Introduction

The emergence of engineered cartilage tissue has

provided novel approaches for the repair of cartilage defects in

plastic and reconstructive surgery. Seeding chondrocytes onto

biodegradable scaffolds to construct three dimensional cartilage

tissue for implantation may be a highly promising strategy for the

repair of cartilage defects (1,2).

Scaffolds represent one of the three essential factors necessary

for tissue engineering and have a significant role in cartilage

regeneration. Various biodegradable polymers have been explored for

use as scaffolds for cartilage tissue engineering, including

calcium alginate gel and polyglycolic acid (3–6).

Among these, the novel polyhydroxyalkanoates (PHAs) have been shown

to be biocompatible, biodegradable and thermoplastic polyesters,

which, due to their enhanced biomechanical properties, may be ideal

for use as biomedical materials. The PHA that has attracted the

most interest is poly(3-hydroxybutyrate) (PHB). Numerous strains of

bacteria have been identified to be capable of producing PHB in

high yields. Poly(hydroxybutyrate-co-hydroxyvalerate) (PHBV), a

copolymer containing hydroxyvalerate and PHB in varying ratios, is

a particularly useful material due to its less crystalline and more

flexible structure, and greater ease of processability than PHB

(7).

Previous studies have used PHBV as a biomaterial for

cartilage tissue engineering. In one such study, Kose et al

(8) investigated the use of

macroporous PHBV scaffolds in the repair of full-thickness

cartilage defects (side length, 4.5 mm; depth, 4 mm) in rabbits

in vivo. At 8 and 20 weeks after seeding, minimal foreign

body reaction was observed and the chondrocytes seeded onto the

PHBV matrices showed early cartilage formation. Furthermore, the

newly formed cartilage had the appearance of normal articular

cartilage (8). Lu et al

(9) confirmed the feasibility of

engineering an entire meniscal structure in a total meniscectomy

rabbit model using biodegradable PHBV scaffolds and cultured

allogeneic meniscal cells. However, PHBV is a hydrophobic

polyester. In a previous study, we revealed that the poor

hydrophilicity and mechanical strength associated with PHBV

resulted in a low percentage of cell adherence and the formation of

thin cartilage layers with poor biomechanical properties (10). Therefore, the present study aimed

to investigate the improvement of the hydrophilic characteristics

and mechanical strength of PHBV scaffolds.

Bioglass® (BG) is a bioactive inorganic

material composed of specific proportions of SiO2,

Na2O, CaO and P2O5, and its

incorporation into PHBV has previously been reported to be capable

of improving the hydrophilicity and mechanical strength of the

composites (7,11). However, few reports have shown

whether the incorporation of BG into PHBV scaffolds has potential

in cartilage tissue engineering. Therefore, in the present study it

was hypothesized that the incorporation of BG into PHBV would

generate composite scaffolds with enhanced properties for cartilage

engineering compared with scaffolds solely composed of PHBV.

To investigate this hypothesis, PHBV scaffolds and

PHBV scaffolds containing 10% BG (w/w) (PHBV/10% BG) were prepared.

Chondrocytes were seeded onto the scaffolds and cultured in

vitro for 24 h, prior to 10 weeks of in vivo

implantation to observe the formation of engineered cartilage

tissue on the different scaffolds. The extracellular matrix (ECM)

production, size, structure and biomechanical properties of the

neocartilage were analyzed to compare the structure and function of

the engineered cartilage tissue produced by the different

scaffolds.

Materials and methods

Ethics statement

All experimental procedures performed in this study

were approved by the Ethics Committee of the Shanghai Jiao Tong

University School of Medicine (Shanghai, China).

Preparation of PHBV and PHBV/10% BG

scaffolds

PHBV, (molecular weight, 300,000 Da) containing 3

mol% 3-hydroxyvalerate was obtained from Tianan Biologic Material

Co. Ltd. (Ningbo, China). A solvent casting/particulate leaching

method was used in the preparation of the PHBV and composite

PHBV10% BG scaffolds as described in a previous study (12). PHBV powder (1 g) was dissolved in

10 ml chloroform to generate a solution with a concentration of 10%

(w/v). To produce the PHBV/10% BG composite scaffolds, the solution

was supplemented with 0.11 g BG powder and stirred continuously for

2 h to ensure uniform dispersal of the powder. NaCl particles were

subsequently added to the solution as pore-generating additives.

The solution was then cast in a 60-mm diameter, 3-mm long

Teflon® mold and air-dried in a fume hood for 24 h to

allow solvent evaporation. Any remaining solvent was eliminated

through vacuum drying at 60°C for 48 h. The pore-generating

additives were then leached from the dried samples by immersion in

deionized water. Samples were subsequently subjected to further

vacuum drying to produce porous scaffolds, which were referred to

as PHBV and PHBV/10% BG scaffolds, respectively. Scaffolds were cut

into identical rectangular prisms that measured 4 mm in length and

were 3-mm thick. Additional PHBV and PHBV/10% BG films were

prepared using an identical method; however, the porogen addition

and particulate leaching processes were eliminated so that the

water contact angles could be determined. AgNO3

titration was performed to ensure complete NaCl leaching from the

scaffolds (12).

Characterization of the PHBV and

PHBV/10%BG scaffolds

Scaffold porosity was determined by measuring the

mass and dimensions of the scaffolds as described previously

(13). In order to test the

compressive strength, PHBV and PHBV/10% BG scaffolds that measured

6 mm in diameter and were 3-mm thick were prepared. The compressive

strength of the scaffolds was determined using an AG-1 Shimadzu

mechanical tester (Shimadzu Co., Kyoto, Japan), with a crosshead

speed of 0.5 mm/min.

The water absorptivity of the scaffolds was

determined as described previously (14). Dry scaffolds were weighed to obtain

the dry weight (Wdry), prior to being placed in deionized water at

room temperature for 4 h. This ensured that water absorption was

equilibrated. The hydrated scaffolds were then extracted from the

water, filter paper was utilized to remove the free surface water

and the scaffolds were weighed to obtain the wet weight (Wwet). The

water absorption ratio was calculated as follows: Water absorption

ratio (%)=(Wwet−Wdry)/Wdry × 100.

Determination of hydrophilicity

Scaffold hydrophilicity was analyzed by measuring

the water contact angles of the nonporous composite cuboids.

Contact angles were measured at 25°C using a contact angle

goniometer (model SZ10-JC2000A; Maikailun Co., Xiamen, China). The

sessile drop method was used to obtain the measurements, and five

different locations were analyzed for each specimen. A total of 0.5

μl deionized water was deposited onto the surface of the specimen

at each location. The degree of reproducibility for the different

specimens was within ±4.0°. Three specimens were tested for each

sample.

Cell isolation and construction of

engineered cartilage

Auricular cartilage was harvested from the ears of

New Zealand white rabbits (SLAC Lab. Animal Ltd., Shanghai, China),

aged between three and five days, prior to being cut into small

pieces as previously described (15). The cartilage slices were digested

using 0.2% (w/v) collagenase II to release the chondrocytes, which

were then cultured in Dulbecco’s Modified Eagle Medium (DMEM)

supplemented with 10% fetal calf serum, 100 U/ml penicillin and 100

μg/ml streptomycin. The chondrocytes were incubated at 37°C in 5%

CO2 and the medium was changed every three days.

Following two subcultures, 30 μl chondrocyte suspension (5 ×

107 cells/ml) at passage 2 was deposited onto each

scaffold, prior to the addition of 5 ml DMEM after 4 h. After 24 h,

the constructs were harvested and subcutaneously implanted into

nude mice (SLAC Lab. Animal Ltd.). Ten weeks after implantation,

the specimens were harvested.

Cell adhesion

The PHBV and composite PHBV/10% BG substrates were

soaked in 75% ethanol for 48 h prior to overnight sterilization

using ultraviolet radiation and washing with sterile

phosphate-buffered saline (PBS, pH 7.4). Chondrocytes were then

seeded onto the sterilized substrates in a 48-well plate (density,

70 cells/mm2) and maintained in a CO2

incubator for 3 h, prior to the addition of 1 ml fresh medium to

each well. Cell viability was determined using an MTT-based

colorimetric assay and the percentage of adhered cells was

calculated in accordance with a method described previously

(16).

Gross observation of in vivo engineered

tissue

The constructs were harvested 10 weeks after

implantation and images were captured so that the side length,

volume and thickness of the constructs could be measured. At each

time-point, the volume was determined using a volumenometer, and

the side length and thickness were measured using a vernier

caliper.

Quantitative analysis of in vivo

cartilage formation

After 10 weeks in vivo culture, the Wwet,

glycosaminoglycan (GAG) (17) and

total collagen (18) content, and

mechanical strength (19) were

determined using previously described methods.

Histology evaluation

Ten weeks after implantation, representative

cartilaginous tissue formed on the PHBV and PHBV/10% BG scaffolds

was fixed in neutral buffered formalin, prior to being embedded in

paraffin and sectioned into 5-μm thick specimens. The

cross-sections were stained using hematoxylin and eosin and

Safranin-O. Immunostaining of the 10-μm cryosections was performed

with an anti-type II collagen antibody. Non-specific binding sites

were blocked by immersing the samples overnight in PBS containing

1% goat serum at 4°C. The sections were then incubated for 4 h at

25°C in PBS containing 1% bovine serum albumin (BSA) and an

anti-type II collagen antibody (Santa Cruz Biotechnology, Inc.,

Santa Cruz, CA, USA) at a dilution of 1:100. Following three washes

with PBS, samples were incubated in PBS containing 3% BSA and then

in PBS containing 1% BSA and a horseradish peroxidase-conjugated

anti-rabbit immunoglobulin G antibody (Santa Cruz Biotechnology,

Inc.) at a dilution of 1:150 at 25°C for 4 h. Color development was

performed using diaminobenzidine tetrahydrochloride (Santa Cruz

Biotechnology, Inc.) (2).

Statistical analysis

All data are presented as the mean ± standard

deviation for n=6. Differences between the PHBV and PHBV/10% BG

scaffolds were analyzed using the Student’s t-test. A value of

P<0.05 was considered to indicate a statistically significant

difference.

Results

Scaffold characterization

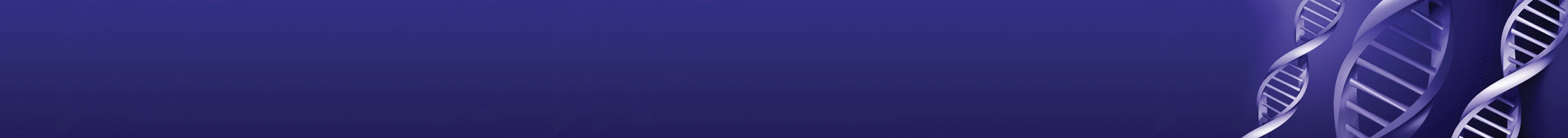

The PHBV and PHBV/10% BG scaffolds were cut into

rectangular prisms with no significant differences in size or

volume (P>0.05) (Fig. 1A).

Furthermore, no significant difference was observed in the porosity

of the scaffolds between the PHBV and PHBV/10% BG groups

(P>0.05) (Fig. 1B). However,

with the addition of 10% BG (w/w) to the PHBV scaffolds,

compressive strength and water absorptivity were observed to

increase from 0.13±0.02 to 0.22±0.05 MPa and from 50±3 to 72±5%,

respectively (P<0.05) (Fig. 1C and

D).

Hydrophilicity and cell adhesion of

different scaffolds

As shown in Fig.

1E, the water contact angles of the PHBV/10% BG composites

(54±1.5°) were observed to be significantly lower than those of the

PHBV specimens (66±2°) (P<0.01), indicating that the addition of

BG to PHBV enhanced the surface hydrophilicity. Furthermore, the

percentage of adhered cells increased from 59±5 to 70±7% with the

addition of 10% BG (w/w) (Fig.

1F).

Gross evaluation of the in vivo

engineered constructs

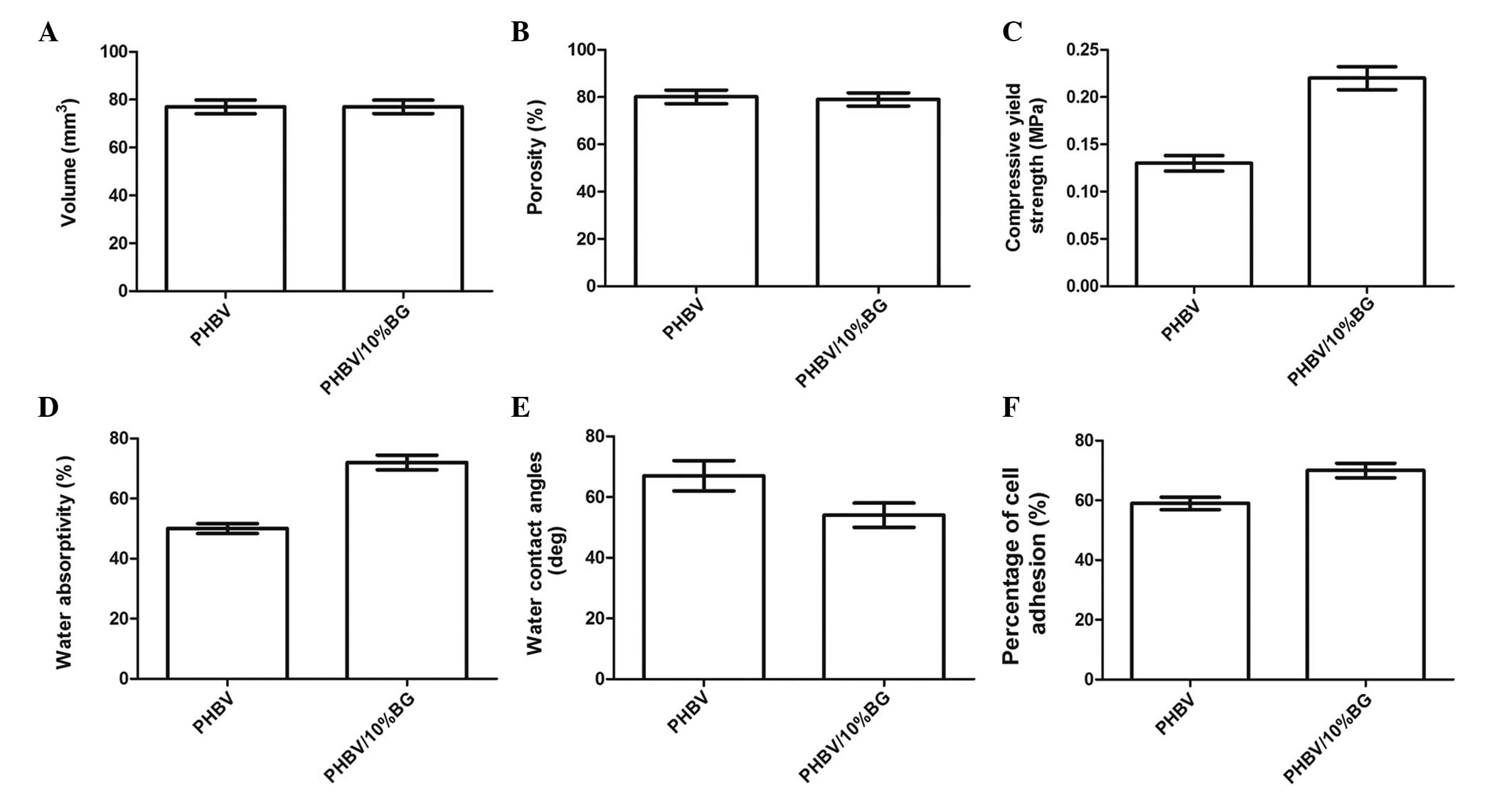

Variations in the gross shape and size of the in

vivo engineered constructs were recorded to assess the impact

of the two different scaffolds on three dimensional cartilage

tissue formation. Following in vivo implantation, the

cell-scaffold constructs were observed to maintain their original

size in the two groups, and form an ivory-white cartilage-like

tissue (Fig. 2A and B).

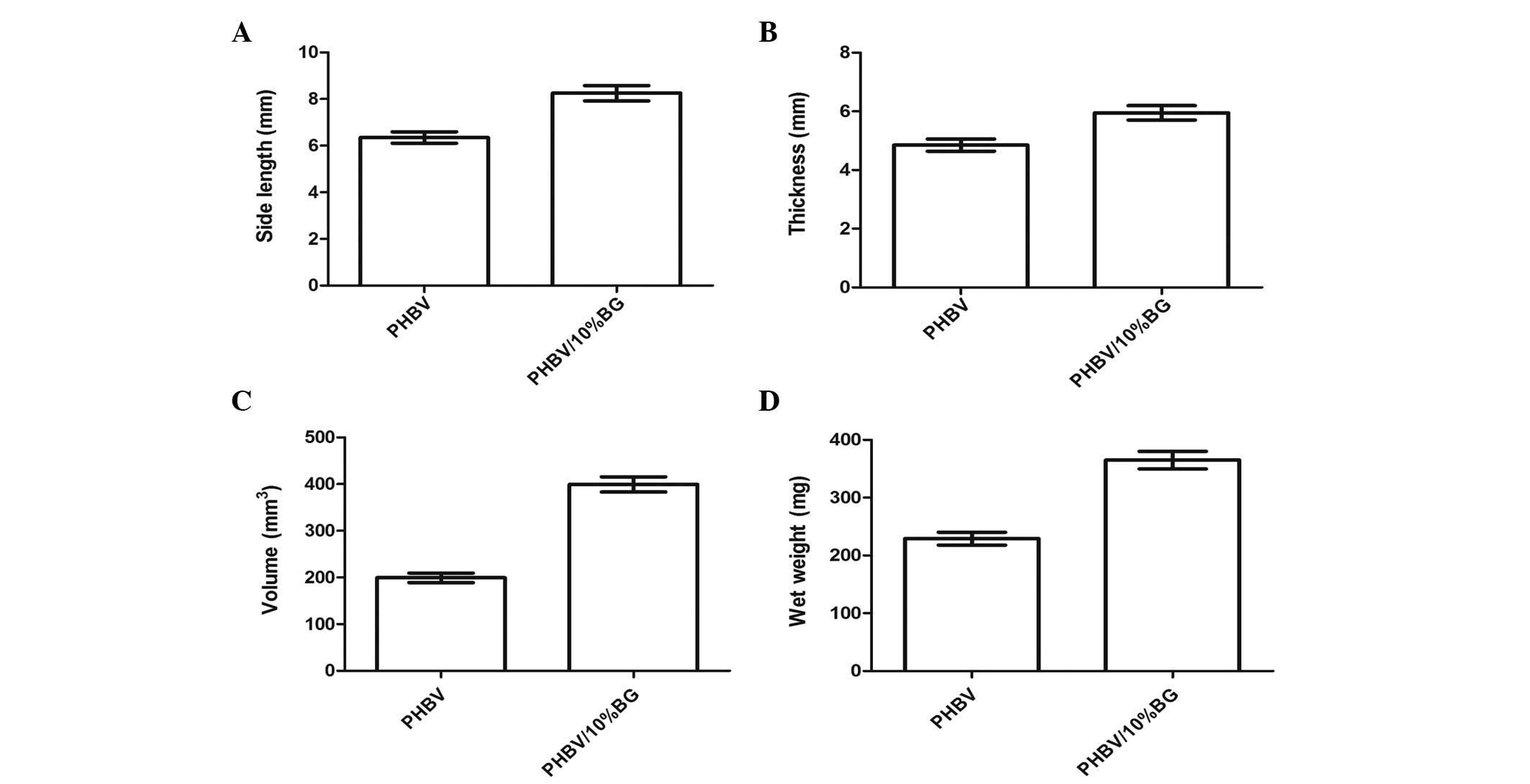

Quantitative analysis revealed that in the PHBV/10% BG group, the

thickness, side length, volume and Wwet were significantly higher

than those in the PHBV group after 10 weeks in vivo

transplantation (P<0.05) (Fig.

3).

Collagen and GAG content and compressive

modulus

Quantitative analysis further revealed that there

were significant differences in the ECM and mechanical properties

between the samples of regenerated cartilage in the PHBV and

PHBV/10% BG groups (P<0.05) (Fig.

4A and B).

Histology and immunohistochemistry

The engineered tissue was subjected to histological

and immunohistochemical analysis to assess the formation of

neocartilage. Cartilage-like tissue was observed to have formed in

the cell-scaffold constructs in the PHBV and PHBV/10% BG groups;

this tissue exhibited a notable cartilage-like lacunar structure

with strong expression of type II collagen (Fig. 4). However, the full-thickness

histological and immunohistochemical staining revealed that the

cartilage-like tissue layers generated by the cell-scaffold

constructs in the PHBV/10% BG group were thicker than those

generated in the pure PHBV group (Fig.

2).

Discussion

Engineered cartilage tissue is used to repair

cartilage defects and has been suggested to be an ideal therapy for

the clinic. The basic method underlying tissue engineering is to

seed cells directly onto a biodegradable scaffold material and then

implant the cell-scaffold complex subcutaneously to construct the

required tissue (6,20). Therefore, scaffolds have a

significant role in cartilage tissue engineering. The following

properties are required for ideal scaffolds: (i) The mechanical

strength necessary for the creation of a macroporous scaffold that

retains its structure following implantation, particularly in the

reconstruction of hard, load-bearing tissues; (ii) the ability to

biodegrade at a controllable rate that approximates the rate of

tissue regeneration under the culture conditions of interest; and

(iii) histocompatibility that promotes cell-biomaterial

interactions, cell adhesion and ECM deposition (21,22).

On the scaffolds, chondrocytes should maintain their chondrogenic

phenotype and produce ECM components to eventually replace the

scaffolds (23,24). The chemistry and physicochemical

properties of the scaffolds determine whether the seeded cells are

able to grow and maintain their morphology and phenotype (25,26).

Such properties include: (i) External geometry, including macro-

and micro-structure and interconnectivity; (ii) surface properties,

including surface energy, chemistry, charge and surface area; (iii)

porosity and pore size; (iv) interface adherence and

biocompatibility; (v) degradation characteristics, including

biodegradation; and (vi) mechanical competence, including

compressive and tensile strength (22,25–27).

PHBV has demonstrated potential as a chondrocyte carrier for

cartilage engineering (7).

However, the cartilage tissue grown using PHBV matrices is not, at

present, suitable for clinical application due to the poor

hydrophilicity and mechanical strength associated with PHBV, which

results in the engineered cartilage tissue exhibiting poor

biomechanical properties. The hydrophilicity of a material has been

reported to significantly influence cell adhesion, growth and

proliferation. Improving the surface hydrophilicity of a material

may enhance its ability to interact with cells and elicit

controlled cellular adhesion, while maintaining a stable

differentiated phenotype (28,29).

Certain techniques have been reported to enhance the hydrophilicity

of PHBV, including combining PHBV with the polymer

poly[(R)-3-hydroxybutyrate]-alt-poly(ethylene oxide) (30), oxygen and nitrogen plasma treatment

(31) and covalently immobilizing

a water-soluble chitosan/chondroitin-6-sulfate polyelectrolyte

complex onto the surface of PHBV membranes using ozone-induced

oxidation and polyacrylic acid graft polymerization (32). Li et al (16) demonstrated that incorporating

hydrophilic inorganic materials into hydrophobic polymers may be a

feasible approach to improve the hydrophilicity of these

composites.

Previous studies have indicated that the

incorporation of bioactive glass into PHBV is capable of improving

hydrophilicity and mechanical properties (11). BG is an inorganic material not

normally present in bone or cartilage tissue; however, bioactive

glass has been utilized in tissue engineering, and studies

(33,34) have shown that this material is

capable of promoting the growth and proliferation of osteoblasts.

Bal et al (35) reported

that bioactive glass was superior to bone allografts with respect

to integrating into the adjacent host bone, regenerating

hyaline-like tissue at the graft surface and expressing type II

collagen in the articular cartilage. Therefore, in the present

study, 10% BG was incorporated into PHBV in order to generate

porous composite scaffolds for in vitro and in vivo

investigations. Hydrophilicity was observed to be significantly

enhanced in the PHBV/10% BG scaffolds compared with that of the

pure PHBV scaffolds, with the water contact angle decreasing from

66 to 54°with the addition of 10% BG (w/w). The enhanced

hydrophilicity was associated with an increase in cell adhesion

from 59 to 70%. Histological and immunohistochemical analyses of

the in vivo engineered cartilage confirmed these findings.

The cartilage-like tissue layers generated using the PHBV/10% BG

scaffolds were thicker than those formed using the pure PHBV

scaffolds, due to the higher percentage of cell adhesion in the

PHBV/10% BG group.

Ideal scaffolds require appropriate mechanical

properties; therefore, various attempts have been made to improve

the mechanical properties of PHBV scaffolds. Wang et al

(36) reported that the addition

of 5% (w/w) acetylated chitin nanocrystals to PHBV scaffolds

improved the tensile strength and Young’s modulus by 44 and 67%,

respectively, compared with improvements of 24 and 43% in

PHBV/chitin nanocrystal composites. Furthermore, it has been

reported that combining PHBV with Ecoflex may improve the

mechanical properties of PHBV and thereby promote its application

in tissue engineering (37). The

incorporation of bioactive inorganic materials into PHBV has also

been reported to improve the mechanical strength of the scaffold

(16). In the present study, the

addition of BG into PHBV scaffolds was observed to generate

scaffolds with enhanced mechanical properties and an increased

capacity for cartilage formation. In addition, the composite

scaffolds produced from the incorporation of 10% (w/w) BG into PHBV

exhibited an increase in compressive yield strength, from 0.13 to

0.22 MPa. This suggests that BG may have a strengthening effect on

PHBV scaffolds; however, the mechanism by which this is achieved is

yet to be elucidated.

The compressive modulus of the cell-scaffold

constructs in the PHBV/10% BG group in the present study was

observed to be significantly higher than that in the pure PHBV

group. This may be a consequence of the enhanced mechanical

strength associated with the PHBV/10% BG scaffolds compared with

that in the PHBV scaffolds, or the thicker cartilage-like tissue

formed with the PHBV/10% BG scaffolds and the fact that the

improved mechanical properties of the neocartilage tissue are

determined by the content of the ECM. Studies have revealed that

improvements in mechanical strength may be partially elicited by

the homogeneous structure and the ECM content, specifically with

regard to the GAG and total collagen content (38–40).

This is consistent with the findings from the analysis of the GAG

and total collagen content in the present study. It was observed in

the present study that the GAG and total collagen content was

significantly higher in the PHBV/10% BG group than that in the PHBV

group, which contributed to the improved mechanical properties of

the neocartilage tissue.

In conclusion, the present study has demonstrated

that composite PHBV/10% BG scaffolds exhibit improved

hydrophilicity and mechanical properties and also form neocartilage

with enhanced biochemical and biomechanical properties. Although

the specific mechanism by which this is achieved is yet to be

elucidated, the incorporation of BG into PHBV may be beneficial for

the generation of composite scaffolds with enhanced properties for

cartilage engineering compared with pure PHBV scaffolds.

Acknowledgements

The authors would like to thank Professor Li Huang

(Department of Plastic and Reconstructive Surgery, Tongji Hospital

Affiliated to Tongji Medical College of Huazhong University of

Science and Technology, China) for the help and support provided.

This research was supported by the National Natural Science

Foundation of China (81272129).

References

|

1

|

Vacanti CA, Langer R, Schloo B and Vacanti

JP: Synthetic polymers seeded with chondrocytes provide a template

for new cartilage formation. Plast Reconstr Surg. 88:753–759. 1991.

View Article : Google Scholar : PubMed/NCBI

|

|

2

|

Xue K, Zhu Y, Zhang Y, Chiang C, Zhou G

and Liu K: Xenogeneic chondrocytes promote stable subcutaneous

chondrogenesis of bone marrow-derived stromal cells. Int J Mol Med.

29:146–152. 2012.PubMed/NCBI

|

|

3

|

Zhu S, Zhang T, Sun C, Yu A, Qi B and

Cheng H: Bone marrow mesenchymal stem cells combined with calcium

alginate gel modified by hTGF-β1 for the construction of

tissue-engineered cartilage in three-dimensional conditions. Exp

Ther Med. 5:95–101. 2013.PubMed/NCBI

|

|

4

|

Gu Y, Zhu W, Hao Y, Lu L, Chen Y and Wang

Y: Repair of meniscal defect using an induced myoblast-loaded

polyglycolic acid mesh in a canine model. Exp Ther Med. 3:293–298.

2012.PubMed/NCBI

|

|

5

|

Kuhne M, John T, El-Sayed K, et al:

Characterization of auricular chondrocytes and auricular/articular

chondrocyte co-cultures in terms of an application in articular

cartilage repair. Int J Mol Med. 25:701–708. 2010.PubMed/NCBI

|

|

6

|

Schlegel W, Nürnberger S, Hombauer M,

Albrecht C, Vécsei V and Marlovits S: Scaffold-dependent

differentiation of human articular chondrocytes. Int J Mol Med.

22:691–699. 2008.PubMed/NCBI

|

|

7

|

Sun J, Wu J, Li H and Chang J: Macroporous

poly(3-hydroxybutyrate-co-3-hydroxyvalerate) matrices for cartilage

tissue engineering. Eur Polym J. 41:2443–2449. 2005. View Article : Google Scholar

|

|

8

|

Köse GT, Korkusuz F, Ozkul A, et al:

Tissue engineered cartilage on collagen and PHBV matrices.

Biomaterials. 26:5187–5197. 2005.PubMed/NCBI

|

|

9

|

Lu HD, Cai DZ, Wu G, Wang K and Shi DH:

Whole meniscus regeneration using polymer scaffolds loaded with

fibrochondrocytes. Chin J Traumatol. 14:195–204. 2011.PubMed/NCBI

|

|

10

|

Wu J, Xue K, Li H, Sun J and Liu K:

Improvement of PHBV scaffolds with Bioglass for cartilage tissue

engineering. PLoS One. 8:e715632013. View Article : Google Scholar : PubMed/NCBI

|

|

11

|

Li H, Du R and Chang J: Fabrication,

characterization, and in vitro degradation of composite scaffolds

based on PHBV and bioactive glass. J Biomater Appl. 20:137–155.

2005. View Article : Google Scholar : PubMed/NCBI

|

|

12

|

Li H and Chang J: Fabrication and

characterization of bioactive wollastonite/PHBV composite

scaffolds. Biomaterials. 25:5473–5480. 2004. View Article : Google Scholar : PubMed/NCBI

|

|

13

|

Hou Q, Grijpma DW and Feijen J: Porous

polymeric structures for tissue engineering prepared by a

coagulation, compression moulding and salt leaching technique.

Biomaterials. 24:1937–1947. 2003. View Article : Google Scholar

|

|

14

|

Zheng X, Yang F, Wang S, et al:

Fabrication and cell affinity of biomimetic structured

PLGA/articular cartilage ECM composite scaffold. J Mater Sci Mater

Med. 22:693–704. 2011. View Article : Google Scholar : PubMed/NCBI

|

|

15

|

Whitney GA, Mera H, Weidenbecher M,

Awadallah A, Mansour JM and Dennis JE: Methods for producing

scaffold-free engineered cartilage sheets from auricular and

articular chondrocyte cell sources and attachment to porous

tantalum. Biores Open Access. 1:157–165. 2012.PubMed/NCBI

|

|

16

|

Li H, Zhai W and Chang J: In vitro

biocompatibility assessment of PHBV/Wollastonite composites. J

Mater Sci Mater Med. 19:67–73. 2008. View Article : Google Scholar : PubMed/NCBI

|

|

17

|

Enobakhare BO, Bader DL and Lee DA:

Quantification of sulfated glycosaminoglycans in

chondrocyte/alginate cultures, by use of 1,9-dimethylmethylene

blue. Anal Biochem. 243:189–191. 1996. View Article : Google Scholar : PubMed/NCBI

|

|

18

|

Reddy GK and Enwemeka CS: A simplified

method for the analysis of hydroxyproline in biological tissues.

Clin Biochem. 29:225–229. 1996. View Article : Google Scholar : PubMed/NCBI

|

|

19

|

Carey J, Small CF and Pichora DR: In situ

compressive properties of the glenoid labrum. J Biomed Mater Res.

51:711–716. 2000. View Article : Google Scholar : PubMed/NCBI

|

|

20

|

Xue K, Qi L, Zhou G and Liu K: A two-step

method of constructing mature cartilage using bone marrow-derived

mesenchymal stem cells. Cells Tissues Organs. 197:484–495. 2013.

View Article : Google Scholar : PubMed/NCBI

|

|

21

|

Yang S, Leong KF, Du Z and Chua CK: The

design of scaffolds for use in tissue engineering. Part I

Traditional factors. Tissue Eng. 7:679–689. 2001. View Article : Google Scholar : PubMed/NCBI

|

|

22

|

Dhandayuthapani B, Yoshida Y, Maekawa T

and Kumar DS: Polymeric scaffolds in tissue engineering

application: A review. Int J of Polym Sci. 2011:1–19. 2011.

View Article : Google Scholar

|

|

23

|

Surrao DC, Khan AA, McGregor AJ, Amsden BG

and Waldman SD: Can microcarrier-expanded chondrocytes synthesize

cartilaginous tissue in vitro? Tissue Eng Part A. 17:1959–1967.

2011. View Article : Google Scholar : PubMed/NCBI

|

|

24

|

Schuh E, Kramer J, Rohwedel J, et al:

Effect of matrix elasticity on the maintenance of the chondrogenic

phenotype. Tissue Eng Part A. 16:1281–1290. 2010. View Article : Google Scholar : PubMed/NCBI

|

|

25

|

Hambleton J, Schwartz Z, Khare A, et al:

Culture surfaces coated with various implant materials affect

chondrocyte growth and metabolism. J Orthop Res. 12:542–552. 1994.

View Article : Google Scholar : PubMed/NCBI

|

|

26

|

Boyan BD, Hummert TW, Dean DD and Schwartz

Z: Role of material surfaces in regulating bone and cartilage cell

response. Biomaterials. 17:137–146. 1996. View Article : Google Scholar : PubMed/NCBI

|

|

27

|

Gugala Z and Gogolewski S:

Differentiation, growth and activity of rat bone marrow stromal

cells on resorbable poly(L/DL-lactide) membranes. Biomaterials.

25:2299–2307. 2004. View Article : Google Scholar : PubMed/NCBI

|

|

28

|

Lydon MJ, Minett TW and Tighe BJ: Cellular

interactions with synthetic polymer surfaces in culture.

Biomaterials. 6:396–402. 1985. View Article : Google Scholar : PubMed/NCBI

|

|

29

|

van Wachem PB, Beugeling T, Feijen J,

Bantjes A, Detmers JP and van Aken WG: Interaction of cultured

human endothelial cells with polymeric surfaces of different

wettabilities. Biomaterials. 6:403–408. 1985.PubMed/NCBI

|

|

30

|

Li X, Liu KL, Wang M, et al: Improving

hydrophilicity, mechanical properties and biocompatibility of

poly[(R)-3-hydroxybutyrate-co-(R)-3-hydroxyvalerate] through

blending with poly[(R)-3-hydroxybutyrate]-alt-poly(ethylene oxide).

Acta Biomater. 5:2002–2012. 2009.

|

|

31

|

Wang Y, Lu L, Zheng Y and Chen X:

Improvement in hydrophilicity of PHBV films by plasma treatment. J

Biomed Mater Res A. 76:589–595. 2006. View Article : Google Scholar : PubMed/NCBI

|

|

32

|

Yu DG, Lin WC, Lin CH and Yang MC:

Cytocompatibility and antibacterial activity of a PHBV membrane

with surface-immobilized water-soluble chitosan and

chondroitin-6-sulfate. Macromol Biosci. 6:348–357. 2006. View Article : Google Scholar : PubMed/NCBI

|

|

33

|

Köse GT, Korkusuz F, Korkusuz P, Purali N,

Ozkul A and Hasirci V: Bone generation on PHBV matrices: an in

vitro study. Biomaterials. 24:4999–5007. 2003.PubMed/NCBI

|

|

34

|

Köse GT, Korkusuz F, Korkusuz P and

Hasirci V: In vivo tissue engineering of bone using

poly(3-hydroxybutyric acid-co-3-hydroxyvaleric acid) and collagen

scaffolds. Tissue Eng. 10:1234–1250. 2004.PubMed/NCBI

|

|

35

|

Bal BS, Rahaman MN, Jayabalan P, et al: In

vivo outcomes of tissue-engineered osteochondral grafts. J Biomed

Mater Res B Appl Biomater. 93:164–174. 2010.PubMed/NCBI

|

|

36

|

Wang B, Li J, Zhang J, et al:

Thermo-mechanical properties of the composite made of poly

(3-hydroxybutyrate-co-3-hydroxyvalerate) and acetylated chitin

nanocrystals. Carbohydr Polym. 95:100–106. 2013. View Article : Google Scholar : PubMed/NCBI

|

|

37

|

Wang A, Gan Y, Yu H, et al: Improvement of

the cytocompatibility of electrospun

poly[(R)-3-hydroxybutyrate-co-(R)-3-hydroxyvalerate] mats by

Ecoflex. J Biomed Mater Res A. 100:1505–1511. 2012.PubMed/NCBI

|

|

38

|

Rieppo J, Töyräs J, Nieminen MT, et al:

Structure-function relationships in enzymatically modified

articular cartilage. Cells Tissues Organs. 175:121–132. 2003.

View Article : Google Scholar : PubMed/NCBI

|

|

39

|

Mikic B, Isenstein AL and Chhabra A:

Mechanical modulation of cartilage structure and function during

embryogenesis in the chick. Ann Biomed Eng. 32:18–25. 2004.

View Article : Google Scholar : PubMed/NCBI

|

|

40

|

Bastiaansen-Jenniskens YM, Koevoet W, de

Bart AC, et al: Contribution of collagen network features to

functional properties of engineered cartilage. Osteoarthritis

Cartilage. 16:359–366. 2008. View Article : Google Scholar : PubMed/NCBI

|