Introduction

Allergic rhinitis (AR) refers to the non-infective

inflammatory disease of the nasal mucosa caused by the release of

IgE-mediated histamine following exposure to allergens by atopic

individuals, and involves a variety of immune active cells and

cytokines (1). The clinical

manifestations of AR are usually nasal congestion, rhinocnesmus,

rhinorrhea and sneezing. AR is the most common chronic refractory

disease reported in recent years in otorhinolaryngology, and it is

also one of the prioritized diseases for prevention and treatment

(2). It is mainly caused by

environmental changes, seasonal alternation, temperature change,

wind, precipitation, pollen and dust (3). The disease is not lethal, but the

nasal symptoms cause obvious discomfort, seriously affecting the

physical health of the patient, their ability to work and study,

and their quality of life. AR is difficult to control and leads to

numerous long-term complications that may cause more severe

diseases, such as nasopharyngeal carcinoma and tympanitis (4). Therefore, the identification of a

safe drug for the treatment of AR is currently a research priority

(2).

Bitongning drops are recognized in Volume 6 of the

Drug Standard of the Ministry of Health of the People's Republic of

China (5). The drops are made by

steam distillation of Flos magnoliae (FM) and Centipeda

minima (CM) to extract their volatile oil or aqua aromatica

(6). Bitongning drops can clear

nasal orifices, and therefore they are used for treating nasal

congestion, acute and chronic sinusitis, AR and colds caused by

wind chill (7–9). Pharmacological experiments have

indicated that the volatile oils of drugs used in Traditional

Chinese Medicine (TCM) have anti-inflammatory and anti-allergenic

effects, and they are currently used to treat acute and chronic

rhinitis, as well as AR. In particular, the volatile oils of FM and

CM serve important roles in the treatment of AR (10,11).

Due to the low and unstable extraction rate of volatile oil,

constituents such as eucalyptol and geraniene D were easy to

volatilize (12). The majority of

TCM volatile oils are used as a raw material only, and therefore

few previous studies have reported the clinical application of its

single preparation. The association between compatibility and

pharmacodynamics of FM and CM has been rarely studied. Our previous

study revealed that the combination of volatile oil from FM and CM

may effectively relieve local inflammatory cell infiltration and

cell necrosis of nasal mucosa in the nasal cavity of rats, thereby

decreasing the histamine content in blood and improving the

symptoms of AR (11). In

Bitongning drops, the active component is aromatic water. Although

aromatic water is mostly composed of volatile oil, it is a type of

solution that is nearly saturated or contains water. Compared with

pure volatile oil, the volatile oil content of aqua aromatica is

lower and extremely perishable, which is an impediment for its

production and storage on a large scale.

As a new drug carrier, microemulsions (ME) are

transparent or translucent, have low viscosity, and are isotropic

and thermodynamically stable systems. ME is spontaneously formed by

an oil phase, water phase, emulsifier and co-emulsifier in an

appropriate ratio (13,14). The particle size of ME ranges from

10–100 nm, and its characteristics include low viscosity, rapid

absorption and targeted drug release, which can increase the

solubility of volatile oil drugs, improve the bioavailability of

drugs and decrease side effects (15–17).

As the volatile oils of FM and CM are fat-soluble components, and

their absorption is poor and their bioavailability is low, the

common method of preparation results in poor absorption and low

bioavailability. Therefore, in the present study, the volatile oils

of FM and CM were prepared as an ME by phase conversion

emulsification, and its basic properties, including stability,

content and skin permeability were evaluated. The results led to

the generation of a novel type of FM and CM volatile oil ME

preparation with high stability, safety and loading capacity.

Materials and methods

Materials

FM volatile oil and CM volatile oil were produced by

the Key Laboratory of New Drugs and Chinese Medicine Foundation

Research, College of Pharmacy, Shaaxi University of Chinese

Medicine (7,20). Eucalyptol (purity >99.5%) was

purchased from Shanghai Aladdin Bio-Chem Technology Co., Ltd.

Hydrogenated castor oil polyoxyethylene ether (RH-40), castor oil

polyoxyethylene ether (EL-40), isopropyl myristate (IPM) and

isopropyl hexadecanoate (IPP) were purchased from Shanghai Yuanye

Bio-Technology Co., Ltd. Tween-80, Tween-20, glycerol,

1,2-propanediol, and oleic acid were purchased from Tianjin Tianli

Chemical Reagent Co., Ltd. Polyethylene glycol-400 (PEG-400) was

purchased Tianjin Kemiou Chemical Reagent Co., Ltd. Sudan III and

methylene blue were obtained from Shanghai Xinsheng Test Chemical

Technology Co., Ltd. Purified water, purchased from Wahaha Group

Co., Ltd., was used throughout the experiments. All other reagents

were of commercial analytical grade. A total of three

three-month-old female bullfrogs (150±20 g) were supplied by

Chengdu Dossy Experimental Animals Co., Ltd. Bullfrogs were housed

in a transparent box with a water depth of 20 cm at 25°C, 30–40%

humidity and a 12-h light day cycle, without food for 3 days.

Bullfrogs were sacrificed by marrow destruction, and the abdominal

skin and subcutaneous fat was removed. The present study was

approved by the Ethical Committee of Shaanxi University of Chinese

Medicine.

Screening of formula and preparation

factors of ME

Emulsifiers

Representing an important component in the

preparation of MEs, an emulsifier is a substance that can improve

the surface tension between various phases in emulsion, and can

form a uniform and stable dispersion system or emulsion (21). The hydrophilic and lipophilic

balance (HLB) value of the emulsifier is the basic metric used for

selecting a certain emulsifier (22). In the present study, RH-40, EL-40,

Tween-80, and Tween-20, emulsifiers with HLB values between 8–18

that can effectively improve the surface tension of oil and water,

were selected to investigate their effects on the formation of

volatile oil ME. The mixed phase with 1:1 ratio of IPM to FM-CM

volatile oil was used as the oil phase, and the preparation

temperature was 25°C. The different ratios of emulsifier to mixed

oil phase examined were 9:1, 8:2, 7:3, 6:4, 5:5, 4:6, 3:7, 2:8 and

1:9. ME was produced by stirring at constant temperature and

uniform speed, adding ultra-pure water drop by drop and measuring

the electrical conductivity. When the electrical conductivity of

the system reached the highest point, it was defined as being an

ME, and the dosage of emulsifier, mixed oil phase and water phase

which can form the ME group was recorded (14,23).

Data input was analyzed using Origin 8.0 drawing software

(OriginLab Corporation) to generate pseudo-ternary phase

diagrams.

Co-emulsifier

According to the screening results, EL-40 was

selected as the emulsifier, the mixed phase of IPM and FM-CM

volatile oil at a ratio of 1:1 was selected as the oil phase, the

Km was 2:1, and the preparation temperature was 25°C. The effects

of the co-emulsifiers such as absolute ethyl alcohol, glycerol,

1,2-propanediol and PEG-400 on ME were investigated.

Oil phase

In the preparation of ME, the size and chain length

of the oil phase molecules are important for the formation of ME.

In the present study, IPM, IPP and oleic acid were selected as the

components of the oil phase. According to the screening results of

emulsifier and co-emulsifier, EL-40 was used as emulsifier, while

anhydrous ethanol was used as co-emulsifier; the Km value was 2:1

and the preparation temperature was 25°C. IPM, IPP, oleic acid and

the FM-CM volatile oil of FM-CM were mixed in a certain proportion

as the oil phase. The optimum oil phase for ME preparation was

screened.

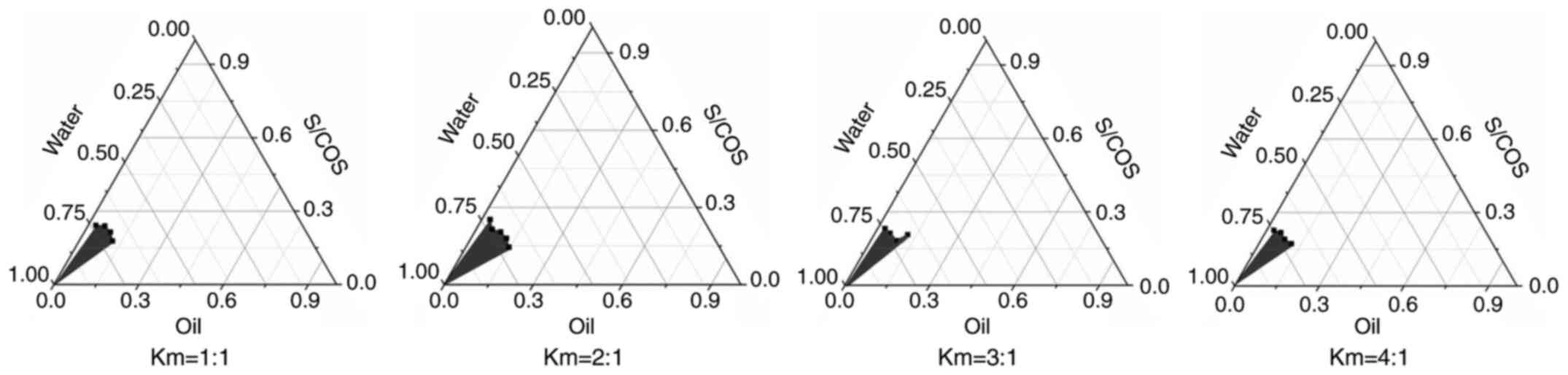

Km value

In the preparation of MR, the Km value is the ratio

of emulsifier quality to co-emulsifier mass. The ability of ME

formation varies with Km value. According to the screening results

of the emulsifier, co-emulsifier and oil phase, EL-40 was used as

emulsifier, anhydrous ethanol as co-emulsifier, and IPM and FM-CM

volatile oil as mixed oil phase. The preparation temperature was

25°C, the effects of Km values of 1:1, 2:1, 3:1 and 4:1 on ME

formation were investigated.

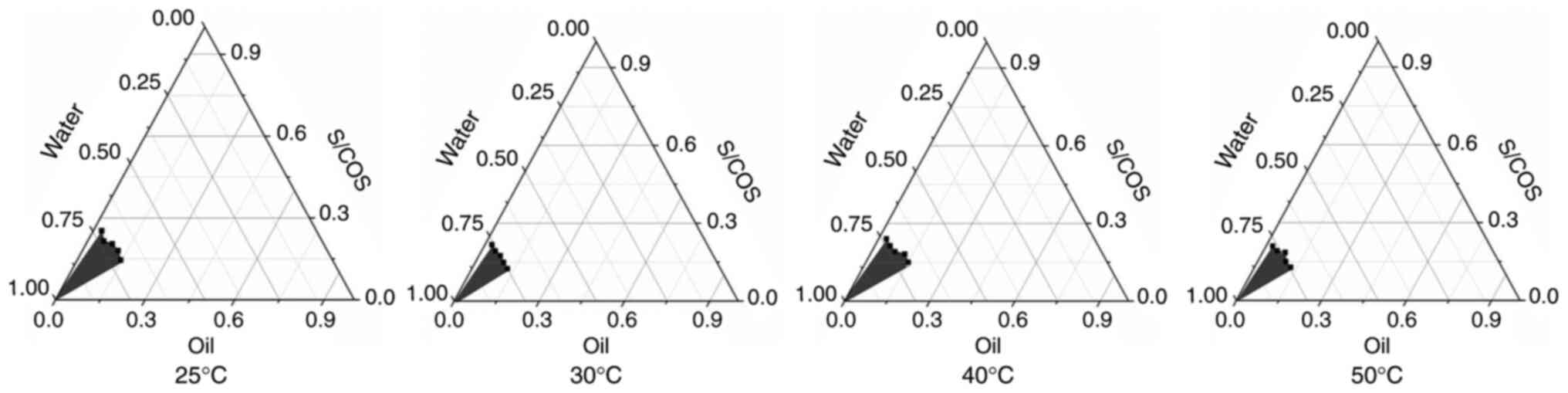

Preparation temperature

Throughout the screening procedures of the above

prescription factors, the basic prescription was determined, and

the effects of different temperatures (25, 30, 40 and 50°C) on the

preparation of ME were investigated.

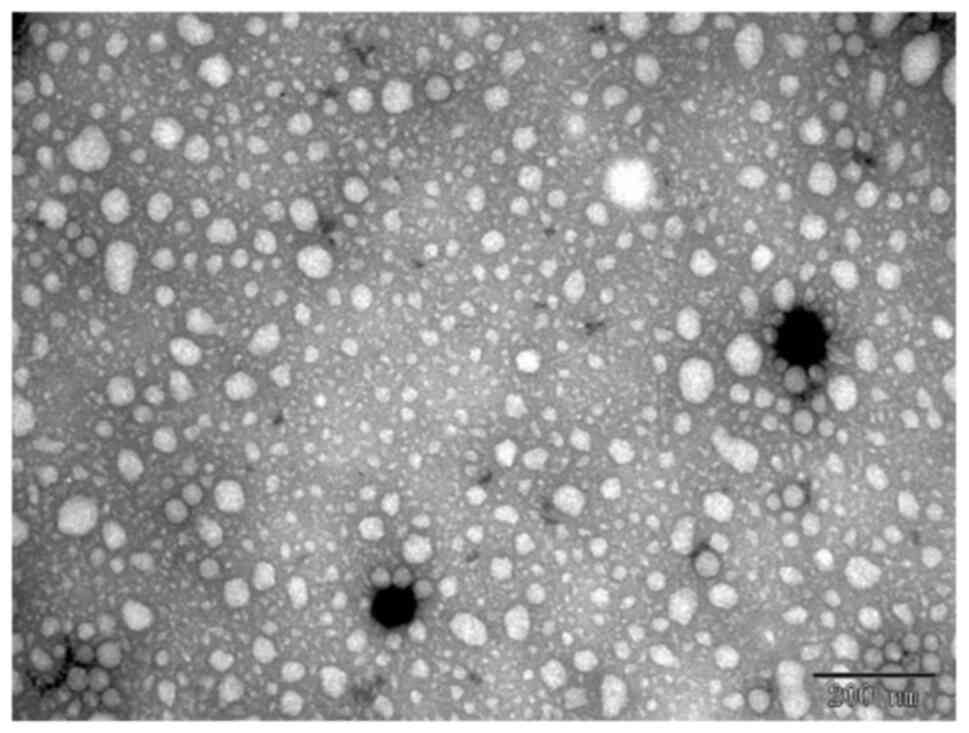

Characterization of ME

ME was characterized as described in previous

studies (15,24–27).

Appearance

The copper mesh of the carbon-plated support film

was placed on the sealing film, and a drop of sample (~30 µl) was

added to the support film. Following incubation for 5–10 min, the

excess solution was removed from the edge of the filter paper with

a pointed sheet of filter paper, and placed on the filter paper for

1 min and allowed to drain. Then, the dried supporting film was

placed on the sealing film, and a drop of uranyl acetate dye

solution was added for 90 sec. Subsequently, the excess dye

solution was removed with a pointed filter paper, clip it on the

filter paper and dried for 3 h. A JEM-1200EX transmission electron

microscope (JEOL, Ltd.) was used for observation, as described

previously (26).

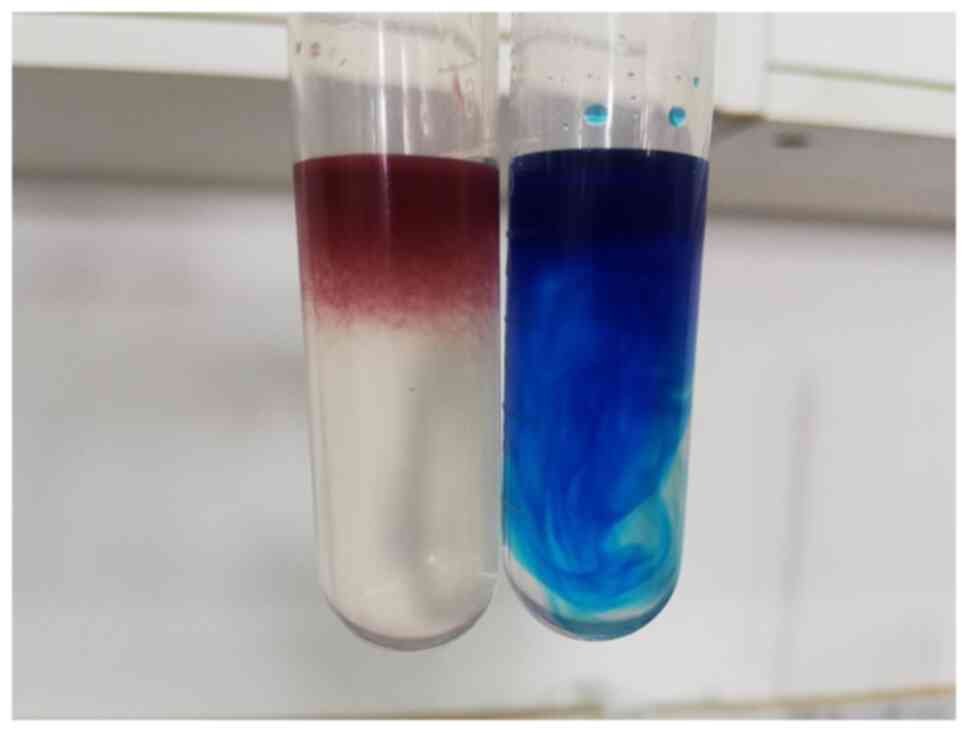

Type identification

According to the principle of ‘similar miscibility’,

1 g/l of sudan III (an oil-soluble dye) and methylene blue (a

water-soluble dye) solution were added at room temperature, and

their diffusion rates in ME were directly observed by the naked eye

for 1 min to determine ME. When the ME was of the water in oil

type, the diffusion rate of Sudan III was increased compared with

that of methylene blue, and when the ME was of the oil in water

type, the diffusion rate of methylene blue was increased compared

with that of Sudan III.

pH and refractive index

Substances delivered by nasal administration must

have a suitable pH value, and the pH value of the ME in turn

affects the stability of the system. The pH and refractive index of

the freshly prepared ME were measured using a PHS-3C pH meter

(Shanghai Yidian Scientific Instruments Co., Ltd.) and WYA-2W Abbe

refractometer (Shanghai Instrument Electrophysical Optical

Instruments Co., Ltd.). At room temperature (25°C), ultra-pure

water was used as the control for calibration. In total, the pH

values of 3 batches of ME were determined, and the average value

was calculated.

Particle size and Zeta potential

In total, 3 batches of 1 ml MEs were selected, and

the particle size and zeta potential of the freshly prepared MEs

were determined by Malvern Zetasizer NanoZS90 instrument (Malvern

Instruments Ltd.). According to the basic definition of ME, the

particle size of ME should be between 10–100 nm (28). Zeta potential measurement is the

use of electrophoretic scattering to detect the potential of

suspended particles in a specific solution environment. Its purpose

is to detect the charged properties of the particle surface,

including electrical properties and potential level, in order to

predict the stability of the whole suspension system.

Physical stability

In total, 3 batches of the same ME quantity were

placed in a centrifuge tube in a 416 low-speed centrifuge (Gene

Company, Ltd.) and centrifuged at 1,890 × g for 30 min at 4°C.

Following centrifugation for 30 min, the appearance of ME was

observed.

Thermodynamic stability

A total of 3 batches of ME were subjected to a

heating-cooling cycle experiment. The 10 ml ME was placed in a

centrifuge tube. Following continuous heating-cooling cycles

between 40 and 4°C for 6 times, its appearance was observed.

In total, 3 batches of ME were subjected to a

freezing-thawing cycle experiment. The 10 ml ME was placed in a

centrifuge tube and frozen in the refrigerator at −20°C for 24 h.

Upon thawing at room temperature for 24 h, after 6 consecutive

cycles, its appearance was observed.

Detection of eucalyptol in ME

Preparation of reference

substance

The weight of the eucalyptol reference substance was

0.2541 g, the volume of anhydrous ether was set as 5 ml as the

reference substance solution, and the concentration of the

reference liquid was 50.82 mg/ml.

Preparation of samples

Weighed ME (1.0 g in 5 ml) was added to a brown

flask, followed by 5 ml of anhydrous ether. Following

demulsification with Eddy for 1 min, centrifugation at 1,890 × g,

at 4°C for 10 min and filtration of the supernatant through a 0.22

µm microporous filter membrane, the sample solution was

obtained.

Gas chromatography-mass spectrometry (GC-MS). An

Agilent 7890GC/5977MS (Agilent Technologies, Inc.) was used to

investigate the subsequent experimental methodology and the content

of Eucalyptol, according to the manufacturer's protocol. In

addition, the content of eucalyptol in ME was determined.

Chromatographic conditions

The chromatographic column used in the present study

was a HP-5 quartz capillary column (30 m × 0.25 mm, 0.25 µm). The

temperature of the injection port was 250°C. The initial

temperature of the oven was 55°C (held for 2 min), with an increase

of 8°C/min until it reached 80°C (held for 0 min), followed by an

increase of 6°C/min until reaching 160°C (held for 2 min), and then

an increase of 8°C/min until reaching 200°C (held for 0 min), with

an increase of 3°C/min until reaching a final temperature of 250°C

(held for 3 min). The total run time was 42.25 min. The sample was

injected at 40:1 with high-purity helium as carrier gas and a

constant flow rate of 1 ml/min.

Mass spectrometry conditions

The ion source was an EI source, the multiplication

voltage was 1.5 kV, the electron energy was 70 EV, the mass

scanning range was 28–555 m/z, and the solvent delay was 3 min.

Methodological investigation

The eucalyptol reference solution was prepared by

pouring 25, 50, 100, 200, 400 or 800 µl of eucalyptol solution into

brown volumetric bottles. Then anhydrous ether was added to a final

volume of 10 ml to prepare reference solutions with concentrations

of 0.12705, 0.2541, 0.5082, 1.0164, 2.0328 and 4.0656 mg/ml were

prepared. Linear regression was performed using the concentration

and peak area as abscissa and longitudinal coordinates with

Microsoft Excel 2016 (Microsoft Corporation).

The same sample solution was injected repeatedly 6

times according to the above conditions. The relative standard

deviation (RSD) of the peak area of eucalyptol was determined, and

the precision of the method was investigated. In total, 6 samples

were prepared in parallel with the same batch of sample solutions.

According to the aforementioned conditions, the RSD of the peak

area of eucalyptol was calculated, and the experiment method was

repeated six times to investigate the repeatability. The same batch

of ME solution was prepared according to the treatment method of

the test sample, and the peak area of eucalyptol was determined at

0, 1, 2, 4, 6, 8, 10, 12 and 24 h. The peak area of eucalyptol RSD

was calculated to investigate the stability of the ME within 24 h.

A total of 9 samples of 0.5000 g ME were precisely weighed and

divided into 3 groups. Eucalyptol reference solution was added

according to the known levels of 50, 100 and 150%, respectively.

Following mixing, the samples were analyzed according to the above

chromatographic conditions, and the recovery and RSD value were

calculated.

Determination of eucalyptol

In total, 3 batches of samples were combined into a

sample solution according to the treatment method of the sample

solution, and the determination was performed according to the

above chromatographic conditions.

Percutaneous permeability test

A marrow-destroying needle was inserted into the

foramen magnum of the bullfrog, the spinal cord was transected left

and right, and the brain was destroyed. The myelocytic needle was

then withdrawn from the foramen magnum and inserted into the spinal

canal to destroy the spinal cord. Death was confirmed by checking

for complete relaxation of the limbs muscles. The abdominal skin of

bullfrog was removed, and the fat and subcutaneous tissues were

stripped, washed repeatedly with normal saline and fixed on the

diffusion interface of the diffusion chamber, while the dermis was

fixed to the reception tank. As the receptor fluid, 20% ethanol

saline (Kunshan Hechuang Ultrasonic Instruments Co., Ltd) was used,

which was injected into the reception tank following ultrasonic

cleaning to remove bubbles. The temperature of the circulating

water bath was 37±0.2°C, and a constant speed of 350 rpm was

employed to drain the bubbles in the receiving solution. Following

balancing of the water bath for 30 min, 2.0 g ME and 2.0 g oil

solution were placed into the supply tank. At 0.5, 1, 2, 4, 6, 8,

10, 12 and 24 h, 1 ml was sampled, and the same volume of blank

receptor fluid was added to the reception tank and the bubbles were

excreted (25,29–32).

The ME solution was extracted with anhydrous ether 3 times, and the

supernatant was collected and combined. The supernatant was

centrifuged for 10 min in a high-speed centrifuge (335 × g, 4°C),

1.5 ml supernatant was extracted with a disposable syringe and

passed through a filter membrane of 0.22 µm, and the receiving

solution at each time-point was obtained. The content of eucalyptol

was determined according to the above chromatographic conditions,

and the data were recorded. The cumulative transdermal volume was

calculated according to the following formula:

Qn=(V x Cn+∑i-1n-1x Vi x Ci)/A

where Qn is the cumulative permeability per unit

area at the time n, A is the effective transdermal area

(superficial area =1.54 cm2 and diameter =1.4 cm), Cn is

the concentration of the drug measured at time n, V is the volume

of the receiving pool (15 ml), and Vi is the volume of each sample.

Cumulative transmittance was calculated using the formula Ln=Qn/W,

where Ln is the cumulative transmittance and W is the content of

eucalyptol in the sample.

Results

Screening of prescription and preparation

factors of ME

Emulsifiers

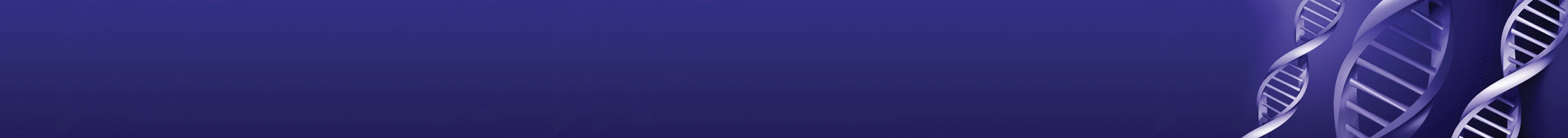

The data from the present study were collated to

draw a pseudo-ternary phase diagram, as shown in Fig. 1, where the area of ME accounts for

SRH-40 =0.0283, SEL-40 =0.0298 and

STween-80 =0.0287. The Tween-20 group could not form ME,

and therefore the pseudo-ternary phase diagram could not be

generated. The proportion of ME area in the EL-40 group was the

largest. Therefore, EL-40 was selected as the emulsifier of FM-CM

volatile oil ME.

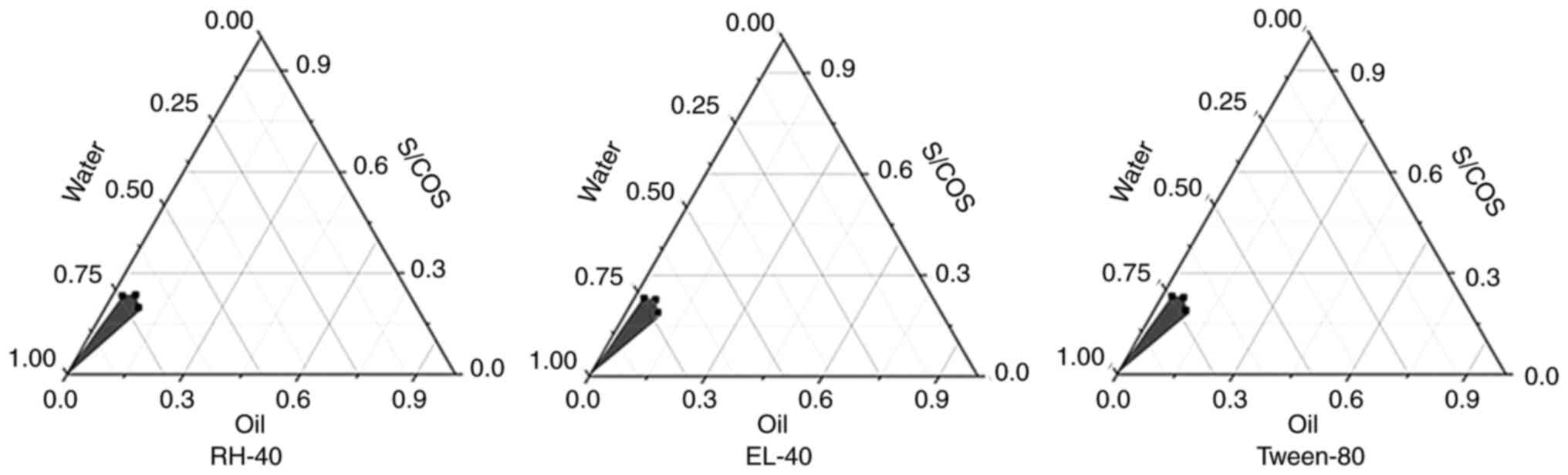

Co-emulsifiers

A co-emulsifier can adjust the HLB value of the

emulsifier and form smaller droplets, and an auxiliary emulsifier

can improve the formation of an ME. The results of pseudo-ternary

phase diagram in Fig. 2 indicate

that the area of ME was Sanhydrous ethanol =0.0782,

S1,2-propanediol =0.0417, Sglycerol =0.0414

and SPEG-400 =0.0522. Anhydrous ethanol had the largest

proportion of ME area; thus, it was selected as the co-emulsifier

of FM-CM volatile oil ME.

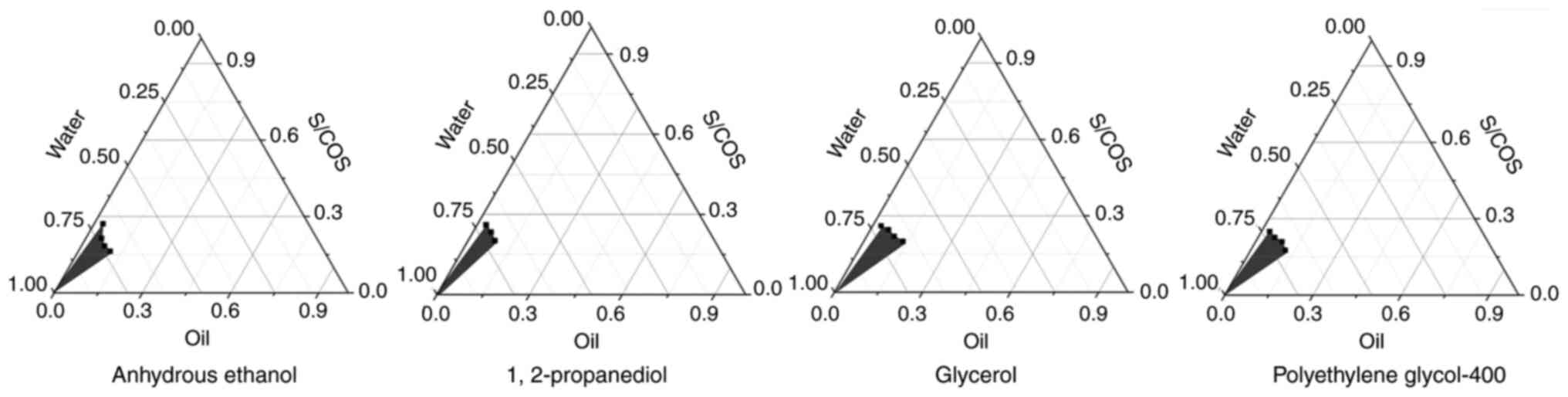

Oil phase

The results of pseudo-ternary phase diagram showed

that the proportion of ME area was SIPP =0.0530,

SIPM =0.0766 and Soleic acid =0.0441. As the

proportion of ME area was the largest in the IPM group, this was

selected as the oil phase of FM-CM volatile oil ME. The results are

presented in Fig. 3.

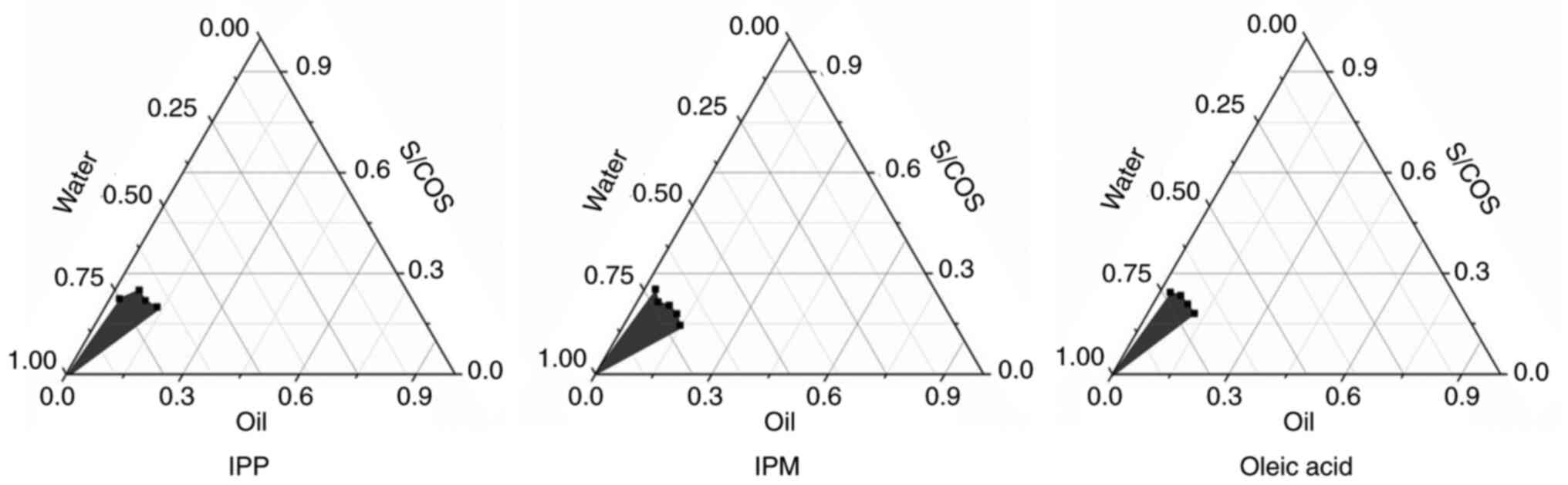

Km values

Different Km values have different effects on the

formation of ME. According to the results of the pseudo-ternary

phase diagram in Fig. 4, the area

of ME was S1:1 =0.0450, S2:1 =0.0766,

S3:1 =0.0540 and S4:1 =0.0398. When Km was

2:1, the ME area was the largest; thus, 2:1 was determined to be

the best Km value.

Preparation temperature

By generating a pseudo-ternary phase diagram, the

area of ME was S25°C =0.0766, S30°C =0.0696,

S40°C =0.0650 and S50°C =0.0613, suggesting

that 25°C was the best preparation temperature. The results are

shown in Fig. 5.

Preparation of optimal prescription

ME

According to the above screening results, the best

prescription of FM-CM volatile oil ME was as follows: Th emulsifier

was EL-40; the co-emulsifier was anhydrous ethanol; the Km was 2:1;

and IPM and FM-CM volatile oil were used as mixed oil phase at 1:1.

The mixed emulsifier accounted for 25.81%; the mixed oil phase

accounted for 2.81%; and the aqueous phase accounted for 71.38% of

the total ME system. The preparation temperature was 25°C. The

water representing 71.38% of the system was slowly added to form

clear and transparent ME droplets.

Characterization

Morphological observation

The results of the observation of the appearance and

morphology of the ME are presented in Fig. 6. The ME was a sphere with a round

appearance and uniform particle size distribution.

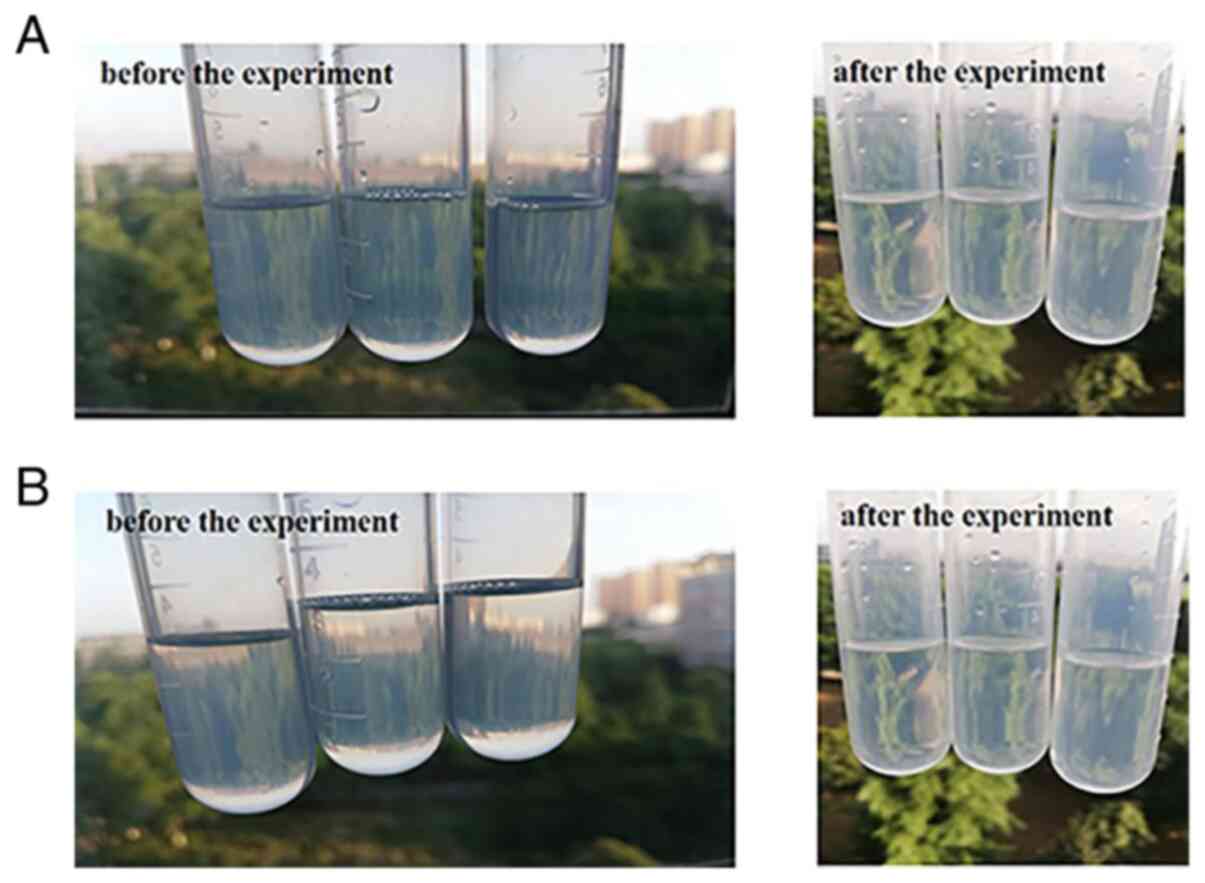

Identification of ME type

The methylene blue diffusion rate of the ME prepared

in the present study was markedly increased compared with that of

Sudan III, which indicates that it was an O/W ME (Fig. 7).

pH and refractive index

The pH value of ME was 5.67±0.01 and the refractive

index was 1.4198±0.0011 nd at 25°C.

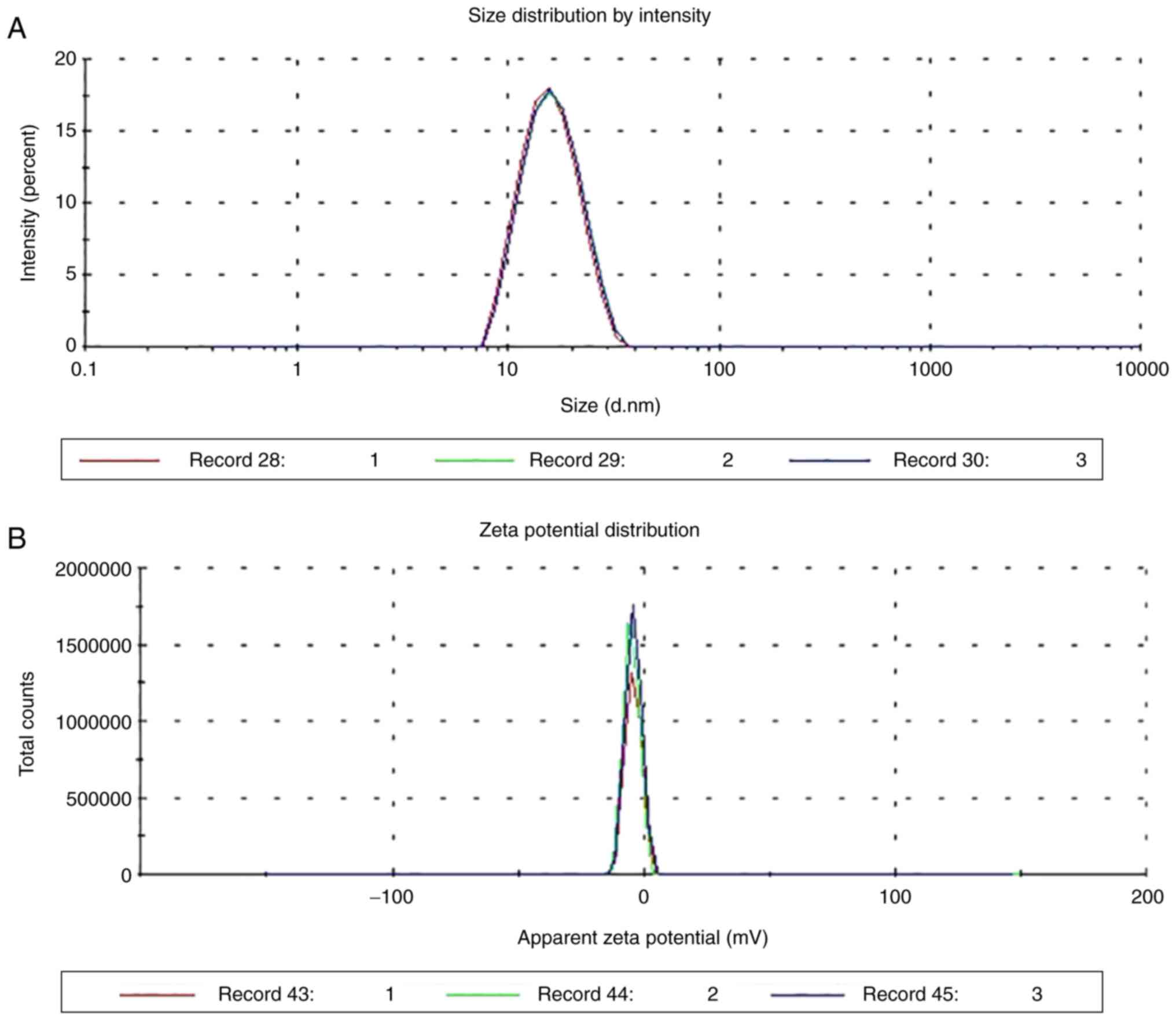

Particle size and Zeta potential

As shown in Fig. 8,

the particle size distribution of ME was uniform and the average

particle size was 14.62±0.4576 nm. The mean polydispersity index

value was 0.0747±0.0265 (n=3), and when there was only one peak in

the range of 10–100 nm, the average potential was −4.06±0.0702 mV

(n=3). These results indicated that the ME met the requirement of

particle size, and the system was stable.

Physical stability

The appearance of the 3 batches of ME following

high-speed centrifugation for 30 min remained uniform, clear, and

transparent, and there was no stratification observed,

demonstrating that the centrifugal stability of ME was good

(Fig. 9A).

Thermodynamic stability

After 6 heating-cooling and freezing-thawing cycles,

the 3 batches of ME remained clear and transparent, and there was

no stratification, indicating that the thermodynamic stability of

ME was good (Fig. 9B).

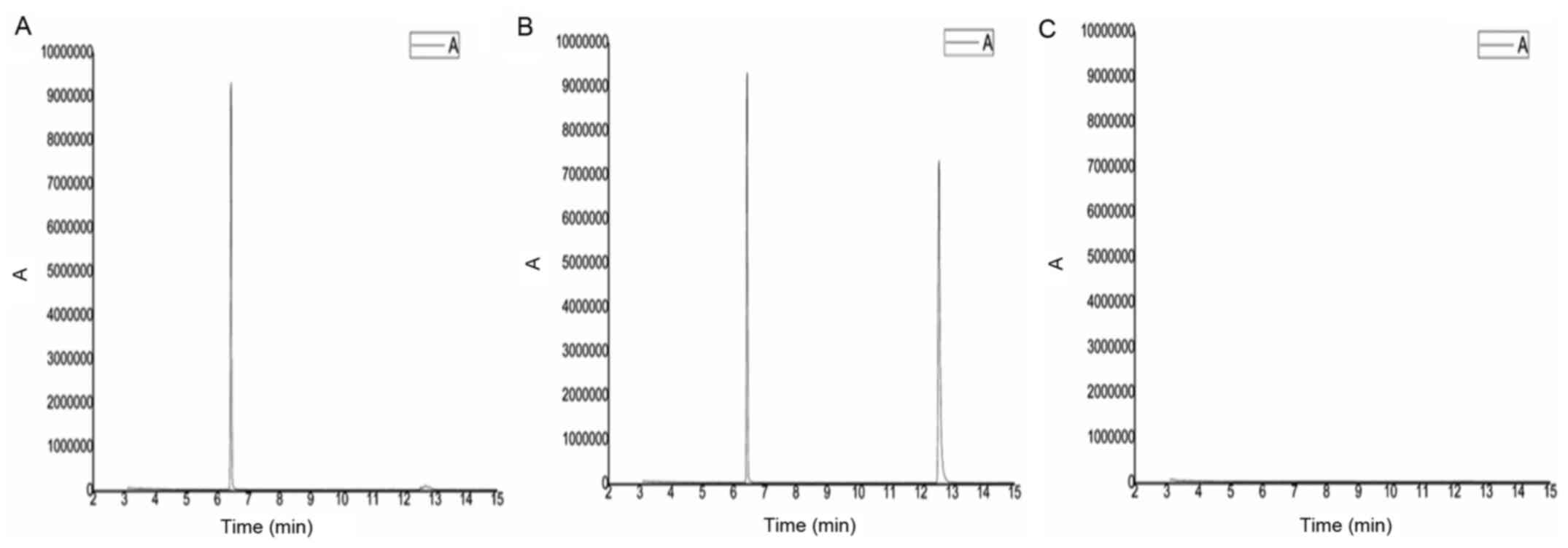

Methodological investigation

The calibration curve of the peak area and

concentrations for eucalyptol was linear, ranging from

0.12705–4.0656 mg/ml. The calibration curve was Y=37,4632X +

2×108 (R2=0.9992), where Y represents the

eucalyptol peak area and X represents the concentration of

eucalyptus reference substance. The chromatograms of the reference

substance and the sample solution are shown in Fig. 10. In the precision experiment, the

RSD of the eucalyptol peak area was 1.36%, demonstrating that the

precision of this method was good. In the repeatability experiment,

the RSD of the eucalyptol peak area was 2.20%, indicating that this

method has good repeatability. In the stability experiment, the RSD

of the eucalyptol peak area was 1.93%, indicating that the sample

remained stable for 24 h. In the sample recovery experiment, the

mean recovery rate was 99.27%, and the RSD value was 2.91%. These

results showed that the accuracy of the experimental observations

was high.

Determination of eucalyptol

concentration

According to the results of sample content

determination, the mean content of eucalyptol in the ME was 2.57

mg/g, as shown in Table I.

| Table I.Eucalyptol content in

microemulsions. |

Table I.

Eucalyptol content in

microemulsions.

| Sample number | Sampling quantity,

g | A1 | A2 | Ā | Eucalyptol content,

mg/g | Average content,

mg/g | RSD, % |

|---|

| 1 | 1.0167 | 412958743 | 383474502 | 398216622.5 | 2.60 | 2.57 | 1.19 |

| 2 | 1.0012 | 381962376 | 405573769 | 393768072.5 | 2.54 |

|

|

| 3 | 1.0032 | 398652865 | 391974721 | 395313793 | 2.56 |

|

|

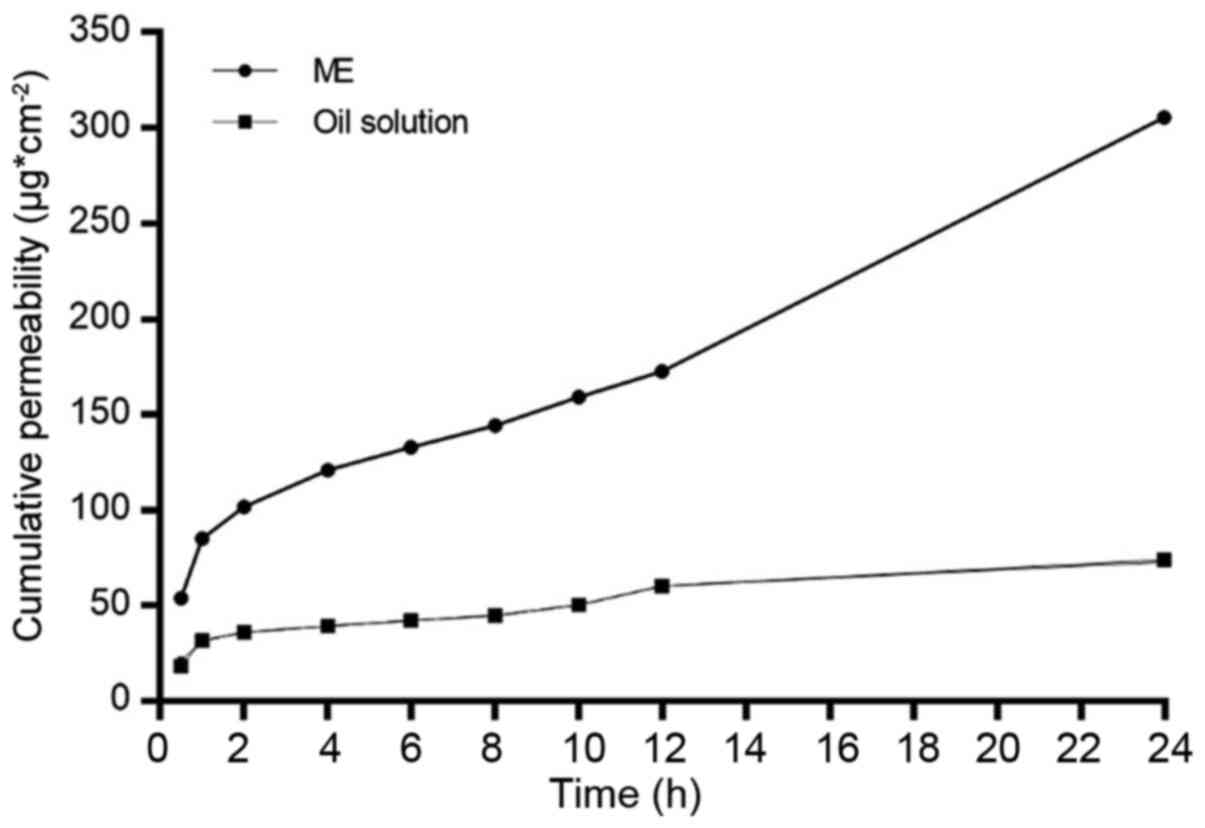

Percutaneous permeability test

The curve was generated by considering the

cumulative permeability Q24 (µg/cm2) as the

longitudinal coordinate and the sampling time t as the abscissa.

Linear regression analysis of the obtained curve was performed. The

linear slope represents the steady penetration rate Jss

(µg/cm2/h). The results are shown in Table II, Fig. 11 and Table III.

| Table II.Qn and Ln per unit area of ME at each

time-point (n=3). |

Table II.

Qn and Ln per unit area of ME at each

time-point (n=3).

|

| Eucalyptol Qn,

µg/cm2 | Ln, % |

|---|

|

|

|

|

|---|

| Time-point, h | ME group | Oil solution

group | ME group | Oil solution

group |

|---|

| 0.5 | 54.2507±0.4277 | 21.3442±1.0544 | 1.06 | 0.42 |

| 1 | 85.4878±3.2467 | 31.9255±3.0570 | 1.66 | 0.62 |

| 2 |

101.6378±1.1280 | 36.3763±1.2314 | 1.98 | 0.71 |

| 4 |

120.9467±1.5481 | 39.6531±0.4615 | 2.35 | 0.77 |

| 6 |

133.4428±1.4452 | 42.5442±0.3600 | 2.60 | 0.83 |

| 8 |

145.0037±3.2474 | 45.3398±0.3371 | 2.82 | 0.88 |

| 10 |

160.0303±0.4325 | 50.6580±1.5446 | 3.11 | 0.99 |

| 12 |

173.7156±3.5513 | 60.7943±0.3699 | 3.38 | 1.18 |

| 24 |

301.0797±2.8009 | 73.3491±2.1919 | 5.86 | 1.43 |

| Table III.Comparison of transdermal permeation

parameters between ME and oil solution groups (n=3). |

Table III.

Comparison of transdermal permeation

parameters between ME and oil solution groups (n=3).

| Group | Cumulative

permeability - time equation | Steady penetration

rate Jss, µg/cm2/h | Cumulative

permeability, µg/cm2 |

|---|

| ME group | Q=9.4349t+70.971

(R2=0.9758) | 9.4349 | 301.0800±2.80 |

| Oil solution

group | Q=2.0082t+29.604

(R2=0.9119) | 2.0082 | 73.3491±2.19 |

These results indicated that the cumulative

permeabilities of eucalyptol in the ME and oil solution were

301.0800±2.80 and 73.3491±2.19 µg/cm2, respectively, and

the steady state penetration rates were 9.4349 and 2.0082

µg/cm2/h, respectively. The cumulative permeability of

the ME was increased 4.10-fold compared with that of the oil

solution, and the steady penetration rate was increased 4.70-fold

compared with that of the oil solution, which indicated that ME

could effectively promote the transdermal absorption of the

drugs.

Discussion

Bitongning drops serve an important role in the

clinical treatment of AR due to their active ingredient, the

aromatic water of FM and CM, and previous studies have shown that

their therapeutic effect on AR is due to their volatile oil

components (33–37). The aim of the present study was to

increase the drug concentration in a standard AR treatment method

by replacing traditional aromatic water with volatile oil. Volatile

oils have an important therapeutic effect in numerous TCM

treatments, and are an indispensable functional ingredient

(38). According to the theory of

TCM, volatile oils function as ‘aromatic strings’. An aromatic

string is called ‘Fangxiangzouchuan’ in TCM. It can be interpreted

as ‘the fragrance of the medicine can be dispersed everywhere’, the

curative effect is exact (39).

However, volatile oils are a fat-soluble component with poor water

solubility that can be highly irritable. In the preliminary

experiments in the present study, the best compatibility ratio of

the volatile oils from FM and CM in the treatment of AR was

screened, and the results revealed that the best proportion was 7:1

FM: CM. In the present study, an ME was generated to improve

bioavailability, to resolve the issues of poor absorption and low

solubility normally associated with volatile oils, and to decrease

drug toxicity, irritation, and adverse reactions.

The ME was prepared by water titration with

different emulsifiers, co-emulsifiers, oil phases, Km values, and

preparation temperatures. The area of the ME was mapped using a

pseudo-ternary phase diagram, and the particle size was combined

with the size of the ME The best formula for the preparation of ME

was determined by centrifugal stability and other factors. When the

Km value increased from 1.0 to 2.0, the area of ME increased, which

was primarily due to the increase of emulsifiers ratio, emulsifiers

can effectively reduce oil/water interfacial tension and decrease

the interfacial film tension formed by ME, thereby enhancing the

emulsification ability to form a larger ME area. When studying Km,

it has been observed that when the Km value increased from 2.0 to

4.0, possibly due to the increase of emulsifiers to a certain

value, an increase in viscosity and expansion of the gel region and

double continuous zone were observed, which led to the decrease of

the formation area of ME (40).

When examining preparation temperature, the area of ME formation

was observed to decrease with the increase in preparation

temperature, since volatile oil was used as part of the mixed oil

phase. It was hypothesized that this may have been caused by the

increase in volatilization of the drug with the increase in

temperature. Therefore, 25°C was selected as the most suitable

temperature for ME preparation. However, this hypothesis requires

further experimental verification. The ME was identified as an O/W

ME, and its particle size, pH value and refractive index all met

the requirements of an ME. It is generally considered that the

absolute value of Zeta potential in a stable-dispersion system

should be >30 mV, and the larger the absolute value is, the more

stable the system is (41).

However, the absolute value of Zeta potential in the present study

was <30 mV. It has been reported that the Zeta potential of ME

may be low (41), which does not

indicate that ME is unstable. Instead, the primary reason for this

is that the ME is an uncharged system. The emulsifier EL-40 in ME

is a non-ionic solubilizer, which can be used in the emulsification

of vegetable, animal, and mineral oils. It can also effectively

promote the transdermal absorption of drugs and decrease skin

irritation (42). The

co-emulsifier anhydrous ethanol may decrease the polarity of the

aqueous phase and surface tension, thus compensating for the poor

fluidity of the oil-water interface film when a emulsifier is used

alone, and when combined with emulsifiers, the preparation of ME is

improved (43,44). Previous studies reported that

adding the volatile oil of TCM to the oil phase of ME could improve

transdermal permeation (45–47).

In the present study, according to preliminary experiments, the

drug with mass ratio of 1:1 and IPM were used as mixed oil phase to

promote drug absorption. During the in vitro transdermal

comparison between ME and oil solution in the present study, it was

identified that the cumulative and steady permeabilities of ME were

significantly increased compared with those of the oil solution

group, indicating that ME may effectively promote the transdermal

absorption of volatile oil. These results provide a reference for

follow-up development and research of ME.

In the present study, the preparation method and

quality of ME were examined systematically. It was identified that

the in vitro transdermal performance of ME was significantly

increased compared with that of the oil solutions, and that its

properties were stable. In order to further demonstrate the good

bioavailability of ME, in vivo pharmacokinetic studies or

cell experiments will be conducted in the future. Notably, in the

preparation process of ME, the specific formula used and

preparation process factors have important effects on the formation

of ME. Consequently, the selection of the appropriate emulsifier,

co-emulsifier, oil phase, Km, and preparation temperature are

important.

Acknowledgements

Not applicable.

Funding

The present study was supported by grants from

Chinese Medicine Pharmaceutical Key Discipline of Shaanxi Province

(grant no. 303061107), Natural Science Foundation of China (grant

no. 81703720), Key R&D Program of Shaanxi Province (grant nos.

2019SF-290 and 2018SF-314). Key discipline of traditional Chinese

Medicine Pharmaceutical Engineering of Shaanxi Provincial

Administration of traditional Chinese Medicine (grant no.

132018004), Discipline Innovation team Project of Shaanxi

University of Chinese Medicine (grant no. 2019-YL11), Shaanxi

Provincial Department of Education Project (grant no. 18JS026), and

the Shaanxi Provincial Administration of traditional Chinese

Medicine Project (grant no. JPC056).

Availability of data and materials

The datasets used and/or analyzed during the present

study are available from the corresponding author upon reasonable

request.

Authors' contributions

YL performed the experiments and data analysis, and

wrote the manuscript. JZ performed the experiment and participated

in the analysis of the experimental data. YS conceptualized the

study and analyzed the experimental data. JT and YW performed

experiments. XZ, DG and MY conceptualized the study. All authors

read and approved the final manuscript.

Ethics approval and consent to

participate

The study was approved by the Ethical Committee of

Shaanxi University of Chinese Medicine.

Patient consent for publication

Not applicable.

Competing interests

The authors declare that they have no competing

interests.

References

|

1

|

Lam HY, Tergaonkar V and Ahn KS:

Mechanisms of allergen-specific immunotherapy for allergic rhinitis

and food allergies. Biosci Rep. Apr 30–2020.(Epub ahead of print).

doi: 10.1042/BSR20200256. View Article : Google Scholar : PubMed/NCBI

|

|

2

|

Mitsias DI, Dimou MV, Lakoumentas J,

Alevizopoulos K, Sousa-Pinto B, Fonseca JA, Bousquet J and

Papadopoulos NG: Effect of nasal irrigation on allergic rhinitis

control in children; complementarity between CARAT and MASK

outcomes. Clin Transl Allergy. 10:92020. View Article : Google Scholar : PubMed/NCBI

|

|

3

|

Rawls M, Thiele J, Adams DE, Steacy LM and

Ellis AK: Clinical symptoms and biomarkers of Bermuda grass-induced

allergic rhinitis using the nasal allergen challenge model. Ann

Allergy Asthma Immunol. 124:608–615.e2. 2020. View Article : Google Scholar : PubMed/NCBI

|

|

4

|

Wang GA: Efficacy of desloratadine citrate

disodium combined with mometasone furoate in the treatment of

allergic rhinitis and its effect on patients' complications.

Chinese Journal of Rational Drug Use. 16:179–181. 2019.(In

Chinese).

|

|

5

|

Yang CS, Xu J and Zhang YY: Determination

of 1,8-cineole in bitongning spray by gas chromatography. Guizhou

Med J. 35:929–930. 2011.(In Chinese).

|

|

6

|

Li XB and Wang P: Determination of

volatile oil content in bitongning drops by GC method. Heilongjiang

Med J. 24:16–17. 2011.

|

|

7

|

Cai XZ: Rudimentary research on

identification of Herba Centipedae and screening of its

active material anti-Allergic Rhinitis. Southern Medical

University; 2008, (In Chinese).

|

|

8

|

Lin YC and Gao M: Research progress on

chemical constituents and pharmacology of Centipeda minima.

J Zhejiang Chin Med Univ. 35:303–304. 2011.

|

|

9

|

Yang XX and Zhuang ZQ: Research progress

on chemical constituents and pharmacological action of Flos

magnoliae. Chin Tradit Herbal Drugs. 7:490–492. 1998.

|

|

10

|

Yuan JM, Huang XY and Zhou YT: Preparation

of Flos magnoliae-Herba Centipedae thermosensitive nasal in

situ gels. Zhong Cheng Yao. 40:2, 656–662. 2018.

|

|

11

|

Liang YL, Zhang XF and Zou JB:

Pharmacology mechanism of and for treating allergic rhinitis based

on pharmacology network. Drug Dev Ind Pharm. 45:547–555. 2019.

View Article : Google Scholar

|

|

12

|

Okińczyc P, Szumny A, Szperlik J, Kulma A,

Franiczek R, Żbikowska B, Krzyżanowska B and Sroka Z: Profile of

polyphenolic and essential oil composition of polish propolis,

black poplar and Aspens buds. Molecules. 23:E12622018. View Article : Google Scholar : PubMed/NCBI

|

|

13

|

Katdare A, Khunt D, Thakkar S, Polaka SN

and Misra M: Comparative evaluation of fish oil and butter oil in

modulating delivery of galantamine hydrobromide to brain via

intranasal route: Pharmacokinetic and oxidative stress studies.

Drug Deliv Transl Res. 10:1136–1146. 2020. View Article : Google Scholar : PubMed/NCBI

|

|

14

|

Mitsou E, Pletsa V, Sotiroudis GT, Panine

P, Zoumpanioti M and Xenakis A: Development of a microemulsion for

encapsulation and delivery of gallic acid. The role of chitosan.

Colloids Surf B Biointerfaces. 190:1109742020. View Article : Google Scholar : PubMed/NCBI

|

|

15

|

Xu T, Ge SM, Deng LH, Wei MY, Xu YH and Wu

CB: Preparation of pseudolaric acid B microemulsion and its

transdermal penetration. Chin Tradit Herbal Drugs. 43:683–689.

2012.

|

|

16

|

Lu SS, Qian YH and Xu BB: Application of

microemulsification technology in transdermal penetration of

volatile oil from Chinese material medical. Sci Technol Vis.

25:237–239. 2018.

|

|

17

|

Wu JY, Li YJ, Han M, Hu XB, Yang L, Wang

JM and Xiang DX: A microemulsion of puerarin-phospholipid complex

for improving bioavailability: Preparation, in vitro and in vivo

evaluations. Drug Dev Ind Pharm. 44:1336–1341, 336–341. 2018.

View Article : Google Scholar : PubMed/NCBI

|

|

18

|

Chen Y, Cheng G, Hu R, Chen S, Lu W, Gao

S, Xia H, Wang B, Sun C, Nie X, et al: A nasal temperature and pH

dual-responsive in situ gel delivery system based on microemulsion

of huperzine A: Formulation, evaluation, and in vivo

pharmacokinetic study. AAPS PharmSciTech. 20:3012019. View Article : Google Scholar : PubMed/NCBI

|

|

19

|

Mishra R, Prabhavalkar KS and Bhatt LK:

Preparation, optimization, and evaluation of Zaltoprofen-loaded

microemulsion and microemulsion-based gel for transdermal delivery.

J Liposome Res. 26:297–306. 2016. View Article : Google Scholar : PubMed/NCBI

|

|

20

|

Cai H, Ma KY and Li HL: Study on

extraction technology of volatile oil from Flos magnoliae.

Jiujiang Xueyuan Xuebao Ziran Kexue Ban. 32:8–12. 2017.(In

Chinese).

|

|

21

|

Cho YH, Kim S, Bae EK, Mok CK and Park J:

Formulation of a cosurfactant-free O/W microemulsion using nonionic

surfactant mixtures. J Food Sci. 73:E115–E121. 2008. View Article : Google Scholar : PubMed/NCBI

|

|

22

|

Shah A, Thool P, Sorathiya K, Prajapati H,

Dalrymple D and Serajuddin AT: Effect of different polysorbates on

development of self-microemulsifying drug delivery systems using

medium chain lipids. Drug Dev Ind Pharm. 44:215–223. 2018.

View Article : Google Scholar : PubMed/NCBI

|

|

23

|

Song WJ and Gu W: Pharmacology study and

prospect of aromatic Chinese herbs. Zhonghua Zhongyiyao Zazhi.

32:2, 609–611. 2017.

|

|

24

|

Yang XY and Yi L: Preparation and in vitro

transdermal study of zolmitriptan-diclofenac microemulsion. China

Pharmacy. 28:1841–1844. 2017.

|

|

25

|

Golmohammadzadeh S, Farhadian N, Biriaee

A, Dehghani F and Khameneh B: Preparation, characterization and in

vitro evaluation of microemulsion of raloxifene hydrochloride. Drug

Dev Ind Pharm. 43:1619–1625, 619–625. 2017. View Article : Google Scholar : PubMed/NCBI

|

|

26

|

Kotmakçı M, Akbaba H, Erel G, Ertan G and

Kantarcı G: Improved method for solid lipid nanoparticle

preparation based on hot microemulsions: Preparation,

characterization, cytotoxicity, and hemocompatibility evaluation.

AAPS PharmSciTech. 18:1355–1365. 2017. View Article : Google Scholar : PubMed/NCBI

|

|

27

|

Akram A, Rasul A, Waqas MK, Irfan M,

Khalid SH, Aamir MN, Murtaza G, Ur Rehman K, Iqbal M and Khan BA:

Development, characterization and evaluation of in-vitro

anti-inflammatory activity of ginger extract based micro emulsion.

Pak J Pharm Sci. 32:1327–1332. 2019.PubMed/NCBI

|

|

28

|

Lee J, Lee Y, Kim J, Yoon M and Choi YW:

Formulation of microemulsion systems for transdermal delivery of

aceclofenac. Arch Pharm Res. 28:1097–1102. 2005. View Article : Google Scholar : PubMed/NCBI

|

|

29

|

Golwala P, Rathod S, Patil R, Joshi A, Ray

D, Aswal VK, Bahadur P and Tiwari S: Effect of cosurfactant

addition on phase behavior and microstructure of a water dilutable

microemulsion. Colloids Surf B Biointerfaces. 186:1107362020.

View Article : Google Scholar : PubMed/NCBI

|

|

30

|

Zhang JJ, Cui SF and Tang XL: Study on

preparation technology and in vitro transdermal permeability of

compound clove microemulsion. Zhong Yao Cai. 608–611. 2007.

|

|

31

|

Liu X, Zhang ZH and Chen Y: Preparation of

colchicine microemulsion and its transdermal permeation in vitro.

Chin Tradit Herbal Drugs. 42:963–967. 2011.

|

|

32

|

Yang F, Zhou J, Hu X, Yu SK, Liu C, Pan R,

Chang Q, Liu X and Liao Y: Preparation and evaluation of

self-microemulsions for improved bioavailability of ginsenoside-Rh1

and Rh2. Drug Deliv Transl Res. 7:731–737. 2017. View Article : Google Scholar : PubMed/NCBI

|

|

33

|

Yang J, Xu H, Wu S, Ju B, Zhu D, Yan Y,

Wang M and Hu J: Preparation and evaluation of microemulsion based

transdermal delivery of Cistanche tubulosa phenylethanoid

glycosides. Mol Med Rep. 15:109–116. 2017. View Article : Google Scholar

|

|

34

|

Zhai XY: Effect of volatile oil from

magnolia on Th cells of Guinea pigs with allergic rhinitis. Shaanxi

J Tradit Chin Med. 31:116–118. 2010.

|

|

35

|

Liu ZG, Yu HM, Wen SL and Liu YL:

Histopathological study on allergic rhinitis treated with

Centipeda minima. Zhongguo Zhong Yao Za Zhi. 30:292–294.

2005.(In Chinese). PubMed/NCBI

|

|

36

|

Wu M, Zhang J and Zhang X: Clinical

observation of Flos magnoliae volatile oil nano-liposome

nasal drops in treating pediatric allergic rhinitis. Zhong guo

Zhong Xi Yi Jie He Za Zhi. 29:740–742. 2009.

|

|

37

|

Jia XS and Zhang YY: Research progress on

essential oils of Cenpiteda minima (L.) A. Br. Aschers.

Shandong Chem Ind. 47:66–68. 2018.

|

|

38

|

Guan Z, Ma XZ and Lv GY: Effects of VOM bp

on IL-12, IFN-γ and histamine levels of rats with allergic

rhinitis. Pharmacol Clin Chin Materia Med. 27:70–72. 2011.

|

|

39

|

Wang YQ, Yang YZ, Wu ZF, Xiong YK and Yang

M: Traditional function and modern research progress on volatile

oil in Chinese materia medica. Chin Tradit Herbal Drugs.

49:455–461. 2018.

|

|

40

|

Das S, Lee SH, Chia VD, Chow PS, Macbeath

C, Liu Y and Shlieout G: Development of microemulsion based topical

ivermectin formulations: Pre-formulation and formulation studies.

Colloids Surf B Biointerfaces. 189:1108232020. View Article : Google Scholar : PubMed/NCBI

|

|

41

|

Li SL, Duan Q, Zhao ZD, Xia L, Liu WH,

Wang XG and Shen XZ: Preparation and quality evaluation of Acori

Tatarinowii Rhizoma-volatile oil microemulsion. Chin Tradit Herbal

Drugs. 50(1): 935–941. 2019.(In Chinese).

|

|

42

|

Xu WT: Study on the regularity of the

formation of microemulsion by nonionic surfactans. PhD

dissertation. Jiangnan University; 2009, (In Chinese).

|

|

43

|

Paulo BB, Alvim ID, Reineccius G and Prata

AS: Performance of oil-in-water emulsions stabilized by different

types of surface-active components. Colloids Surf B Biointerfaces.

190:1109392020. View Article : Google Scholar : PubMed/NCBI

|

|

44

|

Su J, Wu CH and Jiang F: Preparation of

Paeonol self-microemulsion transdermal delivery system with

peppermint oil as carrier. Zhongguo Shiyan Fangjixue Zazhi.

23:11–16. 2017.(In Chinese).

|

|

45

|

Yuan ZZ, Yin SY and Jin Y: Preparation and

quality evaluation of Eugenia oleifera oil bano-emulsion.

Lishizhen Med Materia Med Res. 28:620–622. 2017.

|

|

46

|

Chen JJ, Xia J, Song J, Luo MF and Huang

Z: Effect of Eugenol in the microemulsion as an oil excipient and

enhancer on percutaneous absorption of Baicalin. Xiandai Shengwu

Yixue Jinzhan. 16:410–413. 2016.(In Chinese).

|

|

47

|

Lu SS, Zhao YR, Yao JH, Ren L, Li Y and

Chen J: Preparation technology on essential oil from Chinese

materia medica as penetration enhancers. Chin Tradit Herbal Drugs.

49:2477–2481. 2018.(In Chinese).

|