therefore enzyme production is mostly based on the specific

growth rate of the microbe; thus, growth rate and enzyme synthesis

are primarily influenced by incubation time (4). Indira et al (31) reported 5 days of fungal incubation

for maximum enzyme production (35.72 U). In comparison, the current

fungal strain required a longer incubation period (8 days) to reach

peak enzyme secretion; however, its L-asparaginase yield was

increased by ~30-fold.

The L-asparaginase from R. oryzae AM18 is

classified as an extracellular enzyme. Extracellular L-asparaginase

is more advantageous than the intracellular counterpart due to the

lower production costs, higher degree of accumulation of the enzyme

in the culture broth, ease of extraction and purification, and

simpler downstream processing methods (9,34,35).

Two related families of L-asparaginase have been identified:

L-asparaginase, which is a low-affinity enzyme to the substrate,

found in the cytoplasm and secreted constitutively, and

L-asparaginase II, a high-substrate-affinity periplasmic enzyme

that is activated during anaerobiosis (34). L-asparagine was not found to induce

enzyme production. A possible explanation is that the enzyme could

be induced by its substrate and could also be secreted

constitutively (21,35). Conversely, several pieces of

literature reported L-asparagine as the most favorable source of

nitrogen (4). Other inorganic

nitrogen sources, such as ammonium sulfate by A. terreus

(31) and sodium nitrate by

Fusarium oxysporum (34),

showed increased enzyme production. Generally, the presence of

additional nitrogen sources alongside the native nitrogenous

compounds present in the fermented substrate promotes microbial

growth and, consequently, enzyme secretion, since the various kinds

of nitrogen (organic and inorganic) are metabolized to various

important molecules in the cell, including L-asparaginase (31).

In addition to the nitrogen source, the

concentration of the source also has a pronounced influence on

enzyme production. The majority of the industrially used enzymes

utilize nitrogen sources either in an organic or inorganic form, or

sometimes both. The proteinaceous part of the WB is organic,

accounting for 15.2-16.9% of the nitrogen content, consists of

18.6% glutamic acid and 7.2% aspartic acid (14), and in several instances, growth is

faster when the supply consists of both organic and inorganic

nitrogen sources (31). Supporting

the fermentation medium with additional inorganic N in the current

study boosted L-asparaginase production by R. oryzae AM16.

Additionally, the fungus showed slight differences in the

production pattern in the presence of nitrogen-free medium.

The obtained enzyme yield was higher than those

obtained in previous studies, who reported that inorganic nitrogen

sources, particularly ammonium sulfate and sodium nitrate, were

preferable for L-asparaginase production by fungi (27,34).

However, none of these studies used WB as a substrate, and using

cheap agricultural byproducts, such as WB, could be more

cost-effective. The composition of WB reflects high nutritional

quality; unfortunately, the majority of the minerals (including P,

Fe, Zn and Mg) in WB are stored in the form of phytates, forming

complexes, which drastically reduce their bioavailability (14). Thus, inorganic nitrogen sources,

especially magnesium nitrate, were found to be more favorable than

organic sources, in order to compensate for the shortage of

elements due to its association with phytates. However, earlier

work reported that magnesium nitrate supported favorable growth and

fair sporulation of Claviceps microcephala (36,37).

The submerged fermentation technique has been widely

used, and is well established for L-asparaginase production,

although it carries with it a few disadvantages. Owing to

cost-effectiveness, simplicity of the procedure, lower possibility

of contamination, ease of recovery of the final bioproducts and

lower volume of waste-water generation, SSF has emerged as the

preferred technique for bioproduction, particularly when utilizing

agro-industrial waste and byproducts (4). The optimum ratio of WB: water (1:6),

obtained in the current study, was considered a type of SSF, but

with a higher amount of water, in which the free water content had

been increased in order to facilitate nutrient availability and

fermentation control. Thus, it was termed semi SSF. Similarly,

freshly crushed sorghum was used to produce biodiesel under semi

SSF of sweet sorghum, and this proved to be a more efficient method

(giving yields 9-11%) than SSF (16). According to Pandey et al

(18), the initial moisture content

of the solid substrate plays an important role, dictating the

growth of the organism and enzyme production. A certain quantity of

water is essential for generation and synthesis of new cells. Very

high moisture levels compacts the substrates and prevents oxygen

penetration in the SSF processes, whereas very low moisture content

inhibits growth, enzyme activity and accessibility of nutrients

(38). Since the low free liquid

content binds to and lowers nutrient availability, it restricts

fermentation control. However, this also depends on the kind of

microorganism being assessed; in the case of fungi, a wider

moisture range (20-70%) supports improved growth and metabolic

activities, but for bacteria, only a higher moisture content of the

solid matrix can yield better performance (15-17,38,39).

Another determinant factor during the fermentation

process is the pH of the culture. The initial pH level plays a key

role in successful L-asparaginase production. It is well known that

growth and metabolism along with enzyme production are regulated by

the pH of the culture, and every organism has its own optimal pH.

Any modification in this pH could result in a negative impact on

the enzymatic yield; therefore, pH was considered a significant

issue affecting L-asparaginase biosynthesis (4,39).

Contrarily, the majority of previous studies reported that

L-asparaginase production tends to be maximized under neutral

(31) or alkaline (39) pH conditions and minimum production

was observed at lower pHs. The lower pH condition for the maximum

secretion of the current R. oryzae AM16 L-asparaginase

suggests the presence of a new variant of the enzyme with unique

properties.

Summarizing the fermented substrate; in the SSF

process, the selection of appropriate substrate should be based on

nutrient value, availability and cost. The solid substrate not only

provides nutrients for growth and metabolic activities, but also

provides anchorage for microbe growth. WB is considered as the

universal agro-industrial substrate for biomolecule production, it

has a complete nutritious medium for microorganisms and physically,

remains loose even under various conditions of moisture, providing

a large surface area (39-41).

Determining the unique biochemical structure of WB

showed the presence of high nutritional value of both carbon and

nitrogen, in addition to vitamins, mineral salts and other complex

components (11,14). Of the carbon present, various

soluble sugars such as glucose, xylose, arabinose and galactose

were detected, which assist in the initiation of growth and

replication of microorganisms, WB has a low lignin content, and

relatively more protein content when compared with other

agro-industrial substrates (12-14).

The balanced biochemical composition of WB makes it a determinant

factor for the favored use in microbial growth and enzyme

production. This conclusion could be applied in the present

investigation, with hypersecretion of L-asparaginase of 2,875.9 U

by R. oryzae AM16.

IC50 is commonly used as a measure of

antagonist drug potency in pharmacological research, according to

the FDA, the IC50 represents the concentration of a drug

that is required for 50% inhibition in-vitro. The lower the

IC50, the higher the effectiveness of the drug. Recent

medical research on cancer cells has made L-asparaginases and

related enzymes potentially key therapeutic tools in the treatment

of tumors, suggesting that these protein molecules will most likely

be exploited in future clinical applications. L-asparaginase acts

on extracellular L-asparagine, reducing its concentration.

L-asparagine is a non-essential amino acid, which affects the

viability of the cells when its concentration is reduced below the

threshold level. Unlike tumor cells, normal cells have the ability

to synthesize intracellular L-asparagine using asparagine

synthetase. However, the amount of L-asparagine required by a

specific cell type will vary, and this explains the differences in

the IC50 values observed amongst the four cell types.

Moreover, the difference between crude and partially purified

proteins on the same cell line may be attributed to differences in

the presence of minerals and other components present in each

preparation.

Unlike tumor cells, in the case of deficiency,

normal cells have the ability to synthesize intracellular

L-asparagine, using asparagine synthetase. Neoplastic cells, on the

other hand, lack this enzyme and thus require an abundant exogenous

supply of L-asparagine for proper growth. In the absence of such a

supply of L-asparagine, the levels are rapidly depleted, leading to

the death of the neoplastic cells. The depletion of L-asparagine by

L-asparaginase from the plasma results in the inhibition of DNA,

RNA and protein synthesis, resulting in induction of apoptosis.

Therefore, the therapeutic action of L-asparaginase is mediated by

depletion of such amino acids from lymphatic tumor cells, resulting

in starvation and ultimately death of the cells (4,6,8).

In conclusion, the current study identified a new

L-asparaginase with promising anticancer activity on various cancer

cell lines. The modest sequential optimization trials for

L-asparaginase production by R. oryzae AM16 on semi SSF

succeeded in inducing the hyperproduction of the enzyme, with a

maximum production of 2,875.9 U/gds after 8 days of incubation with

85.7% moisture, in the presence of magnesium nitrate (5 mg N/gds)

at pH 5.8. The anticancer activity of the dialyzed enzyme against

certain types of cancer cells (HepG2, MCF-7, HCT and A549) was

confirmed at low doses.

Acknowledgements

The authors acknowledge Princess Nourah bint

Abdulrahman University Researchers Supporting Project (no.

PNURSP2022R5), Princess Nourah bint Abdulrahman University, Riyadh,

Saudi Arabia.

Funding

Funding: The present study was funded by the Princess Nourah

bint Abdulrahman University Researchers Supporting Project (no.

PNURSP2022R5), Princess Nourah bint Abdulrahman University, Riyadh,

Saudi Arabia.

Availability of data and materials

The datasets used and/or analyzed during the present

study are available from the corresponding author on reasonable

request.

Authors' contributions

AAIM, MMEM and WIAS conceptualized and designed the

study, and performed the experiments. SIO, SAG, MAA, AAA, HAF and

RAE analyzed and interpreted the data. SAG, AAA, AAIM, MMEM and

WIAS drafted the manuscript. All authors revised the manuscript as

well as read and approved the final version. AAIM, MMEM and WIAS

confirm the authenticity of all the raw data.

Ethics approval and consent to

participate

Not applicable.

Patient consent for publication

Not applicable.

Competing interests

The authors declare that they have no competing

interests.

References

|

1

|

Cooper GM: The development and causes of

cancer. In: The Cell: A Molecular Approach. 2nd edition. Sinauer

Associates, Sunderland, MA, 2000.

|

|

2

|

Ramya LN, Doble M, Rekha VPB and

Pulicherla KK: L-Asparaginase as potent anti-leukemic agent and its

significance of having reduced glutaminase side activity for better

treatment of acute lymphoblastic leukaemia. Appl Biochem

Biotechnol. 167:2144–2159. 2012.PubMed/NCBI View Article : Google Scholar

|

|

3

|

Kebeish R, El-Sayed A, Fahmy H and

Abdel-Ghany A: Molecular cloning, biochemical characterization, and

antitumor properties of a novel L-asparaginase from

Synechococcuselongatus PCC6803. Biochemistry (Mosc). 81:1173–1181.

2016.PubMed/NCBI View Article : Google Scholar

|

|

4

|

Naser S, Saber W, El-Metwally M, Moustafa

M and El-Kott A: Fungal assembly of L-asparaginase using

solid-state fermentation: A review. Biocell. 44(147)2020.

|

|

5

|

Duval M, Suciu S, Ferster A, Rialland X,

Nelken B, Lutz P, Benoit Y, Robert A, Manel AM, Vilmer E, et al:

Comparison of Escherichia coli-asparaginase with

Erwinia-asparaginasein the treatment of childhood lymphoid

malignancies: Results of a randomized European Organisation for

research and treatment of Cancer-Children's Leukemia Group phase 3

Trial. Blood. 99:2734–2739. 2002.PubMed/NCBI View Article : Google Scholar

|

|

6

|

Verma N, Kumar K, Kaur G and Anand S:

L-asparaginase: A promising chemotherapeutic agent. Crit Rev

Biotechnol. 27:45–62. 2007.PubMed/NCBI View Article : Google Scholar

|

|

7

|

Kornbrust BA, Stringer MA, Lange NE,

Hendriksen HV, Whitehurst R and Oort MV: Asparaginase-an enzyme for

acrylamide reduction in food products. In: Enzymes in Food

Technology. 2nd edition, pp59-87, 2010.

|

|

8

|

Batool T, Makky EA, Jalal M and Yusoff MM:

A comprehensive review on L-Asparaginase and its applications. Appl

Biochem Biotechnol. 178:900–923. 2016.PubMed/NCBI View Article : Google Scholar

|

|

9

|

Vivekanandha S, Muruganantham S and

Paulraj P: Anovel role of L-asparaginase enzyme production from

fungal species. J Microbiol Biotechnol Res. 3:7–14. 2013.

|

|

10

|

Thomas L, Larroche C and Pandey A: Current

developments in solid-state fermentation. Biochem Eng J.

81:146–161. 2013.

|

|

11

|

Sreenivasulu V, Jayaveera KN and Rao PM:

Solid-state fermentation for the production of L-asparaginase by

Aspergillus sp. J Pharmacogn Phytochem. 1:21–25. 2009.

|

|

12

|

Doriya K and Kumar DS: Optimization of

solid substrate mixture and process parameters for the production

of L-asparaginase and scale-up using tray bioreactor. Biocatalysis

Agricultural Biotechnol. 13:244–250. 2018.

|

|

13

|

Apprich S, Tirpanalan O, Hell J, Reisinger

M, Böhmdorfer S, Siebenhandl-Eh S, Novalin S and Kneifel W: Wheat

bran-based biorefinery 2: Valorization of products. LWT-Food Sci

Technol. 56:222–231. 2014.

|

|

14

|

Prueckler M, Siebenhandl-Ehn S, Apprich S,

Hoeltinger S, Haas C, Schmid E and Kneifel W: Wheat bran-based

biorefinery 1: Composition of wheat bran and strategies of

functionalization. LWT-Food Sci Technol. 56:211–221. 2014.

|

|

15

|

Andersson AA, Dimberg L, Åman P and

Landberg R: Recent findings on certain bioactive components in

whole grain wheat and rye. J Cereal Sci. 59:294–311. 2014.

|

|

16

|

De Brier N, Hemdane S, Dornez E, Gomand

SV, Delcour JA and Courtin CM: Structure, chemical composition and

enzymatic activities of pearlings and bran obtained from pearled

wheat (Triticumaestivum L.) by roller milling. J Cereal Sci.

62:66–72. 2015.

|

|

17

|

Babu CR, Ketanapalli H, Beebi SK and

Kolluru VC: Wheat bran-composition and nutritional quality: A

review. Adv Biotechnol Micro. 9(555754)2018.

|

|

18

|

Pandey A, Soccol CR, Rodriguez-Leon JA and

Nigam PSN: Solid-state fermentation in biotechnology: Fundamentals

and applications. Asiatech Publishers, Inc., New Delhi, 2001.

|

|

19

|

Economou CN, Makri A, Aggelis G, Pavlou S

and Vayenas DV: Semi-solid state fermentation of sweet sorghum for

the biotechnological production of single cell oil. Bioresource

Technol. 101:1385–1388. 2010.PubMed/NCBI View Article : Google Scholar

|

|

20

|

Reid Y, Storts D, Riss T, Minor L,

Markossian S, Grossman A, Brimacombe K, Arkin M, Auld D, Austin CP,

et al: Authentication of human cell lines by STR DNA profiling

analysis. In: Assay Guidance Manual. Markossian S, Grossman A,

Brimacombe K, et al (eds). Eli Lilly & Company and the

National Center for Advancing Translational Sciences, Bethesda, MD,

2004.

|

|

21

|

Gulati R, Saxena RK and Gupta R: A rapid

plate assay for screening L-asparaginase producing micro-organisms.

Lett Appl Micro. 24:23–26. 1997.PubMed/NCBI View Article : Google Scholar

|

|

22

|

Raper KB, Austwick PK and Fennell DI: The

Genus Aspergillus. R.E. Krieger, Malabar, FL, 1977.

|

|

23

|

Pitt JI: The genus Penicillium and its

teleomorphic states Eupenicillium and Talaromyces.

Academic Press, London and New York, 1979.

|

|

24

|

Pitt JI: A Laboratory Guide to Common

Penicillium Species. Commonwealth Scientific and Industrial

Research. North Ryde, 1986.

|

|

25

|

Kitch MA and Pitt JI: A laboratory guide

to the common Aspergillus species and their Teleomorphs.

Published by Commonwealth Scientific and Industrial Research

Organization. Division of Food Processing, Sydney, 1992.

|

|

26

|

Kubicek CP and Harman GE: Trichoderma and

Gliocladium. Taylor and Francis Ltd., London and Bristol, 1998.

|

|

27

|

Domsch KH, Gams W and Anderson TH:

Compendium of Soil Fungi. Academic Press, London, 1980.

|

|

28

|

Baskar G and Renganathan S: Production of

L-asparaginase from natural substrates by Aspergillus

terreus MTCC 1782: Optimization of carbon source and operating

conditions. Int J Chem Reactor Engineering: Oct 18, 2011 (Epub

ahead of print). doi: 10.1515/1542-6580.2479.

|

|

29

|

Bradford MM: A rapid and sensitive method

for the quantitation of microgram quantities of protein utilizing

the principle of protein-dye binding. Anal Biochem. 72:248–254.

1976.PubMed/NCBI View Article : Google Scholar

|

|

30

|

Cheng YL, Chang WL, Lee SC, Liu YG, Lin

HC, Chen CJ, Yen CY, Yu DS, Lin SZ and Harn HJ: Acetone extract of

Bupleurum scorzonerifolium inhibits proliferation of A549

human lung cancer cells via inducing apoptosis and suppressing

telomerase activity. Life Sci. 73:2383–2394. 2003.PubMed/NCBI View Article : Google Scholar

|

|

31

|

Indira K, Jayaprabha N, Balakrishnan S,

Arulmoorthy MP and Srinivasan M: Production, purification and

characterisation of extracellular L-asparaginase from salt marsh

fungal endophytes. J Pharm Pharmac Sci. 4:663–677. 2015.

|

|

32

|

Thirunavukkarasu N, Suryanarayanan TS,

Murali TS, Ravishankar JP and Gummadi SN: L-asparaginase from

marine derived fungal endophytes of seaweeds. Mycosphere.

2:147–155. 2011.

|

|

33

|

Theantana T, Hyde KD and Lumyong S:

Asparaginase production by endophytic fungi from Thai medicinal

plants: Cytotoxicity properties. Int J Integrative Biol. 7:1–8.

2009.

|

|

34

|

Ahmad N, Pandit NP and Maheshwari SK:

L-asparaginase gene-a therapeutic approach towards drugs for cancer

cell. Int J Biosci. 2:1–11. 2012.

|

|

35

|

Shakambari G, Ashokkumar B and Varalakshmi

P: L-asparaginase-A promising biocatalyst for industrial and

clinical applications. Biocatalysis Agricultural Biotechnol.

17:213–224. 2019.

|

|

36

|

Tippani R and Sivadevuni G: Nutritional

factors effecting the production of L-asparaginase by the

Fusarium sp. Afr J Biotechnol. 11:3692–3696. 2012.

|

|

37

|

Uppuluri KB and Reddy DS: Optimization of

L-asparaginase production by isolated Aspergillusniger using sesame

cake in a column bioreactor. J Pure Appl Microbiol. 3:83–90.

2009.

|

|

38

|

Singh SB, Bais BS and Singh DR: Effect of

different carbon and nitrogen sources on the growth and sporulation

of Claviceps microcephal (Wallr.) TUL. Mycopathol Mycol

Appl. 46:373–378. 1972.PubMed/NCBI View Article : Google Scholar

|

|

39

|

Selvaraj S and Murty VR: Semi-solid state

fermentation: A promising method for production and optimization of

tannase from Bacillus gottheilii M2S2. Res J Biotechnol. 12:39–48.

2017.

|

|

40

|

Abdel-Fattah YR and Olama ZA:

L-asparaginase production by Pseudomonas aeruginosa in solid-state

culture: Evaluation and optimization of culture conditions using

factorial designs. Process Biochemistry. 38:115–122. 2002.

|

|

41

|

Reid ID: Solid-state fermentations for

biological delignification. Enzyme Micro Technol. 11:786–803.

1989.

|